3.5mm Adapters

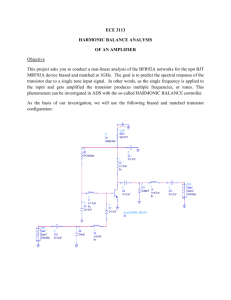

advertisement