A Manual of Practice - Transportation Research Board

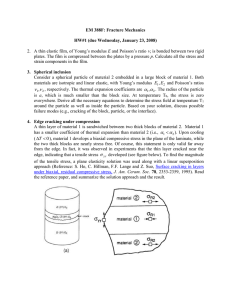

advertisement