5223 UTEX catalog

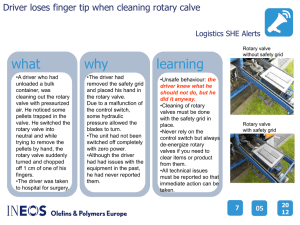

advertisement