σ σ τ τ - Fairfield

advertisement

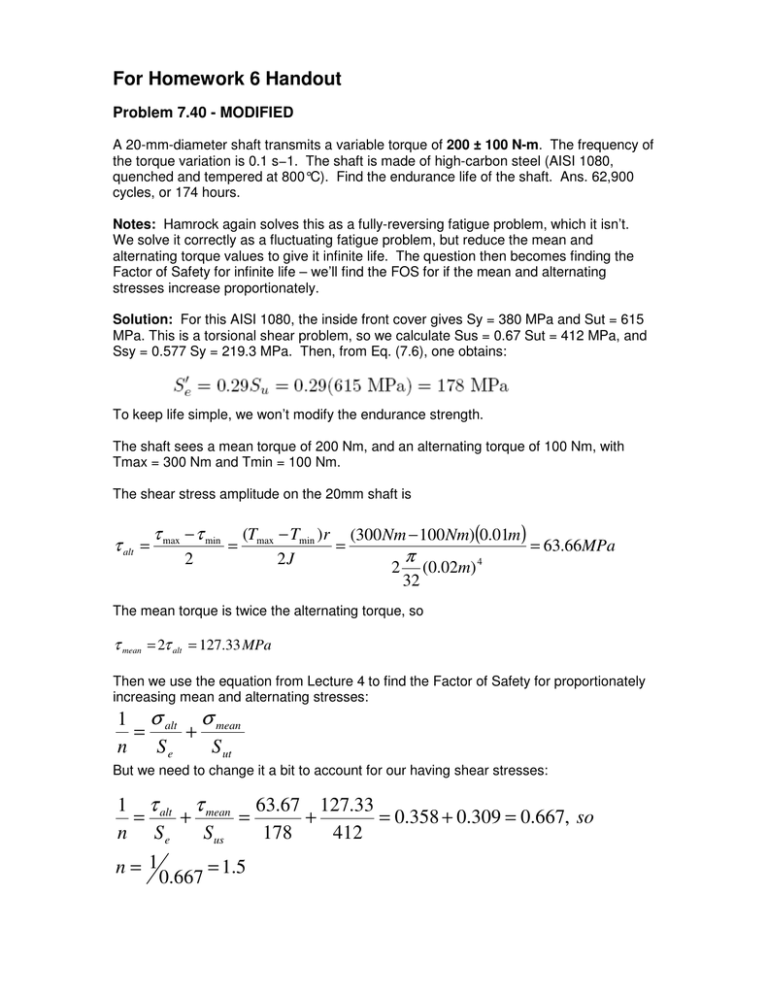

For Homework 6 Handout Problem 7.40 - MODIFIED A 20-mm-diameter shaft transmits a variable torque of 200 ± 100 N-m. The frequency of the torque variation is 0.1 s−1. The shaft is made of high-carbon steel (AISI 1080, quenched and tempered at 800°C). Find the endurance life of the shaft. Ans. 62,900 cycles, or 174 hours. Notes: Hamrock again solves this as a fully-reversing fatigue problem, which it isn’t. We solve it correctly as a fluctuating fatigue problem, but reduce the mean and alternating torque values to give it infinite life. The question then becomes finding the Factor of Safety for infinite life – we’ll find the FOS for if the mean and alternating stresses increase proportionately. Solution: For this AISI 1080, the inside front cover gives Sy = 380 MPa and Sut = 615 MPa. This is a torsional shear problem, so we calculate Sus = 0.67 Sut = 412 MPa, and Ssy = 0.577 Sy = 219.3 MPa. Then, from Eq. (7.6), one obtains: To keep life simple, we won’t modify the endurance strength. The shaft sees a mean torque of 200 Nm, and an alternating torque of 100 Nm, with Tmax = 300 Nm and Tmin = 100 Nm. The shear stress amplitude on the 20mm shaft is τ alt = τ max − τ min 2 = (Tmax − Tmin )r (300 Nm − 100 Nm)(0.01m ) = = 63.66MPa π 2J 4 2 (0.02m) 32 The mean torque is twice the alternating torque, so τ mean = 2τ alt = 127.33 MPa Then we use the equation from Lecture 4 to find the Factor of Safety for proportionately increasing mean and alternating stresses: 1 σ alt σ mean = + n Se S ut But we need to change it a bit to account for our having shear stresses: 1 τ alt τ mean 63.67 127.33 = + = + = 0.358 + 0.309 = 0.667, so n Se Sus 178 412 n= 1 0.667 = 1.5 Problem 7.41 For the shaft in Problem 7.40 determine how large the shaft diameter has to be for infinite life. Ans. D = 17.5 mm. Notes: The stress amplitude must equal the fatigue endurance limit for this case. This solution uses the results of Problem 7.40. Solution: Being just at infinite life means the FOS = 1.0. With a FOS of 1.5 from Prob. 7.40, SigmaAlt was 63.7MPa. So SigmaAlt would now be 1.5 x 63.7 = 95.5MPa. The shear stress amplitude is τ alt = τ max − τ min 2 Therefore, d3 = ( ) d (Tmax − Tmin )r (300Nm − 100 Nm) 2 509.3 Pa = = = = 95.5MPa π 2J d3 4 2 (d ) 32 509.3 = 5.33 × 10 −6 m 3 6 95.5 × 10 or d = 0.0175 m = 17.5 mm Problem 7.63 A toy with a bouncing 50-mm-diameter steel ball has a compression spring with a spring constant of 100,000 N/m. The ball falls from a 3-m height down onto the spring (which can be assumed to be weightless) and bounces away and lands in a hole. Calculate the maximum force on the spring and the maximum deflection during the impact. The steel ball density is 7840 kg/m3. Ans. 1743 N. Notes: The weight of the ball is calculated from its volume and density, and then Eq. (7.54) solves the problem. Solution: The weight of the ball is the product of its volume and density, or We compute the static spring deflection δ st = W 5.03 = = 5.032 × 10 −5 m k 100,000 and the Impact factor Im = δ max Pmax 2h (2)(3) = = 1+ 1+ =1+ 1+ δ static W δ st 5.023 × 10 −5 = 1 + 119450.5 = 1 + 345.6 = 346.6 Then δ max = I mδ static = (346.6)(5.023 × 10 −5 ) = 0.01743m = 17.43mm And Pmax = I mWstatic = (346.6)(5.03) = 1743N