Operating Lights marLED® E9 / E9i / E15

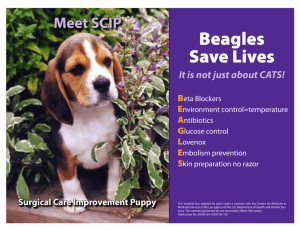

advertisement