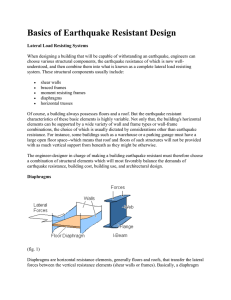

TO SEISMIC RESISTANT CONSTRUCTION

advertisement