RSX Operator Side Mount Installation Instructions

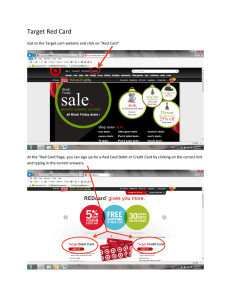

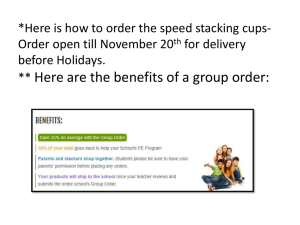

advertisement