USA - National Association of Home Builders

advertisement

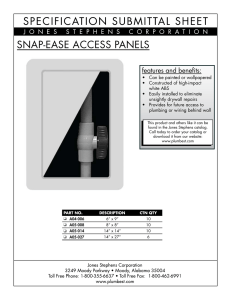

BUILDING PRODUCT CONFORMANCE ACTIVITIES May 2014 NATIONAL ASSOCIATION OF HOME BUILDERS OF THE UNITED STATES 1. Regulatory Interventions – Product Recalls In the United States, the government agency that monitors consumer products is the U.S. Consumer Products Safety Commission (CPSC). The CPSC works at the national level to monitor products that are used by consumers, such as toys, cribs, power tools, and household products. The CPSC also provides the public with a list of products that have been found to be faulty or noncompliant. http://www.cpsc.gov/en/Recalls/ There is some debate in the U.S. whether the CPSC’s authority extends to building materials, as was seen during the concerns over imported drywall from China. Ultimately, the CPSC worked with other federal agencies on a joint task force to identify the scope and extent of the problems with drywall imported from China. It is important to note that this product was never subject to a formal recall by the CPSC. The Federal Interagency Task Force on Problem Drywall was made up of the following federal government agencies: the U.S. Department of Housing and Urban Development, the U.S. Centers for Disease Control and Prevention, and the U.S. Environmental Protection Agency. See, Interagency Drywall Investigation, available at http://www.cpsc.gov/Safety-Education/Safety-Education- Centers/Drywall-InformationCenter/Interagency-Drywall-Investigation/. Because of the problems associated with identifying building materials that do not conform to existing voluntary product standards, NAHB monitors legal cases brought against building product manufacturers. 2. Current Compliance Activities NAHB works with other organizations, industry groups, and stakeholders who manufacture building materials to provide information on new products and assist it s members in developing procedures to assess incorporating new products into their construction projects. NAHB also reaches out to other industry organizations if it identifies areas of concern for existing or new products, in order to encourage product testing or further review, to ensure products conform to current codes and standards requirements, and also to ensure that products can be used for their intended purposes. NAHB works closely with other industry groups and organizations involved with developing standards to ensure building materials and products conform to accepted performance standards and labeling for use in construction projects. 3. Industry Education The National Association of Home Builders (NAHB) monitors and collects information regarding emerging and existing building product defect problems, studies and recommends to the Association methods of reducing builder liability from product and construction defects, and works cooperatively with manufacturers, insurers, product/trade groups and other interested parties on builder liability issues. Page 2 of 3 As part of its efforts, NAHB developed web pages that contain education materials, papers, pamphlets, articles, substantive information about current industry issues, legal briefs filed b NAHB, and information about legal settlements involving product defects. Starting in January 2014, NAHB attorneys have developed an update published every two months that compiles summaries of legal cases, new statutes and regulations, information on potential product defects, and other topics of interest to builders. The most recent edition was published 30 July 2014. While this information does not specifically identify whether certain building materials are counterfeit or nonconforming, it does provide builders with information for additional research and consideration. 4. Industry Developed Conformance Schemes In the United States, there are number of voluntary performance or consensus-based standards for different products and components. Voluntary performance standards organizations include, as examples, the following: ASTM International (formerly American Society for Testing and Materials), American National Standards Institute (ANSI), the International Code Council (ICC), and the Voluntary Product Standards (published by the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) (for wood products), and the American Lumber Standards Committee (grades and sizes of wood products). In the United States, there are also national standards which set the minimum standards for safety and installation for certain types of components such as electrical or plumbing components. An example of the national standard for electrical components can be found in the National Electric Code (NEC). For plumbing fixtures and components, the National Standard Plumbing Code was developed to ensure plumbing systems are properly installed while protecting public health and safety. There is also a model code for plumbing called the Uniform Plumbing Code (UPC) which was developed by the International Association of Plumbing Mechanical Officials (IAPMO) to govern installation and inspection of plumbing systems using the ANSI consensus development process. As with other uniform codes, the UPC works to standardize processes used during installation of these products. In addition, there are organizations such as Underwriters Laboratories (UL), and other independent testing facilities, that will test certain products and provide a recognized certification mark indicating the product meets certain safety requirements as tested by that facility. An example would be the UL mark on electrical components such as power cords or switches. Frequently, these uniform standards are incorporated into the voluntary building codes developed by the International Code Council and its members, who are made up of building code officials. The ICC codes are updated every few years and may become law in the individual states if a state legislature adopts all or part of the relevant code. The ICC develops codes for residential and commercial buildings. In order to comply with a state or local jurisdiction’s building codes, builders must ensure that these products are listed and labeled, and then installed according to their intended purpose (e.g., electrical or plumbing components) to ensure compliance with existing building code requirements. Building code inspectors or code officials will inspect projects during construction to ensure compliance with national standards requirements. Additionally, NAHB and its builder members participate in a number of voluntary groups that work on developing and reviewing changes, updates, or additions to national standards. For example, NAHB staff and members participate in the ICC code development review process, as well as a number of working groups within the ICC and ANSI as those groups develop new standards to recommend or implement. Examples: ASTM International: www.astm.org American National Standards Institute: www.ansi.org International Code Council: www.iccsafe.org National Institute of Standards and Technology: www.nist.gov Underwriters Laboratory: www.ul.com Page 3 of 3 American Lumber Standards Committee: www.alsc.org APA – The Engineered Wood Association: www.apawood.org National Electric Code (NEC) developed by the National Fire Protection Association: www.nfpa.org International Association of Plumbing Mechanical Officials: www.iapmo.org : 5. Regulatory Framework As mentioned in Section 4, in the United States, no single regulatory framework exists for building products and materials, although voluntary performance or consensus-based standards are used to develop some standardization in how certain products are used. Instead, states develop or adopt their own building codes, often starting with voluntary consensus-based building codes such as those developed by the ICC, and incorporating them into their own state building requirement. State building codes will also include sections of other national standards such as the National Electric Code, or the Uniform Plumbing Code to standardize the quality and performance of certain components. For example, electrical and plumbing products are regulated as part of their manufacturing process and are required to meet necessary safety standards to be used legally in residential and commercial buildings. These products must be listed and labeled for the purpose in which they are used and deviations are not allowed. Other products are also tested and labeled before they can be used in construction including steel, lumber, and drywall. Although these products are subject to voluntary standards, they cannot be used in construction unless they are listed and labeled as meeting certain standards for use. In addition, state building code officials and inspectors will conduct inspections during construction and at project completion to ensure that builders use products that are identified as meeting minimal national standards requirements. State building codes are applied during construction and compliance is confirmed by building inspectors as part of the permit and inspections conducted by building code officials before the building or housing can be occupied. Often, these voluntary consensus-based standards and codes will require building products to meet certain quality standards for consistency, but these voluntary codes are not legally binding until a state or local government formally adopts them as part of their laws or regulations. IHA Secretariat 1201 15th Street, NW Washington, DC 20005 Office (202) 266-8182, Fax (202) 266 8521