NM2000

Plugmold Plus Series

Product Specifications

®

NM2000 SURFACE NONMETALLIC RACEWAY

NM2000 PLUGMOLD® MULTIOUTLET SYSTEM

NM2000 PLUGMOLD WITH SNAPICOIL® HARNESS

PART 1 GENERAL

1.1

SCOPE

This specification covers a surface nonmetallic and multioutlet system to provide branch wiring

and convenience power outlets. The surface nonmetallic raceway shall consist of a base, blank

cover, and appropriate fittings to complete the installation per the electrical drawings. The

multioutlet system shall consist of a base, pre-punched cover, wired receptacle harness, field

replaceable surge suppression module, and appropriate fittings to complete the installation per

electrical drawings.

1.2

CLASSIFICATION AND USE

Surface nonmetallic raceway is to be utilized in dry interior locations only as covered in Article

388 of the 2002 National Electrical Code, as adopted by the National Fire Protection

Association and as approved by the American National Standards Institute. The Wiremold

Company NM2000 Raceway System is listed by Underwriters Laboratories under File No.

E4376 Guide RJBT and E41751 Guide RJPR. The multioutlet system is to be utilized in dry

interior locations only as covered in Article 380 of the 2002 National Electrical Code, as adopted

by the National Fire Protection Association and as approved by the American National

Standards Institute. The Wiremold Company's Plugmold NM2000 mulitoutlet system is listed by

Underwriters Laboratories under File No. E15191 Guide PVGT.

1.3

SUBMITTALS

1.3.1 Shop Drawings

For prewired installations, submit drawings for approval showing the complete layout of all products that

make up the complete system for each floor prior to installation with raceway lengths, device type (power

and/or data), locations, and circuits identified.

1.3.2 As Built Drawings

If variations from approved shop drawings occur during the installation of the system, final, as built

drawings, shall be submitted for each floor that has been altered.

PART 2 PRODUCT

2.1

MANUFACTURER

The surface nonmetallic raceway system and/or multioutlet system herein for branch circuit

wiring and convenience power outlets shall be the NM2000 base and blank cover, the

NM2000 Plugmold Multioutlet and the NM2000 Plugmold with Snapicoil Systems as

manufactured by The Wiremold Company. Systems of other manufacturers may be considered

equal if, in the opinion and the written approval of the engineer, they meet all the performance

standards herein.

2.2

MATERIALS

The raceway and all system components must be UL Listed and exhibit nonflammable selfextinguishing characteristics, tested to comparable specifications of UL94V-0. The base and

cover shall be manufactured of a rigid PVC compound. Base and cover shall be ivory in color,

with the NM2000B Base having a smooth texture and the NM2000C Cover having a matte

texture and be suitable for field painting.

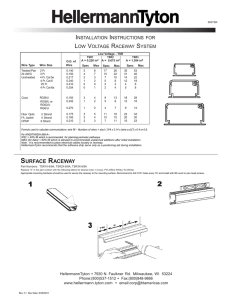

2.2.1 Raceway

The raceway shall be a two-piece design with a base and cover. Total width shall be1.80" wide [45.7mm]

by 1.0" [25.4mm] deep with a cross sectional area of 1.2 square inches [30.5mm]. The NM2000 Base

and Cover sections shall have a minimum thickness of 0.075" [1.9mm]. The NM2000 Base and Cover

shall be available in 8' [2.4m] lengths. The NM2000 Plugmold Multioutlet System shall be available in

standard lengths of 3', 4', 5' and 6' [.9m, 1.2m, 1.5m and 1.8m].

The NM2000 Plugmold with Snapicoil harness shall be available in standard lengths of 48' and 50'

[1.2m and 1.3m].

The NM2000 Cover shall be available as a blank or with pre-punched holecuts for receptacles on

9", 12", 15", 18", 24" and 30" [229mm, 305mm, 381mm, 457mm, 610mm and 762mm] centers for

Plugmold NM2000 or 12", 18" and 30" [305mm, 457mm and 762mm] centers for Plugmold NM2000

with Snapicoil harness.

2.2.2 Fittings

A full complement of fittings must be available including, but not limited to entrance and blank end

fittings; flat, internal and external elbows; tee and cover clips. Transition fittings shall be available to

adapt to an existing flush wall box and to enable raceway to run both vertically and horizontally. The

fitting covers shall have a matte texture, and be ivory in color to match the raceway. They shall overlap

the raceway cover and base to hide uneven cuts. All fittings shall be supplied with a base where

applicable to eliminate mitering.

2.2.3 Device and Extension Boxes

Device boxes shall be available to mount standard devices and device face plates in single-gang and

two-gang configurations. Device box covers must snap onto the box base and be fastened in place

without the use of screws. Device boxes shall function as an extension box by removal of a knockout in

the base. The boxes shall be available in 1 3/4" [44.5mm] depth and shall be ivory in color and textured

to match the raceway.

2.2.4 Multioutlet Wiring Harnesses

Multioutlet wiring harnesses shall consist of both 15A, 125V NEMA 5-15R and 20A, 125V NEMA 5-20R

specification grade duplex receptacles. Receptacles must be UL tested to meet the performance

requirements of Fed. Spec. W-C596G General Specification for Electrical Power Connectors and conform

to NEMA specification WD 1-7.01 to 7.10 "Heavy Duty General Use Grounding Receptacles".

Receptacles shall also be UL Listed and be in compliance with UL-498.

The harnesses shall be available in single-circuit (2 conductor plus ground), two-circuit (3 conductor plus

ground) alternating wiring configuration and a single circuit isolated ground (2 conductor plus isolated

ground) wiring configuration.

The wires shall be #12 AWG solid type THHN conductors, factory assembled to the receptacles.

The Plugmold NM2000 Multioutlet system shall have a factory installed wiring harness with available

receptacle spacings of 9", 12", 15", 18", 24" or 30" [229mm, 305mm, 381mm, 457mm, 610mm and

762mm] centers.

The Plugmold NM2000 with Snapicoil harness shall have a field installed harness with available

spacings of 12", 18" and 30" [305mm, 381mm and 762mm] centers and available on standard 48' and 50'

[14.6m and 15.1m] reels. Harness lengths up to 240' [73.2m] shall be available for receptacle spacing of

12" and 18" [305mm and 457mm] centers; and lengths up to 500' [152m] for receptacle spacing of 30"

[762mm] centers.

2.2.5 Surge Suppression Module

The NM2000 Plugmold system shall offer a field serviceable surge suppression module. This module

must be able to be replaced by the end-user without removing the raceway cover and without the use of

special tools. The surge protection device detailed herein shall be fully applicable for the purpose of

protecting electronic equipment connected to the NM2000 multioutlet assembly from the hazardous

effects of transient overvoltages. The surge protective devices must be listed to UL1449 Transient

Voltage Surge Suppressors, as defined by ANSI/NFPA 70-1990.

2.2.6

Surge Protection Device Function Information (Electrical)

2.2.5.1 Service Voltages. The nominal operating voltage shall be 120Vrms, with the maximum

continuous operating voltage of 150Vrms.

2.2.5.2 Listing. The surge protection device and associated hardware must be listed to UL1449,

as defined by ANSI/NFPA 70-1990.

The suppression voltage of the complete surge protective device shall be assessed by UL; these

figures must not exceed the values shown below.

Suppression Mode

Line - Neutral

Line - Ground

Neutral - Ground

UL 1449

Voltage

500V

500V

500V

Suppression

2.2.5.3 Actual let through voltage. Voltage at 6kV 1.2/50us, 500Amps, 8/20us:

340Volts Peak L-N.

2.2.5.4 Performance Indication. The suppression device must contain visual indication of the

proper operation of the suppression module.

2.2.2.5 "Joule Ratings" and "Response Times". The selection of surge protective devices shall

not be made solely, or in part, based upon either of these two ambiguous specifications. These

terms currently are not longer recognized by ANSI, NEMA, IEEE or IEC Standards as bonafide

suppressor performance parameters. The key selection elements of a quality suppressor are its

low clamping capability and its maximum surge handling capacity.

2.2.5.6 Maximum Single Withstand Surge Current. Surge protective device circuitry shall have

a maximum single impulse rating of no less than 39kA individually between L-N, L-G and

N-G based on the sum of the device components.

2.2.5.7 Three Line Protection. The suppressor must protect all three legs; hot, neutral,

and ground.

PART 3 EXECUTION

3.1

INSTALLATION

Prior to and during installation, refer to system layout drawing containing all elements of the

system. Installer shall comply with detailed manufacturer's instruction sheets that accompany

system components, as well as the complete system instruction sheet, whichever is applicable.

3.1.1 Mechanical Security

All raceway systems shall be mechanically continuous and connected to all electrical outlets, boxes, and

cabinets in accordance with manufacturer's installation sheets.

3.1.2 Raceway Support

Raceway shall be securely supported in accordance to manufacturer's installation sheets.

3.1.3 Completeness

Work shall include furnishing all raceway and appropriate fittings and device boxes and plates to install a

complete nonmetallic surface raceway and/or multioutlet system as indicated on the electrical drawings

and in this specification. All unused raceway openings shall be closed.

Wiremold / Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX: 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX: 905-738-9721

2005 The Wiremold Company All Rights Reserved

ED680R3 Updated January 2005 For latest specs visit www.wiremold.com