SECTION 16289 TRANSIENT VOLTAGE SURGE

advertisement

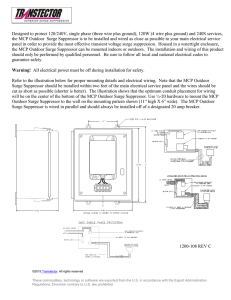

SECTION 16289 TRANSIENT VOLTAGE SURGE SUPPRESSION PART 1 - GENERAL 1.1 1.2 1.3 1.4 DESCRIPTION A. This section describes the materials and installation requirements for Surge Protective Devices (SPDs) and includes all service entrance, distribution and branch panel type surge protective devices suitable for use as Type 1 or Type 2 devices per UL1449 3rd Edition, applied to the line or load side of the utility feed inside the facility. B. This section also includes materials and installation of Transient Voltage Surge Suppressors (TVSS) for the protection of electronic circuits and equipment. RELATED WORK A. Section 16010, "General Electrical Requirements" B. Section 16123, "Wire and Cable" C. Section 16130, "Raceway and Boxes" D. Section 16060, "Secondary Grounding" E. Section 16421, "Motor Control" REFERENCES A. UL 1449 3rd Edition (2009 Revision effective 9/29/2009). B. UL 1283. C. ANSI/IEEE C62.41, Recommended Practice for Surge Voltages in Low-Voltage AC Power Circuits. D. ANSI/IEEE C62.45, Guide for Surge Testing for equipment connected to Low-Voltage AC Power Circuits. E. IEEE 1100 Emerald Book. F. NEMA LS-1, 1992-(R2000) Low-Voltage Surge Protection Devices. G. National Fire Protection Association (NFPA 70: National Electrical Code). SUBMITTALS A. Submit shop drawings, product data and manufacturer's installation instructions. B. The surge suppression submittals shall also include: 1. 2. Copies of Manufacturer’s catalog data, technical information and specifications on equipment proposed for use. Copies of documentation stating that the Surge Protection Device is listed from a 3. 4. 5. 6. 7. 1.5 1.6 Nationally Recognized Testing Laboratory (NRTL) (UL, ETL, etc.) and are tested and multi-listed to UL 1449 and UL 1283. Copies of actual let through voltage data in the form of oscillograph results for both ANSI/IEEE C62.41 Category 3 (combination wave) and B3 (Ring wave) tested in accordance with ANSI/IEEE C62.45. Copies of Noise Rejection testing as outlined in NEMA LS1-1993 (R2000) Section 3.11. Noise rejection is to be measured between 50kHZ and 100MHz verifying the devices noise attenuation. Must show multiple attenuation levels over a range of frequencies. Copies of Surge Fuse Testing. Each unit shall be surge tested with fusing in series to verify that a transient of maximum surge current capacity/magnitude is fully suppressed without fuse failure, operation or degradation per NEMA LS11992 (R2000) Section 3.9. Copies of test reports from a recognized independent testing laboratory, capable of producing 200kA surge current waveforms, verifying the suppressor components can survive published surge current rating on both a per mode and per phase basis using the ANSI/IEEE C62.41 impulse waveform C3 (8 x 20 microsecond, 20kV/10kA). Test data on an individual module is not acceptable. Copy of warranty statement clearly establishing the terms and conditions to the building/facility owner/operator. WARRANTY A. All TVSS units shall be guaranteed to be free of defects in materials and workmanship for a period of five years from the date of installation. B. Any suppressor which fails or operates improperly, even as a result of a direct lightning strike, will be replaced by the manufacturer at no expense to the owner. QUALITY ASSURANCE A. All suppressors shall be manufactured in the United States by a company normally engaged in the design, development, and manufacture of such devices for electrical and electronics systems equipment for a minimum period of five years. B. All manufacturers will provide products which do not interrupt power to the protected system in the event of a suppressor failure, for life safety applications, i.e., fire alarm. Written certification of this parameter shall be provided by the suppressor manufacturer. C. The suppressors listed in this specification shall not impair the performance of the protected systems, including, but not limited to, the following parameters: degradation of signal quality or levels, attenuation, and distortion. The suppressors shall not initiate conditions which jeopardize the life safety features of fire alarms, communications, energy management, and other code related protection. PART 2 - PRODUCTS 2.1 208 VOLT AND 480 VOLT SUB PANEL SUPPRESSORS A. Suppressors shall be listed in accordance with UL 1449, "Standard for Safety, Transient Voltage Surge Suppressors", and UL 1283, "Electromagnetic Interference Filters". B. Declared Maximum Continuous Operating Voltage (MCOV) shall be greater than 115 percent of the nominal system operating voltage and in compliance with test and evaluation procedures outlined in the nominal discharge surge current test of UL1449 3rd Edition, section 37.7. MCOV values claimed based on the component’s value or on the 30-minute 115% operational voltage test, section 38 in UL1449 will not be accepted. C. Unit shall have not more than 10% deterioration or degradation of the UL1449 3rd Edition Voltage Protective Rating (VPR) due to repeated surges. Unit shall have a monitoring option available to be able to test and determine the percentage of protective available at all times. D. Suppressors shall be independently tested with the category C3 high exposure waveform (20 kV, 10kA, 8/20 micro-second waveform) clamp voltage test results. E. Suppressors shall incorporate copper bus bars for the surge current path. Small round wiring or plug-in connections shall not be used in the path for surge current diversion. Surge current diversion modules shall use bolted connections to the bus bars for reliable low impedance connections. F. The unit shall include an engineered solid-state high performance suppression filter system, utilizing metal oxide varistors, and polypropylene capacitors. G. The unit shall contain 200,000 AIC fuses on each phase. H. The status of each phase shall be monitored on the front of the suppressor's enclosure. I. For three phase, four wire plus ground configurations, the unit shall provide protection in all modes, Line to Neutral, Line to Ground, and Neutral to Ground. J. Suppressors shall be equipped with an audible alarm which shall activate upon device failure. An alarm on/off switch shall be provided to silence the alarm and an alarm pushto-test switch shall be provided to test the alarm. The switches and alarm shall be located on the front cover of the suppressor's enclosure. K. Suppressor shall meet or exceed the following criteria: 1. Tested maximum single impulse surge current rating per mode shall be; Line to Line Line to Neutral Line to Ground Neutral to Ground 80,000A 80,000A 80,000A 80,000A 2. Pulse life test: Capable of protecting against and surviving 2500 ANSI/IEEE C62.41 Category C3(20kV, 10 kA) transients without failure or degradation of UL 1449 suppression rating by more than 10%. 3. Protection Modes: SVR(6kV, 500A) and UL1449 3rd Edition VPR(6kV, 3kA) for grounded WYE/delta and High Leg Delta circuits with voltages of (480Y/277), (208Y/120), (600Y/347) 3-Phase/4 wire and (120/240) Split phase/3 wire circuits shall be as follows and comply with test procedures outlined in UL1449 3rd Edition section 37.6. Ratings shall not exceed the following: System Voltage 120/208 Mode MCOV L-N L-G 150 150 UL 1449 UL 1449 2nd Ed. SVR 3rd Ed. VPR 400/400 700/700 500/500 700/700 N-G 150 400/400 L-L 277/480 L-N L-G 320 320 800/800 1000/1000 N-G L-L 4. L. 300 550 900/900 700/700 900/1000 900/1000 1200/1200 320 800/800 1200/1200 1800/1800 1800/1800 The suppressor shall have a response time no greater than five nanoseconds for any of the individual protection modes. The unit shall include a high-frequency extended range tracking filter and shall be UL 1283 listed as an electromagnetic interference filter. The filter shall reduce fast rise-time, high frequency, error producing transients. The filter shall provide minimum noise attenuation as follows: Attenuation Frequency 100KHz 1 MHz Atttenuation dB 41 31 31 10MHz 100MHz 31 M. The unit shall incorporate solid state, long life, externally mounted LED visual status indicators that indicate the on line status of each phase of the unit. N. The unit shall incorporate an integral test point allowing easy off line diagnostic testing which verifies the operational integrity of the unit's suppression filter system. O. The unit shall include mechanical lugs for each phase, neutral and ground. The lugs shall accommodate up to #4 AWG copper conductor with integral fused disconnect switch, and up to 1/0 AWG copper conductor without an integral fused disconnect switch. P. Suppressor manufacturer shall provide certified test data confirming a "fail-short" failure mode. Q. Acceptable manufacturers: Current Technology Eaton Innovative Technology Square D Surge Logic 2.2 TERMINAL STRIP HARD-WIRED (120 VAC) SUPPRESSORS A. Suppressors shall be listed in accordance with UL 1449, "Standard for Safety, Transient Voltage" "Surge Suppressors". B. Suppressors shall consist of a three stage hybrid design: first stage - MOV, second stage - inductor, third stage - silicon avalanche diode or MOV. C. Suppressors shall be internally fused in such a manner that power to protected equipment is not interrupted in the event of a suppressor failure. D. Suppressors shall provide three suppression paths: line to neutral, line to ground, and neutral to ground. E. Suppressors shall provide a maximum single impulse current rating of 25 kA (8/20 micro- second waveform) per mode. F. Pulse life rating: Capable of protecting against and surviving 500 Category B3 transients (6 kV - 1.2/50 micro-second, 3 kA - 8/20 micro-second waveform). G. Suppressors' maximum clamping voltage when subjected to Category B3 transients shall not exceed 350 V peak. H. Visible indication of proper suppressor connection and operation shall be provided. I. The suppressor shall have a two year warranty. J. Acceptable manufacturers: Advanced Protection Technologies, Inc., Model TE/AC03UL, or approved equal. PART 3 - EXECUTION 3.1 3.2 3.3 GENERAL A. Install TVSS equipment according to manufacturer's recommendations. B. Contractor shall properly match TVSS equipment to equipment being protected, including wire sizes, operating voltages and currents. C. Contractor shall coordinate with providers of all equipment being protected and provide TVSS equipment which meets these specifications. D. Provide required NEMA 1 (indoor) or NEMA 3R (outdoor) enclosures for suppressors adjacent to each electronic system cabinet, or coordinate with each electronic system supplier to provide oversized cabinets to incorporate suppressors into electronic systems cabinet. E. Electronic system equipment shall be protected by treating groups of related devices as a "cluster" and protecting all hard wire circuits which enter and leave the cluster. All equipment chassis within a protected cluster shall be bonded to a ground bar at the "window" location for the cluster, the window being the common point where all hard wire circuits enter or leave the cluster. 208 VOLT AND 480 VOLT SUB PANELS A. Install one secondary suppressor at each sub panel location, according to manufacturer's recommendations. B. Conductors between suppressor and point of attachment shall be kept short and straight. C. Neutral and ground shall not be bonded together at secondary panelboard locations. D. Provide suitable three pole breaker in all panels as recommended by suppression manufacturer to connect unit. GROUND INSTALLATION A. Ground Bus Connections 1. Provide local ground bus in each terminal cabinet housing surge protection 2. 3. 4. B. Surge Suppression Equipment Grounding 1. 2. C. Connect each suppressor to local ground bus in terminal cabinet with wire sized as recommended by manufacturer. Where M block type terminations/suppressors are used, bond ground rail to local ground bar with wire as recommended by manufacturer. Ensure that 120 VAC power source/supply suppressor is also grounded to same local ground bus as suppressors provided in this section for same system (i.e., fire alarm, intercom, television, etc.). Grounding Conductors 1. 2. 3. 4. 5. 6. D. equipment (with other materials as required). Bond local ground bus to terminal cabinet with minimum #6 copper wire. Connect terminal cabinet local ground bus to systems ground bus with minimum #6 copper insulated wire (unless otherwise noted) in conduit. Note that the systems ground bar is also to be used for power transformation ground (480 V to 208 V) where applicable. Conductors shall be a minimum size of #12 THWN (in conduit, insulated) unless otherwise noted or otherwise recommended by the manufacturer. Conductors shall be as short as possible. No bend radius shall be less than 6 inches or more than 90 degrees. Conductors shall be secured at 12 inch intervals with an approved copper clamp. Grounding conductors shall be properly connected to the building service ground by approved clamps. Do not bundle unprotected conductors with protected conductors. Grounding Connectors 1. 2. 3. Connectors, splicers, and other fittings used to interconnect grounding conductors, or bond to equipment or grounding bars, shall be approved by UL or NEC for the purpose. All connectors and fittings shall be of the one time crimp or compression setscrew type solderless connection. Special treatment to fittings, lugs, or other connectors of dissimilar material shall be applied to prevent electrogalvanic action. END OF SECTION