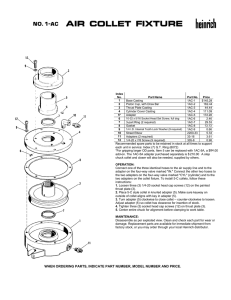

Collets and Sleeves

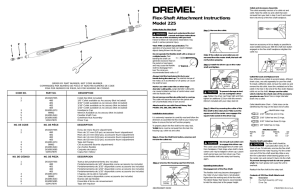

advertisement