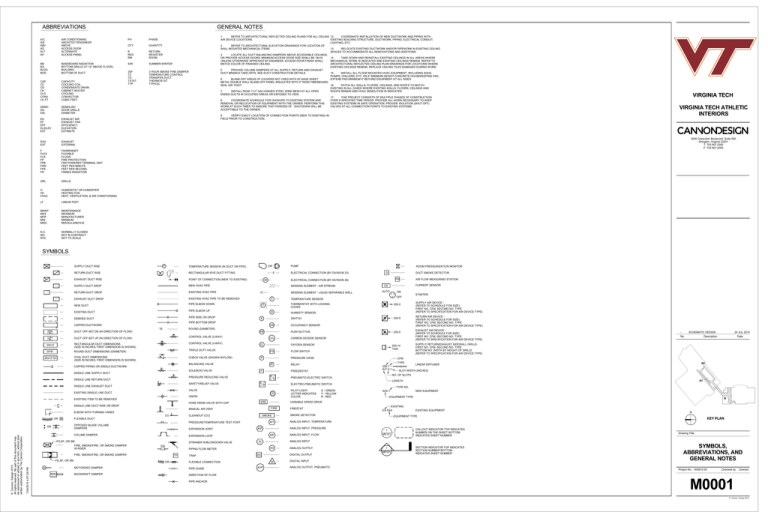

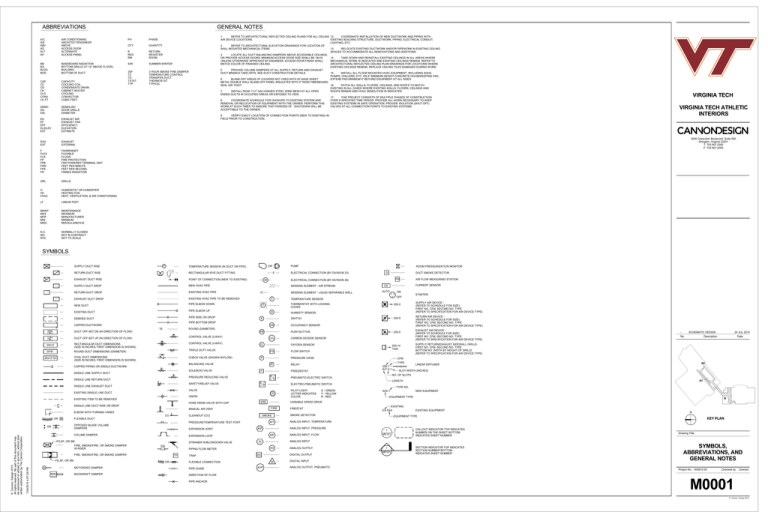

ABBREVIATIONS

GENERAL NOTES

A/C

A/E

ABV

AD

ALT

AP

AIR CONDITIONING

ARCHITECT/ENGINEER

ABOVE

ACCESS DOOR

ALTERNATE

ACCESS PANEL

PH

PHASE

QTY

QUANTITY

R

REG

RM

RETURN

REGISTER

ROOM

BB

BG

BLDG

BOD

BASEBOARD RADIATION

BOTTOM GRILLE (3"-12" ABOVE FLOOR)

BUILDING

BOTTOM OF DUCT

S/W

SUMMER-WINTER

CAP

CC

CD

CH

CLG

CONV

CU FT

CAPACITY

COOLING COIL

CONDENSATE DRAIN

CABINET HEATER

COOLING

CONVECTOR

CUBIC FEET

3SF

TC

TD

TSTAT

TYP

3 HOUR SMOKE FIRE DAMPER

TEMPERATURE CONTROL

TRANSFER DUCT

THERMOSTAT

TYPICAL

DEMO

DG

DIA

DEMOLISH

DOOR GRILLE

DIAMETER

EA

EF

EFF

EL/ELEV

EST

EXHAUST AIR

EXHAUST FAN

EFFICIENCY

ELEVATION

ESTIMATE

EXH

EXT

EXHAUST

EXTERNAL

F

FLEX

FLR

FP

FPB

FPM

FPS

FR

FAHRENHEIT

FLEXIBLE

FLOOR

FIRE PROTECTION

FAN POWERED TERMINAL UNIT

FEET PER MINUTE

FEET PER SECOND

FINNED RADIATION

GRL

GRILLE

H

HC

HVAC

HUMIDISTAT OR HUMIDIFIER

HEATING COIL

HEAT, VENTILATION, & AIR CONDITIONING

LF

LINEAR FEET

MAINT

MAX

MFR

MIN

MISC

MAINTENANCE

MAXIMUM

MANUFACTURER

MINIMUM

MISCELLANEOUS

N.C.

NIC

NTS

NORMALLY CLOSED

NOT IN CONTRACT

NOT TO SCALE

COORDINATE INSTALLATION OF NEW DUCTWORK AND PIPING WITH

1.

REFER TO ARCHITECTURAL REFLECTED CEILING PLANS FOR ALL CEILING 12.

EXISTING BUILDING STRUCTURE, DUCTWORK, PIPING, ELECTRICAL CONDUIT,

AIR DEVICE LOCATIONS.

LIGHTING, ETC.

2.

REFER TO ARCHITECTURAL ELEVATION DRAWINGS FOR LOCATION OF

13.

RELOCATE EXISTING DUCTWORK AND/OR PIPEWORK IN EXISTING CEILING

WALL MOUNTED MECHANICAL ITEMS.

SPACES TO ACCOMMODATE ALL RENOVATIONS AND ADDITIONS.

3.

LOCATE ALL DUCT BALANCING DAMPERS ABOVE ACCESSIBLE CEILINGS,

14.

TAKE DOWN AND REINSTALL EXISTING CEILINGS IN ALL AREAS WHERE

OR PROVIDE ACCESS DOORS. MINIMUM ACCESS DOOR SIZE SHALL BE 18x18

MECHANICAL WORK IS INDICATED AND EXISTING CEILINGS REMAIN. REFER TO

UNLESS OTHERWISE APPROVED BY ENGINEER. ACCESS DOOR FINISH SHALL

ARCHITECTURAL REFLECTED CEILING PLAN DRAWINGS FOR LOCATIONS WHERE

MATCH COLOR OF FINISHED CEILING.

EXISTING CEILINGS REMAIN. REPLACE CEILING TILES DAMAGED DURING WORK.

5.

PROVIDE VOLUME DAMPERS AT ALL SUPPLY, RETURN AND EXHAUST

15.

INSTALL ALL FLOOR MOUNTED HVAC EQUIPMENT, INCLUDING AHUS,

DUCT BRANCH TAKE-OFFS. SEE DUCT CONSTRUCTION DETAILS.

PUMPS, CHILLERS, ETC. ON 4" MINIMUM HEIGHT CONCRETE HOUSEKEEPING PAD.

EXTEND PAD MINIMUM 4" BEYOND EQUIPMENT AT ALL SIDES.

6.

BLANK-OFF AREAS OF LOUVERS NOT USED WITH 20 GAGE SHEET

METAL DOUBLE WALL BLANK-OFF PANEL INSULATED WITH 2" RIGID FIBERBOARD.

16.

PATCH ALL WALLS, FLOORS, CEILINGS, AND ROOFS TO MATCH

SEAL AIR TIGHT.

EXISTING IN ALL CASES WHERE EXISTING WALLS, FLOORS, CEILINGS AND

ROOFS REMAIN AND HVAC DEMOLITION IS INDICATED.

7.

INSTALL RIGID 1"x1" GALVANIZED STEEL WIRE MESH AT ALL OPEN

ENDED DUCTS IN OCCUPIED AREAS OR EXPOSED TO VIEW.

17.

THIS PROJECT CONSISTS OF MULTIPLE PHASES OF CONSTRUCTION

OVER A SPECIFIED TIME PERIOD. PROVIDE ALL WORK NECESSARY TO KEEP

8.

COORDINATE SCHEDULE FOR HOOKUPS TO EXISTING SYSTEM AND

EXISTING SYSTEMS IN SAFE OPERATION. PROVIDE ISOLATION (SHUT-OFF)

REMOVAL OR RELOCATION OF EQUIPMENT WITH THE OWNER. PERFORM THIS

VALVES AT ALL CONNECTION POINTS TO EXISTING SYSTEMS.

WORK AT SUCH TIMES TO ENSURE THAT PERIODS OF SHUTDOWN WILL BE

ACCEPTABLE TO THE OWNER.

9.

VERIFY EXACT LOCATION OF CONNECTION POINTS (NEW TO EXISTING) IN

FIELD PRIOR TO CONSTRUCTION.

VIRGINIA TECH

VIRGINIA TECH ATHLETIC

INTERIORS

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

SYMBOLS

T

SUPPLY DUCT RISE

OR

TEMPERATURE SENSOR (IN DUCT OR PIPE)

PUMP

E

ROOM PRESSURIZATION MONITOR

ELECTRICAL CONNECTION (BY DIVISION 23)

RETURN DUCT RISE

RECTANGULAR WYE DUCT FITTING

EXHAUST DUCT RISE

POINT OF CONNECTION (NEW TO EXISTING)

SUPPLY DUCT DROP

NEW HVAC PIPE

SENSING ELEMENT - AIR STREAM

RETURN DUCT DROP

EXISTING HVAC PIPE

SENSING ELEMENT - LIQUID SEPARABLE WELL

EXHAUST DUCT DROP

EXISTING HVAC PIPE TO BE REMOVED

NEW DUCT

PIPE ELBOW DOWN

EXISTING DUCT

PIPE ELBOW UP

DEMOED DUCT

PIPE RISE OR DROP

26

D

DUCT SMOKE DETECTOR

FM

ELECTRICAL CONNECTION (BY DIVISION 26)

T

CURRENT SENSOR

CS

AUTO

THERMOSTAT WITH LOCKING

COVER

H

ON

OFF

TEMPERATURE SENSOR

T

200-2

HUMIDITY SENSOR

S

200-5

SWITCH

PIPE BOTTOM DROP

CAPPED DUCTWORK

OS

"Ø

DN

UP

PB

CONTROL VALVE (2-WAY)

DUCT OFF-SET UP (IN DIRECTION OF FLOW)

24x12

RECTANGULAR DUCT DIMENSIONS

(SIZE IN INCHES, FIRST DIMENSION IS SHOWN)

24"Ø

ROUND DUCT DIMENSIONS (DIAMETER)

24x12 OV

OCCUPANCY SENSOR

ROUND (DIAMETER)

DUCT OFF-SET DN (IN DIRECTION OF FLOW)

CONTROL VALVE (3-WAY)

O²

TRIPLE DUTY VALVE

OVAL DUCT DIMENSIONS

(SIZE IN INCHES, FIRST DIMENSION IS SHOWN)

CHECK VALVE (SHOWN W/FLOW)

SOLENOID VALVE

SINGLE LINE SUPPLY DUCT

P

SAFETY/RELIEF VALVE

R

SINGLE LINE EXHAUST DUCT

FLOW SWITCH

P

TYPE

250-7

4LF-2-1

VSD

PILOT LIGHTLETTER INDICATES

COLOR:

G - GREEN

Y - YELLOW

R - RED

FIRESTAT

ELBOW WITH TURNING VANES

OPPOSED BLADE VOLUME

DAMPERS

EXPANSION JOINT

VOLUME DAMPER

EXPANSION LOOP

FIRE, SMOKE/FIRE, OR SMOKE DAMPER

IN RISER

STRAINER W/BLOWDOWN VALVE

SMOKE

AIT

FIRE, SMOKE/FIRE, OR SMOKE DAMPER

FD,SF, OR SM

BDD

AIF

TP

OR

TRAP

AO

DO

MOTORIZED DAMPER

PIPE GUIDE

BACKDRAFT DAMPER

DIRECTION OF FLOW

PIPE ANCHOR

AOP

A1

NEW EQUIPMENT

B

EXISTING

EX-XXX

EXISTING EQUIPMENT

N

EQUIPMENT TYPE

KEY PLAN

ANALOG INPUT, TEMPERATURE

ANALOG INPUT, FLOW

ANALOG OUTPUT

DIGITAL OUTPUT

DI

FLEXIBLE CONNECTION

A2

LINEAR DIFFUSER

1

M0101

CALLOUT INDICATOR TOP INDICATES

NUMBER ON THE SHEET BOTTOM

INDICATES SHEET NUMBER

1

M0101

SECTION INDICATOR TOP INDICATES

SECTION NUMBER BOTTOM

INDICATES SHEET NUMBER

Drawing Title:

ANALOG INPUT

AI

PIPING FLOW METER

SUPPLY/ RETURN/EXHAUST SIDEWALL GRILLEFIRST NO. CFM, SECOND NO. TYPE

BOTTOM NO. WIDTH BY HEIGHT OF GRILLE

(REFER TO SPECIFICATION FOR AIR DEVICE TYPE)

EQUIPMENT TYPE

SMOKE DETECTOR

ANALOG INPUT, PRESSURE

AIP

FM

Date

SLOT WIDTH (INCHES)

XXX-1

FLEXIBLE DUCT

FD,SF, OR SM

7/24/2015 4:57:29 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

OR

24 JUL 2015

Description

VARIABLE SPEED DRIVE

FIRE

PRESSURE/TEMPERATURE TEST PORT

SCHEMATIC DESIGN

LENGTH

SINGLE LINE DUCT RISE OR DROP

OR

No.

TYPE NO.

UNION

CLEANOUT (CO)

EXHAUST AIR DEVICE (REFER TO SCHEDULE FOR SIZE)

FIRST NO. CFM, SECOND NO. TYPE

(REFER TO SPECIFICATION FOR AIR DEVICE TYPE)

PNEUMATIC-ELECTRIC SWITCH

EXISTING ITEM TO BE REMOVED

CO

RETURN AIR DEVICE (REFER TO SCHEDULE FOR SIZE)

FIRST NO. CFM, SECOND NO. TYPE

(REFER TO SPECIFICATION FOR AIR DEVICE TYPE)

ELECTRIC-PNEUMATIC SWITCH

P

MANUAL AIR VENT

SUPPLY AIR DEVICE (REFER TO SCHEDULE FOR SIZE)

FIRST NO. CFM, SECOND NO. TYPE

(REFER TO SPECIFICATION FOR AIR DEVICE TYPE)

NO. OF SLOTS

E

G

HOSE DRAIN VALVE WITH CAP

STARTER

CFM

FREEZESTAT

VALVE

EXISTING SINGLE LINE DUCT

200-14

10x8

RELAY

F

E

CARBON DIOXIDE SENSOR

PRESSURE GAGE

PRESSURE REDUCING VALVE

SINGLE LINE RETURN DUCT

200-5

OXYGEN SENSOR

FS

BALANCING VALVE

CAPPED PIPING OR SINGLE DUCTWORK

PUSH BUTTON

CO²

AIR FLOW MEASURING STATION

DIGITAL INPUT

ANALOG OUTPUT, PNEUMATIC

SYMBOLS,

ABBREVIATIONS, AND

GENERAL NOTES

Project No.: 004815.00

Checked by: Checker

M0001

© Cannon Design 2015

23

24

Kx

GENERAL NOTES:

1.

22

2.

3.

21

Jx

4.

MECHANICAL CONTRACTOR SHALL PERFORM

PRE-DEMOLITION BALANCING AND REBALANCE

ALL DIFFUSERS/GRILLES TO MATCH PRERENOVATION CONDITIONS.

FIRE PROTECTION CONTRACTOR SHALL FIELD

VERIFY EXISTING CONDITIONS AND REMOVE ALL

EXISTING SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING. PROVIDE NEW

SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING TO ALIGN WITH NEW

CEILING LAYOUT THROUGHOUT RENOVATED

AREAS AS REQUIRED.

SPRINKLER HEAD TYPE AND MANUFACTURER

SHALL MATCH EXISTING, COORDINATE WITH

ARCHITECT AS REQUIRED.

SPRINKLER HEAD COVERAGE SHALL BE IN

ACCORDANCE WITH NFPA 13 APPLICABLE

ADDITION AND LOCAL AUTHORITIES HAVING

JURISDICTION.

VIRGINIA TECH

VIRGINIA TECH ATHLETIC

INTERIORS

NOTES:

Fx

1.

PROVIDE NEW GRILLE/DIFFUSER TO MATCH

EXISTING.

2.

RELOCATE EXISTING THERMOSTAT TO LOCATION

SHOWN.

3.

EXISTING CABINET UNIT HEATER TO REMAIN.

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

Kx

1

Ex

Jx

1

1

1

1

1

Cx

Fx

24

-

SCHEMATIC DESIGN

No.

23

24 JUL 2015

Description

Date

1

Ex

A2

1

22

A1

1

21gg

B

21ff

21ee

21

N

T

2

KEY PLAN

Cx

3

21dd

AB

LEVEL ONE MECHANICAL PLAN

1

BB

7/24/2015 4:57:30 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

Project No.: 004815.00

Checked by:

SJJ

M0101

© Cannon Design 2015

23

24

Kx

GENERAL NOTES:

1.

22

2.

3.

21

Jx

4.

MECHANICAL CONTRACTOR SHALL PERFORM

PRE-DEMOLITION BALANCING AND REBALANCE

ALL DIFFUSERS/GRILLES TO MATCH PRERENOVATION CONDITIONS.

FIRE PROTECTION CONTRACTOR SHALL FIELD

VERIFY EXISTING CONDITIONS AND REMOVE ALL

EXISTING SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING. PROVIDE NEW

SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING TO ALIGN WITH NEW

CEILING LAYOUT THROUGHOUT RENOVATED

AREAS AS REQUIRED.

SPRINKLER HEAD TYPE AND MANUFACTURER

SHALL MATCH EXISTING, COORDINATE WITH

ARCHITECT AS REQUIRED.

SPRINKLER HEAD COVERAGE SHALL BE IN

ACCORDANCE WITH NFPA 13 APPLICABLE

ADDITION AND LOCAL AUTHORITIES HAVING

JURISDICTION.

VIRGINIA TECH

VIRGINIA TECH ATHLETIC

INTERIORS

NOTES:

1

1.

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

PROVIDE NEW GRILLE/DIFFUSER TO MATCH

EXISTING.

Fx

1

Kx

Ex

1

Jx

1

1

Cx

1

Fx

24

-

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

23

A2

Ex

A1

22

B

1

21gg

N

21ff

KEY PLAN

21ee

21

21dd

Cx

LEVEL TWO MECHANICAL PLAN JAMERSON

AB

7/24/2015 4:57:30 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

BB

Project No.: 004815.00

Checked by: Checker

M0102

© Cannon Design 2015

GENERAL NOTES:

1.

2.

21gg

3.

A

21dd

B

D

4.

21ff

MECHANICAL CONTRACTOR SHALL PERFORM

PRE-DEMOLITION BALANCING AND REBALANCE

ALL DIFFUSERS/GRILLES TO MATCH PRERENOVATION CONDITIONS.

FIRE PROTECTION CONTRACTOR SHALL FIELD

VERIFY EXISTING CONDITIONS AND REMOVE ALL

EXISTING SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING. PROVIDE NEW

SPRINKLER HEADS AND RELATED

BRANCH/ARMOVER PIPING TO ALIGN WITH NEW

CEILING LAYOUT THROUGHOUT RENOVATED

AREAS AS REQUIRED.

SPRINKLER HEAD TYPE AND MANUFACTURER

SHALL MATCH EXISTING, COORDINATE WITH

ARCHITECT AS REQUIRED.

SPRINKLER HEAD COVERAGE SHALL BE IN

ACCORDANCE WITH NFPA 13 APPLICABLE

ADDITION AND LOCAL AUTHORITIES HAVING

JURISDICTION.

VIRGINIA TECH

VIRGINIA TECH ATHLETIC

INTERIORS

NOTES:

BB

21x

21x

21cc

6

1.

PROVIDE NEW GRILLE/DIFFUSER TO MATCH

EXISTING.

2.

PROVIDE NEW EXHAUST GRILLE IN LOCATION SHOWN.

RECONFIGURE DUCTWORK TO ACCOMODATE NEW

GRILLE LOCATION.

3.

RELOCATE EXISTING THERMOSTAT TO LOCATION

SHOWN.

4.

EXISTING FIN TUBE RADIATION TO REMAIN.

5.

PROVIDE NEW ADA COMPLIANT WATER FOUNTAIN

ADJACENT TO EXISTING WATER FOUNTAIN.

PROVIDE NEW DOMESTIC COLD WATER

CONNECTION FROM EXISTING MAIN ABOVE CEILING.

PROVIDE SHUT OFF VALVE AT BRANCH TAKE OFF

FROM MAIN.

6.

EXISTING DIFFUSER/GRILLE TO REMAIN.

6

T

3

18

CB

18

21bb

2

6

6

21aa

15

15

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

DB

21z

6

6

12

EB

12

FB

11

1

5

7

7

6

6

-

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

4

1

A2

1

1

A1

3

3

B

1

1

N

KEY PLAN

LEVEL TWO MECHANICAL PLAN MERRYMAN

7/24/2015 4:57:31 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

A

B

D

F

Project No.: 004815.00

Checked by: Checker

M0103

© Cannon Design 2015

ABBREVIATIONS

1. FOR EXACT LOCATION AND FINISH SURFACE CONDITIONS OF CEILING, WALL, FLOOR MOUNTED DEVICES,

REFER TO ARCHITECTURAL DRAWINGS.

2. FOR EXACT LOCATION OF FACILITY EXPANSION JOINTS, FIRE RATED WALLS AND SMOKE WALLS, REFER

TO ARCHITECTURAL DRAWINGS.

3. FOR EXACT LOCATIONS OF DUCT MOUNTED SMOKE DETECTORS, WATER FLOW SWITCHES AND

TAMPER SWITCHES REFER TO HVAC / FP DRAWINGS.

4. VERIFY EXACT LOCATION OF CONNECTION POINTS PRIOR TO CONNECTION.

5.

MOUNTING HEIGHTS ARE TO CENTER OF DEVICE OR EQUIPMENT, UNO.

6. PROVIDE RACEWAY, WIRE AND CABLE, ASSOCIATED FITTINGS AND CONNECTORS, AND COMPLETE

CONNECTIONS REQUIRED FOR DESIGNATED BRANCH CIRCUITS FROM DEVICE(S) TO FINAL OVERCURRENT

DEVICE AND TO LOCAL CONTROL DEVICE(S) PER SPECIFICATIONS.

7. MINIMUM BRANCH CIRCUIT WIRE SIZE SHALL BE #12 AWG EXCEPT LIFE SAFETY BRANCH CIRCUIT WIRING

WHICH SHALL BE MINIMUM #10 AWG. MAINTAIN MAXIMUM BRANCH CIRCUIT CONDUCTOR LENGTHS AS PER

SPECIFICATIONS AND SCHEDULED ON THIS DRAWING. INCLUDE GROUND CONDUCTOR DERATINGS.

8. PULL A SEPARATE NEUTRAL CONDUCTOR FROM PANELBOARD FOR EACH SET OF INCANDESCENT

LUMINARIES CONTROLLED FROM A DIMMER, EACH BRANCH CIRCUIT SERVING FLUORESCENT LUMINARIES,

EACH BRANCH CIRCUIT SERVING NEMA 5 RECEPTACLES WITHIN SIX (6) FEET OF COMPUTER DEVICE JACKS,

AND EACH BRANCH CIRCUIT PROTECTED BY A GROUND FAULT CIRCUIT INTERRUPTER. DERATE

CONDUCTORS PER NEC ACCORDINGLY.

9. PROVIDE GROUNDING PER NEC. ALSO PROVIDE GREEN GROUND WIRE IN ALL BRANCH AND FEEDER

CIRCUITS SIZED PER NEC.

10. THE SPACE ABOVE THE CEILING IS LIMITED AND THE INSTALLATION OF WORK WILL BE TIGHT. DUE TO

THIS, IT IS IMPORTANT THAT THE TRADE CONTRACTOR SHALL COORDINATE THE INSTALLATION OF THEIR

WORK (IE: DUCTWORK, TERMINAL UNITS, PIPING, ETC) WITH THE EXISTING CEILING SYSTEM HEIGHT AND

CONSTRUCTION, THE STRUCTURAL SYSTEM, THE LIGHTING FIXTURES, THE SPRINKLER HEADS/MAINS, AND

THE PLUMBING PIPES. ROUTE DUCTWORK AND PIPING AS HIGH AS POSSIBLE. LOCATE TERMINAL UNITS

BETWEEN STRUCTURAL BEAMS AND MAINTAIN PROPER SERVICE ACCESS CLEARANCES.

11.

DO NOT INSTALL ANY NEW WORK DIRECTLY ABOVE ANY ELECTRICAL PANELS AND TRANSFORMERS.

12. CIRCUIT NUMBERS SHOWN FOR EQUIPMENT WIRED TO EXISTING PANELBOARD(S) IS SHOWN FOR

DESIGN INTENT ONLY AND MAY NOT CORRESPOND TO ACTUAL CIRCUIT BREAKER MOUNTING POSITION IN

THE PANEL. UPDATE THE AS-BUILT DRAWINGS WITH THE ACTUAL CIRCUIT NUMBERS USED TO

CORRESPOND TO THE PANEL DIRECTORY.

13. CONFIRM ALL LABELS AND ROOM NUMBERS WITH OWNER PRIOR TO FINALIZING LABELING AND

PROGRAMMING.

14. COORDINATE FINAL OUTLET LOCATION WITH ALL TRADES AND FURNITURE/MILLWORK PLACEMENT

PRIOR TO ROUGH-IN.

15.

INSTALL DATA OUTLETS 6" AWAY FROM ASSOCIATED ELECTRICAL OUTLET.

DEVICE SUBSCRIPTS

II

a

7

A

B

BF

BS

C

C*

D

E

EN

EO

EQ

ER

ERL

EX

FL

GFCI

GFI

GFP

H

HA

HG

IG

K

L

LV

M

M*

NL

NLG

P

PP

Q

S

SG

SP

SW

TR

USB

W

WG

WP

WPS

Z*

ROMAN NUMERAL INDICATES QUANTITY OF GANGED DEVICES UNDER COMMON FACEPLATE

LOWER CASE LETTER(S) INDICATES MULTI SWITCH CONTROL ARRANGEMENT

NUMERAL INDICATES BRANCH CIRCUIT NUMBER

WITH AUXILIARY CONTACTS

REMOVE DEVICE AND INSTALL BLANK COVERPLATE

BLANK FACE GFCI

ITEM CONTROLLED BY BED STOP RELAY

ITEM INSTALLED FLUSH IN CEILING

CONTROL POINT IDENTIFIER (*INDICATES CONTROL NUMBER)

120 VOLT DISCONNECT SWITCH ARRANGEMENT

EXISTING BACKBOX TO REMAIN AND BE REUSED

EXISTING LOCATION NEW DEVICE

EQUIPMENT SUPPLIED BY OWNER

ITEM INSTALLED IN EQUIPMENT

EXISTING TO BE REMOVED

EXISTING TO BE RELOCATED

EXISTING DEVICE NEW LOCATION

ITEM INSTALLED FLUSH IN FLOOR

GROUND FAULT CIRCUIT INTERRUPTING RECEPTACLE

GROUND FAULT CIRCUIT INTERRUPTING BREAKER PROTECTED

FEED THROUGH GROUND FAULT CIRCUIT INTERRUPTING PROTECTED

HORIZONTALLY MOUNTED

HIGH ABUSE COVERPLATE

HOSPITAL GRADE

ISOLATED GROUND RECEPTACLE

KEY OPERATED

LOCATOR STYLE SWITCH OPERATING HANDLE

LOW VOLTAGE

MULLION MOUNTED

MONITORING POINT IDENTIFIER (*INDICATES MONITORING POINT)

NIGHT LIGHT RECEPTACLE

NIGHT LIGHT GFCI RECEPTACLE

PILOT TYPE SWITCH OPERATING HANDLE

FOR AUTO DOOR PUSH PLATE

QUAD (DOUBLE DUPLEX) DEVICE

SURFACE MOUNTED

SAFETY GROUNDING RECEPTACLE

SURGE PROTECTOR RECEPTACLE

SPLIT WIRED RECEPTACLE FOR REMOTE SWITCHING

TAMPER RESISTANT

USB PORT CHARGING RECEPTACLE

ITEM INSTALLED 3'-8" AFF OR AS DETAILED

WIRE GUARD

WEATHERPROOF

WEATHERPROOF SPRING COVER

DEVICE ZONE IDENTIFIER (* INDICATES ZONE NUMBER)

BRANCH VOLTAGE DROP

CONDUCTOR AWG

MAXIMUM CONDUCTOR LENGTH AT 120V

MAXIMUM CONDUCTOR LENGTH AT 277V

MAXIMUM CONDUCTOR LENGTH AT 208V 1 PH.

MAXIMUM CONDUCTOR LENGTH AT 480V 1 PH.

GROUND CONDUCTOR AWG

#12

#10

#8

95

225

170

390

#12

160

375

280

650

#10

245

565

425

985

#8

NOTES:

1. INCREASE BRANCH CIRCUIT CONDUCTOR AS INDICATED.

2. BASED ON 20A CIRCUIT LOADED TO 10A USING SINGLE PHASE, 2 WIRE CIRCUITS.

3. SCHEDULE REPRESENTS MINIMUM CONDUCTOR SIZE BASED ON LENGTH OF BRANCH

CIRCUIT CONDUCTOR FROM PANEL TO PHYSICAL CENTER OF LOAD TO OVERCOME

VOLTAGE DROP. 3% VOLTAGE DROP ASSUMED.

4. TRANSITION FROM LARGER CONDUCTOR SIZE TO #12 FOR FINAL TERMINATION TO

OUTLET DEVICE. PROVIDE JUNCTION BOX WITHIN 10' OF OUTLET. EXTEND #12

CONDUCTOR TO OUTLET.

GENERAL

NEW EQUIPMENT

DEVICE TO BE REMOVED (DEMO PLANS) UNDERFLOOR CONDUIT (NEW PLANS)

AMPERE

ARMOR CLAD CABLE

ARC-FAULT CIRCUIT INTERRUPTING

ABOVE FINISHED FLOOR

ABOVE FINISHED GRADE

AUTHORITY HAVING JURISDICTION

AIR HANDLING UNIT

AMPERE INTERRUPTING CAPACITY

ALUMINUM

AMMETER

ANNUNCIATOR

AMERICAN NATIONAL STANDARDS INSTITUTE

AUTOMATIC TRANSFER SWITCH

AUDIO VISUAL

AMERICAN WIRE GAUGE

BAS

BDF

BFC

BFG

BKBD

BKR

BPS

BUILDING AUTOMATION SYSTEM

BUILDING DISTRIBUTION FRAME

BELOW FINISHED CEILING

BELOW FINISHED GRADE

BACKBOARD

BREAKER

BOLTED PRESSURE SWITCH

C

CAT

CATV

CB

CCTV

CEC

CKT

CLG

CM

CO

COAX

CT

CTTS

CU

CONDUIT

CATALOG

CABLE ANTENNA TELEVISION

CIRCUIT BREAKER

CLOSED CIRCUIT TELEVISION

CHICAGO ELECTRICAL CODE

CIRCUIT

CEILING

CONSTRUCTION MANAGER

COMPANY

COAXIAL

CURRENT TRANSFORMER

CLOSE TRANSITION TRANSFER SWITCH

COPPER

DC

DHCP

DIA

DIV

DN

DO

DPDT

DPST

DS

DSP

DVD

DVR

DVS

DWG

DIRECT CURRENT

DYNAMIC HOST CONFIGURATION PROTOCOL

DIAMETER

DIVISION

DOWN

DRAWOUT

DOUBLE POLE DOUBLE THROW

DOUBLE POLE SINGLE THROW

DISCONNECT SWITCH

DIGITAL SIGNAL PROCESSOR

DIGITAL VERSATILE DISC

DIGITAL VIDEO RECORDER

DIGITAL VIDEO SURVEILLANCE

DRAWING

EA

EF

EGS

ELEC

ELEV

EMT

EO

EOL

EQUIP

EWC

EXH

EXP

EACH

EXHAUST FAN

ENGINE-GENERATOR SET

ELECTRIC

ELEVATOR

ELECTRICAL METALLIC TUBING

EQUIPMENT BY OWNER

END OF LINE DEVICE

EQUIPMENT

ELECTRIC WATER COOLER

EXHAUST

EXPLOSION PROOF

FA

FACU

FBO

FI

FLR

FLUOR

FPS

FPU

FS

FTL

FIRE ALARM

FIRE ALARM CONTROL UNIT

FURNISHED BY OWNER

FILM ILLUMINATOR

FLOOR

FLUORESCENT

FRAMES PER SECOND

FIELD PROCESSING UNIT

FUSED SWITCH

FEED THRU LUGS

GA

Gb

GE

GEN

GFCI

GFI

GFR

GFRT

GND

GAUGE

GIGABIT

GROUNDING EQUALIZER CONDUCTOR

GENERATOR

GROUND FAULT CIRCUIT INTERRUPTING

GROUND FAULT INTERRUPTING

GROUND FAULT RELAY

GROUND FAULT RELAY TEST PANEL

GROUND

HCT

HF

HFT

HARMONIC CONDITIONING TRANSFORMER

HARMONIC FILTER

HARMONIC FILTER WITH INTEGRAL

TRANSFORMER

HID

HIGH INTENSITY DISCHARGE

HOA

HAND OFF AUTO

HP

HORSEPOWER

HST

HARMONIC SUPPRESSION TRANSFORMER

HSKPG HOUSEKEEPING

HTR

HEATER

HV

HIGH VOLTAGE

HZ

HERTZ (CYCLES/SECOND)

ICC

ID

IDF

IMC

IP

IPS

iSCSI

IR

INTERMEDIATE CROSS CONNECT

INSIDE DIAMETER

INTERMEDIATE DISTRIBUTION FRAME

INTERMEDIATE METAL CONDUIT

INTERNET PROTOCOL

IMAGES PER SECOND

INTERNET SMALL COMPUTER SYSTEM

INTERFACE

INFRARED

JB

JUNCTION BOX

KO

KV

KVA

KW

KWH

KNOCK OUT

KILOVOLT

KILOVOLT AMPERE

KILOWATT

KILOWATT HOUR

LA

LAN

LCD

LED

LS

LTD

LTG

LV

LIGHTNING ARRESTOR

LOCAL AREA NETWORK

LIQUID CRYSTAL DISPLAY

LIGHT EMITTING DIODE

LIFE SAFETY

LONG TIME DELAY

LIGHTING

LOW VOLTAGE

MAG

MAN

MAX

MATV

Mb

MC

MAGNETIC

MANUAL

MAXIMUM

MASTER ANTENNA TELEVISION

MEGABIT

METAL CLAD CABLE

MCA

MCB

MCC

MCS

MCP

MDF

MDP

MECH

MER

MFGR

MFS

MGP

MH

MI

MIC

MIN

MLO

MM

MOCP

MTD

MTS

MV

MINIMUM CIRCUIT AMPERES

MAIN CIRCUIT BREAKER

MOTOR CONTROL CENTER

MOLDED CASE SWITCH

MOTOR CIRCUIT PROTECTOR

MAIN DISTRIBUTION FRAME

MAIN DISTRIBUTION PANELBOARD

MECHANICAL

MAIN EQUIPMENT ROOM

MANUFACTURER

MAIN FUSED SWITCH

MEDICAL GAS PANEL

MANHOLE

MINERAL INSULATED CABLE

MICROPHONE

MINIMUM

MAIN LUGS ONLY

MULTIMODE

MAXIMUM OVERCURRENT PROTECTION

MOUNTED

MANUAL TRANSFER SWITCH

MEDIUM VOLTAGE

N

NA

NC

NEC

NEMA

NFPA

NIC

NO

NOC

NTS

NEUTRAL

NOT APPLICABLE

NORMALLY CLOSED

NATIONAL ELECTRICAL CODE

NATIONAL ELECTRICAL MANUFACTURERS

ASSOCIATION

NATIONAL FIRE PROTECTION ASSOCIATION

NOT IN CONTRACT

NORMALLY OPEN

NETWORK OPERATIONS CENTER

NOT TO SCALE

OA

OC

OCPD

OD

OH

OUTSIDE AIR

ON CENTER

OVERCURRENT PROTECTIVE DEVICE

OUTSIDE DIAMETER

OVERHEAD

P

PA

PB

PC

PCU

P/E

PH

PNL

PLC

PoE

PRI

PSU

PT

PTZ

PVC

PWR

POLE

PUBLIC ANNOUNCEMENT

PULLBOX/PUSHBUTTON

PERSONAL COMPUTER

PACKAGED CONTROL UNIT

PNEUMATIC- ELECTRIC

PHASE

PANELBOARD

PROGRAMMABLE LOGIC CONTROLLER

POWER OVER ETHERNET

PRIMARY

PATIENT SERVING UNIT

POTENTIAL TRANSFORMER

PAN TILT ZOOM

POLYVINYL CHLORIDE

POWER

RAID

RCP

RCPT

RE

REF

RF

RF

RFID

RGS

RM

RTLS

RUPS

REDUNDANT ARRAY OF INDEPENDENT DISKS

REFLECTED CEILING PLANS

RECEPTACLE

REFER TO

REFRIGERATOR

RADIO FREQUENCY

RETURN FAN

RADIO FREQUENCY IDENTIFICATION DEVICE

RIGID GALVANIZED STEEL

ROOM

REAL TIME LOCATION SYSTEM

ROTARY HYBRID UNINTERRUPTIBLE POWER

SUPPLY

SCHED SCHEDULE

SEC

SECONDARY

SF

SUPPLY FAN

SFL

SUB FEED LUGS

SFP

SURGICAL FACILITY PANEL

SH

SHEET

SM

SINGLE MODE

SP

SINGLE POLE

SPDT SINGLE POLE DOUBLE THROW

SPST SINGLE POLE SINGLE THROW

SPC

SPACE

SPEC SPECIFICATION

SPKR SPEAKER

SPR

SPARE

SS

STAINLESS STEEL

ST

SHUNT TRIP

STD

SHORT TIME DELAY

STP

SHIELDED TWISTED PAIR

STR

STARTER

SWBD SWITCHBOARD

SWGR SWITCHGEAR

SYM

SYMMETRICAL

TB

TBB

TC

TERM

TEL

TGB

TERRA BYTES

TELECOMMUNICATIONS BONDING BACKBONE

TERMINAL CABINET

TERMINAL

TELEPHONE

TELECOMMUNICATIONS GROUNDING

BUS BAR

THD

TOTAL HARMONIC DISTORTION

TMGB TELECOMMUNICATIONS MAIN GROUNDING

BUS BAR

TR

TELECOM ROOM

TRANS TRANSITION

TSER TELECOMMUNICATIONS SERVICE ENTRANCE

ROOM

TTC

TELEPHONE TERMINAL CABINET

TV

TELEVISION

TVSS TRANSIENT VOLTAGE SURGE SUPPRESSION

TYP

TYPICAL

UC

UG

UNO

UPS

USS

UTP

UNDER COUNTER

UNDERGROUND

UNLESS NOTED OTHERWISE

UNINTERRUPTIBLE POWER SUPPLY

UNIT SUBSTATION

UNSHIELDED TWISTED PAIR

V

VAV

VM

VolP

VPI

VSD

VOLT

VARIABLE AIR VOLUME

VOLTMETER

VOICE OVER INTERNET PROTOCOL

VACUUM-PRESSURE IMPREGNATED

VARIABLE SPEED DRIVE

W

WAN

WAP

WLAN

WP

WATT

WIDE AREA NETWORK

WIRELESS ACCESS POINT

WIRELESS LOCAL AREA NETWORK

WEATHERPROOF

XFMR

TRANSFORMER

DRAWING KEYED NOTES

CCR*

CEILING CONCEALED, REGRESSED BACKBOX

X

CABLE ROUTING NOTES

FEW*

FLOOR BOX, EXPOSED, WITH PROVISIONS FOR WHIP

300/4

EXISTING EQUIPMENT DESIGNATION

FEF*

FLOOR BOX, EXPOSED, FLUSH

XXX

LAB EQUIPMENT TAG

FET*

FLOOR BOX, EXPOSED, WITH TOMBSTONE DEVICE

NEW EQUIPMENT DESIGNATION

FCR*

FLOOR BOX, CONCEALED, WITH REGRESSED DEVICES

EQUIPMENT DESIGNATION NUMBER

PEW*

POKE-THRU ASSEMBLY, EXPOSED, WITH PROVISIONS FOR WHIP

FEEDER IDENTIFICATION

PEF*

POKE-THRU ASSEMBLY, EXPOSED, FLUSH

SYMBOL WITH DASHED OUTLINE INDICATES INSTALLATION AT CEILING

PET*

POKE-THRU ASSEMBLY, EXPOSED, WITH TOMBSTONE DEVICE

SYMBOL WITH TAIL INDICATES WALL INSTALLATION, HEIGHT AS INDICATED

PCR*

POKE-THRU ASSEMBLY, CONCEALED, WITH REGRESSED DEVICES

RCR*

RAISED FLOOR BOX, CONCEALED, WITH REGRESSED DEVICES

REW*

RAISED FLOOR BOX, EXPOSED, WITH PROVISIONS FOR WHIP

SCR*

STAGE BOX, CONCEALED, WITH REGRESSED DEVICES

TEF*

TABLE BOX, EXPOSED, FLUSH

TET*

TABLE BOX, EXPOSED, WITH TOMBSTONE DEVICE

TCR*

TABLE BOX, CONCEALED, WITH REGRESSED DEVICES

UEF*

UNDER FLOOR DUCT, EXPOSED, FLUSH

UET*

UNDER FLOOR DUCT, EXPOSED, WITH TOMBSTONE DEVICE

NUMBERS INDICATES SOURCE PANELBOARD AND CIRCUIT(S)

WEW*

WALL BOX, EXPOSED, WITH PROVISIONS FOR WHIP

SPLICE

WCR*

WALL BOX, CONCEALED, WITH REGRESSED DEVICES

X

(E) XXX

WIRE AND CABLE

NEUTRAL WIRE SHOWN AS A LONG LINE, PHASE WIRE SHOWN AS SHORT LINES, AND

GROUND WIRE SHOWN AS LONG LINE WITH DOT

THREE CIRCUIT HOME RUN IN CONDUIT TO ASSOCIATED PANELBOARD. NUMBERS INDICATE

CIRCUIT NUMBERS. ARROWS INDICATE QUANTITY OF 20A-1P CIRCUITS. SLASH MARKS

INDICATE QUANTITY OF WIRE

5

3

1

1LNL1

MULTI-CIRCUIT HOME RUN IN CONDUIT TO ASSOCIATED PANELBOARD. SLASH MARKS

#10 INDICATE QUANTITY OF WIRES. PHASE WIRE SIZE SHOWN FOLLOWING THE # SYMBOL IF

APPLICABLE

30A-2P

1LNL1

1LNL1-12

DETAIL AND/OR SECTION REFERENCE

BRANCH CIRCUIT BOUNDARY

VIRGINIA TECH

NOTE: SPEC REFERENCES ARE GENERAL AND MAY NOT BE SPECIFIC

ACCESS

C - CONCEALED

E - EXPOSED

SERVICE COVER/DEVICE FITTING

B - BLANK

F - FLUSH

R - REGRESSED

S - SEMI FLUSH

T - TOMBSTONE

W - WHIP

LOCATION

F - FLOOR

P - POKE-THRU

R - RAISED FLOOR

S - STAGE

T - TABLE

U - UNDER FLOOR DUCT

W - WALL

SEQUENTIAL NUMBER

LIGHTING BRANCH CIRCUITS

XXX

#

a

XXX

#

a

LUMINAIRE TAG - CORRESPONDS TO LUMINAIRE SCHEDULE

CIRCUIT NUMBER (AND PANELBOARD IF SPECIFICALLY DESIGNATED)

LOWER CASE LETTER(S) INDICATE MULTI-SWITCH CONTROL ARRANGEMENT.

POWER BRANCH CIRCUITS

#

#

CIRCUIT NUMBER (AND PANELBOARD IF SPECIFICALLY DESIGNATED)

WIRING TERMINATIONS

X

#

VIRGINIA TECH ATHLETIC

INTERIORS

IDENTIFICATION CHART

DIVISION 26: LEGEND

1

X

#

1

DIRECT CONNECTION OR MATCHING RECEPTACLE FOR 120V EQUIPMENT

E

DIRECT CONNECTION OR RECEPTACLE FOR 120V CRITICAL EQUIPMENT (NEC 517)

E

DIRECT CONNECTION OR RECEPTACLE FOR 120V EMERGENCY EQUIPMENT (NEC 700)

DMS

DIMMING MASTER STATION, 3'-8" AFF

2

DIRECT CONNECTION OR MATCHING RECEPTACLE FOR 208V EQUIPMENT

RCS

REMOTE CONTROL STATION, 3'-8" AFF

5

DIRECT CONNECTION OR MATCHING RECEPTACLE FOR 277V EQUIPMENT

EQUIPMENT IDENTIFICATION TAG.

CIRCUIT NUMBER (AND PANELBOARD IF SPECIFICALLY DESIGNATED)

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

____

REFER TO MULTI-SERVICE BOX SCHEDULE FOR ADDITIONAL INFORMATION REGARDING THE

FOLLOWING BOXES.

26 0936 WALLBOX DIMMING SYSTEMS

26 2416 PANELBOARDS

26 053* RACEWAY AND PATHWAY

NORMAL BRANCH PANELBOARD

CONDUIT TURNED UP

(LIFE SAFETY / NEC 517) - (EMERGENCY/ NEC 700) BRANCH PANELBOARD

CONDUIT TURNED DOWN

26 2726 WIRING DEVICES

CAPPED CONDUIT

INDICATES MULTIPLE DEVICES INSTALLED UNDER COMMON COVERPLATE AT ONE LOCATION

CONDUIT STUBBED AND BUSHED INTO ACCESSIBLE CEILING CAVITY

SINGLE POLE SWITCH, 3'-8" AFF

26 0535 BOXES AND CABINETS

2

2-POLE SWITCH, 3'-8" AFF

TELECOMMUNICATIONS OUTLET WITH BACKBOX AND CONDUIT, 1'-6" AFF

3

3-WAY SWITCH, 3'-8"

TELECOMMUNICATIONS OUTLET WITH BACKBOX AND CONDUIT, 3'-8" AFF OR 6" ABOVE COUNTER

4

4-WAY SWITCH, 3'-8"

TELECOMMUNICATIONS OUTLET WITH BACKBOX AND CONDUIT, 5'-0" AFF

M

MOMENTARY CONTACT SWITCH, 3'-8" AFF

TELECOMMUNICATIONS OUTLET WITH BACKBOX AND CONDUIT, 8'-0" AFF OR 1'-0" BELOW CEILING

(WHICHEVER IS LOWER)

TELECOMMUNICATIONS OUTLET, INSTALLED IN FLOORBOX / DEVICE, WITH CONDUIT ROUGH-IN IN

SLAB TO ACCESSIBLE CEILING.

F

TELECOMMUNICATIONS OUTLET, INSTALLED IN FURNITURE RACEWAY, WITH CABLE EXTENDED

THROUGH ACTIVATION DEVICE.

B

DEVICE BOX WITH BLANK COVER PLATE, HEIGHT AS INDICATED ON DWG

J

JUNCTION BOX

PB

D

WALLBOX DIMMER (NOT FLUORESCENT) D=600W, D1=1000W, D2=1500W, 3'-8" AFF

F

WALLBOX DIMMER - FLUORESCENT, (3 OR 4 = MULTI LOCATION), 3'-8" AFF

S

SWITCH TO MATCH DIMMER DESIGN FOR GANGED INSTALLATION UNDER COMMON COVERPLATE

L

WALL BOX DIMMER - LED, (3 OR 4 = MULTI LOCATION), 3'-8" AFF

NEMA 5-20R SIMPLEX RECEPTACLE, 1'-6" AFF

NEMA 5-20R RED SIMPLEX RECEPTACLE, 1'-6" AFF

NEMA 5-20R DUPLEX RECEPTACLE, 1'-6" AFF

PULL BOX

NEMA 5-20R RED DUPLEX RECEPTACLE, 1'-6" AFF

CABINET, TOP OF TRIM 6'-2" AFF

X#

TWO (2) NEMA 5-20R DUPLEX RECEPTACLES INSTALLED UNDER COMMON COVERPLATE, 1'-6" AFF

TELECOMMUNICATIONS OUTLET WITH BACKBOX, AND INDICATED DEVICES. PROVIDE CONDUIT STUB

THROUGH FLOOR INTO MILLWORK/ FURNITURE TO MOUNT BOX.

TWO (2) NEMA 5-20R RED DUPLEX RECEPTACLES INSTALLED UNDER COMMON COVERPLATE, 1'-6" AFF

26 0575 CONDUIT ROUGH-IN SYSTEMS

PP

POWER ASSIST PUSH PLATE BACKBOX- MOUNTED 3'-8" AFF

PP1

POWER ASSIST PUSH PLATE BACKBOX- MULLION MOUNTED 3'-8" AFF

26 5100 INTERIOR LIGHTING

INDICATES PENDANT HUNG STYLE LUMINAIRE

TS

WALL BOX STYLE ELECTRONIC TIME SWITCH, 3'-8" AFF

DOWNLIGHT, ROUND OR SQUARE, RECESSED OR SURFACE (INC, CFL, LED, HID)

#

AUTOMATIC SENSING CONTROL DEVICE- REFER TO TABLE BELOW FOR DESCRIPTION

WALL WASH STYLE LUMINAIRE, ARROW INDICATES AIMING DIRECTION

INDICATES WALL MOUNT STYLE, 7'-6" AFF, UNO

LIGHTING TRACK WITH TRACK MOUNTED LUMINARIES

WALL BOX STYLE, LINE VOLTAGE, 3'-8" AFF

2 POLE, WALL BOX STYLE, LINE VOLTAGE, 3'-8" AFF

WALL/CEILING MOUNT, LOW VOLTAGE, WIDE VIEW

CEILING MOUNT, LOW VOLTAGE, WIDE VIEW

WALL/CEILING MOUNT, LOW VOLTAGE, NARROW, LONG RANGE VIEW

WALL MOUNT, EXTERIOR MOTION SENSING

CEILING MOUNT, LOW VOLTAGE, ULTRASONIC, WIDE VIEW

CEILING MOUNT, LOW VOLTAGE, ULTRASONIC, NARROW, LONG RANGE VIEW

CEILING MOUNT, HIGH BAY, LOW VOLTAGE

WALL BOX STYLE, PIR COMBINATION OCCUPANCY SENSOR/DIMMER

WALL BOX STYLE, LOW VOLTAGE, 3'-8" AFF

DS

DAYLIGHT SENSING (ON/OFF), CONTROL DEVICE, CEILING MOUNTED

DH

DAYLIGHT SENSOR FOR DAYLIGHT HARVESTING INTERFACE, CEILING MOUNTED

PC

LINE VOLTAGE, PHOTOELECTRIC CONTROL, 1'-0" ABOVE ROOF, AIMED NORTH

TC

TIME SWITCH, 5'-0" AFF

NC

NURSE CALL LIGHTING INTERFACE DEVICE

24 JUL 2015

Description

Date

(T) INDICATES WALL MOUNT STYLE LUMINAIRE

WALL BOX STYLE ELECTRONIC INTERVAL TIMER, 3'-8" AFF

=

=

=

=

=

=

=

=

=

=

=

SCHEMATIC DESIGN

GEOMETRIC SHAPE LUMINAIRE, RECESSED OR SURFACE

T

# = P

2P

P1

P2

P3

P4

P5

P6

P7

P8

P9

No.

FLUORESCENT STRIP LUMINAIRE

26 0923 AUTOMATIC LIGHTING CONTROL EQUIPMENT

A2

SELF CONTAINED BATTERY LIGHTING UNIT

A1

REMOTE LIGHTING LAMP HEAD(S)

BATT

LOW VOLTAGE CONTROL UNIT, RACK MOUNTED

LUMINAIRE CONNECTED TO LIFE SAFETY / NEC 517 EMERGENCY / NEC 700 BRANCH

B

LUMINAIRE CONNECTED TO CRITICAL / NEC 517 STANDBY / NEC 701 BRANCH

LUMINAIRE CONNECTED TO CRITICAL / NORMAL BRANCH

LUMINAIRE CONNECTED TO OPTIONAL / NEC 702 BRANCH

ELBD#

EMERGENCY LIGHTING BYPASS DEVICE - # INDICATES TYPE (TYPE 2 OR TYPE 3)

N

KEY PLAN

ILLUMINATED "EXIT" SIGNAGE

SINGLE LINE - SINGLE FACE(DIRECTION OF ARROWS AS INDICATED)

DOUBLE LINE - DOUBLE FACE(DIRECTION OF ARROWS AS INDICATED)

Drawing Title:

26 5600 EXTERIOR LIGHTING

26 0933 LOCAL DIMMING SYSTEMS

WIRE AND/OR CONDUIT RUN CONTINUED ON REFERENCED DETAIL

MATCH LINE REFERENCING CONTINUATION ON OTHER DRAWINGS

26 0578 MULTI-SERVICE BOXES AND RACEWAYS

X

FUTURE WORK

7/24/2015 4:28:09 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

EXISTING WORK

A

AC

AFCI

AFF

AFG

AHJ

AHU

AIC

AL

AM

ANN

ANSI

ATS

AV

AWG

DRAWING NOTES AND DESIGNATIONS

X

'E' SERIES GENERAL NOTES

LUMINAIRE(S) AND POLE ASSEMBLY

PDC

PROGRAMMABLE DIMMING CONTROL STATION, 3'-8" AFF

BUILDING MOUNTED LUMINAIRE

PSC

PARTITIONED SPACE CONTROL STATION, 3'-8" AFF

BOLLARD STYLE LUMINAIRE

SDC

SCENE DIMMING CONTROL STATION, 3'-8" AFF

SURFACE AT GRADE OR FLUSH TO GRADE LUMINAIRE

DEC*

DIMMING EQUIPMENT CABINET, TOP OF BACKBOX 6'-2" AFF

LPC

LIGHTING PERSONAL COMPUTER, DESK TOP UNIT WITH WALL BOX RECEPTACLES AND CONNECTORS

INSTALLED 1'-6" AFF

#

SPEAKER STROBE, MIN 6'-8"/ MAX 8'-0" AFF (# INDICATES CANDELA)

FBC

FULL BRIGHTNESS CONTROL (PANIC) STATION, 3'-8" AFF

F

MANUAL PULL STATION, 3'-8" AFF

FS

FLUSH CEILING MOUNTED SPEAKERS

S

SMOKE DETECTOR, SURFACE CEILING MOUNTED

28 3100 FIRE ALARM SYSTEMS

DR

NOTES, LEGENDS,

SYMBOLS AND

ABBREVIATIONS

Project No.: 004815.00

Checked by: Checker

E0001

ELECTRO-MAGNETIC DOOR HOLDER

© Cannon Design 2015

KEYED NOTES

:

1.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT CONTINUITY TO

THIS AREA NOT AFFECTED BY RENOVATION.

22

23

24

Kx

22

21

Jx

Jx

VIRGINIA TECH

21

VIRGINIA TECH ATHLETIC

INTERIORS

P3

BRANCH CIRCUIT NOTES

Fx

Fx

LT1

LT1

:

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN

THIS AREA, UNLESS OTHERWISE NOTED:

120 / 208V PANELBOARDS

PG2 - NORMAL POWER

E1 - LIFE SAFETY POWER (NEC 517)

LT1

LT1

Kx

LT1

LT1

LT1

Ex

Ex

LT1

LT1

LT1

LT1

Jx

LT1

LT1

LT1

LT1

1

P2

LT1

PG2

LT1

LT1

TC

TC

Cx

Cx

TC

LT1

LT1

24

CORRIDOR

A56

LT1

Fx

LT1

LR1

P3

P3

LR1

23

-

SCHEMATIC DESIGN

No.

LR1

24 JUL 2015

Description

Date

Ex

LR1

22

CORRIDOR

A50

LR1

21gg

A1

21ff

LR1

21ee

21

LR1

LD1

Cx

LD1

LD1

LD1

LD1

21dd

LD1

N

LR1

KEY PLAN

21ee

AB

LR1

Drawing Title:

P2

21dd

BB

LR1

7/24/2015 4:28:10 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

VESTIBULE

A49

1

LEVEL 01 LIGHTING PLAN - AREA A1

1/8" = 1'-0"

LEVEL 01 LIGHTING PLAN

- JAMERSON

Project No.: 004815.00

Checked by: Checker

1

E0101

© Cannon Design 2015

KEYED NOTES

24

23

:

1.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT CONTINUITY

TO THIS AREA NOT AFFECTED BY RENOVATION.

Kx

Kx

LT1

23

22

2.

ADDITIONAL LUMINAIRES STACKED VERTICALLY THIS AREA. SEE ARCHITECTURAL ELEVATION

SHEET A0603 FOR MORE INFORMATION.

LT1

CORRIDOR

B51

LT1

LT1

LT1

22

21

VIRGINIA TECH

LT1

LT1

LT1

P2

LT1

Jx

LT1

LT1

VIRGINIA TECH ATHLETIC

INTERIORS

Jx

LR1

LT1

BRANCH CIRCUIT NOTES

LT1

21

LR1

:

P2

CORRIDOR

B51

CORRIDOR

B52

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

LT1

LT1

120 / 208V PANELBOARDS

L2 - NORMAL POWER

E1 - LIFE SAFETY POWER (NEC 517)

LR1

LT1

LT1

2

Fx

Fx

LR1

LL1

P3

P3

LT1

2

LL1

LT1

LR1

LT1

Kx

2

LT1

LL1

LR1

LL1

LT1

2

LT1

LL1

LR1

2

Ex

Ex

LT1

LL1

LT1

LR1

P3

2

LT1

P3

LL1

LT1

LR1

2

Jx

LL1

LT1

LT1

LR1

2

P3

LT1

LR1

LT1

LL1

Cx

P2

L2

LT1

LR1

Cx

LT1

TC

2

LL1

P2

TC

TC

2

Fx

LT1

LR1

LL1

LT1

LL1

LR1

2

24

P2

LR1

CORRIDOR

B52

LL1

LR1

-

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

LL1

2

P3

LL1

LR1

23

P2

LR1

A2

Ex

LR1

22

CORRIDOR

P2

B57

LR1

21gg

N

21ff

KEY PLAN

21ee

21

Cx

21ee

AB

7/24/2015 4:28:11 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

LEVEL 02 LIGHTING PLAN

- JAMERSON

Project No.: 004815.00

1

LEVEL 02 LIGHTING PLAN - AREA A2

1/8" = 1'-0"

1

Checked by: Checker

E0102

© Cannon Design 2015

KEYED NOTES

:

1.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT

CONTINUITY TO THIS AREA NOT AFFECTED BY RENOVATION.

2.

ADDITIONAL OVERHEAD LIGHTING SHOWN ON SHEET E0104.

3.

COORDINATE LOCATION OF REMOTE RIVERS IN ACCESSIBLE LOCATION.

4.

PROVIDE PRESET WALL STATION (LUTRON GRAFIK EYE 4000 OR EQUAL) COORDINATE

THE LOCATION WITH ARCHITECT.

P2

21gg

VIRGINIA TECH

21ff

21ee

LR1

LS1

LR1

A

21dd

B

D

VIRGINIA TECH ATHLETIC

INTERIORS

F

P2

BRANCH CIRCUIT NOTES

LR1

21ee

AB

:

LS1

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

LR1

21dd

BB

21x

21x

21cc

21x

EX

CORRIDOR

B31

120 / 208V PANELBOARDS

LA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

277 / 480V PANELBOARDS

HA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

EM - LIFE SAFETY POWER (NEC 517) (LOCATED IN MECH MEZZANINE A40)

LR1

LS1

1

18

LR1

21cc

CB

CONF. ROOM

228

18

18

21bb

3

LR3

LR1

LS1

21aa 15

15

LR1

15

LW2

3

21bb

DB

LS1

21z

LR1

12

21aa

EB

LS1 CORRIDOR

LR1

B30

LR3

OFFICE

226

LS2

EX

12

LR1

12

3

LS2

LR1

LR3

EXHIBIT HALL

2

222

21z

FB

LR1

LS1

P3

11

LS1

LR2

4

LS1

PD

C

7

7

7

3

LR3

-

6

6

6

3

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

LR3

ENTRY HALL

B28

2

4

LR2

LR2

LR2

VESTIBULE

B26

B

3

3

3

N

KEY PLAN

A

7/24/2015 4:44:14 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

B

D

F

LEVEL 02 LIGHTING PLAN

- MERRYMAN

Project No.: 004815.00

1

LEVEL 02 LIGHTING PLAN - AREA B

1/8" = 1'-0"

Checked by: Checker

E0103

© Cannon Design 2015

KEYED NOTES

:

1.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT CONTINUITY

TO THIS AREA NOT AFFECTED BY RENOVATION.

21gg

21ff

21ee

A

21dd

B

VIRGINIA TECH

D

VIRGINIA TECH ATHLETIC

INTERIORS

21ee

AB

21x

21cc

21dd

BB

21x

BRANCH CIRCUIT NOTES

:

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

LW1

LW1

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

LW1

120 / 208V PANELBOARDS

LA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

LW1

18

21cc

CB

18

21bb

277 / 480V PANELBOARDS

HA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

EM - LIFE SAFETY POWER (NEC 517) (LOCATED IN MECH MEZZANINE A40)

LS2

LW1

LW1

LW1

LW1

21aa 15

15

21bb

DB

LS2

LW1

LW1

21z

LW1

LW1

12

21aa

EB

12

LS2

LW1

LW1

21z

FB

LW1

LW1

LS2

LS2

LS2

LS2

LW1

LW1

7

7

LS2

LS2

LW1

LW1

6

6

LS2

LS2

LW1

-

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

LW1

LS2

LW1

LS2

LW1

3

3

B

1

1

N

KEY PLAN

A

7/24/2015 4:28:13 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

1

LEVEL 03 LIGHTING PLAN - AREA B

1/8" = 1'-0"

B

LEVEL 03 LIGHTING PLAN

- MERRYMAN

D

1

Project No.: 004815.00

Checked by: Checker

E0104

© Cannon Design 2015

KEYED NOTES

:

1.

INSTALL DEVICES INDICATED AT CASEWORK/MILLWORK AS PER ARCHITECTURAL

DETAILS.

2.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT

CONTINUITY TO THIS AREA NOT AFFECTED BY RENOVATION.

22

23

Kx

24

3.

AUTO DOOR - FURNISH AND INSTALL ALL CONDUITS, WIRING, OUTLET OR JUNCTION

BOXES, AND ANY OTHER AUXILIARY ELECTRICAL COMPONENTS NECESSARY FOR PROPER

DOOR OPERATION.

4.

PROVIDE EQUIPOTENIAL GROUNDING THIS AREA AS PER DETAILS FOR

CORRESPONDING SPACE DESCRIPTION.

5.

PROVIDE THREATMENT/DIAGNOSTIC EQUIPMENT RACEWAY ROUGHIN THIS ROOM

PER MANUFACTURER'S RECOMMENDATIONS.

22

21

Jx

6.

REFER TO LIGHTING DRAWING THIS AREA FOR SPLIT WIRED RECEPTACLE(S) SWITCH

LOCATION.

Jx

7.

FURNISH AND INSTALL ALL POWER AND SYSTEMS EQUIPMENT IN INDICATED ROOM

(S) TYPICAL TO REFERENCED LAYOUT(S) WITH NOTED MODIFICATIONS, IF ANY. CONNECT TO

INDICATED BRANCH CIRCUITS.

BRANCH CIRCUIT NOTES

21

VIRGINIA TECH

VIRGINIA TECH ATHLETIC

INTERIORS

:

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

120 / 208V PANELBOARDS

PG2 - NORMAL POWER

Fx

Fx

Kx

Ex

Ex

Jx

PG2

Cx

24

Fx

CORRIDOR

A56

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

23

A2

Ex

22

CORRIDOR

A50

A1

21gg

B

21ff

21ee

21

N

KEY PLAN

VESTIBULE

A49

1

W W

21dd

1

Drawing Title:

21ee

AB

LEVEL 01 POWER AND

SYSTEMS PLAN

21dd

BB

7/24/2015 4:28:13 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Cx

Project No.: 004815.00

1

LEVEL 01 POWER AND SYSTEMS PLAN - AREA A1 1

1/8" = 1'-0"

Checked by: Checker

E0201

© Cannon Design 2015

KEYED NOTES

24

23

1.

INSTALL DEVICES INDICATED AT CASEWORK/MILLWORK AS PER ARCHITECTURAL

DETAILS.

2.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT

CONTINUITY TO THIS AREA NOT AFFECTED BY RENOVATION.

Kx

Kx

3.

AUTO DOOR - FURNISH AND INSTALL ALL CONDUITS, WIRING, OUTLET OR JUNCTION

BOXES, AND ANY OTHER AUXILIARY ELECTRICAL COMPONENTS NECESSARY FOR PROPER

DOOR OPERATION.

23

22

:

4.

PROVIDE EQUIPOTENIAL GROUNDING THIS AREA AS PER DETAILS FOR

CORRESPONDING SPACE DESCRIPTION.

5.

PROVIDE THREATMENT/DIAGNOSTIC EQUIPMENT RACEWAY ROUGHIN THIS ROOM

PER MANUFACTURER'S RECOMMENDATIONS.

6.

REFER TO LIGHTING DRAWING THIS AREA FOR SPLIT WIRED RECEPTACLE(S) SWITCH

LOCATION.

VIRGINIA TECH

7.

FURNISH AND INSTALL ALL POWER AND SYSTEMS EQUIPMENT IN INDICATED ROOM

(S) TYPICAL TO REFERENCED LAYOUT(S) WITH NOTED MODIFICATIONS, IF ANY. CONNECT TO

INDICATED BRANCH CIRCUITS.

22

Jx

21

Jx

BRANCH CIRCUIT NOTES

:

VIRGINIA TECH ATHLETIC

INTERIORS

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

21

120 / 208V PANELBOARDS

L1 - NORMAL POWER

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

Fx

Fx

Kx

Ex

Ex

Jx

24

DR

L2

W

W

Cx

Fx

1

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

23

A2

Ex

A1

22

B

21gg

N

21ff

21

KEY PLAN

21ee

Cx

21ee

AB

7/24/2015 4:28:14 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

LEVEL 02 POWER AND

SYSTEMS PLAN

Project No.: 004815.00

1

LEVEL 02 POWER AND SYSTEMS PLAN - AREA A2

1/8" = 1'-0"

1

Checked by: Checker

E0202

© Cannon Design 2015

KEYED NOTES

1.

INSTALL DEVICES INDICATED AT CASEWORK/MILLWORK AS PER ARCHITECTURAL

DETAILS.

75

EX

CORRIDOR

B57

:

DR

2.

EXISTING TO REMAIN THIS AREA UNLESS OTHERWISE NOTED. MAINTAIN CIRCUIT

CONTINUITY TO THIS AREA NOT AFFECTED BY RENOVATION.

DR

3.

AUTO DOOR - FURNISH AND INSTALL ALL CONDUITS, WIRING, OUTLET OR JUNCTION

BOXES, AND ANY OTHER AUXILIARY ELECTRICAL COMPONENTS NECESSARY FOR PROPER

DOOR OPERATION.

F

21ee

4.

PROVIDE EQUIPOTENIAL GROUNDING THIS AREA AS PER DETAILS FOR

CORRESPONDING SPACE DESCRIPTION.

A

21dd

B

D

6.

REFER TO LIGHTING DRAWING THIS AREA FOR SPLIT WIRED RECEPTACLE(S) SWITCH

LOCATION.

7.

FURNISH AND INSTALL ALL POWER AND SYSTEMS EQUIPMENT IN INDICATED ROOM

(S) TYPICAL TO REFERENCED LAYOUT(S) WITH NOTED MODIFICATIONS, IF ANY. CONNECT TO

INDICATED BRANCH CIRCUITS.

1

AB

BB

21x

21cc

CORRIDOR

B31

VIRGINIA TECH

5.

PROVIDE THREATMENT/DIAGNOSTIC EQUIPMENT RACEWAY ROUGHIN THIS ROOM

PER MANUFACTURER'S RECOMMENDATIONS.

21x

BRANCH CIRCUIT NOTES

VIRGINIA TECH ATHLETIC

INTERIORS

:

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

1.

EXTEND BRANCH CIRCUITS IN THIS AREA TO THE EXISTING BRANCH CIRCUITS IN THIS

AREA, UNLESS OTHERWISE NOTED:

120 / 208V PANELBOARDS

LA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

75

EX

18

CB

EX

CONF. ROOM

228

21bb

18

277 / 480V PANELBOARDS

HA - NORMAL POWER (LOCATED IN MECH MEZZANINE A40)

EM - LIFE SAFETY POWER (NEC 517) (LOCATED IN MECH MEZZANINE A40)

1

1

1

1

DN

EX

1

DR

21aa 15

15

DB

DR

CLOSET

226A

21z

12

EB

12

F

1

F

CORRIDOR

B30

1

1

OFFICE

226

EXHIBIT HALL

222

FB

1

75

EX

1

75

EX

EX

7

7

1

1

6

6

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

ENTRY HALL

B28

1

75

EX

A2

VESTIBULE

B26

EX

EX

A1

F

3

3

B

1

1

1

N

KEY PLAN

EXTERIOR SIGNAGE

A

7/24/2015 4:28:14 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

1

LEVEL 02 POWER AND SYSTEMS PLAN - AREA B

1/8" = 1'-0"

B

D

LEVEL 02 POWER AND

SYSTEMS PLAN

1

Project No.: 004815.00

Checked by: Checker

E0203

© Cannon Design 2015

LUMINAIRE SCHEDULE

TAG

LD1

DESCRIPTION

INSTALLATION

DEPTH

METHOD

3" ROUND ADUSTIBLE

DOWNLIGHT

RECESSED

DW

5-1/2

LIGHT SOURCE

BALLAST/DRIVER

SPEC

VOLT

INPUT

WATTS

MIN. EFF.

660LM

0-10V

120V

17

38LM/W

LED

DIMMING

SPEC

QTY

SHIELDING/OPTICS

FEATURES/OPTIONS

NARROW FLOOD OPTICS, SEMI DIFFUSE

REFLECTOR

LOCKABLE 40 DEGREE MAXIMUM TILT

REFERENCED PRODUCTS

AMERLUX - E2.9RA-G2-HP-17-LED-120-NF-GB-3500-0-10V/E2.9RA-G2-HP-SDC

NOTES

VIRGINIA TECH ATHLETIC

INTERIORS

3500K

85+ CRI

LL1

LINEAR LED

SURFACE

230LM/FT

REMOTE

LED

0-10V

3500K

DIMMING

120V

2.8W/FT

FROSTED LENS

EXTRUDED ALUMINUM 45 DEGREE

MOUNTING CHANNEL, ALUMINUM

FINISH. PROVIDE MOUNTING CLIPS,

JUMPER CABLES AND DRIVERS AS

REQUIRED

90+ CRI

LR1

4" LINEAR LED

RECESSED

DW

4-3/4"

400 LM/FT

0-10v

LED

DIMMING

RECESSED

DW

3'5/8"

400 LM/FT

0-10v

LED

DIMMING

122LM/W

SPOTLESS ACRYLIC REGRESSED LENS

EXTRUDED ALUMINUM HOUSING,

CONTINUOUS LENGTHS PER PLANS, LED

BOARD CONFIGURATION PROVIDE EVEN

LENS ILLUMINATION FOR HOUSINGS IN

1" INCRIMENTS.

AXIS - BBRLED-B3-MF-400-35-SO-RG-S#-W-UNIV-D-1-DF

1,2,4

UNIV

3.6W/FT

111LM/W

SPOTLESS ACRYLIC FLUSH LENS

EXTRUDED ALUMINUM HOUSING,

CONTINUOUS LENGTHS PER PLANS, LED

BOARD CONFIGURATION PROVIDE EVEN

LENS ILLUMINATION FOR HOUSINGS IN

1" INCRIMENTS.

AXIS - BRLED-B3-MF-400-35-SO-S#-W-UNIV-D-1-DF

1,2,4

12/277

3W/FT

94LM/FT

FROSTED POLYCARBONATE LENS

EXTRUDED ALUMINUM CHANNEL WITH

EXTRUDED ALUMINUM HOUSING,

JUMPER CABLES AND DRIVERS AS

REQUIRED

KLUS - K-35-1220 / B5553-HS22 FROSTED / B6638

1,2,4

UNIV

3.3W/FT

122LM/FT

SPOTLESS ACRYLIC FLUSH LENS

EXTRUDED ALUMINUM HOUSING,

CONTINUOUS LENGTHS PER PLANS, LED

BOARD CONFIGURATION PROVIDE EVEN

LENS ILLUMINATION FOR HOUSINGS IN

1" INCRIMENTS, WHITE FINISH

AXIS - BBSLED-B3-MF-400-35-SO-S#-W-UNV-D-1-S

2,4

277

8.5W/FT

30X60 DEGREE OPTICS

LENGTHS PER PLANS, SLIM ADJUSTIBLE

MOUNTING, SILVER SAND FINISH

LUMENPULSE - LOGi-277-LENGTH-35K-30X60-SAM-SI-DIM

2,4

UNIV

28W

78LM/W

FLUSH FORMED FROSTED ACRYLIC

DIFFUSER

STEEL HOUSING, WHITE FINISH

FOCAL POINT - FNVL-22-ACZ-LL1-35K-1C-UNV-LD1

1,2

UNIV

107W

93LM/W

ASYMETRIC FORWARD THROW

DISTRIBUTION, CLEAR LENS

EXTRUDED ALUMINUM HOUSING,

DIECAST ENDCAPS WITH STAINLESS

STEEL HARDWARE, BLACK

POWDERCOAT FINISH

WINONA - WLAWC803-YM1A-INT-24LONG-AL1A3-35-MVOLT-CA-SGB

2

277

5W/FT

110

FROSTED ACRYLIC LENS

EXTRUDED ALUMINUM HOUSING,

MACHINED ENDCAPS, SATIN ANODIZE

FINISH

BARTCO - BSS210-23-35-5-SM-SIN-SA

2

3500K

80+ CRI

LR3

1" LINEAR LED

RECESSED

DW

1.12"

284LM/FT

0-10V

LED

DIMMING

2,3,4

3.3W/FT

3500K

2" LINEAR LED

AION - 4924-35-LE / AT845

UNIV

80+ CRI

LR2

VIRGINIA TECH

1,2

3500K

3030 Clarendon Boulevard, Suite 500

Arlington, Virginia 22201

T: 703.907.2300

F: 703.907.2050

80+ CRI

LS1

4" LINEAR LED

SURFACE

5-1/2"

400 LM/FT

0-10v

LED

DIMMING

3500K

80+ CRI

LS2

LED LINEAR GRAZE

SURFACE

REMOTE

LED

0-10V

3500K

DIMMING

80+ CRI

LT1

2X2 LED TROFFER

RECESSED LG

2200LM

0-10V

LED

DIMMING

3500K

80+ CRI

LW1

LED UPLIGHT

SURFACE

WALL

10,023 LM

0-10V

LED

DIMMING

3500K

80+CRI

LW2

LED LINEAR STRIP

SURFACE

WALL

550LM/FT

LED

INTEGRAL

ELECTRONIC

3500K

80+CRI

SCHEMATIC DESIGN

No.

24 JUL 2015

Description

Date

GENERAL NOTES:

A

REFERENCED PRODUCTS ARE INCLUDED HEREIN, OF MANUFACTURERS & PRODUCTS, THAT GENERALLY CONFORM TO THE LUMINAIRE DESIGN INTENTS ESTABLISHED HEREIN, & IN THE PROJECT MANUAL. EQUIVALENT

PRODUCTS BY OTHER MANUFACTURERS MAY BE CONSIDERED, PRIOR TO BID.

B

C

DETERMINE SPECIFIC LUMINAIRE PART NUMBERS BASED ON THE REFERENCED PRODUCT SERIES, WRITTEN DESCRIPTIONS & PROJECT MANUAL SPECIFICATIONS.

INCLUSION HEREIN OF MANUFACTURER'S SERIES &/OR MODEL NUMBERS DOES NOT IMPLY UNCONDITIONAL PRODUCT APPROVAL - MANUFACTURER'S STANDARD PRODUCTS MAY REQUIRE CUSTOM MODIFICATIONS

TO MEET THE REQUIREMENTS SPECIFIED HEREIN & IN THE PROJECT MANUAL.

D

LISTED SIZES, LAMPING, & TYPES OF LUMINAIRES MAY NOT BE STANDARD PRODUCTS PRODUCED FROM ANY GIVEN MANUFACTURER OR SERIES LISTED. MANUFACTURER'S STANDARD PRODUCTS MAY REQUIRE CUSTOM

MODIFICATIONS TO MEET THE DESIGN CRITERIA, DESCRIPTIONS, & REQUIREMENTS SPECIFIED HEREIN & IN THE PROJECT MANUAL.

E

ALERT ARCHITECT TO DISCREPANCIES PRIOR TO BID.

ABBREVIATIONS:

CONC

CONCRETE

EXP

EXPOSED

LM/W

LUMENS PER WATT

DW

DRYWALL

LG

LAY-IN GRID

NT

D/I

DIRECT/INDIRECT

LO-IRI

LOW IRRIDESCENT

PAF

PPC

POLYESTER POWDER COAT FINISH

S'SPEC

NARROW TEE GRID

P-RS

PENDANT - RIGID STEM

SS

STAINLESS STEEL

PAINT AFTER FABRICATION

REFL'T

REFLECTOR/REFLECTANCE

TBS

TO BE SELECTED BY ARCH

SEMI-SPECULAR

EFF

EFFICIENCY/EFFICACY/LM/W

LM

LUMENS

P-AC

PENDANT - AIRCRAFT CABLE

SP

SPLINE CEILING SYSTEM

UNIV

UNIVERSAL 120-277VAC

ELBD

EMERG. LTG. BYPASS DEVICE

LM/FT

LUMENS PER LINEAR FOOT

PL

PLASTER

SPEC

SPECULAR

WH

WHITE

NOTES:

1 COORDINATE MOUNTING/FLANGE CONDITION WITH REFLECTED CEILING PLAN /ARCHITECT PRIOR TO ORDERING AND INSTALLATION

2

PROVIDE BALLASTS/ DRIVERS TO ACCOMMODATE SWITCHING/CONTROL SHOWN ON PLAN

3

REFER TO ARCHITECTURAL CEILING PLANS/DETAILS FOR MORE INFORMATION

4

LUMINAIRE TO RUN CONTINUOUSLY. COORDINATE AND PROVIDE NECESSARY CONNECTORS, ENDCAPS AND APPURTENANCES TO ENABLE CLEAN ONTINUOUS LINES OF LIGHT

N

KEY PLAN

1

LUMINAIRE SCHEDULE

LUMINAIRE SCHEDULE

7/24/2015 4:44:15 PM

© Cannon Design 2015

All rights reserved. No part of this document may

be reproduced or utilized in any form, without prior

written authorization by The Cannon Corporation.

Drawing Title:

Project No.: 004815.00

Checked by: Checker

E0601

© Cannon Design 2015