Obstruction Lighting Guide: FAA & ICAO Compliance

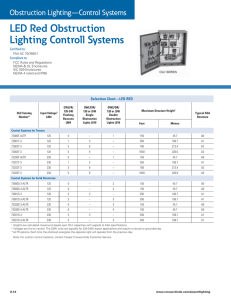

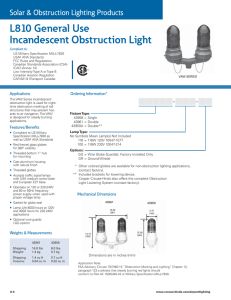

advertisement