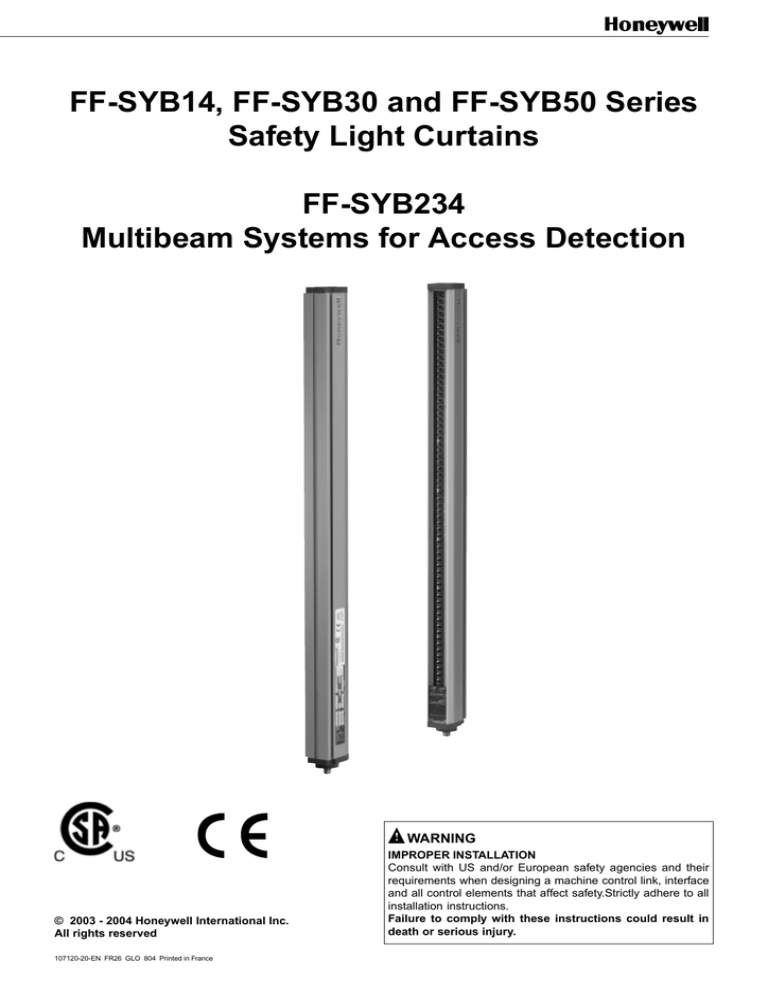

FF-SYB14, FF-SYB30 and FF-SYB50 Series

Safety Light Curtains

FF-SYB234

Multibeam Systems for Access Detection

! WARNING

© 2003 - 2004 Honeywell International Inc.

All rights reserved

107120-20-EN FR26 GLO 804 Printed in France

IMPROPER INSTALLATION

Consult with US and/or European safety agencies and their

requirements when designing a machine control link, interface

and all control elements that affect safety.Strictly adhere to all

installation instructions.

Failure to comply with these instructions could result in

death or serious injury.

Copyright, 2003 - 2004

By Honeywell

All rights reserved. No part of this manual may be reproduced in any form or by any other means,

without permission from the publishers.

Revision History

Reference

Circulation

Description

Languages

EN

107120-10

September 2003

English version

107120-11

December 2003

Change of response time for model numbers

FF-SYB14128 to FF-SYB14176

EN, DE, FR, IT, SP

107120-12

May 2004

Change of the EC declaration of conformity

EN, DE, FR, IT, SP

107120-20

June 2004

Change of approval and rating plates

EN, DE, FR, IT, SP

Printed in France

107120-20-EN FR26 GLO 804 Printed in France

Table of contents

1.

Important Information..................................................................................................................... 4

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

2.

Description and Operation ............................................................................................................. 8

2.1

2.2

2.3

2.4

2.5

2.6

3.

Overview .................................................................................................................................................................. 4

Organisation of Installation Manual .......................................................................................................................... 4

Important highlighted information ............................................................................................................................ 4

Control Reliability ..................................................................................................................................................... 5

Approvals .................................................................................................................................................................. 6

Safety Light Curtain Installation and Use ................................................................................................................. 6

European Directives Compliance ............................................................................................................................. 6

European Standards Compliance ............................................................................................................................ 6

United States Regulations Compliance ................................................................................................................... 7

United States Standards Compliance ...................................................................................................................... 7

Additional Protection ................................................................................................................................................ 7

Overview .................................................................................................................................................................. 8

Machine Guarding and Perimeter Protection ........................................................................................................... 8

Approval and rating plates ...................................................................................................................................... 10

Operation ................................................................................................................................................................ 11

2.4.1 Synchronisation .......................................................................................................................................... 11

2.4.2 Resolution (FF-SYB14, FF-SYB30 and FF-SYB50 series) ........................................................................ 11

2.4.3 Floating blanking ......................................................................................................................................... 12

2.4.4 protection height (FF-SYB14, FF-SYB30 and FF-SYB50 series) ............................................................... 12

2.4.5 Beam spacing and number of beams (FF-SYB234 series) ........................................................................ 12

2.4.6 Scanning range ........................................................................................................................................... 13

2.4.7 Manual restart ............................................................................................................................................. 14

2.4.8 External device monitoring (EDM) .............................................................................................................. 14

2.4.9 Muting function ............................................................................................................................................ 14

2.4.10 Serial connection ....................................................................................................................................... 15

2.4.11 Configuration cards .................................................................................................................................... 16

Indicators ................................................................................................................................................................ 19

2.5.1 Scanning range indicators (emitter) ............................................................................................................ 19

2.5.2 Alarm indicator (emitter) ............................................................................................................................. 19

2.5.3 test indicator (emitter) ................................................................................................................................. 20

2.5.4 Operation indicators (receiver) .................................................................................................................... 20

2.5.5 Signal strength indicator (receiver) ............................................................................................................. 20

2.5.6 Cross-talk indicator (receiver) ..................................................................................................................... 21

2.5.7 Restart indicator (receiver) ......................................................................................................................... 21

2.5.8 Muting diagnosis indicator .......................................................................................................................... 21

2.5.9 Floating blanking indicators ........................................................................................................................ 21

2.5.10 External indicator ........................................................................................................................................ 21

Specifications ......................................................................................................................................................... 22

Installation ..................................................................................................................................... 24

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

Overview ................................................................................................................................................................ 24

Point-of-operation guarding .................................................................................................................................... 24

Perimeter guarding ................................................................................................................................................. 25

How to calculate safety distance ............................................................................................................................ 25

3.4.1 Safety distances per Europe’s EN 999 standard ........................................................................................ 25

3.4.2 Safety distances per USA's OSHA/ANSI requirements .............................................................................. 26

How to calculate minimum distance considering reflective surfaces ..................................................................... 29

Mutual interference or cross-talk ............................................................................................................................ 30

Dimensions and weights ........................................................................................................................................ 30

3.7.1 Dimensions and weights of the FF-SYB14, FF-SYB30 and FF-SYB50 series light curtains ..................... 31

3.7.2 Dimensions and weights of the FF-SYB234 multibeam systems for access detection .............................. 33

Mounting considerations ........................................................................................................................................ 34

3.8.1 Optical alignment ........................................................................................................................................ 34

3.8.2 Vertical mounting ........................................................................................................................................ 34

3.8.3 Vertical mounting / linear assembly ............................................................................................................ 35

3.8.4 Vertical mounting / side by side installation ................................................................................................ 36

3.8.5 Horizontal mounting .................................................................................................................................... 37

3.8.6 Diagonal and right-angle mounting ............................................................................................................. 37

Muting sensors ....................................................................................................................................................... 38

3.9.1 muting function ............................................................................................................................................ 38

3.9.2 Installation of the muting sensors .............................................................................................................. 38

3.9.3 Two-direction muting on a conveyor using two muting sensors .................................................................. 40

3.9.4 Two-direction muting on a conveyor using 4 sensors ................................................................................. 41

3.9.5 One-way muting on a conveyor using 4 sensors ........................................................................................ 42

3.9.6 Muting the safety light curtain during the upstroke of a mechanical power press cycle ............................. 43

107120-20-EN FR26 GLO 804 Printed in France

3.10

4.

Electrical connections .................................................................................................................. 49

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

5.

5.3

Overview ................................................................................................................................................................ 90

Operational test ...................................................................................................................................................... 90

5.2.1 Troubleshooting procedures ........................................................................................................................ 91

Cleaning ................................................................................................................................................................. 94

5.3.1 Using a dry cloth ......................................................................................................................................... 94

5.3.2 Using soap and water ................................................................................................................................. 94

Order guide .................................................................................................................................... 95

Warranty information .................................................................................................................... 99

7.1

7.2

8.

M12 connectors (emitter and receiver) ................................................................................................................... 49

Terminal strip (receiver only) .................................................................................................................................. 49

Power wiring ........................................................................................................................................................... 50

Machine stop contacts ............................................................................................................................................ 51

4.4.1 Permanent self-checking (monitoring) ........................................................................................................ 51

4.4.2 Protection of machine stop contacts ........................................................................................................... 52

4.4.3 Connection to the machine control circuitry ................................................................................................ 52

Test input ................................................................................................................................................................ 53

Manual restart / external device monitoring (EDM) output ..................................................................................... 55

Connection of sensors SM and EM ........................................................................................................................ 57

4.7.1 SM1 & SM2 inputs ...................................................................................................................................... 57

4.7.2 EM1 & EM2 inputs ...................................................................................................................................... 57

Temporary manual muting function (TMM) ............................................................................................................ 58

Muting lamp / diagnosis output .............................................................................................................................. 60

Signalling contact output ........................................................................................................................................ 60

Serial connection .................................................................................................................................................... 61

Recommended wiring diagrams and installation controls ...................................................................................... 62

4.12.1 Basic applications with manual restart ....................................................................................................... 62

4.12.2 Two-direction muting applications with manual restart (2 or 4 sensors) ..................................................... 64

4.12.3 Serial connection applications with manual restart .................................................................................... 67

4.12.4 Two-direction muting and serial connection applications with manual restart ............................................ 70

4.12.5 One-way muting applications with manual restart (4 sensors) ................................................................... 73

4.12.6 Basic applications with automatic restart .................................................................................................... 76

4.12.7 Two-direction muting applications with automatic restart (2 or 4 sensors) ................................................. 78

4.12.8 Serial connection application with automatic restart .................................................................................. 81

4.12.9 Two-direction muting and serial connection applications with automatic restart ........................................ 84

4.12.10 One-way muting applications with automatic restart (4 sensors) .............................................................. 87

Maintenance and troubleshooting .............................................................................................. 90

5.1

5.2

6.

7.

3.9.7 Muting the safety light curtain during the upstroke of a hydraulic press cycle ............................................ 44

Mounting hardware ................................................................................................................................................ 46

3.10.1 Dovetail slot mounting system .................................................................................................................... 46

3.10.2 FF-SYZ634178 right-angle mounting brackets (included on delivery) ....................................................... 47

Warranty and remedy ............................................................................................................................................. 99

Sales and service ................................................................................................................................................... 99

Index............................................................................................................................................. 100

EC declaration of conformity

107120-20-EN FR26 GLO 804 Printed in France

1.

IMPORTANT INFORMATION

1.1 OVERVIEW

Thank you for purchasing this Honeywell safety product. This manual contains description, operation, installation, electrical connections, maintenance and troubleshooting information related to the FF-SYB product. These installation instructions do not

provide instructions for operating the machine on which the FF-SYB product is installed. Information about the machine operation

can be found in the machine manufacturer’s operating instructions.

1.2 ORGANISATION OF INSTALLATION MANUAL

This installation manual has the following sections:

• Important Information contains important highlighted information, the manual’s organisation, control reliability information,

approvals, standards, regulations and directives.

• Description and Operation provides operation and specification information.

• Installation explains how to properly install safety light curtains or the multibeam system for access detection.

• Connections and Setup covers electrical installation, interfacing and set-up procedures.

• Inspection and Maintenance contains inspection, maintenance, and indicator status information.

• Order Guides provide catalog listings of light curtains or multibeam systems, accessories, and spare parts.

• Warranty Information provides important contact information related to sales and service.

• Index contains keywords and their associated pages related to topics found throughout this manual.

1.3 IMPORTANT HIGHLIGHTED INFORMATION

Important danger, warning, caution and notices are highlighted throughout the manual as follows:

! DANGER

A DANGER symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

! WARNING

A WARNING symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

A CAUTION symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

NOTICE

A NOTICE symbol indicates important information that must be remembered and aids in job performance.

1.4 CONTROL RELIABILITY

“Control Reliability” means that, “the device, system or interface shall be designed, constructed and installed such that a single

component failure within the device, interface or system shall not prevent normal stopping action from taking place but shall prevent

a successive machine cycle.” (ANSI B11.19-1990, 5.5)

OSHA 29 CFR 1910.217 states that, “the control system shall be constructed so that a failure within the system does not prevent

the normal stopping action from being applied to the press when required, but does prevent initiation of a successive stroke until

the failure is corrected. The failure shall be detectable by a simple test, or indicated by the control system.”

Honeywell has developed a self-checking technique that combines reliability with safety. The FF-SYB Series safety light curtain

functions with dual channel redundancy and positive self-check monitoring. This means that a faulty component in our product will

make the optoelectronic safety device fail in a safe mode.

This design meets the highest safety requirements (type 4) described in the IEC/EN 61496-1 and IEC/ EN 61496-2 norms. Type 4

devices are designed and manufactured in such a way that a single breakdown or an accumulation of failures does not lead to the

loss of the safety function when a dangerous situation arises. The safety function is maintained on a permanent basis.

107120-20-EN FR26 GLO 804 Printed in France

5

1

1.5 APPROVALS

1

Approvals

CE

Description

Packaging, documentation and the FF-SYB Series products carry the CE mark. The EC declaration

of conformity is at the back of this manual

INRS

“Institut National de Recherche et de Sécurité”: French notified body for the CE certification of

Electrosensitive protective Equipment

cCSAus

The Canadian Standard Association (CSA) has been accredited as a Nationally Recognised

Testing Laboratory (NRTL) by the US Occupational Safety and Health Administration (OSHA). The

CSA is able to carry out tests according to the Canadian and UL standards and deliver a single

certificate which is valid for both Canada and the United States.

1.6 SAFETY LIGHT CURTAIN INSTALLATION AND USE

Installation and use of this product must be performed by a qualified person thoroughly familiar with all instructions contained

within this manual and all applicable safety regulations including those described below.

1.7 EUROPEAN DIRECTIVES COMPLIANCE

Directives

Machine Directive

Low Voltage Directive

Electromagnetic Compatibility Directive

Number

98/37/EC

73/23/EC

89/336/EC as amended 91/263/EC, 92/31/EC, 93/108/EC and 93/97/EC

The EC type examination certificate granted by the French “Institut National de la Recherche et de la Sécurité (INRS)” guarantees

the conformity of the product with respect to the essential requirements of the Machinery Directive 98/37/EC. To complete the EC

type examination, further tests have been carried out by external laboratories to guarantee the conformity of the product with

respect to the Low Voltage 73/23/EC and the Electromagnetic Compatibility 89/336/EC, as amended 91/263/EC, 92/31/EC,

93/108/EC and 93/97/EC.

An EC declaration of conformity will be found at the back of this manual.

1.8 EUROPEAN STANDARDS COMPLIANCE

The FF-SYB Series safety light curtain complies with the following European standards:

Regulation

EN 292

EN 60204-1

EN 954-1

IEC/EN 61496-1

IEC/EN 61496-2

EN 61508

Title

Safety of Machinery - Basic concepts, general principles for design

Safety of Machinery - Electrical equipment of machines

Safety of Machinery - Safety related parts of control systems

Safety of Machinery - Electrosensitive protective equipment - part 1: General requirements and tests

Safety of Machinery - Electrosensitive protective equipment - part 2: Active optoelectronic Protective

Devices

Functional safety of Electrical / Electronic / programable Electronic Safety. Related Systems

Installation and use of the FF-SYB light curtain must comply with the following applicable European standards (non exhaustive list):

Regulation

EN 292

EN 60204-1

EN 954-1

IEC/EN 61496-1

IEC/EN 61496-2

EN 999

EN 294

EN 811

EN 692

pr EN 693

pr EN 12622

EN 201

EN 289

pr EN 11553

EN 775

EN 415-1

EN 415-2

EN 415-3

EN 415-4

6

Title

Safety of Machinery - Basic concepts, general principles for design

Safety of Machinery - Electrical equipment of machines

Safety of Machinery - Safety related parts of control systems

Safety of Machinery - Electrosensitive protective equipment - part 1: General requirements and tests

Safety of Machinery - Electrosensitive protective equipment - part 2: Active optoelectronic Protective

Devices

Safety of Machinery - The positioning of protective equipment in respect of approach speeds of parts

of the human body

Safety of Machinery - Safety distances to prevent danger zones from being reached by the upper limbs

Safety of Machinery - Safety distances to prevent danger zones from being reached by the lower limbs

Machine-tool - Safety - Mechanical Presses

Machine-tool - Safety - Hydraulic Presses

Hydraulic press brakes - Safety

Injection plastic moulding machines

Compression moulding and transfer machines

Laser for material processing

Manipulating Industrial Robots

Safety of packaging machines - Part 1: Common requirements

Safety of packaging machines - Part 2: Preformed rigid container packaging machinery

Safety of packaging machines - Part 3: Form, fill and seal machines

Safety of packaging machines - Part 4: palletisers and depalletisers

107120-20-EN FR26 GLO 804 Printed in France

1.9 UNITED STATES REGULATIONS COMPLIANCE

US Regulation

OSHA 29 CFR 1910.212

OSHA 29 CFR 1910.217

Title

General Requirements for (guarding of) All Machines

(Guarding of) Mechanical Power Presses

1

• Safety light curtains may be used as primary protection for machines where the movement of the functional parts can be interrupted

at any moment in a dangerous phase.

• Safety light curtains may be used as primary protection for machines on which the control circuit has been designed in such a

manner that a fault in one component does not result in any risk.

• Cancellation of the safety light curtain stop signal must not cause the restart of the moving parts. The function to restart can only

be initiated by means of a control designed for this purpose.

1.10 UNITED STATES STANDARDS COMPLIANCE

Installation and use of the FF-SYB light curtain must comply with the following applicable American standards (non-exhaustive list):

Standards

ANSI B11.1

ANSI B11.2

ANSI B11.19

ANSI/RIA R15.06

Title

Mechanical Power Presses

Hydraulic Power Presses

Safeguarding when Referenced by the Other B11 Machine Tool Safety Standards

Safety Requirements for Industrial Robots and Robot Systems

1.11 ADDITIONAL PROTECTION

In some applications, it may be necessary to provide additional protection to maintain the protection level provided by the safety

light curtain. Hard guards or additional presence sensing devices such as safety mats or laser scanner, may be used to ensure the

operator is either forced to move through the sensing field to enter the danger zone, or forced to stand on the sensing area inside

the danger zone.

Hard guards should be installed permanently with the aid of a tool or welded (if possible). If hard guards need to be automatically

positioned, their positioning must be checked. It must not be possible for operators to neutralise the detectors associated with these

hard guards. Hard guards shall comply with the following applicable European Standards:

Standards

EN 953

EN 294

EN 811

EN 1088

EN 954-1

Title

Safety of Machinery - General requirements for the design and construction of guards

Safety of Machinery - Safety distances to prevent danger zones from being reached by the upper limbs

Safety of Machinery - Safety distances to prevent danger zones from being reached by the lower limbs

Safety of Machinery - Interlocking devices with and without guard locking

Safety of Machinery - Safety related parts of control system

Honeywell FF-SR Series safety control modules may be used as an interface between protective safety equipment and machine

control circuitry. The following safety control modules are particularly recommended:

• FF-SRS: safety control module designed for emergency stop

• FF-SRD Series: safety control module designed for door monitoring

• FF-SR2: safety relay control module designed for two-hand controls

• FF-SR0 Series: safety control module designed for standstill detection on inductive motors

• FF-SRT Series: time delay module

• FF-SRE Series: extension relay module

They offer redundancy, monitoring, and control reliability features that ensure the highest level of industrial safety.

Honeywell safety switches and sensors that may be used to check the position of guards include:

• GSS safety limit switches

• GK and GKM key operated safety switches

• GKR/L solenoid key operated safety interlock switches

• 24/924CE miniature safety limit switch

Honeywell safety optoelectronic products that may be used with the FF-SYB Series safety light curtain include:

• FF-SM safety mat

• FF-SPS4 single beam safety device

• FF-SCAN modular safety light curtain.

107120-20-EN FR26 GLO 804 Printed in France

7

2.

DESCRIPTION AND OPERATION

2.1 OVERVIEW

This chapter contains terms and concepts related to safety and the application of the FF-SYB Series light curtain. The importance

of the installer’s role in the set-up and installation of the machine guarding systems is discussed. The section also contains

specification and order guide information.

2

Remark:

In order to simplify this manual, the term “safety light curtain” is used for the FF-SYB14, FF-SYB30 and FF-SYB50 safety light

curtains as well as for the FF-SYB234 safety multibeam systems for access detection.

2.2 MACHINE GUARDING AND PERIMETER PROTECTION

The FF-SYB14 and FF-SYB30 Series through-scan light curtains are non-contact machine guarding devices designed for point-ofoperation protection at power driven machinery (see Figure 2-1) where fingers or hands need to be detected.

The FF-SYB50 Series light curtains are designed for presence detection in dangerous areas where legs or a body need to be

detected.

The FF-SYB234 Series multibeam systems are used for access detection in dangerous areas where a body needs to be detected.

! WARNING

IMPROPER INSTALLATION OF FF-SYB SERIES LIGHT CURTAIN

• Install FF-SYB light curtains in accordance with this installation manual and applicable local safety regulations (OSHA,

ANSI, European standards).

• Allow entry into protected area by interruption of sensing field of the safety light curtain or activation of another safeguarding

device only.

Failure to comply with these instructions could result in death or serious injury.

FF-SYB Series light curtains generate a stop signal if the sensing field is interrupted. Further operation is prevented until the

sensing field is cleared. The FF-SYB Series light curtain monitors itself continuously for component failures, misalignments, and

dirt accumulation. Small misalignments or dirt accumulation are indicated by a flashing LED. If misalignment or dirt accumulations

become too great or a component fails, a stop signal is generated. Operation is prevented until the condition is corrected.

! WARNING

IMPROPER SYSTEM PERFORMANCE

• Comply with local safety requirements when designing machine control link, interface and all control elements that affect safety.

• Install two independent safety relay contacts into machine control stop circuit controlled by FF-SYB Series light curtain.

• Ensure two independent stop circuit relays have mechanically linked contacts to reliably detect a welded contact.

• Using one of the compatible safety relay modules (see chapter 6) will provide safe relay contacts to the machine control stop

circuit.

Failure to comply with these instructions could result in death or serious injury.

FF-SYB Series light curtains are designed so a malfunction or an interruption of the sensing field will immediately cause the light

curtain to generate a stop signal. This stop signal will be generated automatically if a malfunction occurs in the light curtain. All

other machine control components that affect safety should also be designed to the same high level of operation.

! WARNING

IMPROPER MACHINE REACTION

• Ensure the machine control is capable of stopping the machine at any point in the cycle.

• Ensure that a loss of power does NOT impair stopping action of machine.

Failure to comply with these instructions could result in death or serious injury.

! DANGER

FULL REVOLUTION MECHANICAL POWER PRESSES CANNOT BE STOPPED IN MID-STROKE (OSHA 29CFR 1910.217)

DO NOT use FF-SYB Series light curtains on full revolution mechanical power presses.

Failure to comply with these instructions will result in death or serious injury.

8

107120-20-EN FR26 GLO 804 Printed in France

For point-of-operation guarding, the light curtain(s) and any mechanical guards should be installed so no one can stand between

the light curtain and the danger zone. This may require additional hard guarding, horizontal or angled positioning of the light

curtain, or additional light curtains.

Figure 2-1 Perimeter Guarding (use the FF-SYB234 multibeam systems with deflection mirrors)

FSYB3

2

! WARNING

IMPROPER PERIMETER PROTECTION ACTIVATION

• Design control circuit that requires a manual restart before further machine operation can occur.

• Locate manual restart to allow operator a clear view of danger zone.

• Operator must NOT be able to reach manual restart from within danger zone.

• Design control circuit to prevent Programmable Logic Controller from overriding manual restart.

Failure to comply with these instructions could result in death or serious injury.

107120-20-EN FR26 GLO 804 Printed in France

9

2.3 APPROVAL AND RATING PLATES

Figure 2-2 Rating plate of the FF-SYB14, FF-SYB30 and FF-SYB50 Series light curtain

2

Figure 2-3 Rating plate of the FF-SYB234 multibeam systems for access detection

NSR

PH

N

R

BS

V

Nominal Scanning Range

Protection Height

Number of beams

Resolution ("minimum object sensitivity" in USA standards)

Beam spacing

Supply Voltage (power consumption)

T

Response time

Approvals

CE

INRS

cCSAus

10

I

Type

N°

Date

S

L

Output Switching Capacity

Product Part Number

Serial number

Date code (month/year)

Sealing

Loads specifications (max. impedance and min.

turn-on voltage)

Service Honeywell website for Sales and Service

Description

Packaging, documentation and the FF-SYB Series products carry the CE mark. The EC declaration of

conformity is at the back of this manual.

"Institut National de Recherche et de Sécurité": French notified body for the CE certification of

Electrosensitive protective Equipment

The Canadian Standard Association (CSA) has been accredited as a Nationally Recognised Testing

Laboratory (NRTL) by the US Occupational Safety and Health Administration (OSHA). The CSA is

able to carry out tests according to the Canadian and UL standards and delivers a single certificate

which is valid for both Canada and the United States.

107120-20-EN FR26 GLO 804 Printed in France

2.4 OPERATION

The FF-SYB Series are through-scan light curtains. Emitters transmit modulated, infrared light that is detected by photoreceivers

in the receiver. The number of light beams depends on the protected height and resolution of the light curtain.

Figure 2-4 FF-SYB Series Operational Diagram

Sensing range

FSYB4

Protection height

2

Synchronisation beam

Emitter

Receiver

2.4.1 SYNCHRONISATION

The emitter and the receiver are optically synchronised. The synchronisation is an effective beam transmitted by the emitter

towards the receiver. No electrical connection is necessary between the emitter and the receiver that simplifies installation and

maintenance.

2.4.2 RESOLUTION (FF-SYB14, FF-SYB30 AND FF-SYB50 SERIES)

FF-SYB Series light curtain resolution (sometimes called minimum object sensitivity) is the minimum object size that will interrupt

at least one light beam when it enters the sensing field. Anything entering the sensing field equal to or greater than this minimum

size will be detected. Resolution is not affected by scanning distance or dust accumulation. Two factors determine the resolution of

the light curtain: beam pitch and light lens diameter (see Figure 2-5).

Lens diameter is the smallest width that will block a single light beam. The combination of the beam diameter and centre distance

gives the FF-SYB14 a resolution of 14 mm (0.6 in), the FF-SYB30 a resolution of 30 mm (1.2 in) and the FF-SYB50 a resolution of

50 mm (1.97 in).

! WARNING

RESOLUTION AND FLOATING BLANKING

• Resolution is affected by the floating blanking.

• Refer to chapter "Floating blanking" to determine proper resolution.

Failure to comply with these instructions could result in death or serious injury.

Figure 2-5 Light Curtain Resolution

Model

FF-SYB14

FF-SYB30

FF-SYB50

Resolution R

ø 14 / 0.6

ø 30 / 1.2

ø 50 / 1.97

FSYB5

Lens size D

Beam pitch P

øR Resolution

Beam pitch P

10 / 0.4

20 / 0.8

40 / 1.6

Lens size D

4 / 0.16

10 / 0.4

10 / 0.4

Dimensions in mm / in

107120-20-EN FR26 GLO 804 Printed in France

11

2.4.3 FLOATING BLANKING

The built-in floating blanking feature provides a means for the random inhibition of one or two beams of the light curtain except the

synchronisation beam. It is useful in those applications where material or air ejected parts randomly travel through or within the

sensing field. You can also disable light beams in an area where a fixture penetrates the light field, and you can permit stationary

objects to protrude into the light curtain's sensing field. Floating blanking may only be used when material or parts take up a space

no greater than the maximum value in the table below within the sensing field. Larger material would block more than one light

beam at a time. As a result, the light curtain would generate a stop command.

When using floating blanking, the resolution of the light curtain is altered according to the following table:

2

FF-SYB14

FF-SYB30

FF-SYB50

Resolution without

floating/blanking

14 mm / 0.55 in

30 mm / 1.18 in

50 mm / 1.97 in

Resolution with 1 beam

floating/ blanking

24 mm / 0.94 in

50 mm / 1.97 in

90 mm / 3.54 in

Resolution with 2 beam

floating/blanking

34 mm / 1.33 in

70 mm / 2.75 in

130 mm / 5.12 in

NOTICE

The floating blanking IS NOT available with the 2-beam and 3-beam FF-SYB234 systems. Select the 4-beam FF-SYB234 system

if this feature is required.

Anything smaller might fit between two light beams.

Floating blanking blocks one or two light beam(s), creating an additional passageway through the light field where no object will be

detected. Safety distance formulas state that if the resolution increases, the safety distance must also increase.

This means that use of a blanking will require moving the light curtain farther back from the hazardous area.

However, if the area blanked is entirely blocked by a fixture such that operator intrusion into this area is impossible, then you do not

have to change the safety distance. For instance, you might have a work table that juts out into the light field but takes up the whole

space between the emitter and receiver that is blanked and therefore unprotected by the light curtain.

You can enable this feature by selecting the corresponding configuration card. Two yellow indicators at the receiver provide an

indication on floating blanking status. If you use this feature, even occasionally, the safety distance for mounting must be increased.

Refer to "Calculating Safety Distance" in chapter "How to calculate safety distance of this manual".

! WARNING

INCORRECT SAFETY DISTANCE WHEN USING FLOATING BLANKING

• Ensure that the correct safety distance exists between the light curtain and the hazardous area.

• See chapter "How to calculate safety distance" for detailed information on resolution and calculating the safety distance.

Failure to comply with these instructions could result in death or serious injury.

The next illustration shows how coil stock cuts different light beams as the coil unwinds. As long as only one or two beams are cut

at a time (no matter which one it is), the FF-SYB safety light curtain continues to allow machinery to operate.

FSYB6

Figure 2-6 Coil stock unwinding using floating blanking

2.4.4 PROTECTION HEIGHT (FF-SYB14, FF-SYB30 AND FF-SYB50 SERIES)

The protection height is the height on which the test rod will be detected (see chapter 3.7.1).

12

107120-20-EN FR26 GLO 804 Printed in France

2.4.5 BEAM SPACING AND NUMBER OF BEAMS (FF-SYB234 SERIES)

For FF-SYB234 multibeam systems for access detection, beam spacing indicates the distance between the optical axis of two

consecutive beams. The beam spacing of the FF-SYB multibeam system and the beam heights above the reference plane are in

compliance with the European standards EN 999.

Model

Number of beams

Beam spacing

2

3

4

mm

500

400

300

FF-SYB02500 (-L)

FF-SYB03400 (-L)

FF-SYB04300 (-L)

Beam heights above the reference plane

(per EN 999)

mm

In

400 / 900

15.8 / 35.5

300 / 700 / 1100

11.8 / 27.6 / 43.3

300 / 600 / 900 / 1200 11.8 / 23.6 / 35.5 / 47.3

NOTICE

NON COMPLIANCE TO ANSI/RIA 15.06-1999 WITH FF-SYB02500

• Only the three beam FF-SYB03400 (-L) and the four beam versions FF-SYB04300 (-L) are in compliance with the beam

heights, specified in the US Standard ANSI/RIA R15.06-1999 (Industrial Robots and Robot Systems - Safety Requirements).

The two beam version FF-SYB02500 (-L) does NOT comply with ANSI/RIA R15.06 and may require additional protection.

• Refer to applicable standards. In the absence of an applicable standard, ANSI B11.19 and ANSI R15.06 may be used as

reference for the USA, as well as EN 999 (or the relevant European Type C machine standard) for Europe.

• Verify compliance with ANSI/RIA R15.06 and possibly implement additional protection when floating blanking is used on the

4-beam FF-SYB234 system.

2.4.6 SCANNING RANGE

The scanning range is the maximum distance allowed between the emitter and the receiver. A configuration card is used on the

emitter unit for the selection of the adequate emission power. Refer to the chapter "Mutual Interference or cross-talk" for correct

adjustment.

NOTICE

CONFIGURATION CARD SETTINGS

The configuration card in use for the selection of the

• scanning range

• logic of the test input (see chapter "Test input")

is visible through the transparent front window of the emitter without removing the end cap.

Figure 2-7 Scanning Ranges

R1

R1

R2

R1

R2

R2

R3

R3

R3

alarm

alarm

alarm

test

test

test

50% NO

100% NO

FSYB7

23% NO

23% NO

50% NO

100% NO

Factory setting

Version

FF-SYB14

FF-SYB30 / FF-SYB50

FF-SYB02 / FF-SYB03 / FF-SYB04 standard range

FF-SYB02 / FF-SYB03 / FF-SYB04 long range

107120-20-EN FR26 GLO 804 Printed in France

SCANNING RANGE SETTINGS

Minimum: 23 %

Medium: 50 %

0 m to 1,4 m /

1 m to 3 m /

0 ft to 4.6 ft

3.3 ft to 9.8 ft

0 m to 4,6 m /

2 m to 10 m /

0 ft to 15.1 ft

6.6 ft to 32.8 ft

0 m to 7 m /

4 m to 15 m /

0 ft to 23.0 ft

13.1 ft to 49.2 ft

5 m to 18 m /

15 m to 40 m /

16.4 ft to 59.1 ft

49.2 ft to 131.2 ft

Maximum: 100 %

2 m to 6 m /

6.6 ft to 19.7 ft

5 m to 20 m /

16.4 ft to 65.6 ft

10 m to 30 m /

32.8 ft to 98.4 ft

35 m to 80 m/

114.8 ft to 262.5 ft

13

2

! WARNING

MINIMUM SCANNING RANGE (FF-SYB14, FF-SYB30 and FF-SYB50 only)

Using the FF-SYB14, FF-SYB30 or FF-SYB50 light curtains below the specified minimum scanning range will maintain the light

curtain in a lock out condition. To go back to normal conditions of operations, switch the power off, move away the receiver from

the emitter, then restore the power.

Failure to comply with these instructions could result in death or serious injury.

! WARNING

2

IMPROPER MINIMUM SCANNING RANGE (FF-SYB234 only)

Always install the FF-SYB234 multibeam systems at a distance superior to the minimum value of the selected scanning range or select

a lower scanning range on the emitter. When installed at a distance below the specified minimum scanning range, the FF-SYB234

multibeam systems for access detection may NOT comply with IEC/EN 61496-2 optical requirements for aperture angle.

Failure to comply with these instructions could result in death or serious injury.

See chapter "Configuration cards" for scanning range settings.

2.4.7 MANUAL RESTART

The FF-SYB can be used in automatic or manual restart mode. In automatic mode, the outputs will switch back to ON after an

interruption of the protection field, as soon as the field becomes clear again. In manual restart mode, the FF-SYB will not switch

back its outputs to ON until a manual restart push-button is pressed and reset. The push-button must be a normally open type

button. The manual restart will not switch the OSSDs back to ON in case of light curtain lock out (internal failure, light interference,

etc.) or when the protection field is interrupted.

This feature is enabled by selecting the corresponding configuration card.

2.4.8 EXTERNAL DEVICE MONITORING (EDM)

The FF-SYB is fitted with an EDM input which allows users to check the correct state of the final switching devices (relays, contactors,

etc.). After each intrusion into the protection field, the FF-SYB will check that the EDM input loop is closed before switching the

outputs back to ON. If the FF-SYB operates in automatic restart mode, it will restart immediately if the EDM loop is closed. If the

FF-SYB operates in manual restart mode, it will restart when the restart push-button is pressed and if the EDM loop is closed. If the

EDM loop remains open (meaning that the external device has a malfunction) the FF-SYB will keep its outputs open and will not

restart.

2.4.9 MUTING FUNCTION

Muting is the ability to temporarily inhibit the outputs of a light curtain under certain conditions. The FF-SYB is fitted with a built-in

muting function. Sensors are connected to the light curtain through the main connector, optional junction boxes are available to

perform the electrical connections close to the location of the muting sensors.

Muting sensors are used to discriminate authorised materials from people. The muting sensors must be able to detect the passing

material (pallets, vehicles, etc.) according to the material's length and speed.

The muting activation sensors temporarily inhibit the safety light curtain if a package is detected by the sensors. The outputs of

these sensors are connected to the muting inputs of the receiver unit of the FF-SYB. Muting sensors must be actuated within a time

period of 3 s for a correct muting sequence to start.

! DANGER

MECHANICAL POWER PRESS OPERATING IN REVERSE MODE

• The Honeywell muting function shall only be used during non-hazardous portion of the mechanical power press cycle, i.e.

during die opening when the press is running forward (crankshaft is running clockwise).

• If it is foreseeable that the press may be run in reverse or the press crankshaft rotation direction changed, even accidentally,

DO NOT install the Honeywell muting system on the press.

• The muting function provided by the Honeywell product DOES NOT recognize the crankshaft rotation direction (clockwise or

counterclockwise). If muting is installed to operate during the upstroke when running forward (clockwise), then muting should

not occur during the downstroke when running reverse (counterclockwise). Muting is ONLY permitted during the upstroke (die

opening portion of the cycle).

Failure to comply with these instructions will result in death or serious injury.

In case of an incorrect muting sequence, a temporary manual muting procedure may be performed to clear the FF-SYB light

curtain detection field and revert back to normal operation (see chapter "Temporary Manual Muting function (TMM)" for details).

14

107120-20-EN FR26 GLO 804 Printed in France

2.4.10 SERIAL CONNECTION

The FF-SYB safety light curtain allows the connection of an auxiliary safety device with dual outputs through 2 inputs on the

receiver unit. Connection is done through the main connectors. Optional junction boxes are available to perform the electrical

connections close to the light curtain.

NOTICE

The auxiliary safety device may be an electromechanical safety switch or any other safety device with either relay outputs or solid

state outputs. For safety reasons, reversed polarity on these two inputs is mandatory, therefore connection of a second FF-SYB

light curtain is not possible through these two inputs.

In this mode, the FF-SYB expects both outputs of the connected sensor to be ON in order to turn on its outputs. If one or both

outputs of the connected safety sensor go off, the FF-SYB will switch off its outputs within 22 ms.

Figure 2-8 Serial connection of an FF-SYB234 safety light curtain with a safety gate switch

Mechanical fences

Safety

switch

FSYB8

Door

FF-SYB Safety light curtain

Figure 2-9 Serial connection of an FF-SYB safety light curtain with a safety mat

FSYB10

FF-SYB

Safety

light curtain

Safety

mat

107120-20-EN FR26 GLO 804 Printed in France

15

2

2.4.11 CONFIGURATION CARDS

The FF-SYB is set in the required configuration through the use of configuration cards. This simple and elegant method eliminates

the use of jumpers or dip switches. No computer is required: settings are done on site, using one of the small configuration cards.

If the user needs to use a different configuration from the factory settings, he just needs to select the configuration card which

corresponds to the desired settings and install it behind the bottom cap of the emitter or receiver.

If the FF-SYB needs to be exchanged, the configuration card can be installed in another FF-SYB allowing transfer of settings in a

few minutes.

! WARNING

NOTICE

Remove power before changing cards (otherwise the light curtain remains in a lock-out condition after changing card).

Activities detected on inputs that are not configured by the selected configuration card, will set the FF-SYB light curtain into a

lock-out condition. Remove power, insert the proper configuration card and restore power to return to normal operation.

• Emitter configuration card selection

FSYB9

2

TESTS AND CONTROLS

Always perform tests and controls listed in the "wiring diagram and installation controls" after any installation modification.

Failure to comply with these instructions could result in death or serious injury.

Factory setting

Card number (1)

#101

#102

#103

#104

#105

#106

(1)

(2)

Card code (1)

23 % NO

50 % NO

100 % NO

23 % NC

50 % NC

100 % NC

Scanning range (2)

Minimum

Medium

Maximum

Minimum

Medium

Maximum

Test contact

Normally Open

Normally Open

Normally Open

Normally Closed

Normally Closed

Normally Closed

Factory setting: card #102 (code «50 % NO»)

Scanning ranges

Model

FF-SYB14

FF-SYB30 /

FF-SYB50

FF-SYB02 / FF-SYB03 / FF-SYB04 standard range

FF-SYB02 / FF-SYB03 / FF-SYB04 long range

16

Minimum (23 %)

0 m to 1,4 m /

0 ft to 4.59 ft

0 m to 4,6 m /

0 ft to 15.1 ft

0 m to 7 m /

0 ft to 23.0 ft

5 m to 18 m /

16.4 ft to 59.1 ft

Medium (50 %)

1 m to 3 m /

3.3 ft to 9.8 ft

2 m to 10 m /

6.6 ft to 32.8 ft

4 m to 15 m /

13.1 ft to 49.2 ft

15 m to 40 m /

49.2 ft to 131.2 ft

Maximum (100 %)

2 m to 6 m /

6.6 ft to 19.7 ft

5 m to 20 m /

16.4 ft to 65.6 ft

10 m to 30 m /

32.8 ft to 98.4 ft

35 m to 80 m /

114.8 ft to 262.5 ft

107120-20-EN FR26 GLO 804 Printed in France

• Receiver configuration card selection

FSYB11

2

Factory setting

107120-20-EN FR26 GLO 804 Printed in France

17

Card number (1)

2

(1)

(2)

(3)

(4)

Card code (1)

Restart mode

Muting

(2)

Auxiliary Safety

Device

#01

#02

M O NB P

M O 1B P

Manual

Manual

Auxiliary

output (3)

NC signal

NC signal

#03

#04

#05

#06

#07

#08

#09

#10

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

#21

#22

#23

#24

#25

#26

#27

#28

M O 2B P

A O NB P

A O 1B P

A O 2B P

A S O NB P

A S O 1B P

A S O 2B P

M S O NB P

A M2 O NB P

A M2 L NB P

A M4 O NB P

A M4 L NB P

A M2+S O NB P

A M2+S L NB P

M M2 O NB P

M M2 L NB P

M M4 O NB P

M M4 L NB P

M M2+S O NB P

M M2+S L NB P

M M2 L 1B P

M M2 L 2B P

M M4 L 1B P

M M4 L 2B P

M M2+S L 1B P

M M2+S L 2B P

Manual

Automatic

Automatic

Automatic

Automatic

Automatic

Automatic

Manual

Automatic

Automatic

Automatic

Automatic

Automatic

Automatic

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

NC signal

NC signal

NC signal

NC signal

NC signal

NC signal

NC signal

NC signal

NC signal

Muting lamp

NC signal

Muting lamp

NC signal

Muting lamp

NC signal

Muting lamp

NC signal

Muting lamp

NC signal

Muting lamp

Muting lamp

Muting lamp

Muting lamp

Muting lamp

Muting lamp

Muting lamp

yes

yes

yes

yes

2 inputs

2 inputs

4 inputs

4 inputs

2 inputs

2 inputs

2 inputs

2 inputs

4 inputs

4 inputs

2 inputs

2 inputs

2 inputs

2 inputs

4 inputs

4 inputs

2 inputs

2 inputs

yes

yes

yes

yes

yes

yes

1-beam

2-beam

1-beam

2-beam

1-beam

2-beam

1-beam

2-beam

1-beam

2-beam

1-beam

2-beam

(4)

Receiver

Termination

M12 plug

M12 plug

(5)

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

M12 plug

Terminal strip

Terminal strip

Terminal strip

Terminal strip

M12 plug

M12 plug

Terminal strip

Terminal strip

Terminal strip

Terminal strip

M12 plug

M12 plug

Terminal strip

Terminal strip

Terminal strip

Terminal strip

Factory setting: card #01 (code «M O NB P»)

Muting: either 2 inputs available for the connection of 2 or 4 muting sensors to perform a bi-directional muting function, or 4 inputs available for

the connection of 4 sensors to perform a uni-directional muting function.

Auxiliary output: either a Normally Closed signalling output or a muting and diagnosis lamp output.

Floating blanking:

1-beam

Model

FF-SYB14

FF-SYB30

FF-SYB50

(5)

Blanking

Resolution

24 mm / 0.94 in

50 mm / 1.97 in

90 mm / 3.54 in

2-beam

Undetected

object size

6 mm / 0.23 in

10 mm / 0.39 in

30 mm / 1.18 in

Resolution

34 mm / 1.33 in

70 mm / 2.75 in

130 mm / 5.12 in

Undetected

object size

16 mm / 0.63 in

30 mm / 1.18 in

70 mm / 2.75 in

Floating blanking is available with the 4-beam FF-SYB04 model only.

Receiver termination: some modes require direct connections to the internal receiver terminal strip. A M20 cable gland is delivered with the

package. Male M23/12 pole cord sets are available on option.

NOTICE

SERIAL MODE

The EDM/Restart input shall be connected to the 0 Vdc when an auxiliary safety device is connected to the FF-SYB serial inputs.

For any other modes, connect the EDM/Restart input to the +24 Vdc.

NOTICE

MUTING MODES

• The selection of the muting/diagnosis output is recommended when the Temporary Manual Muting (TMM) is required.

• Use of the uni-directional muting requires to change the M12 connector with the M20 cable gland.

NOTICE

COMBINED MODES

• The EDM/Restart input shall be connected to the 0 Vdc when an auxiliary safety device is connected to the FF-SYB serial

inputs. For any other modes, connect the EDM/Restart input to the +24 Vdc.

• The selection of the muting/diagnosis output is recommended when the Temporary Manual Muting (TMM) is required.

• Use of the combined modes requires to change the M12 connector with the M20 cable gland.

18

107120-20-EN FR26 GLO 804 Printed in France

How to program operation modes

If you need a different configuration card than card # 01 ( "M O NB P"

code, factory setting) for the receiver, or card #102 ("50% NO"

code, factory setting) for the emitter, follow the following steps to

change configuration cards:

Ensure the following tools are available:

• A cross point screwdriver (Pz #1)

• A flat-head screwdriver (2 mm / 1/10 in width).

1&4

1. Remove the bottom end cap (use a cross point screwdriver to

unscrew cover).

2

2. Hook up the card hole with a flat head screw driver (the hole is

located on the right hand side, at the bottom of the card), pull

out the configuration card in place.

3. Select the configuration card needed for the application (See

above configuration card selection guide), and insert it into the

slot with inscriptions upward.

2

4. Screw the end cap tight.

3

5. When the whole installation is completed, perform the tests &

controls listed in the "Wiring diagram and installation controls"

chapter.

! WARNING

IF THE RECEIVER UNIT NEEDS TO BE CHANGED

• Check the card code through the clear window located at the bottom of the unit installed on the machine first, then program the

new unit following the above mentioned procedure.

• Always perform tests & controls listed in the "wiring diagram and installation controls", after any installation modification.

Failure to comply with these instructions could result in death or serious injury.

2.5 INDICATORS

The FF-SYB Series emitters have five LED indicators. The receivers have eight LED indicators. These LED indicators provide

important information related to the light curtain status.

Figure 2-11 Emitter Indicators

R1

R2

R3

Scanning range indicators (yellow)

Alarm indicator (red)

test

Test indicator (red)

50% NO

FSYB17

alarm

R1

yellow

yellow

yellow

Maximum scanning range

R3

R2

R1

yellow

yellow

yellow

Medium scanning range

(factory setting)

R3

R2

R1

yellow

yellow

yellow

FSYB20

R2

FSYB19

R3

FSYB18

2.5.1 SCANNING RANGE INDICATORS (EMITTER)

Minimum scanning range

The emitter is equipped with a scanning range selector for the control of the infrared emission power. The scanning range indicators

are 3 yellow indicators which give an information on the selected scanning range. If R1, R2 and R3 are all OFF, the configuration

card is missing. See chapter "Scanning Ranges" for further information.

Normal operation

Red

Alarm

Emitter failure

FSYB22

Alarm

FSYB21

2.5.2 ALARM INDICATOR (EMITTER)

Red

The alarm indicator is a red LED that flashes if the emitter is detecting an emission problem. The receiver is in an alarm state and

the emitter needs to be changed for correct operation. If this LED is off while the receiver is in an alarm state despite the sensing

field is clear, then the receiver may be suspected. If the alarm indicator is permanently ON, the configuration card is missing.

107120-20-EN FR26 GLO 804 Printed in France

19

Normal operation

Red

Test

FSYB21

Test

Test mode

FSYB23

2.5.3 TEST INDICATOR (EMITTER)

Red

The test contact allows verification of external safety-related electromechanical components before each machine cycle. When the

contact in the external test circuit is actuated, the FF-SYB Series light curtain safety outputs switch off. The red test indicator of the

FF-SYB emitter turns on and the static (solid state) safety outputs of the FF-SYB receiver remain open while the test contact is

actuated.

The customer is responsible for providing the external test circuitry (See chapter "Electrical Connections").

Figure 2-10 Receiver Indicators

OFF

ON

restart muting

No blanking

1 blanking

2 blanking

FSYB24

MM20MBP

2.5.4 OPERATION INDICATORS (RECEIVER)

OFF

Red

Green

Outputs are closed

ON

FSYB26

ON

FSYB25

OFF

Red

Green

Outputs are open

The operation indicators are two green and red LED indicators that provide output status. The green LED indicates the receiver

operates normally and the sensing field is clear. This indicator must be on to ensure the equipment is working properly (the red

LED will be off). The red LED indicates that the light curtain outputs are off. If the sensing field is interrupted, the FF-SYB Series

light curtain will immediately generate a stop signal. In this condition, the green LED will be off.

Orange

Optimum signal

FSYB28

FSYB29

2.5.5 SIGNAL STRENGTH INDICATOR (RECEIVER)

FSYB27

2

Orange

Low signal

Orange

No signal

The signal strength indicator is an orange indicator which flashes repeatedly if the received light level is lower than the normal

operating level, but is still sufficient for operation. If the received light level drops too low, the light curtain outputs switch off and

generate a stop signal. To prevent unnecessary shutdowns, this indicator will signal the need for cleaning and/or alignment. This

indicator also provides useful indication for beam alignment during the installation step.

20

107120-20-EN FR26 GLO 804 Printed in France

Cross-talk detection

FSYB30

No cross- talk

Red

FSYB31

2.5.6 CROSS-TALK INDICATOR (RECEIVER)

Red

The cross-talk indicator is a red LED which lit on if the receiver receives two different signals from two different emitters. In this

case, the light curtain is maintained in a lock-out condition. This LED helps identify cross-talk between light curtains. For correct

operation this LED shall be off. To go back to normal operation, switch the power off and eliminate the interferences by reversing

systems emitting orientation, or by using opaque screens, or by adjusting the adequate emission power regarding the application

(see chapter "Mutual Interference or cross-talk").

2.5.7 RESTART INDICATOR (RECEIVER)

Restart

Restart

Yellow

Manual restart expected

Yellow

Wiring error or auxiliary safety device engaged

The restart indicator is a yellow LED which flickers when the FF-SYB is expecting a restart command after an interruption of the

protection field as soon as the protection field is made free again. It will be ON if the Auxiliary Safety Device is engaged or in case

of incorrect wiring.

2.5.8 MUTING DIAGNOSIS INDICATOR

Muting/diagnosis

Muting/diagnosis

Muting/diagnosis

Orange

No muting

Orange

Problem in muting sequence

or wiring error

Orange

Muting in progress

The muting indicator is an orange indicator which is ON when a valid muting sequence is in progress (meaning that the muting

sensors have been actuated with the correct sequence). It is OFF when the FF-SYB operates in normal (or guard) mode. It will

flicker if a wrong muting sequence is detected. When the muting/diagnosis LED flickers while the restart LED is ON, the FF-SYB

has detected an incorrect wiring on its inputs.

2.5.9 FLOATING BLANKING INDICATORS

Blanking off

Floating blanking

1 beam

Floating blanking

2 beams

The floating blanking indicators are 2 yellow LED which are ON when operation without floating blanking is selected (default

configuration). The left indicator is ON and the right indicator is OFF when 1 beam floating blanking is selected. The right indicator

is OFF and the left indicator is ON when 2 beams floating blanking is selected.

2.5.10

EXTERNAL INDICATOR

The FF-SYB provides one additional output which function can either be a normally closed signalling contact or a muting lamp/

diagnosis output, depending on the light curtain set up. When an indicator is connected to this output, it displays the same information as the muting/diagnosis embedded indicator.

! WARNING

STATUS OUTPUT NOT SUITABLE FOR SAFETY USE

• DO NOT use the status output for personnel protection. It cannot be used to stop the machinery.

• Use the safety outputs for personnel protection.

Failure to comply with these instructions could result in death or serious injury.

107120-20-EN FR26 GLO 804 Printed in France

21

2

2.6 SPECIFICATIONS

OPERATING CHARACTERISTICS

Nominal Scanning Range

FF-SYB14

FF-SYB30/FF-SYB50

FF-SYB02/FF-SYB03/

FF-SYB04 standard range

FF-SYB02/FF-SYB03/

FF-SYB04 long range

2

Protection Height

Object detection size

Minimal object

detection size

Beam spacing

FF-SYB14

FF-SYB30

FF-SYB50

FF-SYB02500

FF-SYB03400

FF-SYB04300

FF-SYB02500

FF-SYB03400

FF-SYB04300

Minimum: 23%

0 m to 1,4 m/

0 ft to 4.6 ft

0 m to 4,6 m/

0 ft to 15.1 ft

0 m to 7 m/

0 ft to 23.0 ft

Medium: 50%

1 m to 3 m/

3.3 ft to 9.8 ft

2 m to 10 m/

6.6 ft to 32.8 ft

4 m to 15 m/

13.1 ft to 49.2 ft

Maximum: 100%

2 m to 6 m/

6.6 ft to 19.7 ft

5 m to 20 m/

16.4 ft to 65.6 ft

10 m to 30 m/

32.8 ft to 98.4 ft

5 m to 18 m/

16.4 ft to 59.1 ft

15 m to 40 m/

49.2 ft to 131.2 ft

35 m to 80 m/

114.8 ft to 262.5 ft

320 mm to 1760 mm / 12.60 in to 69.34 in

No blanking

1beam

14 mm / 0.55 in

24 mm / 0.94 in

30 mm / 1.18 in

50 mm / 1.97 in

50 mm / 1.97 in

90 mm / 3.54 in

2beam

34 mm / 1.33 in

70 mm / 1.75 in

130 mm / 5.12 in

50 mm / 1.97 in

500 mm / 19.7 in (body detection)

400 mm / 15.76 in (body detection)

300 mm / 11.82 in (body detection)

± 2° ± 25 %

Infrared, pulsed, 880 nm

20 000 Lux

15 000 Lux

Angle of Divergence

Emitting Light Source

Immunity to Ambient Light sunlight

lamplight

ELECTRICAL CHARACTERISTICS

Supply voltage

24 Vdc (±15%) for the emitter and the receiver

Power consumption

5 W max. for the emitter, 5 W max. for the receiver

Safety outputs (OSSDs)

Output type

2 safety static (solid state) outputs (PNP with Normally Open characteristics) with permanent

short-circuit and cross-fault detections

Switching capability

350 mA max. at 24 Vdc

Response time (beam interruption) 22 ms (28 ms max. for model numbers FF-SYB14128 to FF-SYB14176)

Response time (ASD engaged)

28 ms

Restart time after power up

> 1 s (automatic mode)

Restart time after beam release

80 ms (without EDM), 150 ms (with EDM)

Response to the test

50 ms

Leakage current

0,25 mA

Loads impedance

70 Ω min. / 5 kΩ max.

Voltage drop

< 2 Vdc

Loads turn-on voltage

5 V min. on resistive loads / 7 V min. on inductive loads

Test pulse width / recurrence

2 pulses (width 200 µs and 75 µs), separated by 500 µs, frequency from 5 ms to 10 ms

(depending on height)

Protections

Short-circuits and cross-faults, overloads (0,4 A max. / 0 Vdc; 0,9 A max. / 24 Vdc),

reversed polarity, micro-cut-off 10 ms (100 % voltage breakdown, 10 Hz)

Max. cable length

100 m / 328.08 ft (capacitance: 100 nF)

Auxiliary and muting lamp/diagnosis output

Output type

1 PNP non safety output, normally closed (signalling contact)

or normally open (muting/diagnostic indication)

Switching capability

100 mA max. at 24 Vdc (see chapter "Muting lamp/diagnosis output")

Protections

overloads, reversed polarity, micro-cut-off (10 ms)

Test input (emitter)

Input type

Floating input with selectable NO/NC test logic (see "Test input" chapter)

External contact type

Relay contact, or static (solid state) PNP or static (solid state) NPN

(must be activated for at least 20 ms)

Voltage switching thresholds

(High/Low)

11 Vdc min (I > 6 mA) / 5 Vdc (I > 2 mA) (IEC 61131-2)

Test loop current

13 mA typical

Test loop resistance

750 Ω max.

Protections

3000 Vdc galvanic insulation, reversed polarity, micro-cut-off (14 ms)

22

107120-20-EN FR26 GLO 804 Printed in France

Restart / EDM input

External contact type

Relay contact (must be activated for at least 150 ms filtering time but less than 3 s)

Voltage switching thresholds

(High/Low)

14,5 Vdc min. / 4,5 Vdc (comply with IEC 61131-2, for type 2 sensors)

Input current (high/low)

20 mA / 10 mA at 24 Vdc

Max. voltage

29 Vdc

Muting or serial connection inputs

External contact type

Relay contact, or static (solid state) PNP or static (solid state) NPN (automatic recognition - no

push-pull output allowed)

Timing conditions

3 s between SM1/SM2 and serial

Filtering time

Muting/serial : 25 ms

Voltage switching thresholds

(High/Low)

14,5 Vdc min. / 4,5 Vdc (comply with IEC 61131-2, for type 2 sensors)

Input current and impedance

20 mA / 10 mA at 24 Vdc, 20 Ω

Max. voltage

29 Vdc

Max. cable length

100 m / 328.08 ft (no limitation in capacitance)

ENVIRONMENTAL/PHYSICAL CHARACTERISTICS

Operating Temperature Range 0 °C to 55 °C (32 °F to 131 °F)

Relative humidity

95 %

Storage Temperature Range

-20 °C to 75 °C (-4 °F to 167 °F)

Sealing

NEMA 4, 13, and IP 65

Vibrations

IEC/EN 61496-1: 10 to 55 Hz frequency range, 1 octave/ min.sweep rate, 0,35 mm

±0,05 amplitude, 20 sweeps per axis, for 3 axes

Shocks

IEC/EN 61496-1 - 15 G - 11 ms - 3 per axis, for 3 axes

Bumps

IEC/EN 61496-1: 10 G - 16 ms - 1000 per axis, for 3 axes

Housing Dimension

Width, 42 mm (1.65 in); Depth, 55 mm (2.16 in); Height**

Connection

Emitter: M12/5 pole male receptacleReceiver: M12/8 pole male receptacle or

terminal strip with M20 cable gland

Material

Housing

Aluminium Alloy and (conductive )polycarbonate (end caps)

Front Plate

Polymethylmethacrylate (PMMA)

Weight per device 1 kg to 4,8 kg (2.20 lbs to 10.56 lbs)***

**Refer to the Unit Height Table for individual unit heights.

***Refer to Emitter and Receiver dimensions / weights.

107120-20-EN FR26 GLO 804 Printed in France

23

2

3.

INSTALLATION

3.1 OVERVIEW

This chapter contains information about calculating the safety distance and properly mounting a safety light curtain. Mirror information is also provided.

! DANGER

FULL REVOLUTION MECHANICAL POWER PRESSES CANNOT BE STOPPED IN MID-STROKE (OSHA 29CFR 1910.217)

DO NOT use FF-SYB Series light curtains on full revolution mechanical power presses.

Failure to comply with these instructions will result in death or serious injury.

! DANGER

MECHANICAL POWER PRESS OPERATING IN REVERSE MODE

• The Honeywell muting function shall only be used during non-hazardous portion of the mechanical power press cycle, i.e.

during die opening when the press is running forward (crankshaft is running clockwise).

3

• If it is foreseeable that the press may be run in reverse or the press crankshaft rotation direction changed, even accidentally,

DO NOT install the Honeywell muting system on the press.

• The muting function provided by the Honeywell product DOES NOT recognize the crankshaft rotation direction (clockwise or

counterclockwise). If muting is installed to operate during the upstroke when running forward (clockwise), then muting should

not occur during the downstroke when running reverse (counterclockwise). Muting is ONLY permitted during the upstroke (die

opening portion of the cycle).

Failure to comply with these instructions will result in death or serious injury.

! WARNING

IMPROPER INSTALLATION OF FF-SYB SERIES LIGHT CURTAIN

• Install FF-SYB Light Curtains in accordance with this installation manual and applicable local safety regulations (OSHA, ANSI,

European standards).