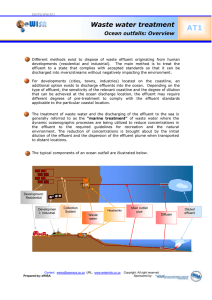

Practical Experience from the Treatment of Gaswork Site

advertisement