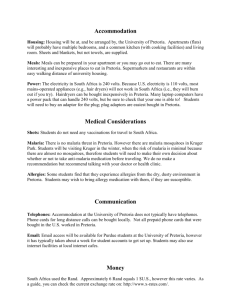

View/Open - University of Pretoria

advertisement