August 2008

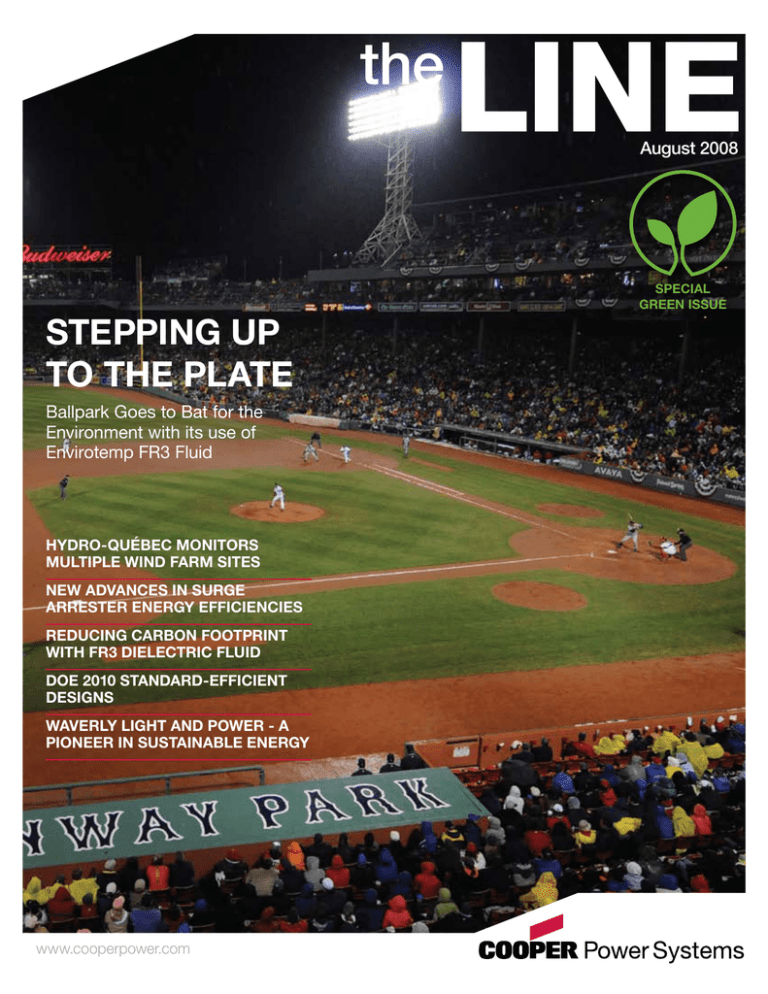

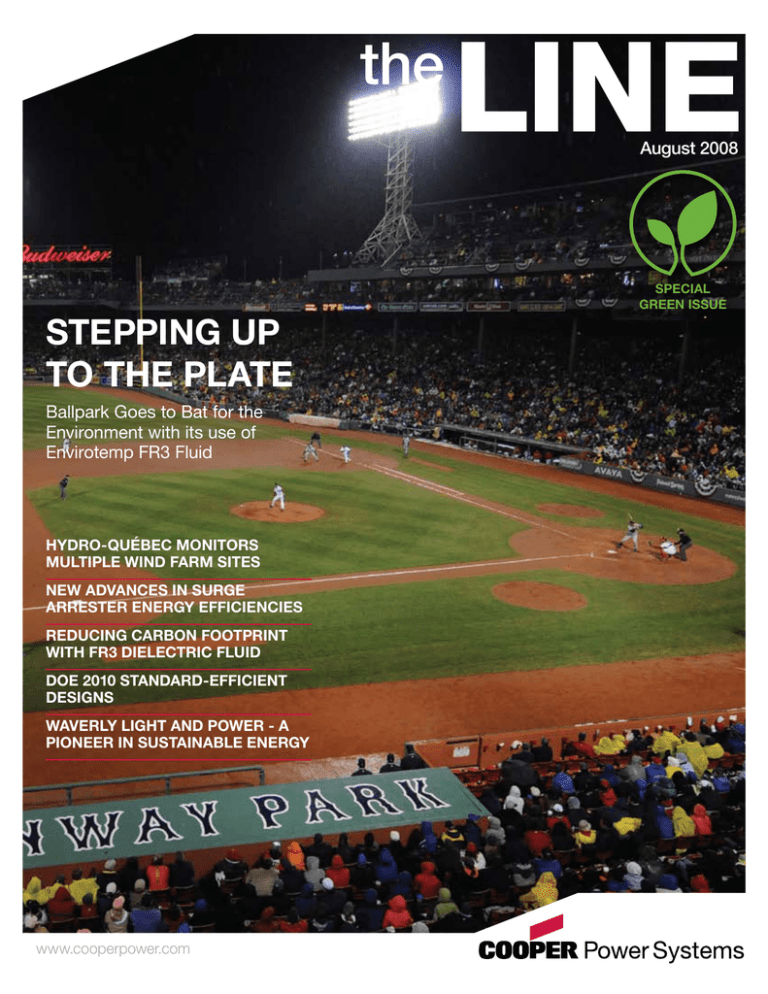

Stepping up

to the Plate

Ballpark Goes to Bat for the

Environment with its use of

Envirotemp FR3 Fluid

Hydro-Québec Monitors

multiple wind farm sites

New Advances in Surge

arrester Energy efficiencies

Reducing carbon Footprint

with FR3 Dielectric Fluid

DOE 2010 Standard-Efficient

Designs

Waverly Light and Power - a

Pioneer in Sustainable Energy

www.cooperpower.com

SPECIAL

GREEN ISSUE

Published by Cooper Power Systems Editorial Board

Editor in Chief, Jerry Yakel, Director, Worldwide Strategy, Pricing

and Communications

Executive Editor, Steve Weinstein

Editor, Kristine Kucera

Technical Editor, Arvind Chaudhary, Staff Engineer, Energy

Automation Solutions

August 2008

1

Jeff Romig, Vice President, Marketing

Steve Benna, Vice President, Sales and Marketing,

C&I and OEM

Lawrence Coble, Vice President & General Manager,

Energy Automation Solutions

Power Quality and Equipment

Monitoring in distributed generation

of multiple wind farm sites for

Hydro-QuÉbec

Donald Dutoit, Vice President, North American Sales

3

Contributing Authors:

Stepping up to the plate: Ballpark

Goes to Bat for the Environment

with its use of Envirotemp FR3 Fluid

5

Technology Advances in Surge

Arresters Improve Reliability and

Energy Efficiencies

7

José Ángel Martinez, Vice President & General Manager,

Latin America

Richard Rocamora, Vice President & General Manager, Asia Pacific

David Bingenheimer

Glenn Cannon

Phil Holt

Patrick McShane

Michelle Meyer

Robert O’Reilly

Michael Ramarge

Michael Skowronek

Mario Vandal

Martin Boulay

Ken Easterday

Jim Kozak

Dan Merilatt

David Mullally

Charles Parsons

Connie Schnick

James Strong

Address questions, inquiries and letters to:

Kristine Kucera

Cooper Power Systems

11131 Adams Road

Franksville, WI 53126

P: 262.835.1538

F: 262.835.1544

kristine.kucera@cooperindustries.com

FR3 Fluid Provides Sustainable

Alternative for Reducing Carbon

Footprint

Change of Address? Please email any name or address updates to

lois.gerard@cooperindustries.com

10

Photocopy permission: Photocopy permission extended to single

copy only. Permission for all other reprints must be obtained from

The Line editor.

Positive Regulations and Standards

Developments for Natural Ester

Dielectric Fluids

11

Demand Response: A Good Thing for

Everybody

13

Cooper Provides Utilities DOE 2010

Standard-Efficient Designs

15

The Winds of Change:

Waverly Light and Power - a Pioneer

in Sustainable Energy

cooperpower.com

Design and Layout, James Hart

Previous issues of The Line are available on the

Cooper Power Systems web site: www.cooperpower.com

©2008 Cooper US, Inc., or its affiliates.

All Rights Reserved.

Envirotemp, Envirotran, Evolution, FR3, R-Temp, and UltraSIL are valuable

trademarks of Cooper US, Inc. in the United States and other countries. You are

not permitted to use the Cooper trademarks without prior written consent of

Cooper US, Inc.

Yukon is a registered trademark of Cannon Technologies.

Alliant Energy is a trademark of Alliant Energy.

BEES is a registered trademark of the National Institute of Standards and

Technology.

ComEd is a registered trademark of Exelon Corporation.

Federal BioPreferred ProgramSM is a service mark of the U.S. Department of

Agriculture (USDA).

FM Global is a trademark of Factory Mutual Insurance Company.

IEEE C62.11™-2005 Standard is a trademark of the Institute of Electrical and

Electronics Engineers, Inc., (IEEE). This product is not endorsed or approved

by the IEEE.

IEEE® is a registered trademark of the Institute of Electrical and Electronics

Engineers, Inc., (IEEE). This publication is not endorsed or approved by the

IEEE.

Hydro-Québec is a crown corporation of the Québec government.

National Electric Code and NEC are registered trademarks of the National

Fire Protection Association.

UL is a registered trademark of Underwriters Laboratories, Inc.

Waverly Light and Power, and Waverly Light and Power Iowa Energy Tags

are a trademarks of Waverly Light and Power.

Xcel Energy is a trademark of Xcel Energy, Inc.

Power Quality and Equipment Monitoring in Distributed

Generation of Multiple Wind Farm Sites for Hydro-Québec

Mario Vandal, Eng., Project Manager, DPPTC, HQE, Hydro-Québec;

Robert O’ Reilly, Senior Application Engineer – Cybectec, Cooper Power Systems, Energy Automation Solutions;

Martin Boulay, Eng., Automation Engineer, The Ohmega Group Inc.

For a number of years now, HydroQuébec has been working with private

producers to implement sizeable

wind farm generating sites. Currently,

Hydro-Québec has 1,400 MW of wind

generation either on-line or coming online by 2012 at the latest. Also, within

the next few months of 2008, HydroQuébec will be signing with private

producers for an additional 2,000 MW

to come from renewable energy—in this

case, from wind farms. With all of this

renewable and private power generation,

Hydro-Québec developed new tools and

new approaches in the management

and modeling of these non-continuous

generating sites. Because the wind sector

will soon represent an appreciable portion

of their distributed power, Hydro-Québec

required better visibility on the private

wind production sites and an increase in

the quantity of data coming from the field

in their prediction model of production.

Connecting a wind site to the power

network requires many complex realtime or semi-real-time calculations. Wind

conditions are always changing and

production must be balanced by alternate

sources if the wind falls. Implementing

these calculations at a control center uses

up a lot of communications bandwidth

and is a challenge to implement in real-

time; therefore, while there are many

advantages in performing the calculations

locally, there was no obvious way to do

this. To implement their requirements—

after having tested the limits of the

SCADA systems that were already in

place in the few wind farm projects

that were under operation—the private

producers decided to turn to the use

of advanced intelligent Cybectec SMP

Gateways to perform the required data

calculations and data transfers necessary

for their operations and meeting HydroQuebec requirements.

Advanced Intelligent Data

Acquisition

This article presents the results

of the implementation of advanced

intelligent data acquisition solutions to

perform specific computations on the

power, the wind, and the turbine status

information. These calculations include

specific algorithms and statistical and

real-time computations to provide

valuable information on the operation and

prediction of wind farms.

Hydro-Québec developed a list

of requirements and criteria for the

treatment and the transfer of the data

coming from the turbine manufacturer’s

SCADA, the substation SCADA, and

the meteorological towers. These

requirements cover several points such

as the identification of the required

information of each group of data, the

sampling rates, the time latency of each

type of data to be received, the protocol

configuration, the specific algorithms of

some calculations, and the type of data

(statistical, resolution, sign), as well as the

quality information of this data.

This specific situation consists of

distributed generation from wind farm

sites—each containing an average of

70 generating turbines of 1.5 MW—for

a typical 100 MW generating capacity

per site. The principal goal was to

centralize all the information coming from

the different systems on the sites into

the Cybectec SMP Gateways and then

apply some calculations and send the

required information to Hydro-Québec’s

control center. This information contains

some specific algorithms of calculation

required to be performed on the raw

data that was available from the turbines

before being sent to Hydro-Québec

in the required format. The production

information had to be correlated to the

number of available turbines as well as to

the wind characteristics. All this important

information on wind, production, and

turbine status data could then be used

by the private producers for real-time

evaluation as well as for short- and longterm planning of the generating facilities’

operations and maintenance.

THE LINE – August 2008

1

By using Cybectec SMP Gateways to centralize the collection of important information on wind, production, and

turbine status, this data could then be used by the private producers for real-time evaluation as well as for short- and

long-term planning of the generating facilities’ operations and maintenance.

In addition, Hydro-Québec required all the

real-time information on the status of the

sites’ substations. They also required that

the production information be available

for the private producers’ remote control

centers as well as to their operating

personnel, working on-site or, in some

cases, remotely.

One of Hydro-Québec’s objectives was

to reduce the uncertainty related to the

planning of the production from the other

generating assets. This objective was

achieved with the use of the Cybectec

SMP Gateways via the higher quality of

information about the sites’ availability

for production. This approach has also

enabled securing the sites per cybersecurity standards while providing the

required real-time information for the

operations of the sites. This last feature

was a requirement for both the private

producers and Hydro-Québec, who are

sharing the equipment via two accesses.

It is well understood that for statistical

computations to be meaningful an

important volume of sample data is

required. Data quality must be monitored,

taking into account the possibility of

questionable data (unfit to use in statistical

computations). If not identified, the impact

of incorrect data could invalidate a whole

sampling period. Also important is the

capability to process the information

in a timely fashion—ideally in real time

for Hydro-Québec’s implementation.

2

cooperpower.com

They required sampling of the data at a

200 ms rate to be used in the statistical

calculations based on a 10-minute period.

As mentioned earlier, HydroQuébec also developed criteria for

the required information coming from

the statistical data. First is the wind

direction information—which is of

primary importance in wind farm power

generation. Also, due to the northern

climate, the temperature with the

indication of ice buildup is also of primary

importance for operation of the turbines.

Cybectec SMP Gateway

Benefits

Since the application was implemented

using a commercially available

communication Cybectec SMP Gateway,

this allowed a number of direct and

indirect benefits—such as use of the

available communication bandwidth—to

provide critical information both at the

remote control centers and locally at the

generating sites.

With the implementation of a scalable

environment, these concepts can

now also be used in other sectors of

distributed generation such as hydro,

wind, or other types of power production.

This allows facility owners to centralize

their data, transform it into the most

valuable format or equation to derive a

maximum of benefits, and make the sum

of all this information the most useful

for them. The Cybectec SMP Gateway

provides a toolbox to understand the

detailed relationships between the

different types of information available

from all these systems—relating them

to the power production and its overall

quality. The Cybectec SMP Gateway is

designed to process and concentrate

data at the substation level. Acting as

a data concentrator, it ties in all the

data sources and can easily be used to

perform complex real-time or semi-realtime calculations locally—freeing up both

time and resources. n

Stepping up to the plate: Ballpark Goes to Bat for the

Environment with its use of Envirotemp FR3 Fluid

Connie Schnick, Marketing Communication Specialist – Cooper Power Systems;

David Mullally – R.M. Clark Associates, Inc.

In recent years, hospitality and major entertainment and

individual stadium light towers, were put in as standard stadium

sporting venues, like many industries, have increasingly been

upgrades to replace the stadium’s existing R-Temp transformers.

placed under the microscope regarding their environmental

The installation was the second round in a series of planned

impact on the cities and neighborhoods in which they inhabit.

replacements for all seven light-tower transformers at Fenway

Operations managers at these facilities have become highly

Park, with the initial installation completed in the winter of 2006.

cognizant of the myriad environmental implications of every

“The existing transformers that are responsible for

action associated with their stadiums’ daily operations, often

providing voltage to the lighting units at Fenway Park are in

searching for different ways to

excellent shape,” said Neal

improve energy efficiency and

Doherty, Granite City Electric.

“The upgrades to the new transformers

increase sustainability.

“The upgrades to the new

One recent trend that has

transformers are being

are being performed to keep Fenway at the

emerged with professional

performed to keep Fenway at

forefront of environmental stewardship.”

baseball stadiums is the use of

the forefront of environmental

Neal Doherty, Granite City Electric

liquid-filled transformers that

stewardship.”

employ Envirotemp FR3 fluid,

The new transformers will

a biodegradable, biobased

power the lights at Fenway

dielectric coolant that offers an improved environmental profile as

Park using an environmentally preferred alternative to the more

well as enhanced transformer performance over traditional units

traditional transformers of yesteryear. Filled with the revolutionary

insulated with mineral or synthetic oils.

Envirotemp FR3 fluid, the new transformers ensure a clean,

environmentally sustainable distribution of power.

Staying Ahead of the Game

This past winter, Boston’s historic Fenway Park reaffirmed its

place on the growing list of venues that have recently installed

liquid-filled transformers that utilize the Envirotemp FR3 fluid.

In February of 2008, Cooper Power Systems teamed with

Granite City Electric in Quincy, MA, to install a pair of Envirotran

transformers into the hallowed grounds at Fenway Park. The

new transformers, which provide operational voltage for two

FR3 Fluid Becoming a Fan Favorite

Envirotemp FR3 fluid is a unique dielectric coolant whose

base oils come from a renewable natural resource—seeds.

Specially formulated with performance-enhancing food-grade

additives, the essentially non-toxic, readily biodegradable

insulating fluid is changing the landscape in the commercial

power industry.

THE LINE – August 2008

3

“Envirotemp FR3 fluid is quickly

becoming a mainstream product, with

over 100,000 transformers utilizing the

ground-breaking biobased dielectric

coolant in service worldwide,” said Patrick

McShane, Global Technical Manager at

Cooper Power Systems. “In addition,

recent tests show that, due to the

CO2-absorbing qualities of the soybean

plants used to make the product, FR3

fluid actually produces a negative carbon

footprint. There is no question FR3 fluid is

truly an industry revolution in the making.”

The Complete Package

In addition to its positive environmental

attributes, FR3 fluid offers an exceptionally

high flash point of 330 °C (compared

to 145 °C for petroleum-based mineral

oil), making it considerably less of a fire

hazard. Plus, FR3 fluid is listed as a LessFlammable Dielectric Liquid by Factory

Mutual Insurance Company (FM Global®)

and Underwriters Laboratories (UL®)

for use in complying with the National

Electrical Code standards (NEC) and

insurance requirements.

These listings can qualify all Cooper

Power Systems Envirotran transformers

for installation indoors as well as on

pedestrian walkways, adjacent to

buildings, or even on rooftops, proof that

transformers filled with FR3 fluid pose

very minor threats as fire hazards. In fact,

Miller Park in Milwaukee, Wisconsin, has

been powered by six indoor Envirotran

transformers since it opened in 2001.

“Virtually all of the stadium’s power is

supplied by transformers that use FR3

fluid,” said Roger Bengtson, Market

Segment Manager, Cooper Power

Systems. “Miller Park was one of the first

large-scale venues to enjoy all the benefits

of FR3 fluid. The park made a commitment

to install the relatively new Envirotran

transformers instead of the more

traditional dry-type transformers, which, at

the time, was very forward-thinking.”

Whether it’s a need for undisputable

fire safety in Milwaukee or a commitment

to sustainable methods of operation in

Boston, it’s clear that more and more

venues across the country are seeing the

benefits of using Envirotran transformers.

“The benefits of FR3 fluid are

immeasurable,” said McShane. “It

represents a true commitment to the

players and the fans that they are in an

environmentally friendlier and sustainable

place to work and enjoy a ball game.

Envirotran transformers are safer for the

environment, as well as the people and

buildings they serve.”

4

cooperpower.com

An FR3 Fluid-filled transformer is integrated into Fenway Park’s structure.

A Truly GREEN Monster

As with the first project, there were

again some challenging obstacles

associated with placing two new

transformers into a 95-year-old inner-city

stadium. Strict electrical codes combined

with the many idiosyncrasies associated

with the very old ball park made for a

complex assignment that required the

experience and insight of proven industry

professionals.

“This was far from an ordinary

installation,” said Neal Doherty. “Fenway

is an old park, in an older, historic city with

numerous obstacles around every corner.

Add the unfavorable weather associated

with a Northeast winter, and you get an

idea of the challenges we faced getting

these units installed and operating in time

for the start of the baseball season.”

The end result of the installation was a

grand slam. The new transformers were

successfully installed in early February

2008, two months prior to the start of the

2008 season.

“Fenway Park is virtually a national

landmark, comparable to other great

symbols of history and architectural

accomplishment,” said McShane. “The

ballpark’s use of Envirotemp FR3 fluid

in its new transformers carries with it

a strong message of environmental

accountability to the fans, players, and

employees of the park.”

Since 2006, Fenway Park has

equipped four of its seven light towers

with Envirotran transformers to provide

voltage to light up the field at night. Over

the next three years, there are plans to

replace the three other transformers

with Envirotran transformers. To many in

the industry, Fenway Park’s use of FR3

fluid serves as an illustrative model of

responsible, forward thinking. Although

this recent installation is just one small

gesture towards a more environmentally

responsible way of life, it proves to the

fans, the players, and the staff in Boston

that Fenway Park will remain committed to

reducing the environmental impact of its

operations. That’s one commitment that

fans of any team should be rooting for. n

Technology Advances in Surge Arresters

Improve Reliability and Energy Efficiencies

Michael Skowronek, Global Product Manager, Surge Arrester Products;

Michael Ramarge, Senior Product Engineer, Surge Arrester Products; and

James Strong, Field Product Engineer, Surge Arrester Products – Cooper Power Systems

Performance expectations are set high for electric utilities.

Reliable service, environmental leadership, financial returns for

shareholders, and value creation for customers are common

goals set by the more than 3,5001 electric utilities serving the

United States.

Historically a low-cost, often commoditized asset, surge

arresters were purchased only to protect distribution equipment

from overvoltages and offered little in added value beyond basic

surge protection. With the introduction of the UltraSIL polymerhoused Evolution distribution-class surge arrester, Cooper

demonstrates that, through technology advancement, a surge

arrester can provide added value:

■■ Measurably improve energy efficiencies

■■ Reduce carbon emissions

■■ Boost asset utilization

■■ Support inventory objectives

■■ Improve system reliabilities

Cost-Effective, Energy-Efficient Improvements

Electric power generation is a large contributor of

greenhouse gas emission in the world. Because of this,

environmental leadership is a role that utilities are taking on in

increasing numbers. This is driving demand for energy-efficient

technologies.

Each year millions of distribution-class surge arresters are

sold into the market to protect transformers and underground

lines. Some large investor-owned utilities estimate that their

arrester installed base exceeds one million arresters. A common

10 kV class surge arrester can generate up to 500 mW of power

loss. One arrester energized 24 hours/day results in measurable

inefficiencies on an annual basis:

500 mW × 24

hour

× 365 days = 4.38 kWh

day

For a utility with one million arresters on their system, this

represents 4,380,000 kWh of unbilled energy, generating 3,408

metric tons2 of CO2 emissions.

The technology used to construct the Evolution surge arrester

reduces watts loss to 20 mW on average. Assuming the same

conditions described above but calculating energy lost if the

Evolution surge arrester replaced the common 10 kV product,

the utility could avoid releasing 3,271 metric tons of CO2 into

the atmosphere. As a point of reference, in 2001 a single-family

home’s electricity consumption generated 7.55 metric tons of

CO2 annually2.

Modernizing the electric grid to reduce harmful emissions

will come through investment in new technologies. But it

begins with incremental changes taken one transformer, riser,

and mid-line arrester at a time. The Evolution surge arrester

is a small, cost-effective, energy-efficient modern technology.

Utilities with a financial interest in saving energy now have an

option—adopting arresters that cost tens of dollars adds up to

big savings for the climate.

THE LINE – August 2008

5

Boost Asset Utilization

8x20uS IR Comparison

35.0

30.0

Discharge Voltage (kV)

Utilities maximize asset utilization by

ensuring systems are running efficiently

and reliably. The Evolution surge arrester

addresses efficiencies with the 20 mW loss.

Maximizing asset utilization demands

an evolution in surge arrester technology.

Based on field experience, moisture

ingress has been widely accepted

as the most significant contributor

to premature arrester failure. The

Evolution surge arrester incorporates a

patented manufacturing process that

utilizes composite matrix technology

to encapsulate the arrester module

assembly. A photograph of a composite

matrix module is shown in Figure 1.

Evolution

31.6

28.1

HD

RP

25.4

25.0

20.0

15.0

10.0

5.0

0.0

10

Arrester Rating (kV)

Figure 2. The Evolution surge arrester has lower discharge voltages as

compaired to standard heavy-duty and riser-pole arresters.

Lower Discharge Voltage,

Potentially Lower Inventories

Figure 1. 10 kV Composite Matrix

Module.

The composite matrix material consists

of a homogenous fiberglass and epoxy

resin matrix. The composite matrix

has excellent dielectric properties and

moisture impermeability. Cooper Power

Systems performed the Water Immersion

Test (IEEE C62.11™-2005 Standard) on

the Evolution surge arrester without the

polymer housing installed. The arrester

module was submersed in deionized

water with 1kg/m³ NaCl content while

elevated to 80 ºC for 52 hours.

Parameters for pre- and post-tests

consisted of the following:

■■ < 10% Change in 60 Hz Power

Frequency Sparkover

■■ < 10 pC Internal Partial Discharge

Each sample met the verification

testing and demonstrated superior

resilience against moisture ingress.

The result is an arrester that will survive

the elements and protect equipment from

damaging overvoltages.

6

cooperpower.com

The demand for better discharge

voltages and improved margins of

protection for equipment has led Cooper

Power Systems to develop an arrester

that can be used for overhead and riserpole applications. The Evolution surge

arrester will lead the way in reducing

equipment failure rates by vastly improving

discharge voltages. The Evolution surge

arrester has lower discharge voltages as

compared to standard heavy-duty (HD)

and riser-pole (RP) arresters, which are

shown in Figure 2.

Lower discharge voltages result in

greater margins of protection. The greater

the margin of protection, the less stress is

on the protected asset, resulting in longer

asset life.

By applying the Evolution surge

arrester for both riser-pole and heavy-duty

installations, one arrester can be stocked

for both applications.

■■ Reduce inventory

■■

■■

Better match supply

with demand

Have the right arrester

at the right time

Consolidating part numbers reduces

forecast complexity. This allows for

reductions in safety stock, decreased

freight costs due to fewer expedites, and

lowered cost of inventory.

Increased Expectations

As expectations for performance

increase, electric utilities will turn to

manufacturers to assist them in achieving

their goals. Green supply chain managers

will expect products that meet their

requirements; supply chain improvement

initiatives will continue to be a top

corporate priority; and system reliability

requirements will increase. With the

UltraSIL polymer-housed Evolution surge

arrester, utilities can achieve measurable

improvements in reliability and energy

efficiencies, while reducing carbon

emissions—satisfying those increased

expectations. n

1. Source: The EIA Form 861-Annual Electric Industry Report

2. http://epa.gov/greenpower/pubs/calcmeth.

htm#homeelectric EPA Emissions Green Power

Equivalency Calculator 7.78 x 10-4 metric tons CO2 / kWh.

FR3 Fluid Provides Sustainable Alternative for

Reducing Carbon Footprint

Michelle Meyer, Marketing Analyst Associate, Distribution Transformers and Fluids – Cooper Power Systems

With the mounting evidence of global

warming and the growing recognition that

increasing atmospheric levels of carbon

dioxide (CO2) are a key contributing

factor, regulatory pressure to reduce CO2

emissions has been gaining momentum.

As the global community is focused on

mitigating the effects of global warming

by reducing greenhouse gases, there is

an increased demand for products and

solutions that would limit and/or offset a

company’s carbon footprint.

FR3 Fluid Information

Envirotemp FR3 transformer fluid is a

soy-based, biodegradable, fire-resistant

dielectric coolant used to insulate electric

transformers. Because FR3 fluid is derived

from 100% edible seed oils and uses safe

additives, it has a superior environmental

and safety profile when compared to

mineral oil.

Among the many notable

environmental advantages FR3 fluid has

over mineral oil, there is one in particular

that is gaining awareness in the industry.

Studies show that using FR3 fluid instead

of conventional petroleum-based mineral

oil will reduce a company’s carbon

footprint. The primary material for FR3

fluid is derived exclusively from soybean

plants, which sequester carbon dioxide

from the atmosphere.

A Comparison

The U.S. National Institute of

Standards and Technologies (NIST)

developed software—Building

for Environmental and Economic

Sustainability (BEES)—that provides a

life-cycle assessment of building materials

at every stage in the production life that

includes initial investment, replacement,

operation, maintenance and repair, and

disposal. Using the BEES software, NIST

performed an analysis on transformer oil,

juxtaposing conventional mineral oil and

its environmental performance to that of

the soy-based biodegradable FR3 fluid.

The results indicate that petroleumbased mineral oil has a significantly higher

environmental impact in comparison

to Envirotemp FR3 fluid. The primary

component of FR3 fluid is derived from

soybean plants, which act as a carbon

sink. This CO2 absorption during the

growing period for soy plants contributes

to the sequestering of carbon emissions

and assists in reducing a facility’s carbon

footprint.1 FR3 fluid, manufactured from

domestically grown soybeans, performs

considerably better as it has a significantly

smaller carbon footprint than mineral oil.

According to the latest BEES report (4.0e),

a 1000 kVA rated transformer containing

500 gallons of Envirotemp FR3 fluid

lasting 30 years has an estimated carbon

footprint of roughly 34,260 g CO2e/unit,

whereas a transformer with the same

specifications containing mineral oil has

a carbon footprint of 1,899,973 g CO2e/

unit. In other words, mineral oil produces

56 times more carbon emissions than that

of the FR3 transformer fluid.

Another benefit of using FR3 fluid

is that it extends the lifespan of the

transformer, providing longer utilization.

Cooper Power Systems has done

extensive studies showing FR3 fluid

extends the life of the insulating paper by

5 to 8 times—which directly extends the

expected thermal life of a transformer.

From testing, this life-extending property

of soy-based FR3 fluid has been

conservatively estimated to double the

lifespan of the transformer. By deferring

the need for replacement, the longer

lifespan also delays the amount of carbon

emitted from manufacturing and installing

a new transformer and disposing the old

units. In addition to having a significantly

larger carbon footprint, mineral oil, which

is a derivative of crude oil, is a finite

resource. World demand of petroleum is

expected to increase over 40% by 2030,

which will contribute to the depletion of

our increasingly limited supplies of oil.2

As supplies are limited, FR3 fluid provides

a sustainable alternative to traditional

mineral oil as its main ingredient is from a

renewable resource.

Utilities Commitment

Utilities across the United States

are becoming aware of the exceptional

environmental performance FR3 fluid has

over conventional mineral oil. Xcel Energy

was one of the first major utilities to make

the switch and plans to install as many as

15,000 new single-phase transformers

filled with FR3 fluid. Based on their

annual purchasing history of distribution

transformers, Xcel Energy would avoid

the use of approximately 336,000 gallons

of mineral oil by specifying FR3 fluid,

ultimately reducing their CO2 emission by

nearly 16,000 tons annually.

Other utilities have also committed

to using FR3 fluid in their distribution

transformers, in attempts to reduce their

carbon footprint. It has been estimated

that ComEd will reduce annual carbon

dioxide emissions by more than 1,400

tons of carbon dioxide per year by using

overhead transformers with soy oil

insulation fluid. Alliant Energy has also

made the switch to FR3 fluid—reducing

its carbon footprint by 7,280 tons

annually. “That’s the equivalent of taking

1,210 cars off the road each year. Those

numbers include eliminating the need

for about 168,000 gallons of petroleumbased mineral oil annually.”3

Continued on page 17

THE LINE – August 2008

7

Protecting the

Dungeness Spit.

Cooper Power Systems’ FR3 fluidfilled transformers provide safer

power for environmentally sensitive,

historic locations.

It’s been a local landmark since 1857, and the New

Dungeness Lighthouse is now a living museum

following an upgrade to commercial electrical power

and facility and foghorn automation. For more than a

decade, the New Dungeness Light Station Association

has been performing maintenance and working on

restoring the facility to its early 20th century condition.

As part of the restoration, the original three-phase drytype transformer was removed from the lighthouse.

So as not to detract from the restoration efforts, a

FR3 fluid-filled single-phase transformer was installed

away from the lighthouse, in the Dungeness National

Wildlife Refuge, home to 250 species of birds, 41of

land mammals, and 8 of marine mammals.

Prior to installation, approval was sought and secured

from the U.S. Fish and Wildlife Service for the use of

the FR3 fluid-filled transformer. Approval was granted

based on the fluid’s foundation of edible oils and

impressive level of biodegradability. In addition, the

transformer’s stainless steel construction protects

its contents from the salt-water conditions it endures

during the winter rising sea levels. This two-tiered

transformer protection is the perfect fit for the

environmentally sensitive location.

If the environment is a factor in your transformer

installation plans, please contact your Cooper Power

Systems representative or visit www.cooperpower.com.

www.cooperpower.com

All Cooper logos are valuable trademarks of Cooper US, Inc., in the U.S. and other countries. You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

Positive Regulations and Standards Developments for

Natural Ester Dielectric Fluids

Patrick McShane, Global Technology Manager, Fluids Products – Cooper Power Systems

Natural ester dielectric coolants, led by

Envirotemp FR3 fluid, are migrating to the

mainstream. This trend is further bolstered

by the release of a new technical standard

and an amendment to the U.S. Federal

biobased procurement guideline.

New Industry Standard

the Federal Biobased Products Preferred

Procurement Program (FB4P). Included

in the nine new product categories are

fluid-filled transformers. A subcategory

includes vegetable oil-based fluid-filled

transformers, such as the Cooper Power

Systems Envirotran transformers. Starting

in May 2009, all federal agencies and

their contractors are required to purchase

biobased products listed in the program

using Total Life-Cycle Cost as the criteria,

provided the product meets their functional

specifications.

The federal program requires that

the biobased natural esters used in the

transformers contain at least 95% bio-

federal agencies that have the responsibility

for drafting or reviewing specifications for

items to be procured shall ensure that the

relevant specifications require the use of

biobased vegetable oil-based fluid-filled

transformers.

Looking Ahead

A new Institute of Electrical and

There is no question that more and more

Electronic Engineers, Inc., (IEEE®) standard

companies, institutions, and government

Guide for Acceptance and Maintenance of

agencies are incorporating “green” in their

Natural Ester Fluids in Transformers—was

strategic goals. Reducing their environmental

approved by the Standards Association

impact and increasing their supply

Board on May 9, 2008. This standard guide

sustainability are important components

was published July 2008. Having an IEEE®

of their green goals. FR3 fluid has become

Standard Guide is often a requirement

increasingly recognized as a means of

by standards engineers for

contributing to both goals.

acceptance and approval of

The favorable results from the

FR3 fluid is becoming widely recognized as

a new technology. The IEEE®

National Bureau of Standard’s

guide’s 28 pages provide practical

BEES life cycle includes

a sustainable, carbon-friendly product that

information and recommendations

substantiating FR3 fluid’s lower

meets industry standards.

for acceptance of new fluid,

overall environmental impact

new fluid as received in new

than petroleum-based dielectric

equipment, and limit values for continued

coolants. The analysis substantiates the

content and should have received an

service. It provides information on the

carbon-offsetting potential of FR3 fluid,

acceptable total life-cycle analysis, based

differences and similarities of key properties

allowing utilities, federal agencies, and large

on the National Institute of Standards and

between natural esters and mineral oil. The

Technology’s Building for Environmental and users of electricity to help mitigate and

standard guide is the result of five years

reduce their CO2 emissions.

Economic Sustainability (BEES) evaluation.

The inclusion of biobased dielectric

of collaboration and consensus among

Envirotemp FR3 fluid meets these

fluid-filled transformers in the new federal

technical leaders representing end users,

requirements.

preferred purchase program is solid

transformer manufacturers, suppliers of

Envirotemp FR3 fluid-filled transformers

evidence of the sustainability potential and

natural esters, and testing laboratories.

received the program’s official designation

recognition of FR3 fluid.

for product eligibility under this expansion

Federal BioPreferred ProgramSM on June 10. The listing of FR3 fluid is

The pending issuance of the IEEE®

The U.S. Department of Agriculture

guide for natural ester fluids is another

now on the USDA BioPreferred web site.

(USDA) announced on May 14, 2008,

giant step in the industry acceptance

In accordance with this act, procuring

that it is adding nine product categories

and recognition of the new, revolutionary

agencies must give a preference for

(items) for designating biobased products

technology for distribution and power

qualifying biobased vegetable oil-based

for the federal program formerly known as

transformers. n

fluid-filled transformers. By that date,

10

cooperpower.com

Demand Response: A Good Thing for Everybody

Phil Holt, Proposal Writer, Marketing Communications;

Dan Merilatt, Manager, Demand Response Systems; and

Charles Parsons, Business Development Manager, Demand Response Solutions – Cooper Power Systems

Stories about environmental issues and global warming are

in the news headlines every day. Behind the headlines lurk the

very real challenges of addressing these large-scale issues of

preserving the environment on a local level while balancing the

need for sound economic energy management. The Cannon

demand response solution by Cooper Power Systems is uniquely

positioned to help utilities address these tough problems, while

bringing balance to the equation.

Reducing emissions is the key to address the challenge of

preserving the environment. Cooper Power Systems has the tools

required to handle this important task. Assuming 100 hours of

control per year, each megawatt of control (about 1,000 residences

allowing some reduction in their air conditioning usage) has the

potential to eliminate approximately 700,000 pounds of carbon

dioxide (CO2), 700 pounds of nitrogen oxide (NOx), and 3,000

pounds of sulfur dioxide (SO2). This reduction is crucial because

both CO2 and NOx are greenhouse gasses while SO2 is the main

component of acid rain. The significant environmental impact of

these reductions is seen in the fact that currently the United States

has over 3,600 MW of residential demand under control.

Cannon’s demand response (DR) solution significantly impacts

the local environment by decreasing pollutants. These pollutants

contribute on a global scale as well. This benefit pleases users

and as a result they are more inclined to enroll and stay enrolled in

these programs. The DR solution using the Cannon programmable

communicating thermostats (PCTs) will create greater benefits

for the environment through documented energy savings. There

are documented energy savings from 10% to 15%—provided

participants use the programming features.

DR programs can displace the need for some new peaking

capacity. With wide deployment, they can reduce the likelihood for

brownouts and rolling blackouts. Many consumers welcome an

opportunity to participate in DR programs due to these benefits,

because they want to help keep electricity costs manageable, and

they view these programs as environmentally benign.

To be sure, it is vitally important to balance the need to

preserve the environment with the needs for sound economic

energy management. Today, our national electric grid stresses

because of generation and transmission capacity constraints—

growing demand pressing against fixed capacity. The cost for

peaking generation continues to rise. Today it varies between

$650 and $850 per kW while DR networks are from one- to

two-thirds less. Part of the solution will be to grow the grid in

an economical and environmentally responsible way. Another

part of the answer lies in the further promotion of peak demand

management programs—demand response programs. Cooper

Power Systems is working toward the goal of finding this balance.

Cannon Demand Response

With Cannon solutions, Cooper Power Systems currently

offers one of the largest and fastest-growing brands of peakload management tools in North America. DR/load management

solutions include load control relays (LCRs). These devices are

for the direct load control of electric HVAC systems, electric

water heaters, and electric pumps and motors. Cooper also

offers advanced programmable communicating thermostats

(PCTs) enabling the more efficient use of HVAC systems. Utilities

can also use our PCTs for the direct load control of customers’

HVAC systems or for implementing dynamic and innovative

pricing options.

Networks of load management devices (as well as other

“smart grid” equipment of various kinds) require management.

Cooper’s network management system is a versatile energymanagement software platform known as Yukon. This platform

helps improve important parts of the electrical distribution network

while connecting utilities with their customers through its load

management products.

Why Demand Response?

That’s a fair question. Cooper has been successful in selling its

demand response solutions to utilities throughout North America.

Why? Why would utilities be interested in reducing their peak

demand? Why would their consumers voluntarily relinquish some

control over their air conditioning, water heating, and other major

electrical loads to the electric utility serving them? The answers to

these questions illustrate the benefits that DR provides.

Benefits of Mass-Market Demand Response

A successful mass-market DR program is beneficial to both

the utility and its customers. Many customers like these programs

because they lead to reduced outages. These programs provide

opportunities to participate in environmentally friendly programs.

Utilities are happy because peak-load management programs

do not materially affect kWh sales. They help utilities avoid using

interruptible contracts and they help avoid spot market purchases

while sometimes allowing additional spot market sales. Massmarket demand response programs support many utility goals

including community value, environmental responsibility, saving

scarce resources, increasing system reliability, and increasing

customer satisfaction.

THE LINE – August 2008

11

Peak Load Reduction

Customer Satisfaction

One of the misconceptions of demand

response programs is that customers

become uncomfortable and therefore

unhappy with their participation in the

program. Metered evidence has shown

that with air conditioning load controlled,

indoor temperatures only rise slightly as

shown in figure 1.

Participants in well-run demand

response programs are more satisfied with

their utility than are its non-participating

consumers. Consumers appreciate it

when utilities introduce programs designed

to help keep the lights on and electricity

cost low—especially when they are not

discomforted.

Environmental Considerations

Cooper’s Cannon DR Solution has a

significant impact on the local environment

by decreasing pollutants and contributing

on a global scale as well.

The Economic Bottom Line

In addition to the environmental

benefits, perhaps the most surprising thing

about this impressive list of benefits is the

cost. The total cost for mass-market peakdemand reduction programs is lower than

the cost of supplying those peak demands

from generation. They are not just a little

lower, but can be one-third to two-thirds

as much. The total present-value cost

for a mass-market DR program including

the costs for program management,

marketing, recruitment, equipment,

installation, service, and maintenance will

vary from about $250 per kW of peak

reduction to about $500 depending on the

DR equipment used and the overall size

of the program. When peaking-capacity

costs about $750 per kW installed plus its

annual operations and maintenance costs,

the value of mass-market DR becomes

obvious.

The Market for Demand

Response

Is the market nearly saturated or will

it grow? If it will grow, at what rate will it

12

cooperpower.com

Controlled versus Uncontrolled 96 °F Max Temp Day

76

75.5

75

Indoor Temperature Reading

The purpose of mass-market DR

programs is to reduce the peak demand

placed on utility systems. This peak

demand typically occurs on the hottest

summer days. Research has shown that

a load management network of LCRs or

PCTs can significantly reduce this peak

demand and provide greater stability to the

electrical system, while reducing the need

for new peaking capacity.

Max Temp

Difference 1.24 ° F

74.5

74

73.5

73

Control Event

control

72.5

no control

72

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Hour of Day

Figure 1. Indoor temperature variation between controlled and uncontrolled

electricity loads using Demand Response systems.

Actual Peak Load Reductions from Load Management (in MW)

(Source: DOE/EIA Form 861 Filings)

17,000

16,000

15,000

14,000

13,000

12,000

11,000

10,000

9,000

8,000

1994

1995

1996

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

Figure 2. The residential Demand Response market has room for growth.

grow and for how long? These are difficult

questions because they involve anticipating

the future. Some contributors to the

answers are in the facts.

Recent Demand Response

Activity

■■

In 2006, the latest year for which

data is available from the United

States (U.S.) Department of Energy

(DOE), North American utilities

delivered 11,281 MW of peakperiod load reductions.

■■

This amount of demand response

is encouraging but not recordbreaking and far short of the over

16,000 MW of peak-period load

reductions recorded for 1995.

■■

Of the 11,281 MW of peak-period

load reductions delivered in 2006:

• The industrial sector delivered

53%.

• The commercial sector

delivered 15%.

Continued on page 17

Cooper Provides Utilities DOE 2010 Standard-Efficient Designs

Jim Kozak, PE, Field Product Engineer, Distribution Transformers ­– Cooper Power Systems

On October 12, 2007, the U.S.

Department of Energy (DOE) issued

its long-awaited transformer efficiency

standard. The standard establishes

required efficiencies for new distribution

transformers rated 2500 kVA and below

sold in or imported to the U.S. after

January 1, 2010. The standard defines

a legal requirement rather than merely a

guideline or recommendation for these

transformers.

Cooper Power Systems is offering

a proactive approach to meeting

requirements of the DOE standard

early packaged along with innovative

Envirotemp FR3 fluid to provide

utilities with “green” energy-efficient

transformers. These highly efficient FR3

fluid-filled transformers combine the

most environmentally favorable dielectric

fluid available with energy-saving, highefficiency designs. The result is a more

favorable carbon footprint along with

reduced energy generation requirements.

Background

The U.S. Federal government has

been setting energy efficiency standards

for products for several years. These

products include home appliances such

as air conditioners, washers, dryers,

and refrigerators, as well as fleet miles-

per-gallon averages for automobiles.

There are several objectives for these

efficiency standards; deferral of additional

generation and transmission capacity,

reduced greenhouse gas emission,

and less dependence on imported

energy. Reducing energy consumption

decreases the amount of power that

is required to be generated and allows

postponement of building new power

plants and transmission lines. It also

reduces the amount of primary fuels like

coal and natural gas burned in power

plants to generate electricity. Gasoline

and electric power generation primary

fuels are both big sources of greenhouse

gasses. Additionally, reduction in

consumption of gasoline and other

petroleum products lessens U.S. reliance

on foreign petroleum products.

Implications for Transformer

Manufacturing

Transformer buyers typically specify

evaluation formulae for losses which

dictate the most economical transformer

design given their cost of power. By one

manufacturer’s estimate, at least 60%

of distribution transformers purchased

in 2007 were below the DOE’s efficiency

levels established for 2010. This implies

that in order to comply with the DOE

standard, the majority of transformers

sold in the U.S. will require redesign

before 2010. Higher grades of conductor

material and core steel will be necessary

to obtain required efficiencies. In some

cases, aluminum conductors will be

replaced with copper and in most

cases, lower-grade M5 core steel will be

replaced with lower-loss M2 and M3 core

steel to increase transformer efficiency to

compliant levels.

Transformers represent a small sliver

of total mild steel, aluminum, and copper

use. The large markets for these metals

will be primarily influenced by world-wide

demand from all sectors—rather than

changes in demand from the transformer

industry. Surging economic growth in the

emerging Asian and Far East markets

will be primarily responsible for the price

pressure for these commodities.

However, it is estimated that price

and availability of mild steel, copper, and

aluminum will be largely unaffected by the

DOE’s action. The same is not necessarily

true for the specialty grain-oriented

silicon core steel used in distribution

transformers. Transformers represent a

very large portion of the consumption of

this core steel; therefore, the prices for M2

and M3 core steel are quite inelastic

with transformer demand.

THE LINE – August 2008

13

Complicating the issue, there are very

few manufacturers of this magnetic core

steel and adding capacity at these mills

is an extremely lengthy and expensive

undertaking. Capital expansion projects

at the steel mills can take years to

implement and cost millions of dollars.

Global demand for the premium core steel

is expected to surpass global supply, and

it may take several years for the small

number of existing suppliers to catch up.

Proactive Approach Helps

Customers Now

Quite a number of customers are

proactively moving to DOE efficiency levels

rather than waiting until the mandate to

purchase DOE-compliant transformers.

These customers have chosen to

take advantage of higher-efficiency

transformers sooner—locking in the lower

cost and smaller-size designs while there

is M2 and M3 core steel available.

In the future, when transformer

manufacturers cannot get enough of the

low-loss, efficiency-friendly M2 and M3

core steel to meet demand, they may be

required to make do with sub-optimal

designs using the more plentiful M5 core

steel. The resulting designs will be larger,

heavier, and more expensive than the

optimal M2/M3 core steel designs.

Dimensions, weight, and cost can

increase anywhere from 10% to 30%

when lower-grade core steel must be

used instead of the optimized M2 or M3

core steel-based designs. Additionally,

for overhead transformers, the increased

weight of the transformer may require

more expensive and heavier-duty utility

poles. Replacing utility poles typically

costs utilities $3,000 to $4,000 in material

and labor costs.

For pad-mounted transformers,

existing concrete pads may be too small

to accommodate the larger designs. And

for all transformers, larger and heavier

transformers mean fewer per truck,

increasing logistic costs and fuel used in

transportation. Transformer consumers

will definitely be at an advantage if they

can obtain the scarce M2 and M3 core

steel for their designs. Late adopters will

most likely be left to settle for the best

configurations that can be obtained with

the inferior core materials and the higher

transformer costs and larger units that go

with M5 core steel limitations on design.

Soy-Based Transformer Fluid

Helps Meet Green Objectives

The redesign efforts necessary to meet

the DOE minimum efficiency requirements

also present a great opportunity for

14

cooperpower.com

First installation of a FR3 fluid-filled transformer at ComEd in March 2008.

customers to re-evaluate dielectric fluid

options. Fully embracing the “green” effort

includes specifying FR3 fluid, which is

made almost entirely from soy oil. Growing

soy consumes CO2 and produces O2.

Even considering the CO2 produced

to support the growth of seed crops,

the soy is a net CO2 consumer rather

than producer, and CO2 reduction is a

big reason why the DOE established its

standard efficiencies.

FR3 fluid is also non-toxic1 and fully

biodegradable per an EPA Standard

test2—extremely beneficial properties in

the event of accidental spill. Specifying

FR3 fluid also reduces the demand

for petroleum-based mineral oil and

requisite drilling activities. Finally, the

life-extending properties of FR3 fluid

mean that transformers do not require

replacement as often. More infrequent

transformer replacement means less

aluminum, copper, and steel required for

manufacture. Production of each of these

materials introduces greenhouse gasses

to the environment.

Studies show that using FR3 fluid

instead of conventional petroleum-based

mineral oil will reduce a company’s carbon

footprint. As related to transfomers, per

NIST BEES report, the soybeans used

in FR3 fluid consume CO2 from the air

while they are growing. The CO2 impact

from the soy is still a net reduction for

the environment even after considering

the tractor fuel, fertilizer, processing and

transport used in production of FR3 fluid.

This contrasts with mineral oil which is a

net CO2 emitter in the drilling, refining,

processing, and transport processes.

The list of utilities opting to convert to

FR3 fluid concurrently with the change to

DOE standard efficiency levels includes

Alliant Energy, ComEd, Xcel Energy, and

American Electric Power. They have all

selected FR3 and DOE compliant designs

in 2008. Many more customers are in the

process of converting to DOE standard

efficiency early and including FR3 fluid in

their conversion plans. These utilities are

embracing both the intent and the letter of

the DOE standard. Their proactive actions

benefit both the customers and the

environment—a win for all involved. n

1. Per OECD G.L.203

2. EPA OPPTS 835.3110

For more on greenhouse gas emission, refer to the related

article, FR3 Fluid Provides Sustainable Alternative for Reducing

Carbon Footprint, on page 7.

Photo courtesy of Waverly Light and Power

The Winds of Change:

Waverly Light and Power - a Pioneer in Sustainable Energy

Connie Schnick, Marketing Communication Specialist – Cooper Power Systems

Glenn Cannon, Former General Manager – Waverly Light and Power

Waverly Light and Power™ is a cityowned electric utility providing service to

almost 5,000 customers in a 33 square

mile area located in the Northeast corner

of Iowa, along the scenic Cedar River.

Waverly Light and Power (WLP) has

been leading the way in sustainable

energy since the late 1980s when it

was the first municipal utility to own and

operate wind generation in the Midwest.

As they are continually searching for

environmentally friendly, renewable

energy resources, wind has been an

important resource—leading the way

in providing a clean, emission-free, and

inexhaustible energy resource.

Response to Increased

Energy Demand

During the late 1980s, Waverly’s

energy demand grew at a rate of 4.2%

per year—almost twice the national

average. Faced with termination of its

purchased power contract in 1999 and

steady growth in demand, WLP became

increasingly concerned about future

energy supplies. A study was performed

by an independent utility consultant to

evaluate options for conserving energy

and generating it from renewable

sources. The study showed wind to be a

viable resource in Iowa.

In 1993, after receiving grants from

the American Public Power Association,

Waverly Light and Power erected Skeets

1, the first turbine, located on a farm

just outside of Waverly (Zond 80 kW),

and according to Glenn Cannon, former

General Manager of WLP, “became the

first public power system in the Midwest

to own and operate wind generation.”

Positive response from local consumers,

a grant from the National Renewable

Energy Laboratory, and the success of the

original turbine lead to additional turbines.

In 1999, two 750 kW Zond Z-50 wind

turbines, Skeets 2 and 3, were placed on

small farms near Alta, Iowa. They are part

of the Storm Lake Wind Facility which

contains 259 wind turbines.

Late in 2001, Skeets 1 was retired

and replaced with a 900 kW turbine. The

NEG Micon NM52 turbine came on-line

in December 18, 2001, and produced

over 111,000 kWh through January

1, 2002. The production during those

15 days was greater than the previous

turbine, ‘Skeets 1,’ produced in an

average year.

In order to ensure future reliability,

two of WLP’s wind turbines were sold in

November 2005. The selling of these two

units allowed Waverly Light and Power

to continue researching and investing in

turbine and wind renewable upgrades.

Two additional turbines are planned for

installation in 2009.

Innovative Program

Waverly Light and Power Iowa Energy

Tags™ program was launched in March

of 2001. This innovative program allows

companies and individuals to purchase

tax-deductible certificates (tags) to

help pay for future renewable energy

resources. Iowa Energy Tags have been

purchased worldwide. From Denmark to

Waverly, residents realize the value in the

Iowa Energy Tags program.

Each tag represents the

environmental benefit of 2,500 kWh of

wind generation, offsetting fossil fuel

production and importation of the same

amount of energy. This means a savings

of 5,300 lbs. of CO2 emissions—along

with a host of other greenhouse gases—

for each Iowa Energy Tag sold.

Envirotemp Transformers and

FR3 Fluid

In 1992, Cooper Power Systems

began research and development of

vegetable oil-based transformer fluids. In

1996, the first field trials began, and a soy

oil-based dielectric coolant, trademarked

Envirotemp FR3 fluid, was commercialized

in 1999. Also forward thinking, Waverly

Light and Power, in cooperation with the

University of Northern Iowa’s AgricultureBased Industrial Lubricants (ABIL)

Laboratory, developed a soybean-based

transformer oil. In 2002, their technology

was acquired by Cargill, Inc. In 2004,

Cooper and Cargill formed an alliance

to transfer the production of FR3 fluid

to Cargill Industrial Oils and Lubricant

facility in Chicago to take advantage of

their larger manufacturing base. Waverly

Light and Power continues to support

and promote the sale of FR3 fluid. Cooper

Power Systems developed a line of

transformers, Envirotran transformers,

that solely use FR3 fluid. WLP uses FR3

fluid exclusively for both new and retrofil

applications to support their commitment

to the environment. In September of 2007,

WLP purchased two 1000 kVA Envirotran

3-phase pad-mounted transformers,

connective equipment including inserts

and bushing wells, and Bayonet fuses to

be used with two new wind turbines to be

installed in early 2009.

Exceeded Expectations

Today, Waverly Light and Power’s

wind generation serves the

THE LINE – August 2008

15

equivalent of 261 homes annually. It

also offsets nearly 2,330 tons of carbon

dioxide (CO2), a leading greenhouse

gas associated with climate change.

Renewable generation contributes 3% to

their total generation portfolio annually.

In May of 2002, NEG Micon USA, Inc.,

stated Waverly’s wind turbine was among

the highest producers for NEG Micon

turbines in the United States. “It was the

highest producer of all NEG Micon turbines

in the Midwest in May,” said Steve Butler,

Technical Services Advisor for Waverly

Light and Power. The Utility had an

estimated capacity factor of 27% annually,

but to-date it has averaged 32.5%.

Commitment to Future

Development

Through the strong leadership of the

WLP Board of Trustees, Waverly Light and

Power has maintained its position as an

industry leader in renewable energy and

energy efficiency over the years. In 2006,

the Board committed to make renewable

resources the source for 20% of WLP’s

system energy requirements by the year

2020. This commitment has reaffirmed

WLP’s position at the threshold of energy

markets for the next century. New

options are currently being pursued in this

visionary effort. Cooper Power Systems

has been developing new and exciting

equipment to help WLP and other utilities

meet the ever increasing demands for

safer, environmentally friendly, and more

efficient transformers. n

For more on Cooper Power Systems proactive approach

to meeting the requirements of the Department of Energy

standard while incorporating innovative FR3 fluid to provide

utilities with “green” energy-efficient transformers, please

read: Cooper Provides Utilities DOE 2010 Standard-Efficient

Designs by Jim Kozak, PE.

Efficiency in the field

starts with training in

the classroom.

Cooper Power Systems’ training program

improves operator performance,

increases efficiency, and optimizes

equipment operation. For product

training information, visit:

www.cooperpower.com/EventCalendar

www.cybectec.com/training

16

cooperpower.com

Cable Preparation and Termination Training

Ken Easterday, Product Specialist, LiPE - C&I – Cooper Power Systems

The need for lower-cost mediumvoltage installations, in an extremely

competitive contract environment, which

is under short time constraints—all

of these issues are running through

the minds of Cooper Power Systems

customers. Also of importance, but

at times overlooked, is the need for

experienced and trained cable and

termination installers. No matter who the

customer, the location of the installation,

or the application, there is potential that

the contracted installers are new to the

project and they may have very little

experience with proper medium-voltage

cable preparation. Cable Preparation

and Termination Training (CPTT) is not

only needed, but sometimes required,

depending on the end customer.

Since cable preparation training needs

have become more frequent, some

Cooper representatives have filled the

need and conducted these training events

themselves. Michael McClellan, Jr., of

Haddon-McClellan Associates, Inc., looks

to provide CPTT for his customers with

medium to large cable accessory orders.

“We provide cable training because it is

necessary to support the sale, solidify

the customer relationship, and provide

customer service for both HaddonMcClellan Associates, Inc., and Cooper

Power Systems,” says McClellan. “We

usually provide 3 to 4 training sessions

per year.” In addition, McClellan mentions

“It’s a great opportunity to talk to the

customers about the tools needed for the

preparation and perhaps get clarification.”

Another Cooper representative, Rick

Denno, from RM Clark Associates, Inc.,

uses CPTT as an opportunity to get

Cooper cable accessories in front of

potential customers. “I talk to them about

separable connectors, and then we all

go through the CPTT. Five times out of

ten, it results in added requirements for

loadbreak elbows, junctions, splices,

and sector cabinets. I call on several

large government campuses that require

their contractors to have training before

they can work on MV terminations. This

is a good opportunity to get Cooper in

front of them, provide CPTT, as well as a

certificate of training.”

Cooper Power Systems can provide a

certificate of completion for all CPTT that

includes a Cooper logo, description of the

training, the location, and a signature of

the person performing the training.

In addition, Cooper will be introducing

a 200 A and 600 A CPTT training video

on DVD that covers the latest techniques

and tools for proper cable preparation

and terminations. Look for this DVD in the

summer of 2008. n

FR3 Fluid Provides Sustainable Alternative for Reducing Carbon Footprint

From page 7.

By utilizing a soy-based dielectric

fluid, utilities across the nation are able to

deliver reliable service to their customers

and participate in the global effort of

reducing atmospheric levels of CO2.

Public owned utilities are also using FR3

fluid in their distribution transformers,

including the California-based electrical

utility Sacramento Municipal Utility District.

Regulation

In the current political climate,

FR3 fluid has the potential to do more

than just reduce a company’s carbon

footprint. The volume of domestic and

international carbon regulatory bodies,

such as the Regional Greenhouse Gas

Initiative, the Carbon Climax Exchange,

and the European Union Emission Trading

Scheme, has been increasing substantially

in recent years. In many cases, these

institutions place limits to the amount

of carbon that can be emitted into the

environment—allowing for companies to

purchase carbon offsets to reduce their

carbon footprint. Examples of carbon

offset projects include those which

incorporate wind generation, contain

methane generated by farm animals and

landfills, include planting trees, or enhance

energy efficiency.

Carbon regulation has also manifested

into policy at the local level. California,

Connecticut, Delaware, Maine, New

Hampshire, New Jersey, New York,

and Vermont are taking the first

steps to limit carbon emissions, while

Massachusetts and Kansas are in the

process of developing CO2 regulatory

legislation. Oregon and Washington have

already mandated that power plants are

required to offset a certain percentage

of anticipated carbon emissions.4

Considering the carbon political activity

at the local level, a national policy that

implements a carbon cap and trade

system is likely to occur within the

next presidential administration. If a

national cap and trade policy were to

be passed, the value of a carbon credit

has been estimated to reach or exceed

$40 USD per carbon ton. Under these

circumstances, a utility making annual

distribution transformer purchases of

$1,000,000 would yield a potential carbon

credit value of $19,000. Companies would

be gaining roughly a two percent rebate

on their transformer purchase.

significant reduction in greenhouse gases

as compared to mineral oil. From reducing

the harmful effects of transformer spills

and avoiding fires to reducing a company’s

carbon output, it is evident that FR3 fluid

not only enhances safety and reliability

for the electrical grid but assists utilities

in implementing sustainable business

practices. n

1. “Building for Environmental and Economic Sustainability

Technical Manual and User Guide” National Institute of

Standards and Technology. August 2007.

2. “International Energy Outlook 2007” Energy Information

Agency. (May 2007) < http://www.eia.doe.gov/oiaf/ieo/

oil.html>

3. “Alliant Energy makes the move to FR3 fluid for its

distribution transformers.” 26 February 2008. <http://www.

alliantenergy.com/docs/groups/public/documents/pub/

p016407.hcsp>

4. “States with a Carbon Cap or Offset Requirement for

Power Plants” PEW Center on Global Climate Change. (2

April 2001) <http://www.pewclimate.org/what_s_being_

done/in_the_states/cap_and_offset_map.cfm>

FR3 Fluid and the Future

There are many environmental and

economic benefits to be gained by using a

biobased fluid in distribution transformers.

Using FR3 fluid would allow for a

Demand Response: A Good Thing for Everybody

From page 12.

•

The residential sector delivered

32% or 3,600 MW.

■■ These results are encouraging

because:

• DR has risen steadily since

2004.

• 2007 results may well exceed

13,000 MW.

• DR in Canada is increasing.

■■ These results indicate that the

residential sector’s market potential

for DR is primarily untapped.

The Residential Demand

Response Potential

■■ The U.S. has about 66 million

families living in single-family,

owner-occupied housing units.

■■ These 66 million families are the

primary candidates for participation

in utility-sponsored residential

demand response programs.

•

46 million of them have central

electric air conditioning.

• 24 million have electric water

heating.

• 18 million have central electric

heating systems.

■■ Assuming that 25% of these

candidates could be persuaded to

participate in summer peak-period

demand response programs:

• 11.5 million families having

more than 12.5 million central

air conditioning units would

provide over 12,500 MW of

summer peak-demand relief.

• The U.S. has yet to tap over

70% of the air conditioning

load control potential.

The Emerging Demand

Response Market—Cooper

Power Systems’ Role

States have made large investments in

load management systems. Cooper is

supporting these existing systems with its

Cannon Yukon software platform alongside

its newest technologies—allowing utilities

to migrate smoothly from older to new

technology without needing to replace the

entire investment immediately.