An Evaluation of Two Refrigerant Mixtures in a - Purdue e-Pubs

advertisement

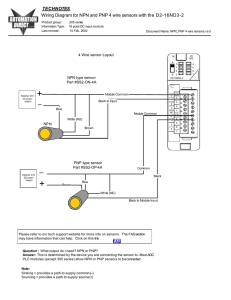

Purdue University Purdue e-Pubs International Refrigeration and Air Conditioning Conference School of Mechanical Engineering 1988 An Evaluation of Two Refrigerant Mixtures in a Breadboard Air Conditioner W. Mulroy National Bureau of Standards M. Kauffeld National Bureau of Standards M. McLinden National Bureau of Standards D. Didion National Bureau of Standards Follow this and additional works at: http://docs.lib.purdue.edu/iracc Mulroy, W.; Kauffeld, M.; McLinden, M.; and Didion, D., "An Evaluation of Two Refrigerant Mixtures in a Breadboard Air Conditioner" (1988). International Refrigeration and Air Conditioning Conference. Paper 34. http://docs.lib.purdue.edu/iracc/34 This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact epubs@purdue.edu for additional information. Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/ Herrick/Events/orderlit.html AN EVALUATION OF TWO REFRIGERANT MIXTURES IN A BREADBOARD AIR CONDITIONER William Mulroy Michael Kauffel d Mark McLinde n David Didion Nationa l Bureau of Standar ds Gaither sburg, Marylan d 20899 Abstrac t that is An experim ental, water-to -water, breadbo ard heat pump, for one which could easily be reconfig ured, was constru cted 4 ahd compari son of pure R22 to the refrige rant mixture s R22/R11 . Three evapora tor configu rations were extensi vely studiedcy R13/Rl2 . best efficien In all cases the best mixture outperfo rmed R22. The higher than with R22/Rl1 4 was 32% higher and with R13/Rl2 was 16% other obserya tions were, the best e~ficiency measure d with R22. er efficien cy first, that mixture s can take advanta ge of heat exch~ng rant is that, ih a gliding tempera ture applica tion; a pure refrige e between the incapab le of utilizin g. Secondl y, that heat exchang to some mixed condens ed and evapora ting refrige rant is benefic ial of enthalpy refrige rants . . Finally , mixture s exhibit nonline arity signific ant versus tempera ture in the two phase region which has impact on both heat exchang er and cycle design. EVALUAT~ON DE DEUX MELANGES D'AIR EXPERIMENTAL DE FRIGORIGENES DANS UN CONDITlONNEUR d~re Une pompe a chaleur eau-eau , exper~mentale, c'est-aRESUME ration, a ete une pompe dont on peut facilem ent modifie r la configu s de cbnstru ite en vue de la compara ison du R22 pur aux melange ete etuont R22-Ril4 et Rl3-Rl2 . Tro~s configu rations d'evapo rateur melange avait r diees de fa~on poussee . Dans tous les cas, le meilleu nt du melange une meilleu te perform ance que le R22, le meilleu r rendeme de Rl3-Rl2 melange du de R22-Rll4 etait superieu r de 32 % et celui On a observe superieu r de 16 % au meilleu r rendeme nt mesure du R22. ben~fice du de plus, d'abord que les melange s pouvaie nt tirer un applica tion de rendeme nt de l'echang eur de chaleur pur que, dans une le d'utilis er ; tempera ture glissan te, un frigorig ene pur est incapab condens e et le ensuite que l'echang e de chaleur entre l.e frigorig enes melange s de frigorig ene en evaporat~on etait favorab le a certains non-lin earite de frigorig enes. Enfin que les melange s present ent une diphasiq ue, l'entha lpie en fonction de la tempera ture dans la region de chaleur et eur ce qui a un impact net sur la concept ion de l'echang du cycle. 2 I , An Evaluatio n of Two Refrigera nt MiXtl.il"es in a Breadboar d Air Condition er by W. Mulroy, M. Kauffeld, M. McLinden and D. Didion INl'RODUCTION The National Bureau o£ Standa-:cds has evaluated two nonazeotr opic refrigera nt mixtures, R22/R114 and R13/R12, in a water-to- water breadboar d heat pumping apparatus at temperatu res typical of air condition ing applicati ons. As is sh01m i_n figure 1, the best perfo1:min g test series with the mixture R22/R114 resulted i.n a coefficie nt of performan ce of 6.9 (EER = 23.6), 32% higher than the best efficienc y obcained with pure R22. In figure 2, the best efficienc y with the mixture R13/R I2 was 16% better than R22. 7r-----~-=~,-----,-----, -----. R22/R114 ~ ci 5 ci 44% 4 • WHh liquid IinS neat exchang~;~r • Without liquid line heat exchanger 3 ~-----L------L-----~------~----_J 100 80 60 40 20 0 WEIGHT% R22 figure 1: Performan ce of the mixture R22/R114 fo1: evaporate !: configura tion No 4. 7r---- -,----- .------ .-----. -----. R13/A12 6 ~ ci 0 C.O.P for R22 • With liquid lino heat exchanger • Without liquid line Mat exchanger 4 100 80 60 40 20 0 WEIGHT %A13 Figure 2: Performan ce of the mixture R13/R12 for evaporato r configura tion No. ''. TEST CONDITIONS The -cwo primary criteria used to define comparab le condition s for evaluatin g the tested refrigera nts were fixed water temperatu res and constant capacity. Tl1e fixed wate,; temperatu res chosen as typical of air condition ing were 80°F (26.7°C) inlet and 55°F (12.8°C) outlet for the evaporato r, and 82"F (27.8°C) inlet and l17°F (11? .2°C) outlet for the cond~nser. Because water temperatu res were fcxecl, refrigera nt tempe~atures and pressures were dependen t on refrigera nt propertie s_ Since the evaporato r area was to be kept constant for each test series constant heat flux criteria requil:ed constant capacity. For this r-eason, refrigera nt propertie s chang~d it was necessary to change compresso r speed. 1 3 ~:ho t-~s itions were the evapora tor The test vari.abl es other than refrige rant compos (UA) and the use of intracy cle heat overall heat transfe r coeffic ient cimes area s as sho~n in figure 3. The evapora tor heat exchang er had three passage e~change. through passage s of differe nt cross By routing water or evapora ting refrige rant drops and water·t o·refrig erant heae section or surface area, differe nt pressur e rations were. examine d for a full exchang e coeffic ients were obt.aine d. Three configu The third evapora tor passage was range. of refrige rant mixture cornpos lt.ions. ed liquid refrige rant and the availab le for heat exchang e between the condens out the length of the evapora tor. evapora ting refrige rant in counter flow through ized in table 1. The te.sted evapora tor configu rations are summar Configu ration 4 Table 1: Evapora ting Refrige rant c B A Liquid Refrige rant B c B Water A A c A B to Figure 3). Tested evapora tor configu rations (letter s refer Cross Sect1onal Area 227 mm' A 122 mm2 B mm 2 c Figure 3: 310 ~ 100 mm 120 mm BO mm Evapora tor cross section (not to scale). APPARATUS The pump is shown in figure 4. A schema tic diagram of the breadbo ard heat A shaft. dynamom eter e speed motor. open compres sor is belt dr ive.n by a variabl tachome ter) mounted between the (strain gage torquem eter plus magneti c pickup primary cycle power input measuremG!nt. compres sor pulley and flywhee l was used as the through an oil eeparat. or and then enters From the compres sor the refrige rant pas~es Condens er count.er flow water loop. the condens er which ;LejeC1;:S i"T;;:S heat: to a ent: and by compari son of the water capacit y was measure d by a wate:L side measurem manual The clec"T;;:r.ic trimmin g heater. t-empera ture rise to there over the metered ing as observe d at the subcool slight n maintai to d adjuste was expansi on valve condens ar exit slghtgl ass. y which was use:d to calcula te cycle The primary meas~~e of evapora tor capacit heat input (electr ic heaters , water total the ng measuri by d provide was cy efficien l heat gain) to the calorim eter box the·wal · through eter calorim pump, cing circula loop. Seconda ry 1neasure s of evapora toi" -which surroun ded the evapora tor and its water son of the water tempera ture drop compari and tion calcula side water a -were. y capacit turc rise through the metered heaters through the evapora tor to the water tempet'a used to match the cvapoxa tor capacit y. return hole was used at "Che evapora tor A special accumu lator which l.:3cked an oil only saturat ed vapor returnin g 'o che outlet to allow flooded coil operatio n with se refrige rant-si de heat transfe r compres sor so that t.he evapora tor area in two-pha insensi tive. Mixed refrige rant would stay constan t and the system be charge sor dischar ge gas samples using a compos ition was determi ned by analysi s of compres ograph. chromat gas Figure. 5 shows variatio n of system effici<!-n cy with compress or speed for pure R2'2 whlle holding suction and discharg e pressure s constant . Efficien cy ~as felt co be sufficie ntly constant to allow mixture testing without correcti on for this variable . Because of vibratio ns in the compress or mounting m.1.d drive systems (resultin g in n market decrease in measured system efficien cy) tests were not run near the speed of 750 rpm. Figure 4: Schemati c of breadboa rd heat pump. -------·-~-- - 0.: 0 c.i ----- 4 3L--------h~~------~--------~ 500 Figure 5: 750 1000 COMPRESSOR SPEED, rpm i250 System efficien cy as a function of compress or speed for pure R22. DISCUSSION AND RESULTS Water and refriger ant temperat ure profiles through the evaporat ors for pure R22 are shown in figure 6. The four parts of this figure are for four differen t evaporat or configur ations (i.e. flow routed through differen t passages ) which resulted in differen t: overall heat t:ransfer coeffici ent times area (UA) values. rn the best configur ation (figure 6d-confi guration 4) the water t.ernperat .ure has reached that of the refriger ant in a quarter of the length of the evapora tor. "I he remainde r of the evaporat or is ineffect ive. This "pinch point 11 resultin g frorn a mismatch of the refriger ant and water temperat ure glides limi t:s the efficien cy attainab le with a pure refriger ant to that resultin g from its thermody namic properti es and the LMTD (log mean temperat ure differen ce) when pinching first occun. As can be seen in figure 7 (for the mixture R22/Rll4 ) properly chosen miXLurcs do not have a pinch point. Unlike a pure refriger ant, their LMTD continuo usly decreas~s and cycle efficien cy continuo usly increase s with increasi ng heat exchange r size. It should be noted that :mixtures always have: a th~rmody namic advantag e ovet" pure refriger ants because of Carnot versus Lorenz cycle consider ations and this advantag e is greatest when temperat ure lifts are low and pinch points approach ed. Whct:her this theoreti cal advantag e results in better efficien cy relacive to a given pure refriger ant depends on the respectl ve performa nce of the refriger ants in question . Figures 7c and d are temperat ure profiles for a heat exchange r configuJ: "ation (configu ration 3 is shown, configur ation 1 would be similar) in which pure R22 has 5 mixtur e efficie ncy (Figur e 7c) occurs with a The best than that result ing in the temper ature contai ning consid erably more R22 (75% R22) (Figur e 7d, 57% R22). In figure 1 ature temper water the ng matchi glide most nearly higher cycle efficie ncy in the much a in ed result R22 pure that seen lt could be this case where the mixtur e and the in Hence, R114. pure did than tus test appara LMTD' s, best perform ance occurs in a pure refrig erant can operat e at compa rable ent. Howeve r as can be seen in figure compon ming perfor better the in mi~ture rich cycle efficie ncy compar ed to pure R22. 8, the mixtur e still result s in improv ed not reache d a pinch point. 1 90 90 ~ ~ .. ... . . 75 ~ "' < ffi "" ~ 30 30 60 ~ .. ? 20 10 "' ai a: ~ t- 45 C.O P,- _. ~ ;;> ~ 75 u.i "'~"' 60 ~ ~ 111 .~ Re!ri~Qrllrlt ...... ? 20 ui ~0:"' 10 C.O f' • S ~ ~ 45 • ,!:i ~13 30 30 OISTANCe THROUGH EVAPORATOR DISTANCE THROUGH EVAPORATOR a) b) Config uratio n 1 Config uration 2 90 90 :;'- 75 g! "'~ 60 ~ "'....'" 30 30 ~ ' 45 c 0 p . 4.85 ? 20 u.i 0: "'~ 0: 10 ~ "~ t 75 L • W.,_l!!l • Rc!rlgertlnl w 0: ;;> 60 • \< 0: ~ ~ ? 20 10 45 C O.P • 5 ,II uf a: ;;> ~ "''" t- 30 DISTANc,; THROUGH EVAPORATOR 30 DISTANCE THROUGH EVAPOR ...TOR c) d) Config uratio n 3 Figure 6: WaLer and ~efrigerant Config uratio n 4 R22. evapor ator temper ature profil es using pure there is a high evapor ator UA and a Figure 7a and b are for a case in which Becaus e of the tenden cy for. 2)" on gurati (confi dt'op Both high refrig erant pressu re much of the glide is lost. re pressu W:i.th drop t.o ature satura tion temper re drop case has only for a 5n R22 mixure , but the high pressu 1 fisure 7b and 7d are case has a 25°F glide. A second liabil ity a l6°F glide where the low pressu re dr.op n result s from the consta nt heat in the hie;h pressu re drou co!lfig uratio for mixture~ tration s ty is reduce d with increa sed Rll4 concen flux 1;:e.st criter ion. Refrig erant. capaci gas sed compr essor speed result ing in highe-c which was compen sated for by increa For this case in which increa sed pressu re drop. veloc ities and, conseq uently nance a signif icant effact on system perforr pressu re drop was high enough to have 1 1 than expect ed conce ntratio n of R22. thi& result ed in best efficie ncy with a higher " which had low pressu re drop and the Figure 7e and 7f are for config uratio n an R22 concen tration which ncy occurs at best overa ll UA. In thi5 case best efficie glide glide closer to the water temper ature result s in a refrig erant temper ature efficie ncy measur ed in t.his cycle best t.he in and s uration than in the other confl"g Simple ement over pure R22 is shown. Referr ing to figure 1, a 32% improv study. using pure R22 and pure R1 J 4. cycles for ency effici. equal t predic eye le simula tions being t.o be caused by the compre ssor design Greatl y reduce d efficie ncy believ ed If compr essor ed with pure R114. observ was res, pressu ing operat the unsuit ed to ated, s mixtur e requir ements it is then est:.im design s were availa ble t.o suit the variou may be possib le. 1 over pure R22 as shown in figure 1, that a 44% improv ement n which result ed in the greate st It should again be noced that chis config uratio heat heat exchan ger area that the times four ed employ R22 pure improv ement over (see figure 6d). The pure R22 experi ences would be reason able for a pure R22 system utiliz e large heat. exchan gers y to effect ively a "pinch point" which limits its abilit riate te.rnperatur12 glides - a limit.a tion that mixtur es with approp do not experience. operating with If the heat eo<changer were s tlll larger, the mixture, "\ton the system, still better effie l~':.IIC)' would be expected to have a wh:i.c.h would not occur with pure R22. sor-------------------~ ?S 30 ~•W1Ii>t R22/R11417312-----71 1 . ~ ~ 20 ~~ ~ ~ Aatr.gnr~nt gt.~ll 45 coP .J § 10 r~ ~ P.~lfiOillrAnl !- c0 p • gild!! • 16 ;)"F 50~ 3QL_______________________ ~· 0 00~----------------------~ DISTANCE THROUGH EVAPORATOR DISTANCE THROUGH EVAPORATOR a) b) Configuration 2, best t:lide _ Configuration 2, best COP. 90 30 30c_________________________ , 30~----------------------~ DISTANCE THP.QUGH EVAPORATOR c) DISTANCE THROUGH EVAPORATOR Configuration 3 1 best COP_ d) Configuration 3, bcs t glide sor-------------------------,,0 so.-------------------------._,0 I W<'ltM ~ "'''"''"" ~ ~ 45 10 ~ R~lrtgcrJnt gtldo e se ~ OOL------------------------~ DISTANCE THROUGH EVAPORATOR DISTANCE THROUGH EVAPORATOfl. Configuration 4, best COP" Figure 7; ~ ~ coP L __ _ _ _ _ _ _ _ _ ____ e) 20 GO i 30 R2:?1R114 l6014QJ _______. ~? 75 f) Configuration 4, best glicle _ Evaporator temperature profiles for mixtures of R22/R114 which resulted in the highest COP and in a refrigerant glide most n<?:arly matching t:hat of the water (25'F, 3.9'C). 7 R22/R114 o W /0 liquid Ime H~ Conf1gurat1on 2 W /0 liquid line HX Configuration :3 c W/0 liquid line HX • W1th liquid line HX • With liquid line HX * With liquid l1nc HX r:. 4 100 so Conflguratlon Configuration Conf1gurC!.t1on Conf1gurat1on 60 4 2 S 4 40 WEIGHT %R22 Figure 8: Performance of the mixture R22/R114 for evaporator configurations 2, 3 ancl 4_ tion two! ~hree, 9 summarize s the test results for evaporato r configura Figure compositi ons of R13 and four for the mixture R13/R12. Tests were not run at high because of high discharge pressures . differenc e ng the between system performan ce for the mixture An outstandi in figure 8, is th~ R13/R12, as shown in figure 9, and that with R22jR114, as shown between the evaporati ng refrigera nt. and subcooled liquid effect of heat exchange refrigera nt leaving the This condenser . heat exchange dramatic ally improved the mixture R22/R114. efficienc y for the mixture R13/R12 but has lictle effect for R13/R12 v W/0 liquid line HX Conf1gurat1on 2 1J. W/0 l1quid l1ne HX Configuration 4 c With liquid line HX Configuration 2 4 o With l1q11id l1ne HX Configuration 3 <:1 W1th llqu1d line HX Configuration 4 100 80 20 40 60 WEIGHT % R13 Figure 9: 2, Performan ce of the mixture R13/Rl2 for evaporato r configura tion 3 and 4. '"!kJ/I<gl Eml1a1py Figure 10: ng Effect of heat exchange betw,en subcooled liquid and evaporati refrigera nt for a 40tj60% mixture of R13/R12. 10, a to be expected from this heat exchange can be seen in figure The benefits heat exchange for t:he pressure enchalpy plot of the cycle with and Wit:hout this 1' The intracycl e heat exchange results in expansion from point: mlxt:ure R13/R12. of the slope of t:he isocherms to point 2' instead of flashing from 1. to 2 _ Because 1 1 phase region evaporati on from poin~ 2 to point 3 results in the same in the t~o resulting in less average temperatu re as from point 2 to 3 but at: a higher pressure gj heat exchange must compresso r ~ork. Note that to achieve the requisite subcoolin r because of the take place in counterfl ow throughou t the length of the evaporato nearly vertical isotherms in the subcooled region. 1l. It can Similar cycle plot:s for che mixture R22/R114 are shown in figure t:wo phase region are be seen that the isothecms in the low quality portion of the r pressure for che nearly flat: resulting in no significa nt differenc e in evaporato pure refrigera nts. with case the also is as exchange heat Without and with cycles and not the The reason that intracycl e heat exchange can benefit one mixt:ure re as is temperatu of function Unear a ily necessar not is enthalpy other is chat nonlinea rity this o£ e importanc the o£ ation demonstr further ~ generally supposed. nt. and water temperatu res is shown in figure 12, comparing plots of refrigera has been drawn between line straight a figures these In r. evaporato through the the entering and leaving refrigera nt temperatu res t.o emph.;isizc t.hat one refrigera nc ha.s a concave and the other a convex temperatu re profile. This manifesta tion of nonlinea rity would interfere with cycle performan ce predictio n u:.ing simple computer programs in which only inlet and outlet temperatu res are specified and linearity is assumed within the heat exchange rs. Addi t:ionally, the pinch polnts whi.ch result: b:om this nonlinea rity reduce cycle efficienc y. Figure 11: Effect of heat exchange bet:ween subcooled liquid and evaporati ng refrit;era nt for a 60%/1.<0% mixture of R22/R114. 90 Ll. •Water 75 R13/R22 132/681 30 • Refrlgorant \? ui ui 20 CL CL ::> ::> ~ 60 "'w ::;: ~ w CL [)._ 10 w 45 >- [)._ ::; w >- 30 DISTANCE THROUGH EVAPORATOR 90 ~ ui 75 • Water • Refrigerant R22/R114 166/341 30 \? ::> 20 ui a: "'::; ~ c: w [)._ CL ::> ~ 60 w [)._ w >- 10 45 ::;: w >- 30L---------------------------~ DISTANCE THROUGH EVAPORATOR Figure 12: Compariso n of typical evapor.;to r temperatu re profiles for che mixtures R22/Rll4 and R13jR12. CONCLUSION 2 16% be 32t bette r, and a mixtu re of R13/R1 A mixtu re of R22jR1 14 was found to Some system ation. applic g cionin condi air an bette r, in effici ency than R22 in ancia lly it likely that mixtu res will subst design chara cteris tics that make gers~ large heat exchanger5~ exchan heat erflow count outper form pure refrig erant s are eranc and sourc e/sink fluid, match ing of refrig high tempe rature glide in the heat lift. rature tempe low a and heat sourc ejsink tempe rature glides region on of tempe rature in the two phase Nonli nearit y of enthal py as a functi intrac ycle heat to ct respe with design system on was observ ed to have an effec t model s. exchan ge and cycle simul ation using ACKNOWLEDGEMENT nity of the Office of Build ings and Commu The autho rs acknow ledge the suppo rt g chis work throug h the O"k fundin for Energy of tment Depar System s of the U.S. Marie cca ct DE-AC 05-840 R21400 with Martin Ridge Natio nal Labor atory under contra Energy System s, Inc. 10