Schneider Electric

Data Centre Facility Modules

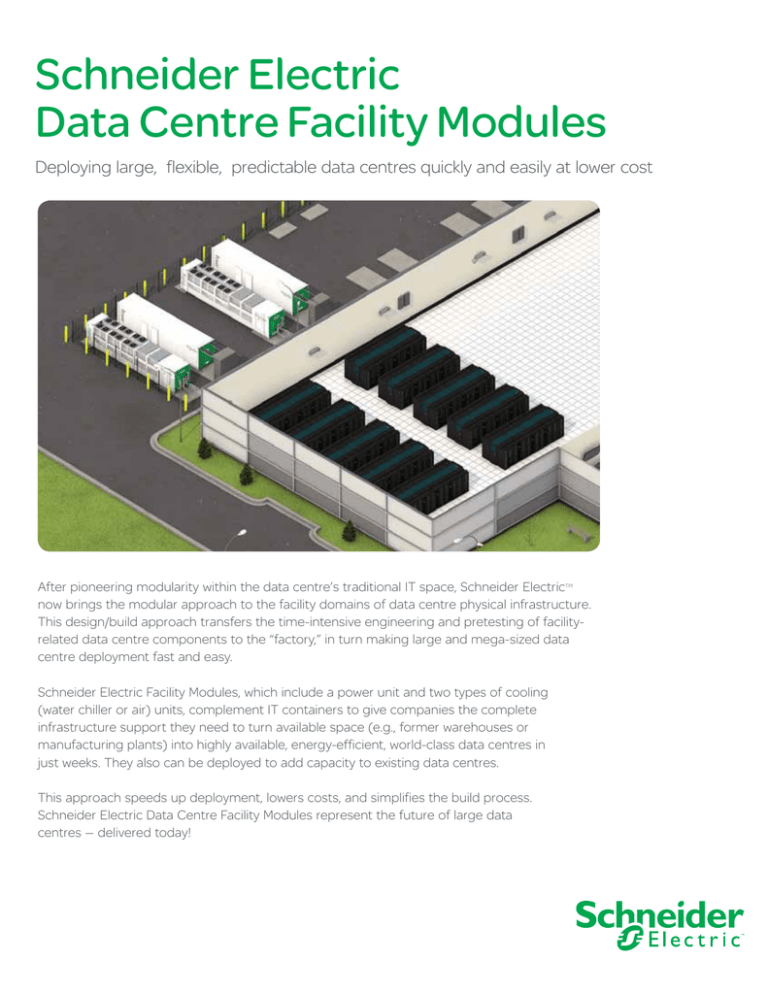

Deploying large, flexible, predictable data centres quickly and easily at lower cost

After pioneering modularity within the data centre’s traditional IT space, Schneider ElectricTM

now brings the modular approach to the facility domains of data centre physical infrastructure.

This design/build approach transfers the time-intensive engineering and pretesting of facilityrelated data centre components to the “factory,” in turn making large and mega-sized data

centre deployment fast and easy.

Schneider Electric Facility Modules, which include a power unit and two types of cooling

(water chiller or air) units, complement IT containers to give companies the complete

infrastructure support they need to turn available space (e.g., former warehouses or

manufacturing plants) into highly available, energy-efficient, world-class data centres in

just weeks. They also can be deployed to add capacity to existing data centres.

This approach speeds up deployment, lowers costs, and simplifies the build process.

Schneider Electric Data Centre Facility Modules represent the future of large data

centres — delivered today!

Step-and-repeat approach enables right-sizing

Cooling (water chiller option)

and Power Modules

500 kW

1.0 MW

1.5 MW

Schneider Electric has revolutionized large data centre build projects with the scalable, easy-to-deploy Data Centre Facility

Modules. You can grow your power and cooling capacity in 500 kW increments as you need it.

Why modular facility-level building blocks?

> Schneider Electric facility modules are pretested,

prewired and reduce overall data centre design

and deployment time to weeks

versus a traditional approach, which could take

months or years to complete.

> They deliver CapEx cost savings ranging

from 10 to 20 percent and OpEx savings

ranging from 20 to 35 percent.

> The modularization of the facility modules

enables right-sizing, or matching power

and cooling to the exact IT loads, thereby

optimizing PUEs.

> Highly efficient components, including UPS

units and chillers, in combination with

economization mode, contribute to

minimizing electricity use.

> Supply chain improvements are significant

as well, with lead times reduced from

months to just weeks.

Redundancy is scalable to availability needs

A 1N deployment (1 MW)

Scale up redundancy to 2N (1 MW)

The pre-engineered modules can be deployed according to the data centre’s specific redundancy needs.

Introducing the only modular, indirect economizer: EcoBreeze

> An economizer, EcoBreezeTM provides

indirect evaporative cooling or air-to-air

heat exchange in one footprint

> Right-sized cooling is made possible by

individual 50 kW modules that can be

grouped up to 400 kW per frame

> The IT airstream is isolated from the

outdoor ambient airstream

EcoBreeze is the air

cooling facility module

> Flexible and cost-effective deployment

since the unit uses no data centre space

Technical Specifications

400V 500kW Power Module

400V 500kW Chilled Water

Cooling Module

EcoBreeze™ 400V 400kW

Air Cooling Module

General

General

Generals

Output capacity

Primary bus/critical bus

Up to 1100kW Continuous /

Up to 500kW or 475kW N+1 UPS

ATS

2000A 4 Pole Closed & Open

Transitions

UPS topology

Modular, Scalable Double

Conversion Online

Climate control

Fire suppression

Efficiency at 100% load

Max. Capacity

500kW N+1 (143 tons) @ 35°C

ambient, CHW flow and return

15/21°C 30% Glycol solution

(100kW each chiller)

Free Cooling Capacity @15°C

500kW @ 5°C and constant water

flow (100kW each chiller)

Air cooled, direct expansion with free

cooling. Optional humidity control

Compressor Type

Tandem Dual Scroll

Refrigerant Type

R410A

IG541 (Inergen) fire extinguishing

system with smoke/heat detection,

VESDA, auto/manual actuation,

audible/strobe alarms

Chilled Water Storage Volume

(Apprx:)

4800 Litres (6 x 800 Litres)

4 minutes thermal capacity

Number of Chiller Modules

Up to 96%

Number of

Free Cooler Modules

Max. Water Flow Rate

26.88 litres/second

3.35 (at 35°C) and 13.85 in free

cooling mode (at 5°C)

Input

Input power voltage

(nominal)

400VAC

CoP

Grid system

3 phases + Neutral + PE

(Dual/Single mains)

Input (Pump House)

Voltage Range

+/- 10%, -6%

Frequency (Nom)

Air cooled, direct expansion with free

cooling. Optional humidity control

Max. Input Current

2000A @ 400V

Power Factor

>0.995 @ load = 100% (UPS)

ITHD

<5% @ Full Load (UPS)

Output

Voltage

Primary Bus 230/400V AC

Critical Bus 230/400V AC

Grid System

3 phases + neutral + PE,

(Dual/Single mains)

Voltage Regulation

<2% from 0 to 100%linear load/

<6% full non linear load per IEC/

EN62040-3

Output Current (Nominal)

Primary Bus 2000A Continuous

Critical Bus 722A Continuous

Battery System

Battery type

VRLA – Long Life Battery Modules

Estimated Runtime

5mins @ Full Load

Cooling

Cooling Redundancy

N+1

Cooling Capacity (nominal)

26.4kW (N+1) - DX

Refrigerant

R407C

Physical

Length

12,000mm

Width

2,720mm

Height

3286mm

Max. weight

22,500 kg

Stacking containers

Yes - Recommended

Two High Maximum

Environmental

Operating min/max temp.

-20° to 50°C

Operating humidity range

0-100%

Operating Altitude

0-1000m

Audible Noise

<60dB(A)

Main Options

Dual Feed Input ;

Load Bank Connection Breaker

Additional Features

Physical surveillance cameras; fire

suppression system; integrated power

management system and controls;

Fibreport; Digital entry locks

400kW

Frame

Module

200kW

Frame

Weight

1202 kg*

7711 kg*

15 422 kg*

Length

2,9 m

6,1 m

12,2 m

Height

2,6 m

2,9 m’

2,9 m

6 (5 +1 redundant)

Width

1,1 m’

2,4 m

2.4 m

6 (5 +1 redundant)

IT air flow

8495 m3/H

33 980 m3/H

67 960 m3/H

Outside air flow

11 893 m3/H

47 572 m3/H

95 144 m3/H

Cooling capacity

50 kW

200 kW

400 kW

Input Power Voltage

(Nominal)

230V / 400V AC

Frequency (Nom)

50Hz +/- 1 Hz

Typical Current Draw

(Full Load)

Apprx: 28 A @ 400VAC

Input (Chillers)

Input Power Voltage

(Nominal)

400V AC

Frequency (Nom)

50Hz +/- 1Hz

Typical Current Draw

(Full Load)

68.5 A (each Chiller)

Input Current Rating / Full

Load current (FLA)

93A (each Chiller)

Inrush Current

215A

Locked rotor amperage (LRA)

267A

Mechanical

Economization Comparisons

1 MW Design Data @ 60% Load

System

Architecture

Partial PUE

kW - Hr/Yr

Relative

Power

EcoBreeze

1.09

466,518

45%

Air econ w/heat

Wheel

1.10

503,999

48%

Water-cooled

chiller w/econ

1.14

728,195

70%

Air-cooled

chiller w/eco

1.16

846,039

81%

Fresh air econ

1.14

718,159

69%

DX fluid-cooled

CRAC w/econ

1.20

1,044,073

100%

Number of

Chilled Water Pumps

2 (Run & Standby operating

at variable speed)

Pump Motor Size

15kW

Maximum Head

300 (kPa) (includes allowance for

field pressure drop – final selection

to suit client’s installation)

VFD’s

One Altivar VFD per pump

Hydronic Module Provided:

Glycol Injector, Dosing Pot,

Deaerator, Expansion Vessel,

Pressurization Units, Y pattern

Strainers, Temperature Sensors,

Pressure Gauges, Flow switches,

Pressure Relief Valve, Motorized

2 Port Valves, Commissioning

valves, Flushing Bypasses, Local

isolating valves to all plant items.

*Approximations based on current

design subject to change

125mm diameter flanged

heavy grade steel

1. Hot aisle containment 38.6° C Return to A/C

Cooling Water Supply/Return

Physical

2. Supply air/cold aisle 25° C

Length

12,910mm

Width

2,611mm

Height

3187mm

Max. Weight (Est.)

27,000 kg

Environmental

Operating min/max

temperatures

-25°C to 50°C (52°C at full load

for short time / 60°C at part

load for short time)

Operating humidity range

0-100%

Operating Altitude

0-1000m

Audible Noise (Apprx:)

60dB(A) @ 9.1m (52dB(A) |

@ 9.1 m each chiller)

3. Bin Weather Data, Saint Louis, MO

4. Does not reflect humidification losses

5. All systems should have fan control proportional

to IT load of design

© 2011 Schneider Electric. All Rights Reserved. Schneider Electric, APC, and EcoBreeze are trademarks owned by Schneider Electric Industries SAS or its affiliated companies. All other trademarks are property of their respective owners.

132 Fairgrounds Road, West Kingston, RI 02892 USA