CARRIER GAS SELECTOR MODEL CGS

advertisement

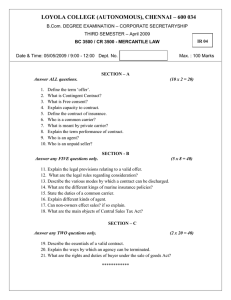

Ver 1.10 CARRIER GAS SELECTOR MODEL CGS-1050Ex OPERATION MANUAL www.frontier-lab.com BEFORE USING THIS DEVICE Thank you for purchasing the Carrier Gas Selector from Frontier Laboratories Ltd. This manual contains descriptions on installation and operation. Read this manual along with operation manuals of your gas chromatograph, Frontier Lab’s Pyrolyzer and/or Selective Sampler. Specification and replacement parts are subject to be changed without notice. PRODUCT WARRANTY Frontier Laboratories Ltd. warrants this product against defects or failures in accordance with the warranty terms and conditions stipulated in a separate sheet. The product warranty can also be downloaded from our website. ABOUT PRODUCT SUPPORT PERIOD We will stock consumable and maintenance parts and will accept inspection and repair orders seven years from the date of product sales termination. However, in the event where electronic parts supplied from parts manufacturers are discontinued; thus our stock level becomes too low, we may not be able to provide support even within seven years from the date of product sales termination. A-2 Ver. 1.10 FOR YOUR SAFETY To use this product safely and properly, be sure to read the safety precautions and warnings before attempting to operate. If this product is used in a manner not instructed in this manual, the protective functions of this product may not be activated. Frontier Laboratories Ltd. will not be responsible for losses incurred due to the neglect of these precautions and warnings. WARNING SYMBOLS AND SIGNAL WORDS The following warnings precautions labels are affixed to this product and this manual. When these precautions are displayed, it indicates that misoperations may cause severe injury to your body and the products. In this manual, the safety instructions are ranked as warning and caution. Be sure to fully understand and follow these precautions. ! ! ! WARNING CAUTION This hazard signs indicates that incorrect handling may cause hazardous conditions, resulting in death or severe personal injury. This sign indicates that incorrect handling may cause hazardous conditions resulting in minor or moderate personal injury and physical damage. NOTE Other important handling information is placed in a frame like this. A-3 Ver. 1.10 CONTENTS IN THE PACKAGE CGS-1050Ex Packing contents check list This product is including following items. We recommend that you first examine the contents of the package you have received. If the contents differ from the package list below, or some items are missing, contact your dealer immediately. A) contents: C) contents: C1) PY1-7052 A1) C) Operation Manual CD, etc Operation Manual CD Installation guide B) Accessories A) Carrier Gas Selector ※ View from top Inspection report Carrier Gas Selector (1unit) B) contents: B2) CG1-4020 B1) AC Power Cable (1ea) 100V (Re-order: PY1-7001, 1ea) B3) CG1-6800 Valve Control Cable (2m, 1ea) CGS tubing Kit for Agilent6890/7890 (1set) Tubing Kit [one of these kit is included in this package B3) CG1-2010 B3) CG1-1700 B4) Common Tubing Kit (1ea) CGS tubing Kit for Shimadzu GC-17A (1set) B3) CG1-9001 CGS tubing Kit for Shimadzu GC-2010 (1set) B3) CG1-9003 CGS-1050Ex tubing kit for TRACE GC Ultra (1set) CGS tubing Kit for TRACE 1300/1310GC (1set) B3) CG1-3800 B3) CG1-5800 CGS tubing Kit for VarianGC3800/450 (1set) CGS tubing Kit for PerkinElmer Clarus580/680 (1set) A-4 Ver. 1.10 CONFIGURATION OF THE CONNECTING KITS 1. Connection kit for Agilent GC 6890/7890 (CG1-6890) Connect to the outlet tubing from the GC carrier gas flow controller. Use this fitting to connect to HP5890 Connect to GC injection port Connect to “IN (From GC)” of the flow controller. Connect to “OUT(GC INJ)” of the flow controller Extension tube for carrier gas tubing to the Pyrolyzer 2. Connection kit for Shimadzu GC-17 (CG1-1700) Connect to the outlet tubing from the GC carrier gas flow controller. Connect to “IN (From GC)” of the flow controller. Connect to GC injection port Connect to “OUT(GC INJ)” of the flow controller Extension tube for carrier gas tubing to the Pyrolyzer 3. Connection kit for Shimadzu GC-2010 (CG1-2010) Connect to “IN (From GC)” of the flow controller. Connect to the outlet tubing from the GC carrier gas flow controller. Connect to GC injection port Connect to “(OUT GC INJ)” of the flow controller Extension tube for carrier gas tubing to the Pyrolyzer A-5 Ver. 1.10 4. Connection kit for Trace GC (CG1-9001) Connect to the outlet tubing from the GC carrier gas Connect to GC injection port Connect to “IN(From GC)” of the flow controller. Connect to “OUT GC INJ)” of the flow controller Extension tube for carrier gas tubing to the Pyrolyzer 5. Connection kit for Trace GC (CG1-3800) Connect to the outlet tubing from the GC carrier gas flow controller. Connect to “IN(From GC)” of the flow controller. Connect to GC injection port Connect to “OUT GC INJ)” of the flow controller Extension tube for carrier gas tubing to the Pyrolyzer A-6 Ver. 1.10 TABLE OF CONTENTS BEFORE USING THIS DEVICE ························································································ A-2 PR O D UCT W AR R AN T Y ····························································································· A-2 AB O UT P RO DU CT S U P PO RT P E RIO D ····································································· A-2 FO R Y O U R S AF ET Y ·································································································· A-3 CONTENTS IN THE PACKAGE ························································································ A-4 CONFIGULATION OF THE CONNECTIONG KITS ······························································· A-5 TABLE OF CONTENTS ·································································································· A-7 CHAPTER 1 INTRODUCTION ·························································································· 1-1 1.1 Product Features ·································································································· 1-1 1.2 System Overview ·································································································· 1-1 1.3 Front and Rear Views ···························································································· 1-3 CHAPTER 2 SPECIFICATIONS ························································································ 2-1 CHAPTER 3 INSTALLATION ··························································································· 3-1 3.1 Installation Procedure ···························································································· 3-1 3.2 Testing Gas Leakages and Checking Tubing Connections ············································· 3-3 CHAPTER 4 OPERATION ······························································································· 4-1 4.1 Operation ············································································································ 4-1 4.2 Example of Switch Settings ····················································································· 4-2 4.3 Remote control ····································································································· 4-3 CHAPTER 5 USING AIR AS CARRIER GAS ······································································· 5-1 A-7 Ver. 1.10 CHAPTER 1 INTRODUCTION 1.1 Product features Feature 1: Useful to conduct experiments of chemical reactions between samples and an active carrier gas (e.g. air). Experiments with varied heating conditions can be performed using the programmed heating feature of Multi-Shot and Double-Shot Pyrolyzer. Feature 2: Quick and easy switching of carrier gases. Employing magnetic valves, dead volume of the flow path is minimized (less than 5ml). Feature 3: Fail-safe mechanism is employed. When the pyrolyzer is not in use, the mechanism prevents the active carrier gas from flowing into the separation column. Feature 4: Auto switching of flow path with electromagnetic valves through only PC control display of EGA/PY-3030D or PY-3030S. 1.2 System Overview Fig. 1.1a-c show the flow diagrams of the CGS-1050Ex connected with Py-GC system in the cases of each switch position. Two kinds of different carrier gases (normally He and air) connected to the device are switched by the magnetic valves 1 and 2. And the gas selected is introduced into the pyrolyzer or GC injection port by the magnetic valve 3. The flow rate of He gas is controlled by the flow controller of GC (FC). The air flow rate is controlled by the mass flow controller mounted on this device. See chapters three and four for details in connections. GC Inj. FC He CGS-1050EX He “IN (From GC)” GC Magnetic valve1 MFC Air PY To GC Inj. “OUT (GC INJ)” Magnetic valve3 Air “IN (Air)” To Pyrolyzer “OUT (PY)” Magnetic valve2 EGA/PY-3030D Control Magnetic valve1&2 Fig. 1.1a Flow Diagram (He-Py) 1-1 Ver. 1.10 GC Inj. FC He CGS-1050EX He “IN (From GC)” GC Magnetic valve1 MFC Air PY To GC Inj. “OUT (GC INJ)” Magnetic valve3 Air “IN (Air)” To Pyrolyzer “OUT (PY)” Magnetic valve2 EGA/PY-3030D Control Magnetic valve1&2 Fig. 1.1b Flow Diagram (Air-Py) GC Inj. FC He CGS-1050EX He “IN (From GC)” GC Magnetic valve1 MFC Air PY To GC Inj. “OUT (GC INJ)” Magnetic valve3 Air “IN (Air)” To Pyrolyzer “OUT (PY)” Magnetic valve2 EGA/PY-3030D Control Magnetic valve1&2 Fig. 1.1c Flow Diagram (He-GC) 1-2 Ver. 1.10 1.3 Front and Rear Views Fig. 1.2 shows the front view and Fig. 1.3 shows the rear view of the device. Power Lamp AUTO POWER Control mode switch GC He MANUAL Air/He Selection Switch AIR FLOW PY AIR PY/GC Selection Switch Mass Flow Controller for Air Fig. 1.2 Front View of the Device GC Injection port joint PY joint OUT (PY) OUT (GC INJ) ON Power Switch Air IN joint POWER He IN joint Connects to outlet of carrier gas flow controller of GC. OFF IN (From IN (Air) GC) 0.5A AC 100V/115 10W AC Power Socket VALVE CONTROL Fuse Valve control cable connector Fig. 1.3 Rear View of the Device 1-3 Ver. 1.10 CHAPTER 2 SPECIFICATIONS 1. Maximum gas pressure : 600kPa 2. Carrier : Either one of Air, O2, H2, and CH4 can be used as an active gas. gases The other gas must be either He or N2, and must be connected to the He IN port. If active gases other than these are used, seek advice from us. 3. Power requirement : AC100/115V, 0.5A 4. Required PY : Multi-Shot pyrolyzer (EGA/PY-3030D), Single-Shot pyrolyzers (PY-3030S, PY-2020iS), Double-Shot pyrolyzer (PY-2020iD). 5. Required GC : Agilent 7890/6890 Shimadzu GC-2010 Perkin Elmer Clarus 500 Thermo Fisher TRACE GC Ultra, TRACE 1300/1310GC) Varian GC-CP3800/450 *If your GC is not listed above, contact our sales rep. or Frontier Labs. 6. Display of Carrier gas in use : Red (Air or other active gas) Green (He or N2 ) 7. Carrier gas switching : Flow path switching by magnetic valves. Manual mode: manual switching Auto mode: PC controlled by EGA/PY-3030D or PY-3030S ** Appearance and specifications are subject to modifications without notice for product improvements. ! WARNING Frontier Laboratories shall not be liable for any damage or loss incurred by the use of flammable, corrosive or toxic gas. 2-1 Ver. 1.10 CHAPTER 3 INSTALLATION 3.1 Installation Procedure Follow the steps 1 through 7 to properly install the device. Please refer to Table 3.1, Fig 3.1 of this manual and Chapter 3 of the Pyrolyzer Operation manual. Step 1: Set the device in the vicinity of a GC system. Step 2: Referring to Fig. 1.1 and Fig. 1.3 connect the GC flow controller (He or N2) to the “IN (From GC)” port on the rear panel using a tubing supplied. Step 3: Connect the “Out (GC INJ)” port to the tubing from the GC injection port using a tubing supplied. Step 4: Connect the Pyrolyzer “Carrier IN” tubing to the “OUT (PY)” port. enough to connect them, use a 1/16・tubing supplied. If the tubing is not long To connect this tubing to “Pyrolyzer Carrier IN” tubing, use a 1/8” union and rubber seals (contained in the Pyrolyzer installation kit). Step 5: Connect an active gas, e.g.. Air, to the “IN (Air)” port. The customer must prepare the tubing for this purpose. Step 6. Connect the valve control cable (to connect with EGA/PY-3030D or PY-3030S only) between valve control connector and the “CGS VALVE” connector of the temperature controller of pyrolyzer. Step 7: Plug the power cable supplied to the power socket. ! CAUTION When using Air as an active gas, GC grade air from a cylinder should be used and set the pressure to 300kPa. Using compressed air (e.g. air from a compressor) may result in contaminations (moisture and/or old) of the flow path. 3-1 Ver. 1.10 Connection Port Connect To OUT (GC INJ.) GC injection port Pyrolyzer Carrier In OUT(PY) IN (From GC) GC Carrier gas controller IN (Air) Air cylinder Table 3.1 Gas tube Connections OUT (GC INJ.) OUT (PY) PY GC AIR IN (From GC) IN (Air) Fig.3.1 Overview of Gas Tubing Connections When GC is used without pyrolyzer, turn “AUTO/MANUAL” switch to “MANUAL”. 3-2 Ver. 1.10 3.2 Testing Gas Leakages and Checking Tubing Connections 3.2.1 Testing Gas Leakages When tubing connections are completed, test the whole system to make sure there is no gas leakage using a gas leak detector or leak check liquid. 3.2.2 Checking Tubing Connections If gases are connected to wrong ports, serious damage of the separation column may result. To avoid misconnections of tubings, check connections of tubings according to the procedures described below. Step 1: Remove the pyrolyzer furnace from the GC injection port. Step 2: Remove the separation column from the GC and plug the outlet of injection port with something like a cap nut. Step 3: Set the switches of the device “He”, “GC” and “MANUAL” as shown in Fig.3.2 (He selected as carrier gas, and supplied to GC injection port) Step 4: Set the column inlet pressure to 100kPa, total flow rate to 100mL/min by the GC flow controller. Then check the column pressure to see if it reaches the set point. Wear a pair of safety goggles ! CAUTION When the pyrolyzer is removed from the GC injection port, the sharp needle becomes exposed. He AUTO GC MANUAL AIR PY AIR FLOW Fig.3.2 Switch Settings in STEP 3 3-3 Ver. 1.10 STEP 6: Gently turn the mass flow controller knob (Air Flow knob, see Fig. 1.2 ) clockwise until the air flow stops. Do not force to turn the knob. ! CAUTION STEP 7: Turning the mass flow controller knob excessively will damage the mass flow controller. Set the switch of the device as shown in Fig.3.3 (Select He as the carrier gas, supplied to Pyrolyzer). Immerse the tip of the pyrolyzer needle to methanol (Fig. 3.4) to confirm that gas is coming out from the needle. He GC AUTO MANUAL AIR PY AIR FLOW Fig.3.3 Switch settings in STEP 7 Carrier gas Bubbles Pyrolyzer furnace Methanol Fig. 3.4 Confirming Gas Flow through the Pyrolyzer 3-4 Ver. 1.10 STEP 8: Set the switch of the device as shown in Fig. 3.5 (Select Air as carrier gas, fed to Pyrolyzer) and set the He carrier gas flow from the GC to zero by GC flow controller. STEP 9: Turn the mass flow controller knob (Air Flow, Fig.1.2 ) counterclockwise by six turns to increase the Airflow. And make sure that the gas is coming out from the needle in the same manner described in STEP 7. AUTO He GC MANUA L AIR PY AIR FLOW Fig.3.5 Switch settings in STEP 8 If abnormal symptoms are observed, check the gas tubing connections again and perform testing procedures from STEP 1 through 9. ! CAUTION Wrong gas tubing connections may cause serious damage to the separation column. 3-5 Ver. 1.10 CHAPTER 4 OPERATION 4.1 Manual operation STEP 1: Turning the power switch to ON. Plug the power cable to the device, then turn the power switch to ON. Power indication lamp on the front panel will come on. STEP 2: Set the control mode switch (Fig. 1.2) to “MANUAL”. STEP 3: Selecting carrier gas. Select either He or Air (or any other active gas) by the Air/He selection switch. The selected gas is indicated by the lamp on the front panel. STEP 4: Setting carrier gas flow direction. Set carrier gas flow direction to either Pyrolyzer or GC Injection port by the PY/GC selection switch. When the Pyrolyzer is used, flip it to “PY” and flip it to “GC” while the Pyrolyzer is not used, STEP 5: Adjusting carrier gas flow rate. Each carrier gas flow rate can be adjusted by the flow controller shown below. ! He: GC flow controller Air: Mass flow controller mounted on the device (Fig. 1.2). When selecting “GC” flow direction, please note that only He will CAUTION flow to GC injection port, even if the switch is set to Air. 4-1 Ver. 1.10 4.2 Example of Switch Settings. 1) PY-GC analysis under He atmosphere using a pyrolyzer Select He and PY as shown in Fig. 4.1 Adjust carrier gas (He) flow rate using the GC flow controller. With this setting, He will be fed to GC through Pyrolyzer. AUTO GC He MANUAL AIR PY AIR FLOW Fig. 4.1 Switch Settings in PY-GC Analysis Under He 2) PY-GC Analysis Using Air Select Air and PY as shown in Fig. 4.2. Indicator lamps will come on. Adjust carrier gas (air) flow rate using the flow controller on the device. With this setting, Air will flow to GC through Pyrolyzer. Make sure that the column oven temperature is low enough to protect the separation column. AUTO GC He MANUAL PY AIR AIR FLOW Fig. 4.2 Switch Settings in PY-GC Analysis Under Air 4-2 Ver. 1.10 3) IF Pyrolyzer is Not Used Select He and GC as shown in Fig. 4.3. Note that AIR cannot be selected as a carrier gas. Adjust carrier gas (He) flow rate using the GC flow controller. Even when the device power is OFF, He gas stays streaming into GC, independent of the switch settings; therefore normal GC analysis can be performed. AUTO He GC MANUAL PY AIR AIR FLOW Fig. 4.3 Switch Settings When Pyrolyzer is not used. 4.3 Remote control Verify that the valve control cable is connected between “VALVE CONTROL” connector on the back panel of the CGS-1050Ex and the “CGS VALVE” connector of the temperature controller of EGA/PY3030D or PY-3030S. Set the control mode switch to “AUTO”. When “AUTO” mode is selected, “PY” is automatically selected and “GC”/”PY”, “He”/”AIR” switches become nonfunctional. “He”/”AIR” selection can only be done through EGA/PY-3030D or PY-3030S temperature control software. Refer to the Chapter 4 of the operation manual of your pyrolyzer for detail about controlling CGS-1050Ex from EGA/PY-3030D or PY-3030S. 4-3 Ver. 1.10 CHAPTER 5 USING AIR AS CARRIER GAS An example of PY-GC analysis using Air as carrier gas is described below. 1) Plain glass liner (no packing) is recommended for the GC injection port. ! CAUTION We strongly recommend that you use this device in combination with Selective Sampler (SS-1010E) when conducting Py-GC analysis using air as a carrier gas to prevent the separation column from accidental damage. 2) Cool the column oven down to room temperature. Then load up a sample to the double-shot sampler or single-shot sampler and install it on your pyrolyzer. 3) Select Air and PY. 4) Immerse the front of a separation column into liquid nitrogen in a Dewar as shown in Fig. 5.1. GC injector ~ ~ SS adapter To detector Separation column Immerse 10-30 cm of the head of column into liquid nitrogen. Liquid nitrogen in Dewar Fig. 5.1 Trapping gases at the front of a separation column using liquid nitrogen 5-1 Ver. 1.10 5) Drop the sample cup. Gases formed from the sample will be trapped at the front of the column dipped in liquid nitrogen. 6) Switch the carrier gas to He after 30 seconds since the pyrolysis has started. 7) If Selective Sampler (SS-1010E) is used, switch the sampling “OFF”. 8) Wait for at least 10 min to purge the air with He. 8) Remove liquid nitrogen, close the GC oven door then start the oven temperature program to analyze the gases. ! CAUTION If MS (Mass Spectrometer) is in used as a detector, wait enough time to purge air from the MS chamber after switching the carrier gas to He. For example, 30m-long, 0.25mm id column is used, wait at least 5 min after the carrier gas is switched to He. Waiting time depends on column flow rate of carrier gas and the pumping efficiency of MS. 5-2 Ver. 1.10