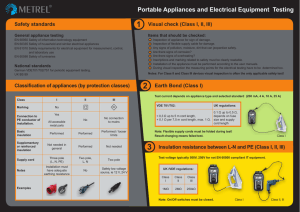

SAFETY OF HOUSEHOLD AND SIMILAR ELECTRICAL

advertisement