1. introduction 2. historic background

advertisement

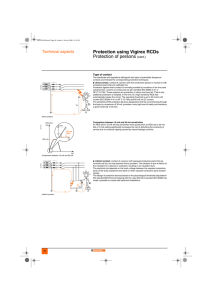

SAFETY OF PHOTOVOLTAIC MODULES – AN OVERVIEW OF THE SIGNIFICANT CHANGES RESULTING FROM MAINTENANCE OF IEC 61730 SERIES Bengt Jaeckel1, Guido Volberg2a, Joerg Althaus2b, Gerhard Kleiss3, Peter Seidel4, Markus Beck5 and Arnd Roth6 1 UL International GmbH, Admiral-Rosendahl-Strasse 9, 63263 Neu-Isenburg (Zeppelinheim), Germany 2a TÜV Rheinland LGA Products GmbH, Am Grauen Stein, 51105 Köln, Germany 2b TÜV Rheinland Energie und Umwelt GmbH, Am Grauen Stein, 51105 Köln, Germany 3 SolarWorld AG, Martin-Luther-King-Straße 24, 53175 Bonn, Germany 4 First Solar GmbH, Rheinstraße 4, 55116 Mainz, Germany 5 Siva Power, 2387 Bering Drive, San Jose, CA 95131, United States 6 VDE Prüf- und Zertifizierungsinstitut GmbH, Merianstraße 28, 63069 Offenbach, Germany ABSTRACT: Since release of Edition 1 of IEC 61730 series the photovoltaic industry has experienced rapid growth and undergone a large number of changes. As a result, during the past two years Working Group 2 (WG2) of the technical committee for Solar Photovoltaic Energy Systems (TC82) of the International Electrotechnical Commission (IEC) invested a considerable effort in updating the governing PV module safety standards to respond to PV industry needs as well as reflect technological changes and advances. In particular, with the revision of IEC 61730 a need to reflect the current understanding of low voltage DC (up to 1,500V d.c.) components and materials used in the construction of PV modules arouse. This includes permitting new materials and new designs while at the same time complying with international horizontal standards that need to be met in order to comply with governing national electric codes. Part 1 of IEC 61730 addresses the minimum requirements for module design while Part 2 deals with the required tests protocols and test sequences. New tests have been added to Part 2 of Edition 2 as the material requirements necessitate the confirmation of their properties during PV module operation. This paper explains the most crucial changes to Edition 1 of IEC 61730 series and shows that most PV modules on the market today already fulfill the requirements of the second edition. In this context it is important to understand the concepts of component approvals, insulation coordination, protection against electric shock, overvoltage category, protection class, material group and pollution degree as well as the resulting voltage limitation conjunction to minimum clearances (cl) and creepage distances (cr) and distance through insulation (dti) for cemented joints. Keywords: IEC, IEC 61730, safety, insulation coordination, protection against electric shock, protection class, pollution degree, cemented joint 1. INTRODUCTION In 2013 the globally installed photovoltaic (PV) capacity reached the 100 GWp milestone. While distributed generation (DG) of small (≈1 kW - 20 kW) roof top PV systems still constitutes a significant market share, the trend in today’s PV systems is to medium (≈100 kW - 1 MW) and increasingly large-scale (> 1MW) installations. With average PV module sales prices decreasing to the ≈$US0.70/Wp level balance of system (BOS) costs constitute a far larger portion than in the past. In particular, labor and cabling dominate BOS costs driving system designs to increasingly higher system voltages – in the 1,000 V - 1,500 V range. Higher voltages further reduce electrical system losses. Such high DC voltages constitute new challenges for PV system component designs and materials that need to be addressed in the relevant standards. As such, maintenance of the pertinent standards needs to assure compliance with state-of-the-art knowledge and best practices. 2. HISTORIC BACKGROUND The first international standard governing minimum construction requirements for the safety of photovoltaic (PV) modules, IEC 61730 Ed. 1, was published in 2004. Prior national standards were based on commonly observed field failure modes – most prominently from the JPL Block Buys I-V (1975-1981) [1], [2]. The main focus was on crystalline PV modules with solar cells of typically 500µm thickness. Out of the JPL blocks, UL 1703, and standards specific to several regional certification laboratories Edition 1 of IEC 61730 was developed to supplement the type approval standards IEC 61215 and IEC 61646 [3]. The following list summarizes the most important steps during the development of both standards [1], [2]. 1975-1981: JPL ‘Block Buys’ I-V (c-Si) 1986: 1st Edition of UL 1703 1981-1991: ESTI – EU Specifications 501-503 1990: SERI IQT modifications for TF (a-Si) 1993: 2nd Edition of UL 1703 1995-2000: IEEE 1262 – for all PV technologies, a hybrid between IQT and IEC 61215 2002: 3rd Edition of UL 1703 2004: IEC 61730-1 Edition 1 published 2004: IEC 61730-2 Edition 1 published 2008: Edition 2 of IEC 61730-1 initialized (IEC document 82/536/MCR) 2012: IEC 61730-1 Edition 1.1 published with reference corrections and implementation of Amendment 1 2013: ETF-9 decision sheet (DSH 1051) for cemented joints Both parts of the IEC 61730 standard series work in conjunction. Part 1 states the construction and component requirements for individual applications while Part 2 contains all testing requirements to verify the materials used and manufacturing processes result in a safe PV module. A large portion of the related accelerated stress tests are similar or identical to those from IEC 61215 and IEC 61646. The rationale of this approach is rooted in the fact that failure modes and requirements are similar for both performance and safety aspects. However, IEC 61730 focuses primarily on the safety aspects related to protection against electric shock as well as fire hazard. Over the past decade PV module technology changed significantly, hence, a comprehensive correlation cannot always be established between past observed field failures for older module constructions to failures in accelerated stress tests for newer module types. To this effect, the newly introduced tests and test sequences in Edition 2 aim to better represent outdoor failures with the main focus on assuring the PV module design is safe. 3. MOTIVATION Over the past several years TC 82 WG 2 spend a significant effort on updating the IEC 61730 series. Amendments and decision sheets were issued to correct the most pressing issues. However, the fundamental problems were not completely resolved. The objective was to address the latter in a new edition of the standard. To this end a dedicated project team was formed in 2013 with the task to thoroughly revise and update the standard and to bring it to the voting stage (CDV) within 2 years. The following objectives were set: Align the PV safety standard and its requirements with horizontal IEC standards Full implementation of 1,500V system voltage requirements Updates related to technology and material advances such as cemented joints 4. TERMS AND DEFINITIONS The new standard series of IEC 61730 requires numerous key definitions and a detailed understanding of electro technical horizontal standards. To better comprehend the underlying concepts of IEC 61730 Ed. 2 the paragraph below lists several essential definitions. Further detail can be found in the Terms and Definitions clauses of the upcoming IEC 61215 Ed.3 and IEC 61730 Ed.2 series. Distance through Insulation (dti): The distances through insulation that are required for supplementary, double or reinforced insulation. Thickness depends on several parameters and distances are stated in Tables 3 and 4 of the most recent IEC 61730-1 draft. Basic insulation: Insulation of hazardous-live-parts which provides basic protection against electric shock. Double insulation: Insulation comprising both basic insulation and supplementary insulation. Functional insulation: Insulation that is necessary for the proper functioning of the equipment. Reinforced insulation: Insulation of hazardous-live-parts which provides a degree of protection against electric shock equivalent to double insulation. Reinforced insulation may comprise several layers that cannot be tested separately as basic insulation or supplementary insulation. Solid insulation: Solid insulating material interposed between two conductive parts or between conductive parts and outer accessible parts or surfaces. Clearances distance (cl): The shortest distance through air between two conductive parts, or between a conductive part and an accessible surface. Creepage distances (cr): The shortest distance along the surface of the insulating material between two conductive live parts or between conductive live parts and accessible parts. 5. CONCEPTS FROM STANDARDS HORIZONTAL For over a century the different technical committees (TC) within IEC have developed a series of fundamental horizontal standards that apply to several TCs. IEC defines a horizontal standard as follows: “Standard on fundamental principles, concepts, terminology or technical characteristics, relevant to a number of technical committees and of crucial importance to ensure the coherence of the corpus of standardization documents. “ Horizontal standards are assigned by the Standardization Management Board (SMB) with the purpose of: Ensuring the coherence of the corpus of standardization documents, Avoiding duplication of work and contradictory requirements, and are part of IEC Guide 108 “Guidelines for ensuring the coherency of IEC publications – Application of horizontal standards” [4]. The next paragraphs review the most important and fundamental concepts from the horizontal standards that have to be applied to PV as well. a. Concept of Insulation Coordination Insulation coordination was introduced in power system to arrange the electrical insulation levels of different components in the electrical power system in such a manner that the failure of insulators, when occurring, is confined to the place where it would result in the least damage of the system and is easy to repair and replace. This leads to a probability of failure study of all insulating parts to find the weakest insulation point nearest to the power source. I.e. the aim of insulation coordination is to reduce the risk of failure to an economically and operationally acceptable level of cost and disturbance of normal operation caused by insulation failure. The IEC 60664 series defines and uses the concepts of insulation coordination [5], [6], [7]. The respective IEC definition of Insulation coordination is as follows: Insulation co-ordination [IEV 604-03-08]: The selection of the electric strength of equipment in relation to the voltages which can appear on the system for which the equipment is intended, and taking into account the service environment and the characteristics of the available protective devices. Subsequently the following aspects are essential: 1. What are the voltages that can occur? ! Overvoltages 2. The intended use of the equipment – here the PV module. 3. Environment and serviceability of the equipment. b. Overvoltage Category The overvoltage category is defined in IEC 60664-1 clause 4.3.3.2 [5]. The concept of overvoltage categories is used for equipment energized directly from the low voltage mains. The overvoltage categories have a probabilistic implication rather than the meaning of physical attenuation of the transient overvoltage downstream in the installation. An overvoltage category is a measure which defines a condition concerning the transient overvoltage. Categories I, II, III, and IV are applied for equipment used in low voltage systems; PV installations need to comply with these requirements. Category IV: Equipment for use at the origin of the installation, e.g. electricity meters. Category III: Equipment for use in fixed installations and for cases where the reliability and the availability of the equipment is subject to special requirements, e.g. equipment for industrial use with permanent connection to the fixed installation and that includes PV system. Category II: Equipment that is energy-consuming equipment and supplied with power from the fixed installation. Examples of such equipment are appliances or other loads within a household. If such equipment is subjected to special requirements with regard to reliability and availability, overvoltage category III applies. Category I: Equipment for connection to circuits in which measures are taken to limit transient overvoltage to an appropriately low level. These measures shall ensure that the temporary overvoltage that could occur are sufficiently limited so that their peak value does not exceed the relevant rated impulse voltage. Equipment of overvoltage category I cannot be directly connected to the supply mains. Examples are computer mice or keyboards. Overvoltage in general is a voltage in a circuit or part of it, when it is raised above its upper design limit. The conditions may be hazardous, but this will depend on the overvoltage event duration. The overvoltage event can be transient, a voltage spike, or permanent, leading to a power surge. As per the definitions above from IEC 60664 and with agreement of TC 109 (Insulation co-ordination for lowvoltage equipment) PV modules are Overvoltage Category III equipment. c. Concept of Classes: IEC 61140 Protection against electrical shock is achieved by a combination of the constructional arrangements for the equipment and device, together with the method of installation. Four classes are defined per IEC 61140 [8] and Table 1 below provides a brief overview. For an easier correlation to application classes used in Edition 1 of IEC 61730 the table also contains the descriptions from Edition 1. The fundamental idea behind the classes is to categorize electronic equipment with respect to their protection means against electric shock. The following short definitions introduce the concept which is important for the understanding of classes in the new edition of IEC 61730-1. Class 0: Equipment comes with basic insulation as provision for basic protection and with no provisions for fault protection. Class I: Equipment with basic insulation as provision for basic protection and protective bonding as provision for fault protection. Exposed-conductive-parts of the equipment shall be connected to the protective equipotential bonding terminal. Class II: Equipment with basic insulation as provision for basic protection, and supplementary insulation as provision for fault protection, or alternatively in which basic and fault protection are provided by reinforced insulation. Class II equipment must be marked with the graphical symbol no. 5172 of IEC 60417 (double square) [9]. Class III: Equipment relying on limitation of voltage to ELV (extra-low voltage) values as provision for basic protection and with no provision for fault protection. Equipment must be designed for a maximum nominal voltage not exceeding 50 V a.c. or 120 V d.c.. Typically Class III equipment must be marked with the graphical symbol no. 5180 of IEC 60417. How to apply this concept to PV modules: Modules of Class 0: Class 0 modules have individual and/or system level electrical outputs at hazardous levels of voltage, current and power. These modules are provided with basic insulation only as provision for basic protection and with no provisions for fault protection. All conductive components that are not separated from hazardous live parts by at least basic insulation shall be treated as if they are hazardous live parts. Due to the limited safety features of Class 0 modules the application is limited to areas with restricted access that are protected from public access by fences or other measures preventing general access. Such modules are only to be accessed by persons knowledgeable of the inherent hazards associated with their use and failure modes. Accessible conductive parts on a Class 0 module are intended to be earthed or considered to be at hazardous potential. Modules of Class I: These will not be covered in the next edition of IEC 61730-1. Class I equipment needs special installation measures for electrically safe operation, the latter being outside the scope of IEC 61730. Modules of Class II: Class II modules may have individual and/or system level electrical outputs at hazardous levels of voltage, current and power. The modules must provide outputs with basic insulation as basic protection, and supplementary insulation as precaution for fault protection, alternatively reinforced insulation as basic and supplementary insulation. Accessible conductive parts must be separated from hazardous live parts by double or reinforced insulation, or designed with constructional measures which provide comparable protection. These modules are intended for installation where general user access is anticipated. This can be any kind of PV installation from a standard rooftop application to large MW-type PV power plants (e.g. access by O&M teams – not necessarily electricians). Modules of Class III: Representative modules and series/parallel connections thereof are not allowed to have electrical ratings greater than 35 V DC, 240 W, and 8 A Isc when tested under standard test conditions. Based upon the inherently limited electrical output capability of Class III modules their use, misuse, and failure are unlikely to result in a risk of electric shock or fire. Consequently, there are no requirements for construction or insulation beyond functional insulation. These modules are intended for installation where general user access and contact to uninsulated parts is anticipated, e.g. consumer electronics. These modules are not intended for use in parallel with other modules or energy sources unless the combination provides protection from back feed current and overvoltage protection. Table 1: Application of equipment in a low-voltage installation from IEC 61140 Table 1 and correlation to IEC 61730-1 edition 1 Class of equipment Class 0 Equipment marking or instructions - Only for use in nonconducting environment; or - Protected by electrical separation Marking of the protective bonding terminal with symbol no. 5019 of IEC 60417 Class I Conditions for connection of the equipment to the installation Application class (IEC 61730-1 ed.1) Description from IEC 61730-1 ed. 1 B Application in restricted access area Connect this terminal to the protective-equipotential bonding of the installation Special installation measures required Special installation measures required No reliance on installation protective measures A Application in nonrestricted access area Connect only to SELV or PELV systems C No restrictions for protection against electric shock Non-conducting environment Electrical separation provided for each equipment individually or letters PE, or color combination green/yellow Marking with symbol no. 5172 of IEC 60417 Class II Marking with symbol no. 5180 of IEC 60417 Class III d. Concept of pollution degree (IEC 60664-1 Clause 4.6) The micro-environment determines the effect of pollution on the insulation. The macro-environment, however, has to be taken into account when considering the microenvironment. Means may be provided to reduce pollution at the insulation under consideration by effective use of enclosures, encapsulation or hermetic sealing. Such means to reduce pollution may not be effective when the equipment is subject to condensation. Small clearances can be bridged completely by pollutants such as solid particles, dust and water and therefore minimum clearances are specified where pollution may be present in the micro-environment. Generally pollution will become conductive in the presence of humidity or water. Pollution caused by contaminated water, soot, metal or carbon dust is inherently conductive. To design the product with the required clearance and creepage distances the micro-climate must be assessed. Based on present pollutions in the application minimum requirement for insulation exist. IEC 60664-1 sates four degrees of pollutions: Pollution degree 1: No pollution or only dry, nonconductive pollution occurs. The pollution has no influence. Pollution degree 2: Only non-conductive pollution occurs except that occasionally a temporary conductivity caused by condensation is to be expected. Pollution degree 3: Conductive pollution occurs or dry non-conductive pollution occurs which becomes conductive due to condensation which is to be expected. Pollution degree 4: Continuous conductivity occurs due to conductive dust, rain or other wet conditions. The dimensions for creepage distance cannot be specified where permanently conductive pollution is present (pollution degree 4). For temporarily conductive pollution (pollution degree 3), the surface of the insulation may be designed to avoid a continuous path of conductive pollution, e.g. by means of ribs and grooves. Assessing the micro-climate of PV modules: PV modules are exposed to a variety of climates with very different temperature, humidity, rain and irradiance levels. Based on the definition of pollution degree from IEC 60664-1 and the knowledge of their installation location PV modules should be generally considered to be in a pollution degree 3 micro-environment. This assessment should result in a very safe PV module due to the extreme required spacing. Comparing the latter to requirements for 1,000V system voltage in Edition 1 would nearly quadruple the spacing. Thus, the challenge is to design PV modules enabling the reduction in pollution degree. In case of enclosures having a degree of protection higher and including IP55 the pollution degree can be directly reduced to 2 for such components (e.g. inside a PV module junction box). For parts enclosed or encapsulated to provide protection against ingress of dust and moisture, and satisfying the relevant requirements according to Annex C of IEC 61730-1 Ed. 2, pollution degree 1 or 2 might be readily applicable to PV modules. Annex C outlines the application of coatings as an option to reduce pollution degree. Coatings are commonly used to protect materials against corrosion. Thin coating layers can also enclose live parts, but the applicable pollution degree for a specific live part depends on the coating. E.g. a permissible coating can encapsulate live parts in such way that no pollution (dust, moisture) will affect spacing. Compliance to requirements of Annex D also reduces the micro environment to pollution degree 1. e. Concept of Material group from IEC 60664-1 clause 4.8 IEC 60664-1 [5] defines four material groups as follows: • material group I: 600 ≤ CTI; PLC=0 • material group II: 400 ≤ CTI < 600; PLC=1 • material group IIIa: 175 ≤ CTI < 400; • material group IIIb: 100 ≤ CTI < 175. PLC=4 CTI (comparative tracking index) is determined in accordance to IEC 60112 [10] using solution A. The CTI compares the performance of various insulating materials under test conditions to form tracks or show tracking induced by high voltages. CTI gives a qualitative comparison and in the case of insulating materials having a tendency to form tracks, it also gives a quantitative comparison. UL746A [11] uses a PLC classification at 0 to 5. For glass, ceramics or other inorganic insulating materials which do not track, creepage distances need not be greater than their associated clearance for the purpose of insulation coordination. Based on CTI material test materials are classified into the different groups and can used appropriately in a PV module. Materials used today in photovoltaic typically fall within material groups I and II. For some time now UL 1703 requires a CTI >250 (PLC=2). f. Concept of Cemented joints A new and important concept is that of cemented joints or parts. The fundamental idea behind the latter is to reduce spacing while still maintaining insulation requirements to build a product that does not cause the risk of electrical shock or represents a fire hazard. The new edition of IEC 61730 includes this concept as Annex D and supersedes the ETF-9 decision sheet (DSH 1051) for such joints. The standard clearly states requirements and a test sequence to test material combinations for compliance. Adhesive joints within PV modules are considered cemented joints and are acceptable as equivalent to reinforced insulation under consideration of distances through cemented joints per Tables 3 and 4 of IEC 61730 Edition 2. The following requirements apply: 1. Passing the required tests for qualification as defined by IEC 61730-2 such as Lap shear test (MST 36). 2. Electrical and mechanical TI or RTI or RTE thermal rating for the electrically insulating adhesive/sealant shall be the higher than 90°C and the maximal determined module temperature during temperature test (MST 21). 3. Test voltages for dielectric strength are increased by a factor of 1.35x. 4. The electrically insulating adhesive/sealant shall have a volume resistivity of greater than 50 x 106 Ω-cm (dry) and greater than 10 x 106 Ω-cm (wet), with volume resistivity as measured via ASTM D257IEC 62788-1-2 and wet/dry conditioning defined as per section 14 of UL 746C. After the tests there shall be neither cracks nor voids in the insulating compounds which either by themselves or in combination reduce the distances through the cemented joint below the required values. 6. MAJOR CHANGES This chapter highlights the most important changes of IEC 617130 Ed. 2 Part 1 and Part 2. a. Modifications to IEC 61730 Part 1 Changes to Part 1 bring the standard into compliance with IEC horizontal standards: As described previously, IEC provides rules and definitions for electronic equipment and devices to protect the user from harm caused by electric shock or fire hazard. Horizontal standards form the basis for insulation coordination and must be applied were ever possible. In contrast to this concept, Edition 1 of IEC 61730-1 was based on best practices from module manufacturing of the 90’s, no longer applicable today. Back then modules were primarily assembled via manual processes as opposed to today’s automated high volume manufacturing methods. Further cost reduction was achieved via changes to the materials employed in module construction. New materials have been introduced and/or thinner/less material is used. The insulation requirements for PV modules are now clearly defined and are based on materials properties (! material groups, section 5e), location of installation (! pollution degree ! section 5d) and installation type (! Class ! section 5c). While the new standard indeed appears more complex it draws on the established horizontal standards, complies with IEC regulations, enables innovative new ways to apply advanced materials and construction methods, and can lead to lower costs via reduced spacing. The following example provides a comparison between Edition 1 and 2. Two scenarios are discussed: First, a formally application class A module; now a Class II module and second, a formally application class B module; now a Class 0 module. All details are summarized in Table 2. The same scheme can be applied for all other options. Note, the example does not use the concept of cemented joints, but it should be apparent from the prior discussion that the latter allows further reduction of spacing. All materials to be used for insulation have a CTI rating of >600 and therefor fall under the Material Group I (MG=I). Based on the installation site and the required Class (e.g. by national electric code – for this example Class II) it is assumed that the insulation system must be treated as pollution degree II (PD=II). Table 3 of Edition 2 provides all spacing requirements. The resulting module will have a live part – outer surface (touchable) – spacing of 10mm which is slightly larger than today. But if it can be proven that the encapsulation system of live parts reduced the pollution degree to PD=I the spacing could be reduced to 6.4mm, lower than today. Table 2: Comparison of two modules classes designed for a system voltage of 1,000V and the impact of edition 2 on spacing. (PD=Pollution Degree, MG=Material Group) Application Class / Class Requirements of polymeric materials serving as support for live parts Thickness of Backsheet/Frontsheet Clearance Creepage Spacing live part to outer surface Edition 1 Edition 1 Edition 2 Edition 2 Where to find in Edition 2 Class A Class B II 0 Table 1 Based on UL746A Based on UL746A CTI>600 for MG=I CTI>600 for MG=I Section 5.3 CTI>250 (Usys<600V) Not defined, results from partial discharge test 8.4mm (Table 4 in edition 1) Section 5.3 CTI>250 (Usys<600V) Not defined, results from partial discharge test 4.2mm (Table 4 in edition 1) Annex B Section 2.1.4.1. Material groups V-1 V-1 0.15mm 0.15mm Table 3 and 4, 1b) Thickness in thin layers 14.0mm 8.0mm Table 3 and 4, 1a) Live parts and outer accessible surfaces Not defined and differently interpreted Not defined and differently interpreted 8.4mm 4.2mm 6.4mm for PD=1 10.0mm for PD=2 and MG=I 6.4mm (PD=1) or 10.0mm (PD=2) 3.2mm for PD=1 5.0mm for PD=2 and MG=I 3.2mm (PD=1) or 5.0mm (PD=2) Another important change to Ed. 2 of IEC 61730-1is the requirement of component approvals, in particular for junction boxes, connectors and lead wires. Junction boxes will be required to be in compliance with IEC 62790 (82/876/FDIS, close to publication). Connectors will be required to be in compliance with IEC 62852 (82/878/FDIS, close to publication). Lead wires will be required to be in compliance with EN 50618 (FprEN 50618:2014-07, close to publication – later scheduled to be replaced by IEC 62930, 20/1492/CD). The above component approval requirements mirror standards from other industries of electrical products, and going forward will simplify the module approval process as well as assure ease of comparison. In fact, the PV industry at large is likely already prepared for these new requirements as similar testing protocols from third parties were used for years in the absence of such component standards. It will, however, be necessary for module manufacturers to request the required component approvals from their respective suppliers or where this is not possible switch to approved components. - - - - b. Modifications to IEC 61730 Part 2 The following list gives a brief summary of the changes made to Part 2 of IEC 61730: Table 3 and 4, 1a) Live parts and outer accessible surfaces MST 05 Durability of markings: Checks for readability of the markings on the PV module before and after stress tests. MST 06 Sharp edge test: All accessible modules surfaces should be smooth and pose no risk for injury; verified via test. MST 13 Continuity test of equipotential bonding: Test renamed to better reflect its purpose. MST 23 Fire Test: new reference, also see Appendix of IEC 61730-2 Ed. 2. MST 24 Ignitability test: This new test determines the ignitability of PV modules by direct small flame impingement under zero impressed irradiance using vertically oriented test specimens and is based on ISO 11925-2. This is important for all polymeric materials used in a PV laminate. MST 33 Screw connections test: Any screw connection in the module should remain secure. Tests described in MST 33 look for proper material design, installation and tightness of screws. MST 35 Peel test: The purpose of this test is to provide confidence regarding the durability of the adhesion between different layers of the photovoltaic module stack. MST 36 Lap shear strength test: The purpose of this test is to provide confidence regarding the durability of the adhesion between rigid-to-rigid bonded assemblies (e.g. glass/glass modules) for cemented joints of the photovoltaic module stack. - MST 37 Materials creep test: Validates that the materials used in the module will not show creep or lose adhesion when operated at the highest temperatures that modules normally experience in the field. In particular the test determines possible creep between the following interfaces: o frontsheet to backsheet o frontsheet or backsheet to directly attached mounting system (e.g. back rail) o junction box to backsheet respectively frontsheet The implementation of new tests is the result of changes in module manufacturing as well as requirements from horizontal standards implemented in Part 1 of IEC 61730 Edition 2. Consequently the test flow has been updated and Figure 1 shows the test flow as of September 2014. The latest revision includes all comments from national committees (NCs) that were received based on the draft distributed to all NCs for the IEC TC 82 WG 2 2014 spring meeting. 7. SUMMARY A significant amount of work has been invested in developing Edition 2 of IEC 61730 over the course of the past 6 years. Several drafts have been created, modified or withdrawn. Simultaneously, the fast price reduction of PV modules not only raised concerns about their quality, but also about their safety. To better define safety relevant parameters and to comply with IEC regulation to use horizontal standards the current draft was developed employing the concepts of insulation coordination, Classes, pollution degree and material groups. These new concepts result in a larger parameter space for PV module design, but unambiguously state safety relevant boundaries. The new material requirements lead to new test requirements, addressed in Part 2. As opposed to Edition 1, Part 1 of Ed. 2 no longer contains test requirements. The current draft will be discussed at the 2014 fall meeting of TC 82 WG2 and it is expected that the final document can be submitted to IEC central office as CDV by the end of the year. 8. REFERENCES [1] Ross, R. G., et al, “Engineering Sciences and Reliability”, JPL - Flat-Plate Solar Array Project (1986) [2] Osterwald, C. R., et al, “History of Accelerated and Qualification Testing of Terrestrial Photographic Modules: A Literature Review”, Progress in Photovoltaics: Research and Applications, 17 (2009), 11-33 [3] Jaeckel, B., et al, “Combined standard for PV module design qualification and type approval: New IEC 61215 – series”, 29th European Photovoltaic Solar Energy Conference – Amsterdam (2014) [4] IEC Guide 108 “Guidelines for ensuring the coherency of IEC publications – Application of horizontal standards.” [5] IEC 60664-1: Insulation coordination for equipment within low-voltage systems – Part 1: Principles, requirements and tests [6] IEC/TR 60664-2-1: Insulation coordination for equipment within low-voltage systems – Part 1: Principles, requirements and tests [7] IEC 60664-3: Insulation coordination for equipment within low-voltage systems – Part 3: Use of coating, potting or molding for protection against pollution [8] IEC 61140:2001, Protection against electric shock – Common aspects for installation and Equipment with Amendment 1 (2004) [9] IEC 60417: Graphical symbols for use on equipment –Symbol originals [10] IEC 60112:2003, Method for the determination of the proof and the comparative tracking indices of solid insulating materials [11] UL 746C: Polymeric Material- Use in Electrical Equipment Evaluations Figure 1: IEC 61730-2 Test flow.