Metal Lath, Beads and Trims - Ron Blank and Associates, Inc.

advertisement

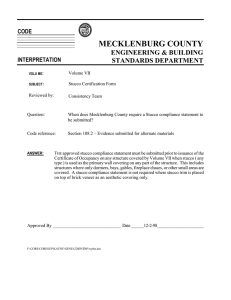

Metal Lath, Beads and Trims Stucco and Plaster Accessory Products and Applications Course Number: DIE05L An AIA Continuing Education Program Credit for this course is 1.5 AIA HSW CE Hours ClarkDietrich Building Systems Janine Dallies, CSI, CDT 1985 N. River Road Warren, Ohio 44483 330-372-5564 ext. 64235 janine.dallies@clarkdietrich.com www.clarkdietrich.com © Ron Blank & Associates, Inc. 2009 An American Institute of Architects (AIA) Continuing Education Program Approved Promotional Statement: Ron Blank & Associates, Inc. is a registered provider with The American Institute of Architects Continuing Education System. Credit earned upon completion of this program will be reported to CES Records for AIA members. Certificates of Completion are available for all course participants upon completion of the course conclusion quiz with +80%. Please view the following slide for more information on Certificates of Completion through RBA This program is registered with the AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA or Ron Blank & Associates, Inc. of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. An American Institute of Architects (AIA) Continuing Education Program Course Format: This is a structured, web-based, self study course with a final exam. Course Credit: 1.5 AIA Health Safety & Welfare (HSW) CE Hour Completion Certificate: A confirmation is sent to you by email and you can print one upon successful completion of a course or from your RonBlank.com transcript. If you have any difficulties printing or receiving your Certificate please send requests to certificate@ronblank.com Design professionals, please remember to print or save your certificate of completion after successfully completing a course conclusion quiz. Email confirmations will be sent to the email address you have provided in your RonBlank.com account. Course Description Become familiar with metal lath products and stucco and plaster accessories that are available in galvanized steel, zinc alloy and vinyl. Examine trim and bead products used for veneer, stucco and plaster applications, and identify the benefits of using vinyl accessory products. Course Introduction This course is divided into 4 Sections: 1. Sheet Metal Lath 2. Rolled Metal Lath Alternatives 3. Stucco Accessories 4. Veneer Plaster Accessories Learning Objectives Upon completion of this course, the design professional will be able to: • Discuss differences in metal lath products and understand materials and procedures for safe and proper installation • Describe stucco and plaster accessories that are available in galvanized steel, zinc alloy and vinyl and which accessory to use depending on the application to ensure optimum performance • Describe trim and bead products used for veneer, stucco and plaster applications and which accessory to use depending on the application to ensure optimum performance • Discuss the types of vinyl accessory products and how they compare and contrast to their metal counterparts Section #1 Sheet Metal Lath Sheet Metal Lath Product Overview • Manufactured from steel sheets that are slit and expanded to form small diamond openings (approximately 11,000 per square yard). • Metal lath’s main function is to aid in the application of Portland cement stucco to a structure. • Openings provide for plaster keying. This allows for better stucco bonding in either pumped or troweled applications. The stucco must be properly keyed or forced through the diamond mesh, to ensure proper embedment. • Can be used for wall, ceiling, floor construction as well as for ornamental designs. • Standard nominal size of 27” x 96” Commonly Used Industry Terms • Stucco: A cementitious mixture used for exterior plaster. It consists of a Portland based cementitious mix combined with water and with or without aggregate. This material provides the plasticity and the cohesive and adhesive properties necessary for placement and formation of a rigid mass. • One Coat System: Utilizes metal lath with an acrylic modified stucco. This is applied in one application and the finished surface has an EIFS (Exterior Insulation and Finish Systems) appearance. • Two Coat System: Utilizes the application of plaster in two successive coats. Commonly Used Industry Terms Three Coat System: Utilizes the application of plaster in three successive coats, leaving time between coats for setting, drying or partial drying. • • • Scratch Coat: Refers to the first coat of plaster in a three coat system. Brown Coat: Refers to the coat of plaster directly beneath the finish coat. In a two coat system, it is the base coat. Finish Coat: Refers to the final coat of plaster (applied to the top of the brown coat. ) Metal Lath Industry Standards The American Society for Testing and Materials (ASTM) is the governing body that prescribes standard specifications for products used in construction. ASTM C- 847 is the applicable specification providing guidelines for the manufacture of metal lath. ASTM C-847 Abstract This specification covers sheet lath, expanded metal lath, diamond mesh, flat and selffurring, and rib metal lath, all with or without backing and designed to be used as a base for gypsum or Portland cement plaster. Metal lath shall be fabricated from coldrolled carbon steel sheet of commercial quality as specified and galvanized metal lath shall have a G60 coating. Physical properties such as thickness, width, length, and weight shall be specified. Metal lath shall be fabricated from hot-dipped galvanized steel. 1. Scope 1.1 This specification covers sheet lath, expanded metal lath, diamond mesh, flat and self-furring, and rib metal lath, 1/8 and 3/8 in. (3.2 and 9.6 mm), all with or without backing and designed to be used as a base for gypsum or Portland cement plaster. 1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Metal Lath Industry Standards • The ICC-ES (International Code Council Evaluation Service) references ASTM C-847 in product evaluation reports as the standard that must be met. • The following slides represent a sample report. Metal Lath Industry Standards Metal Lath Industry Standards Expanded Metal Mesh • Metal lath is sold based upon weight per square yard of material. • It is available in three different weights: • 1.75 lbs./sq. yd. • 2.5 lbs./sq. yd. • 3.4 lbs./sq. yd. • What do these weights mean? Buyer Beware! • The specified weight of product means one square yard of product (9 square feet) should weigh that stated weight. – Example: 3.4 lbs./sq. yd. means that one square yard of this lath should weigh 3.4 pounds – The typical sheet of metal lath is manufactured in 27” x 96” sheets which contains 2 square yards of product • One sheet of 3.4 lath should weigh 6.8 pounds +/allowable tolerances (see ASTM C847). • Beware - some manufacturers are selling product that weighs less than it should!!!! Expanded Metal Mesh Installation • This variety of lath is generally applied to studs (wood or metal) in open frame construction. Flat mesh should not be used over a solid surface (gypsum, concrete, wood sheathing) as the absence of a “furring mechanism” will cause the stucco to bond only to the sheathing and not complete the embedding process. • Note: 1.75 lath is not recommended for open frame use other than in tested proprietary one coat systems. Expanded Metal Mesh Installation Wafer head screws are power driven to allow quick and easy attachment to the framing member (wood or steel). Expanded metal mesh lath can be cut to size with hand tools. Self-Furred Metal Lath There are two types of self-furred metal lath – dimpled (photo on left) and v-grooved (photo on right). This lath is very similar to regular expanded metal mesh lath but it has dimples or embossed v-grooves measuring approximately 1/4” deep manufactured into the surface of the lath. Self-Furred Lath Application • This variety of lath is generally used in applications over solid surfaces such as block, concrete or sheathing products. • Available in three different weights: – 1.75 lbs./sq. yd. – 2.5 lbs./sq. yd. – 3.4 lbs./sq. yd. Self-Furred Lath Application • The “self-furring” lath allows the stucco to key or lock into the metal lath ensuring that it becomes fully embedded. The lath also acts as an “attachment mechanism” for the lath and stucco to the structure or structural framing. • Note: Individual market preference dictates use of VGrooved or Dimpled. Self-Furred Lath Installation *Ex. - Three coat system utilizing LAD Self-furred lath is secured to masonry surfaces with hardened nails or powder driven fasteners at the furring dimples. Paper backed lath is often used in this type of application as a bond breaker. The scratch coat is applied with complete embedment of the plaster into the self-furred lath. Self-Furred Installation “Scratching” the scratch coat for maximum bonding of brown coat to the scratch coat. This is done to increase adhesion of the second coat. “Darbying” the brown coat to render a plumb and even surface. A “Darby” is a flat wooden tool designed to smooth out or “float” the brown coat. *The last coat of stucco would simply be the “Finish Coat.” Rib Lath • Rib lath is the most rigid of all sheet laths and is commonly used for soffits and ceilings. • It is available in 3/8” High Rib and 3.4 lbs./sq. yd. • Rib lath is not considered a self-furred product. Rib Lath Application • • • The main difference between rib lath and flat mesh or self-furring is that it contains solid ribs running the length of the piece. The solid ribs provide additional rigidity to the lath product. High Rib is used primarily in horizontal applications and is also an excellent product for framing spaced no more than 24” on center. Asphalt Paper-Backed Metal Lath • • Type: 2” double offset paper Available in three different weights: – 1.75 lbs./sq. yd. – 2.5 lbs./sq. yd. – 3.4 lbs./sq. yd. Asphalt paper-backed metal lath is expanded metal mesh lath, regular or selffurred to which asphalt saturated Kraft building paper is applied. The paper sheet acts as a water barrier, care must be taken not to rip or puncture the paper Asphalt Paper-Backed Application • • • • Asphalt papered lath is designed to reduce moisture penetration while allowing for the dissipation of moisture vapor from within the structure. The paper is designed to aid in the funneling or “wicking” of moisture to the bottom of the stucco membrane where it can escape from the wall cavity. The paper backing also aids in plaster “keying” and stucco curing. It provides for protection of the sheathing during the curing process. Deterioration of the sheathing may occur without this protection. Industry standard paper provides a 10 minute water resistance rating. This is referred to as Grade D paper. Some metal lath manufacturers offer increased water resistant paper. The paper can also be applied directly to the solid structure and non-paper lath products can then be used. In most areas of the country, two layers of Grade D paper are required, the paper would be applied to the structure followed by the application of a paper-backed lath product. A house wrap (moisture barrier) may be used in lieu of one layer of Grade D paper but must be applied directly to the structure and topped by the second layer of the paper backed lath product. Asphalt Paper-Backed “Over Lap” Installation • • ASTM C-1063 requires that the paper backing must overlap a minimum of 2” and the lath-to-lath must overlap 1”. Fasteners must penetrate both sheets of metal lath. Paper backing overlap Lath overlap Asphalt Paper-Backed Installation Scratch coat is fully embedded in the lath and is isolated from supporting structure. Water resistant backing paper allows for controlled and uniform curing of this plaster foundation. Notice in this picture the extra fasteners at the “overlap” of the lath. Where side laps occur, wire ties are required between the fasteners. Kraft Paper-Backed Lath • • • Kraft paper-backed lath products are very similar to the asphalt impregnated Kraft paper-backed products. However the paper used is not asphalt saturated thus it does not provide a water resistant barrier. The paper is simply used to act as a “backer” to conserve machine applied stucco. Another benefit is during attachment of the lath to the structure the framing members are visible behind the paper. Kraft paper-backed lath is available in rib lath as well as diamond mesh Traditionally Kraft paper-backed lath has been used exclusively on the west coast. 3/8” rib lath with Kraft paper-backing ribs Fastening to Wood Framing • • When fastening metal lath to wood framing use 1-1/2” roofing nails or 6d common nails driven into the framing member 3/4”. Then bend nail over to engage not less than (3) “diamonds”. Large head nails (7/16”) can be driven in flush. Also one-inch staples may be used. It is recommended that mechanical fasteners be attached at 7” intervals. However, check local requirements as they may be more restrictive. When fastening Rib Lath to any framing member the fastening mechanism must be attached through or over the rib. Fastening to Metal Framing When attaching metal lath to steel framing use screws that have a minimum number “8” shank with a wafer head not less than 7/16” wide. The screw must penetrate the framing member by 3/8”. Mechanical fastening is recommended at 7” intervals but again, local requirements will prevail. Fastening to Concrete or Block When attaching metal lath directly to concrete or block use powder activated fasteners in unison with washers 3/4” in diameter. These fasteners must be located at each corner and mid-span on the sheet. The interior portion may be fastened with concrete “stub nails.” Fastening to Cold Rolled Channel in a Suspended Ceiling Application When fastening metal lath to cold rolled channel in a suspended ceiling application, wire tying with 18 gauge hanger wire is required . Wire ties must be no more than 7” on center. (Refer to IBC and ASTM C-1063 for furring and main support spacing.) Ceramic Tile Application • • Paper-backed metal lath is often used as a backer for ceramic tile in unison with Portland cement as a tile base. Lath types and installation are similar to that of exterior framing. If you are constructing an “open frame” use a paper-backed flat mesh and if it is used over a solid surface use paper-backed self-furring. Note: This application is considered for “high humidity” areas. Zinc or vinyl trims are recommended over galvanized trims. “Floor Leveling” Application Metal lath may also be used to aid in the leveling of uneven floors. Self-furred 1.75 or 2.5 is attached to the floor with powder actuated fasteners or stub nails. Portland cement stucco is then used to level the floor. This method is especially popular when a concrete pour will be done over an existing concrete base. The lath ties both layers together. Ornamental Application Expanded metal mesh lath can be formed into “trees and rocks”, then coated with stucco. Painting it gives a realistic appearance. Section #2 Rolled Metal Lath Alternatives Alternative Stucco Reinforcing Products ICC Approved alternatives for 2.5, 3.4 and 3/8” rib sheet lath products • Welded wire in rolls • Comply with IBC, IRC, & UBC • Tested and evaluated • Performance in transverse load tests show products are equal to or better than traditional metal lath sheets Alternative Stucco Reinforcing Products Alternative products incorporate new benefits for plaster walls: • Engineered to improve embedment • Reduce cracking in stucco • Promotes uniform plaster thickness • Easy to install – less cuts – less overlaps • Easy attachment for steel and wood stud construction • Engineered to provide a strong, durable stucco wall assembly Improved Corrosion Resistance Additional coating enhancements are available that can provide upwards of 20% more corrosion resistance than regular zinc coated metal products. Ideal for use on coastal and higher humidity area projects. Welded Wire Stucco Reinforcing Various Types: Regular • 1-1/2" x 1-1/2" welded wire (17 ga) – self furred Welded Wire Stucco Reinforcing • 1-1/2" x 1-1/2" welded wire (17 ga) with the addition of eight secondary cold-rolled longitudinal wires that add strength to form a 'track' for convenient attachment. • Potential alternative wherever 2.5 metal lath has been specified. Welded Wire Stucco Reinforcing Various Types: Heavy Duty • • • Dense product made from 17 ga galvanized steel wire welded to form 0.7 inch x 1.5 inch openings Reinforcing for both stucco and stone installation Potential alternative wherever 3.4 metal lath has been specified Heavy Duty Welded Wire Stucco Reinforcing Veneer Stone Reinforcing • • • Problems with simulated stone installations have also grown dramatically. These problems are associated with moisture ingress and subsequent deterioration of the structure and elements in behind the stone. Dense Heavy-Duty welded wire lath provide full ¼” furrs (minimum 28 per sq/ft) that ensure a minimum 3/8” to ½” scratch coat. This thick plaster coat is critical to effective water barrier When welded wire is installed with approved fasteners & spacing, the lath can safely support over 100psf dead load. Maximum stone weight is 15psf and plaster weight is 10psf. Therefore there is a 4:1 safety factor. Welded Wire Stucco Reinforcing Various Types: Truss Sheet Product • Series of 3/8 - inch ' V ' shaped trusses, and heavy perforated draft paper that is sandwiched between the primary sheet and a back layer of stiffening wires. • The sheets are light weight yet strong and easy to cut. • Potential alternative wherever 3.4 Rib Lath has been specified • Improved performance on soffits. Welded Wire Stucco Reinforcing Truss Sheet Product Truss Sheet Product Features • • • • • • • Made from 17 ga galvanized steel wire weld wire Rectangular openings Self furred to ensure a full 3/8" scratch coat Flat bottomed furr will not puncture vapor barrier Cold rolled - flat longitudinal wires reduce curvature memory for an easy to handle roll – while increasing tensile strength Cold rolled longitudinal wires form a twin track that simplifies attachment Rolls are more manageable than sheet products and make for easy installation Section #3 Stucco Accessories Terminology • • • Stucco: Term used within the industry to refer to a Portland cement-based cementitious mixture. Many industry experts use the term plaster to denote interior work and stucco to denote exterior work. Veneer Plaster: Often referred to as gypsum plaster. It refers to a plaster that is applied over a gypsum product to create a “finished” stucco appearance on interior walls. Ground: This is a term that is used to identify the “depth” of the plaster base and thus the size of the accessory. The thickness of the plaster is determined by the height of the ground on those accessories with grounds. Industry Standards • ASTM C-1063 is the applicable specification which covers the minimum requirements for lathing and furring for the application of exterior and interior Portland cement-based plaster. In simpler terms it covers attachment and the associated accessory products that are used with metal lath and stucco. • One key piece of information to remember from ASTM C-1063 is the following: “All materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from the weather and surface contamination.” • Vinyl products must meet or exceed ASTM D-1784 and D-4216 cell class 13244C. Corrosion Resistance • Zinc alloy and vinyl plaster trims should be used for installations where abnormal corrosion is possible due to high humidity and continual moisture exposure. • Examples include: bath and shower rooms, green-houses, swimming pool areas, etc. • They are also prescribed where adverse atmospheric conditions may exist (high saline content or acid rain) such as in coastal regions or heavy industrial areas. 1-A Expanded Corner Bead • • • • • 1-A Expanded Corner Bead is the standard accessory for providing exterior corner protection and providing a reliably straight ground. Easily flexed for irregular corners. Reinforced close to the nose of the bead. Made with 2-7/8” or 3” wide expanded flanges in galvanized steel and zinc alloy. Available in: – Galvanized: 8’ and 10’ – Zinc: 10’ 1-A Vinyl Corner Bead Dimensions 2–1/2” x 2–1/2” • provides rust-proof corner reinforcement 2–1/2” x 2–1/2” • corner reinforcement for narrow returns 1–1/2” x 1–1/2” • corner reinforcement for narrow bands and reveals 2–3/4” x 2–3/4” • heavier version and increased flange width, used in high traffic areas 2–3/4” x 1–1/2” • for applications requiring increased damage resistance Double-X Corner Bead Ideal for structural tile and rough masonry. Adjusts easily for varying plaster depth on columns. The added stiffener strip affords additional rigidity to the flange. # 66 Expanded Flange Casing Beads The expanded flange casing bead is used as a plaster stop or exposed trim around doors and windows. May also be used as an expansion joint when installed “back to back.” Available in galvanized and zinc. # 66 Expanded Flange Information • • • Galvanized: Available in grounds ranging from 3/8” - 1 1/4” (additional sizes available on special order). This part is also available with weep holes. Weep holes are designed to allow moisture trapped behind the stucco to escape. Zinc: Available in grounds ranging from 1/2” - 1” (additional sizes available on special order). This part is also available with weep holes. Caution: Punched holes in the ground of casing beads should not be construed as a replacement for foundation weep screeds for traditional three-coat stucco applications. This should be used only were required by certain one-coat systems. # 66 Short Flange Casing Bead This product is very similar to the #66 expanded flange product except that it does not have the expanded flange. Both nail and key holes are provided in the flange. The product is available in both galvanized and zinc and with or without weep holes. Both products are available in grounds ranging from 3/8” through 1” Vinyl Casing Bead - Short and Long Flange Short Flange - 1 3/4” Long Flange - 2 1/2” Used to terminate stucco and plaster against doors, windows and dissimilar materials. Available in ground heights: • 1/4” (short • 3/8” • 5/8” • 7/8” flange only) • 1/2” • 3/4” • 1” Control/Expansion Joints • Stucco, under various types of stress and deflection, will develop cracks. Control/expansion joints are used to minimize this problem. It has been determined that if stucco is divided into smaller areas (144 square feet for walls/100 square feet for ceilings), the stress on the stucco membrane is reduced enough to significantly reduce most cracking. Control joints are used to make divisions and to allow movement/stress to occur in order to minimize the effect of such stress on the stucco membrane. • Market preference will often dictate use of a particular control joint. Zinc Control Joints • Common ground heights: • 3/8”, 1/2”, 3/4” and 1” This product is designed to relieve stresses of expansion and contraction in large plastered (stucco) areas. This product offers a 1/4” slot which is protected with a plastic tape. The tape should not be removed until both plastering and finishing are completed, leaving a clean, finished appearance. Vinyl Control Joint with Removable Tape Recommended for smooth finishes. Positive attachment of each flange of control joint to separate framing is required Ground heights: • 1/4” • 3/8” • 5/8” • 7/8” • 1/2” • 3/4” • 1” #15 Double - V Control Joint This product provides stress relief to control cracking in large plastered (stucco) areas. The flanges are expanded metal. Available in both galvanized and zinc and in grounds ranging from 3/8” to 1-1/4”. This product is not protected with a plastic tape. #15 Double-V Vinyl Control Joint Vinyl beads and trims are used to provide durable, corrosion and impact-resistant edges, corners, arches, curvatures and numerous other finishing applications. Ground heights: • 3/8” • 5/8” • 7/8” • 1/2” • 3/4” • 1” Double - J Control Joint Double-J is available in both galvanized as well as zinc and in grounds ranging from 1/2”, 3/4” and 7/8”. Removable tape provides for easy joint cleaning. This product provides excellent expansion control for both walls and ceilings while offering positive locking of the stucco to the edge of the joint. This is accomplished by “forcing” the stucco up under the “J” during application. With this product, the shrinking that often occurs as freshly applied stucco dries is hidden under the “J”. #40 Two Piece Expansion Joint Many people consider this product to be the only true expansion joint in the industry, due to the fact that each piece can move independently of the other. This product should be used where excessive horizontal and vertical movement occur. Atriums and other wide walls are areas where this product is recommended. The prescribed expansion opening/reveal is 1/4” to 5/8”. It is available in both galvanized and zinc and in 1/2”, 3/4” and 7/8” grounds. Vinyl Two Piece Expansion Joint Designed to relieve stress in wall and ceiling areas where excess horizontal and vertical movements might occur. Ground heights: • 3/8” • 3/4” • 1/2” • 7/8” • 5/8” • 1” Corner Control Joint An “inside corner” expansion joint, it is designed to reduce cracking and allow movement at inside corners of wall to wall junctures resulting from expansion and contraction. Ground Depth Available in both galvanized and zinc and in 1/2”, 3/4” and 7/8” grounds. Vinyl Corner Control Joint Relieves stress caused by expansion and contraction in wall and ceiling inside angles. Removable tape protects deep “V” expansion slot during construction. Ground heights: • 1/2” • 3/4” • 5/8” • 7/8” • 1” Channel Reveals Reveal Channel reveals are used to create 1/2” to 4” reveals in stucco and plaster surfaces. They allow for precision field assembly and clean appearance when decorative applications are designed. Channel Reveals • Factory fabricated intersections are used to form clear channels in vertical and horizontal intersections of Crosses, T’s, L’s, Inside and Outside Corners and End Closures of channel reveals. • The following two slides are examples of some of the factory fabricated channel reveal intersections that are available. Channel Reveal Intersections Channel Reveal Intersections One-Piece Soffit Vent One-piece soffit vent designed for plywood, soffit board and three-piece stucco and plaster vents. Use vent clips to connect soffit vent and assist in alignment. Continuous One-Piece Soffit Vent Continuous one-piece soffit vent with reinforcing rib to key into stucco and plaster. Again, use clips to connect and assist in alignment. Vent area is 15 square inches per lineal foot. J-Style Soffit Vent Another example of a continuous onepiece soffit vent. “J” bead flanges cover raw edges of soffit board. Strip Lath Strip lath is essentially diamond mesh lath formed into strips. This product is used at the corners of all openings such as doors and windows for reinforcement. Openings often cause weakened areas that are prone to cracks. Strip lath can be used to reinforce any weakened area in the lath assembly. Available in: 4” x 8’ and 6” x 8’ Corner Lath Corner lath is strip lath bent to an obtuse angle with smooth edges also formed like diamond mesh. It is used in corners (intersections) where walls meet walls or ceilings. This reinforcing of interior corners helps prevent cracks. Available in: 2” x 2” x 4’ 2” x 2” x 8’ 3” x 3” x 8’ #7 Foundation Screed This part is often referred to as F.H.A. Screed because it meets all pertinent requirements. The screed provides an angular, straight-edge stop at the sill plate line and can be attached by nail or staple. The product is manufactured from 26 gauge material and is available in ground heights of 7/8” and 1-3/8”. It has a 3-1/2” nailing flange and weep holes are provided to eliminate condensation problems. Vinyl Foundation Weep Screeds Designed to relieve moisture from stucco and act as a stop. Installed on frame construction where stucco and foundation walls meet. Ground heights: • 3/8” • 1/2” • 5/8” • 3/4” • 7/8” 4” overall width, with unperforated flange J Weep High Back Plaster Stop This part is manufactured from 26 gauge galvanized steel. It is available in both a 7/8” and 1-3/8” grounds with a 3-1/2” nailing flange. It is designed to be used as a plaster stop at the sill plate or door and window openings. It is designed with weep holes to allow for drainage of moisture from the stucco membrane. J Weep Low Back Plaster Stop This part is similar in application to the high back plaster stop. The only difference is it has a 2” nailing flange versus the 3-1/2”. Without weep holes it is available in 1-3/8” grounds. If weep holes are required the part is available in both 7/8” and 1-3/8” grounds. Caution: Punched holes in the ground of casing beads should not be construed as a replacement for the foundation weep screeds for traditional three-coat stucco applications. This should be used only were required by certain one-coat systems. Vinyl J-Weep Screed • • • • High back plaster stop 3-1/2” overall width Ground heights: – 7/8” – 1-3/8” Acts as a stop, and designed with an unperforated flange to allow moisture removal from stucco installations at stucco termination points. Not to be used in place of a foundation weep screed. • Section #4 Veneer Plaster Accessories ASTM C-1047 Abstract This specification covers accessories used in conjunction with assemblies of gypsum wallboard and gypsum veneer base to protect edges and corners and to provide architectural features. Steel accessories and steel components of accessories manufactured from steel and paper in combination shall be manufactured from zinc-coated cold-roll sheet steel before application of coating. Phosphatizing or other surface treatments may be used to ensure compatibility and bond. Paper components of accessories manufactured from steel and paper in combination shall comply with requirements for thickness, tensile strength, dimensional stability, and bond of joint tape to joint compound. Accessories shall be free of twist or camber of a degree that will prevent their use in the assembly for which they are intended. Edges of accessories shall be free of burrs and sharp edges. ASTM C-1047 1. Scope 1.1 This specification covers accessories used in conjunction with assemblies of gypsum wallboard and gypsum veneer base to protect edges and corners and to provide architectural features (see Fig. 1). 1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Mini-Beads • • • • • Mini-mesh corner beads are manufactured with a 1-1/4” expanded flange. The flange may be either nailed or stapled to the gypsum substrate. They can be used with veneer plaster or even drywall compound over a gypsum base. Mini-beads are available in two ground heights: – 1/16” for one-coat veneer plaster systems – 3/32” for two-coat veneer plaster systems Mini-beads are manufactured in both galvanized and zinc. 701A & 801A Veneer Trims • This “J” shaped trim is manufactured in different depths and grounds to accommodate veneer finishes. The product is available in galvanized or zinc for cement board applications. Both 701A & 801A are available in either 1/2” or 5/8” depths to match up to the different substrate thickness. • The “J-trim” provides for neat edge protection at cased openings and ceiling/wall intersections. The fine mesh expanded flanges strengthen veneer plaster bond and eliminate shadowing. 701B & 801B Veneer Trims This is an “L” shaped trim designed for use at the junction of the gypsum base with rough concrete or a masonry ceiling. This product is manufactured in various grounds and depths of 1/2” and 5/8” to accommodate the different substrate thicknesses. It is available in galvanized as well as zinc. 093 Control Joints The 093 Control Joint is used to relieve the stresses of expansion and contraction across the joint in large ceiling and wall areas in veneer finish systems. The product is made from zinc or vinyl to resist corrosion and has 3/32” grounds. “Plastic Tape” protects the opening and it is to be removed only after finishing is complete. 093 Control Joint Application According to the Association of the Wall and Ceiling Industries, control joints should be installed in ceilings exceeding 2500 square feet. The distance between control joints shall not exceed 50’. Control joints should also be installed where ceiling framing or furring changes direction. In partitions, walls or wall furring, the distance between control joints shall not exceed 30’. Course Summary The design professional will now be able to: • Discuss differences in metal lath products and understand materials and procedures for safe and proper installation • Describe stucco and plaster accessories that are available in galvanized steel, zinc alloy and vinyl and which accessory to use depending on the application to ensure optimum performance • Describe trim and bead products used for veneer, stucco and plaster applications and which accessory to use depending on the application to ensure optimum performance • Discuss the types of vinyl accessory products and how they compare and contrast to their metal counterparts Metal Lath, Beads and Trims Stucco and Plaster Accessory Products and Applications Course Number: DIE05L An AIA Continuing Education Program Credit for this course is 1.5 AIA HSW CE Hours ClarkDietrich Building Systems Janine Dallies, CSI, CDT 1985 N. River Road Warren, Ohio 44483 330-372-5564 ext. 64235 janine.dallies@clarkdietrich.com www.clarkdietrich.com © Ron Blank & Associates, Inc. 2009