HVAC Operation Qualification Protocol

advertisement

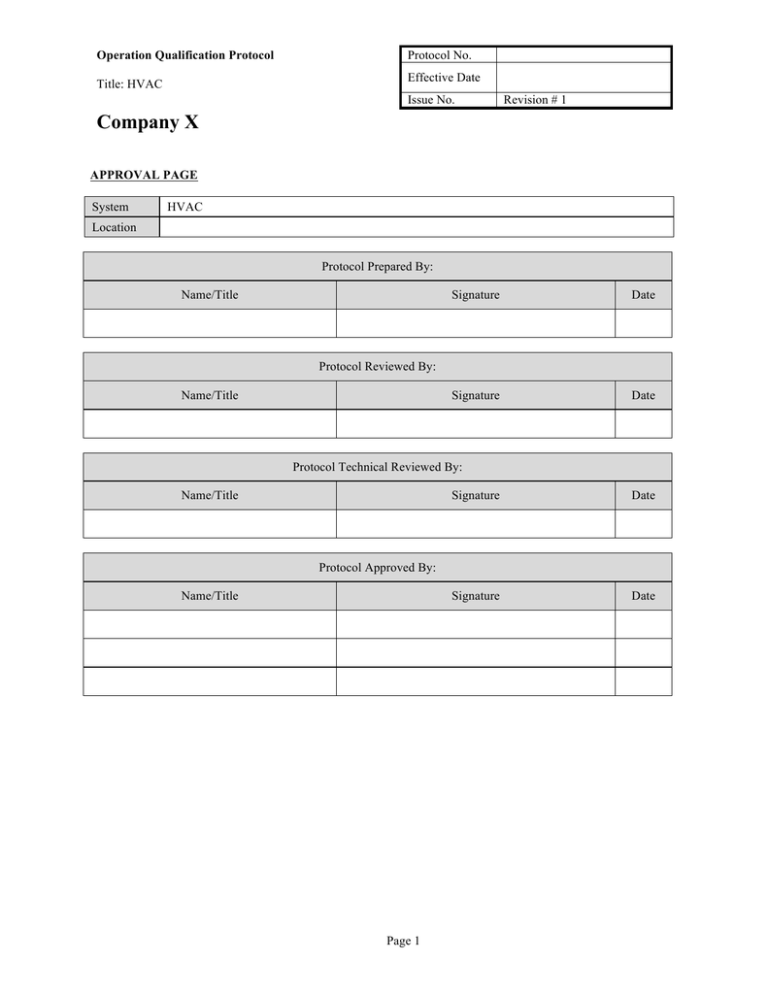

Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X APPROVAL PAGE System HVAC Location Protocol Prepared By: Name/Title Signature Date Signature Date Protocol Reviewed By: Name/Title Protocol Technical Reviewed By: Name/Title Signature Date Signature Date Protocol Approved By: Name/Title Page 1 Operation Qualification Protocol Title: HVAC Protocol No. Effective Date Issue No. Revision # 1 Company X Table Of Contents 1.0 SYSTEM OVERVIEW .................................................................................................................................... 4 2.0 SYSTEM BOUNDARY ................................................................................................................................... 5 3.0 OBJECTIVE ..................................................................................................................................................... 6 4.0 SCOPE .............................................................................................................................................................. 6 5.0 QUALIFICATION STUDY OVERVIEW .................................................................................................... 6 6.0 RESPONSIBILITY .......................................................................................................................................... 7 7.0 PREREQUSITES ............................................................................................................................................. 8 8.0 ACRONYMS .................................................................................................................................................... 8 9.0 DEFINITIONS ................................................................................................................................................. 9 10.0 GENERAL DOCUMENTATION REQUIREMENTS ................................................................................ 9 11.0 DATA COLLECTION AND DOCUMENTATION PROCEDURES ...................................................... 11 12.0 OPERATION QUALIFICATION TEST REQUIREMENTS .................................................................. 12 13.0 REFERENCES ............................................................................................................................................... 12 Page 2 Operation Qualification Protocol Title: HVAC Protocol No. Effective Date Issue No. Revision # 1 Company X Index Of Attachments General Data Worksheet .............................................................................................................................................. 13 ATTACHMENT 1 - Personnel Identification List ...................................................................................................... 14 ATTACHMENT 2 - Test Equipment Identification/Calibration ................................................................................. 15 ATTACHMENT 3 – Test Equipment Operation ......................................................................................................... 16 ATTACHMENT 4 - Testing, Adjusting and Balancing (TAB) Verification .............................................................. 17 ATTACHMENT 5 - Operation, Maintenance and Calibration SOPs.......................................................................... 18 ATTACHMENT 6 – Calibration Verification (Instruments) ...................................................................................... 19 ATTACHMENT 7 – HEPA Filter Integrity Test Verification Using.......................................................................... 20 ATTACHMENT 8 – Verification of Operation – Exhaust Fan / Motor...................................................................... 22 ATTACHMENT 9 – Verification of Operation – Pumps / Motors ............................................................................. 23 ATTACHMENT 9 – Verification of Operation – Pumps / Motors ............................................................................. 23 ATTACHMENT 10 – Verification of Operation – Cooling / Reheating Coils ........................................................... 24 ATTACHMENT 11 – Verification of Operation – Variable Air Volume Box ........................................................... 25 ATTACHMENT 12 – Verification of Operation – Smoke Sensor.............................................................................. 26 ATTACHMENT 13 – Safety Device(s)-Machine Guarding Checklist ....................................................................... 27 ATTACHMENT 14 – Verification of Operation – Interlocks..................................................................................... 28 ATTACHMENT 15– Verification of Operation – Alarms .......................................................................................... 30 ATTACHMENT 16 – Environmental Conditions Verification – Static Conditions ................................................... 35 ATTACHMENT 17 –Differential Pressure Verification – Static Conditions ............................................................. 39 ATTACHMENT 18 – Air Changes Verification ......................................................................................................... 40 ATTACHMENT 19 – Power Loss and Recovery ....................................................................................................... 41 ATTACHMENT 20 – Non-Viable Particle Count Test .............................................................................................. 42 ATTACHMENT 21 Support Utilities Verification-Chilled Water ............................................................................. 43 ATTACHMENT 22 Support Utilities Verification-Hot Water ................................................................................... 44 ATTACHMENT 23 Support Utilities Verification-Compressed Air .......................................................................... 45 Page 3 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 1.0 SYSTEM OVERVIEW History The AHU-6 and MAU-1 HVAC system includes Air Handling Unit (AHU-6) and Make Up Air Unit (MAU-1). AHU-6 was purchased from York International in October 1994. AHU-6 was designed and installed to supply recirculating air to rooms: 123–125. MAU-1 was purchased as part of the building and operated to supply make up air to the AHU-6 and rooms 120-125, 111, 113, 114, 117, 118,and both service corridors. . Description The major equipment / components of the AHU-6 and MAU-1 HVAC system include Air Handler Unit AHU-6, Make Up Air Unit MAU-1, Humidifier H-1, twelve (12) reheat coils RHC-1-RHC-9 and RHC-19 – RHC-21 and fourteen (14) exhaust fans EF-1 - EF-12, and EF-15 - EF-17. AHU–6 is a recirculating air handling unit, which provides a constant volume of airflow to rooms 123,124, and 125. It is equipped with a Pre Cooling coil, Preheat coil and 65% efficiency air filters. AHU-6 provides airflow using outside air from MAU-1 mixed with return air. MAU-1 provides conditioned air to rooms 111, 113, 114, 117, 118, and 120-125 utilizing 100% outside air. It is equipped with one (1) reheat coil and two (2) cooling coils. It has 35% efficiency pre-filters and 95% efficiency bag filters, it also utilizes eleven (11) Variable Air Volume controllers VAV-A, B, C, D, E, F, G, H, J, K and L. one (1) Steam Humidifier H-1 located in the supply air duct downstream from MAU-1 provides humidification. The operation of AHU-6 and MAU-1 are controlled by Johnson Controls’ Metasys Air Handling Unit Controllers with sensors monitoring air/water temperature, humidity and air/water pressure. The operation is monitored through the use of the Metacomm system as a Building Management System (BMS). Metasys VAV Controllers are provided for the control of each VAV box. The HVAC system will be qualified to provide personnel comfort. Performance criteria for the system are: Temperature: 70°F ± 5°F Humidity: 20-80% R.H. Rationale This protocol will be executed in compliance as per the requirements in 21CFR 210 & 211, ICH Q-7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, August 2001. Upon final approval of this Protocol and Summary Report the system will be placed under formal change control in accordance with Company X Change Control Program summarized in Standard Operating Procedure DNAP/QM/012 entitled “Change Control System”. Page 4 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 2.0 SYSTEM BOUNDARY The system boundary is defined as the supply utility service first point of contact with the system/equipment being installation qualified. In most cases this is interpreted as the first inlet manual valve or motor control/electrical panel providing supply of said utility. Supplied Utilities ID Number Description Compressed Instrument Air Inlet at respective valve Compressed Instrument Air Inlet at respective valve Low Pressure Steam Compressed Instrument Air Inlet at respective valve Inlet at respective valve Chilled Water In-AHU-6 Chilled Water Out-AHU-6 Low Pressure Steam OutMAU-1 Low Pressure Steam InMAU-1 Chilled Water Out-MAU-1 Hot Water In-RHC-1 Hot Water Out-RHC-1 Hot Water In-RHC-2 Hot Water Out-RHC-2 Hot Water In-RHC-3 Hot Water Out-RHC-3 Hot Water In-RHC-4 Hot Water Out-RHC-4 Hot Water In-RHC-5 Hot Water Out-RHC-5 Hot Water In-RHC-6 Hot Water Out-RHC-6 Hot Water In-RHC-7 Hot Water Out-RHC-7 Hot Water In-RHC-8 Hot Water Out-RHC-8 Hot Water In-RHC-9 Hot Water Out-RHC-9 CHWS-18 CHWR-19 To Be Field Verified Supply air to all applicable pneumatic valves on the AHU-6 Supply air to all applicable pneumatic valves on the MAU-1. Supply to appropriate inlets of H-1 Supply air to all applicable pneumatic valves on all VAV boxes: 1-9,19-21. Supply to Cooling CoilReturn from Cooling Coil Return from steam reheat coil To Be Field Verified Supply to steam reheat coil- To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified Return from cooling coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Page 5 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X Supplied Utilities Hot Water In-RHC-19 Hot Water Out-RHC-19 Hot Water In-RHC-20 Hot Water Out-RHC-20 Hot Water In-RHC-21 Hot Water Out-RHC-21 Chiller-1 Chiller-2 Chiller-3 Hot Water Boilers (7) Low pressure Steam Boilers (10) Electrical Electrical 3.0 ID Number Description To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified To Be Field Verified Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Supply to hot water coil Return from hot water coil Outlet to respective Valve Outlet to respective Valve Outlet to respective Valve Outlet to respective Valves Outlet to respective Valves AHU-6 MAU-1 Main Breaker Supply to Unit Main Breaker Supply to Unit OBJECTIVE The objective of the Operational Qualification (OQ) Protocol is to verify and document that the AHU-6 and MAU-1, HVAC system perform as intended throughout all operating ranges under at rest (static) conditions. Dynamic conditions will be evaluated in the Performance Qualification (PQ) Protocol. The execution of the OQ protocol determines if the AHU-6 and MAU-1, HVAC system consistently operates in accordance with the design specifications, NEBB and SMACNA standards and intended performance. The operation of the AHU-6 and MAU-1, HVAC system will be verified and documented by executing the qualification test cases and recording the results in the corresponding test case forms. 4.0 SCOPE This protocol will be limited to the HVAC AHU-6 & MAU-1 System at Company X, Inc., Address01757. 5.0 QUALIFICATION STUDY OVERVIEW During the execution of this protocol, determination of the operational ranges, calibration frequencies and formalized procedures will be provided to AAC Consulting Group, Inc.(AAC) by Company X, Inc. Company X will ensure that all instrumentation requiring calibration is calibrated with traceability to NIST. Certificates of calibration provided to AAC for inclusion in this protocol. The BMS control system will be qualified in a separate protocol, as part of the Computer System Validation (CSV). The Installation Qualification of this system was performed as per protocol # MF/VAL/IQ/013/PRO entitled “Installation Qualification of HVAC AHU-6 and MAU-1 System”. The Performance Qualification of this system will be performed in accordance with protocol entitled “Performance Qualification of HVAC AHU-6 and MAU-1 System”. Page 6 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 6.0 RESPONSIBILITY 6.1 6.2 6.3 6.4 Validation Department: 6.1.1 Prepare and submit the protocol for approval in accordance with current industry standards, regulatory requirements, and approved Standard Operating Procedures. 6.1.2 Perform and coordinate the execution of the protocol and recording of all raw data. 6.1.3 Review deviations and support the preparation of all corrective action reports that may be required to resolve discrepant situations. 6.1.4 Prepare and/or coordinate the preparation of a final test report analyzing and summarizing the data and submit for review and approval. AAC Consulting Group: 6.2.1 Provide technical input into the preparation of the test protocol in accordance with cGMPs, industry, USFDA standards and guidelines, and Company Xapproved Standard Operating Procedures. Provide expert review of the finished protocol and procedures. 6.2.2 Assist in the performance of the execution of the test protocol and recording/analysis of the test results. 6.2.3 Assist in the preparation of deviation reports and recommend corrective actions to resolve discrepant situations that may arise during execution of the test protocol. 6.2.4 Assist in the preparation of a final report and provide input as to the conclusions summarizing the study and submit to Company Xmanagement for review and approval. Manufacturing Department: 6.3.1 Review and approve the test protocol content. 6.3.2 Provide qualified personnel to assist with the execution of the protocol and the collection of samples. 6.3.3 Assist in preparation of deviation reports and recommend corrective action to resolve discrepant situations that may arise during execution of the protocol. 6.3.4 Review and approve the final report. Engineering and/or Facilities Department: 6.4.1 Review and approve the test protocol content. Page 7 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 6.5 6.0 6.4.2 Provide documentation required for the generation and execution of the protocol. 6.4.3 Provide equipment that has been commissioned and functional as specified by Site Acceptance Test Report. 6.4.4 Provide assistance in evaluating and resolving equipment malfunctions that may be encountered during execution of the protocol. Quality Assurance Department: 6.5.1 Review and approve the test protocol content in accordance with the approved SOPs, cGMPs, and current industry guidelines. 6.5.2 Review deviations and support preparation of corrective action reports that may be required to resolve discrepant situations. 6.5.3 Review and approve the final report. PREREQUSITES All Standard Operating Procedures required for the execution of this OQ such as operation, maintenance and calibration of the equipment undergoing OQ must be approved before the approval of the OQ Final Report. This section lists acronyms and definitions specific to this document. 8.0 ACRONYMS AHU AL CGMP CPH CAV Air Handling Unit Airlock current Good Manufacturing Practice Changes per hour Control Air Volume Boxes EWT GPM HEPA HVAC IWG LAT LWT MAU NEBB NLT Entering Water Temperature Gallons Per Minute High Efficiency Particulate Air Heating, Ventilating, and Air Conditioning Inches of Water Gage Leaving Air Temperature Leaving Water Temperature Make-Up Air Unit National Environmental Balancing Bureau Not Less Than Page 8 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X NMT IQ PSI PM P&ID RPM SOP’s RHC TAB VAV 9.0 Not More Than Installation Qualification Pound per Square Inch Preventive Maintenance Piping and Instrumentation Diagram Revolutions Per Minute Standard operating Procedures Re Heat Coils Testing, Adjusting, and Balancing Variable Air Volume (Dampers or Boxes) DEFINITIONS 9.1 Acceptance Criteria The system specifications and accept/reject criteria that is necessary for making a decision to accept or reject the system and/or component being qualified. 9.2 Summary of Results A written summary of the qualification policies, procedures, and results that may include graphs and tables to support conclusions and final acceptance. Also included in this summary would be documentation of deviations, their investigation, and final corrective action implemented to provide final closure. 9.3 System The term “system” as used in this protocol refers to the series of components, measuring or control devices and/or equipment, that when working together perform a function considered critical to the manufacturing of a product intended for medicinal use. Within the scope of this procedure, the term “system” equally applies to computerized systems, process control systems, utilities, services, and equipment set-ups (e.g., a reactor-condenser-motor-agitator set-up). 10.0 GENERAL DOCUMENTATION REQUIREMENTS 10.1 10.2 Personnel Identification List 10.1.1 All personnel involved in the execution of the protocol must review and complete Attachment 1. 10.1.2 Curriculum Vitae for all contract personnel have been submitted to the Validation Department, documented in the Approved Personnel List maintained by the Document Control Department at Company X, Inc. Test Equipment Identification/Calibration Page 9 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 10.3 10.2.1 Document on Attachment 2 the test equipment that is used during execution of this protocol. 10.2.2 All test equipment descriptions have been submitted to the Validation Department, documented in the approved Test Instrument List maintained by the Document Control Department at Company X, Inc. 10.2.3 All test equipment must be calibrated against standards that are NIST traceable. Copies of all calibration certificates for the test equipment must be included in this attachment. Test Equipment Operation 10.3.1 10.4 Protocol Corrections 10.4.1 10.5 Protocol corrections must be documented by the issuance of a protocol amendment providing the correct information. Raw Data Corrections 10.5.1 10.6 Document on Attachment 3 the SOPs and/or Operation Manuals that are required for the test equipment used in the execution of this protocol. Corrections to the raw data must be performed using a single line cross out and explanation with the person’s initials and date. Protocol Deviations 10.6.1 A protocol deviation indicates the discovery of discrepant results, methods, information, or procedures resulting from the execution of this protocol. 10.6.2 All protocol deviations must be documented in accordance with the current Company X Standard Operating Procedure # MF/SOP/097, entitled “SOP for Reporting and Investigation of Incidents, Discrepancies, and Deviations”. Each deviation must be documented on the Deviation Report found MF/SOP/097. 10.6.3 Document all protocol deviations that may occur during the execution of this OQ on the protocol deviation report log found in MF/SOP/097. Page 10 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 10.7 11.0 Worksheets 10.7.1 Data, other than laboratory data, must be documented on one of the following types of worksheets during the execution of the protocol: 10.7.2 Protocol specific data worksheets, provided in the attachments, will be used to record data as required. 10.7.3 The General Data Worksheet provided in the attachments, may be customized for additional data collection or clarification. 10.7.4 Copies of raw data from notebook pages or laboratory test results shall be attached to the summary package. DATA COLLECTION AND DOCUMENTATION PROCEDURES 11.1 Operation Qualification Worksheets 11.1.1 Each OQ worksheet must be completed as directed on the individual worksheet. 11.1.2 The executed OQ worksheet raw data should be compared against the acceptance criteria, evaluated, and initialed/dated. In the event the acceptance criteria are not met, a deviation report must be prepared, reviewed and approved, and recorded on the deviation report log for each occurrence. 11.1.3 All data and results are to be recorded on approved copies of OQ worksheets. 11.1.4 Initial and date each entry and sign and date each worksheet. 11.1.5 Each page of any attachments to the protocol must reference the protocol #, section and page #, and must be initialed and dated. 11.1.6 A summary of results reflecting conclusions for all verifications should be prepared and this document inserted at the beginning of the data package. 11.1.7 The acceptance criteria as indicated for each OQ worksheet must be met. 11.1.8 All specified data available at the time of protocol generation should be entered on each worksheet prior to approval of the protocol. The source of each specified value entered should be referenced in the comment section of each OQ worksheet. All specified data that cannot be determined at the time of protocol generation would be recorded as “Not specified” and the actual value from field verification will be recorded. In the event a specified cannot be field verified a reason should be entered in the comment section of the form. Page 11 Operation Qualification Protocol Protocol No. Effective Date Title: HVAC Issue No. Revision # 1 Company X 12.0 OPERATION QUALIFICATION TEST REQUIREMENTS 12.1 Objective 12.1.1 To verify that the HVAC system and its components have been operated in accordance with the requirements as indicated in the system designs. 12.2 Acceptance Criteria 12.2.1 The acceptance criteria as indicated on each protocol attachment must be met or written explanation providing resolution must be documented. 12.3 Procedure 12.3.1 Complete each protocol attachment as directed on the individual attachment making sure all required data is properly recorded, initialed, and dated. 12.4 Methods of Data Analysis 12.4.1 Review all completed attachments and compare against the acceptance criteria to assure that all criteria have been met. 13.0 REFERENCES 13.1 ISO-14644-1, Cleanrooms and Associated Controlled Environments, Part 1: Classification of Air Cleanliness, First Edition, 1999-05-01. 13.2 ISO-14644-2, Cleanrooms and Associated Controlled Environments, Part 2: Specifications for Testing and Monitoring to Prove Compliance with ISO 14644-1 , First Edition, 2000-09-15. 13.3 ISO-14644-4, Cleanrooms and Associated Controlled Environments, Part 4: Design, Construction, and Start-up, First Edition, 2000-04-01. 13.4 ISO-14644-7, Cleanrooms and Associated Controlled Environments, Part 7: Separative Enclosures (Clean Air Hoods, Gloveboxes, Isolators, Mini-Environments, Draft. 13.5 Title 21, Code of Federal Regulations, Parts 210 and 211 13.6 ICH, Q7A August 2001. Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, 13.7 Standard Operating Procedures Page 12 Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 GENERAL DATA WORKSHEET Attachment # Page 1 of 1 Use this worksheet for additional data gathering or data clarification. Include in applicable section of summary package. NOTE: Make copies of this worksheet as necessary. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 13 Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 1 - Personnel Identification List Page 1 of 1 Each person who will be executing the protocol must complete an entry on this page. Signatures signify that they have been trained in the protocol and understand the protocol requirements. NOTE: Make copies of this attachment as necessary. Name Title Signatures Reviewed by: Date: QA Approval: Date: Page 14 Initials Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 2 - Test Equipment Identification/Calibration Page 1 of 1 Document test equipment not installed on the equipment/system being qualified that are required for execution of this protocol. NOTE: Make copies of this attachment as necessary. Test Equipment Calibration Description Model # Serial # Tag # Last Cal Date Cal Due Date Criteria Met? (Yes/No/NA) Acceptance Criteria The test equipment is calibrated and the calibration is current. The calibration standards are traceable to NIST. A copy of the calibration certification(s) for the test equipment used is attached. Comments: Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 15 Initials Date Initials Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 3 – Test Equipment Operation Page 1 of 1 Document SOPs and/or Operation Manuals that are required for operation of the test equipment used in the execution of this protocol and verify they are current. NOTE: Make copies of this attachment as necessary. Document # Effective Date Title Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 16 Current and Documented? (Yes/No) Initial/Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 4 - TESTING, ADJUSTING AND BALANCING (TAB) VERIFICATION Document the testing, adjusting and balancing (TAB) performed meet the design specifications. Yes/No Initial/Date Actual Initial/Date Was the testing adjusting and balancing conducted? Did the system comply with specifications? Was the TAB Test Report Generated? Is the firm’s current NEBB certification current ? Description Testing performed by: Location of Original Report (s) Criteria Met? (Yes/No/NA) Acceptance Criteria All TAB Testing for room 111 meets the design specifications A copy of the firm’s NEBB certification attached. A copy of the current TAB test report is attached or location where it can be found is referenced. Written justifications are provided for documents that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 17 Initial/ Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 5 - OPERATION, MAINTENANCE AND CALIBRATION SOPS Page ______ of _______ List and verify the SOPs that relate to the operation, maintenance and calibration of the system. Also include any additional SOPs required for execution of this protocol. SOP Title Procedure Number Effective Date Criteria Met? (Yes, No, NA) Acceptance Criteria SOPs are approved and current. Comments: Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 18 Initials Date Initials Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 6 – CALIBRATION VERIFICATION (INSTRUMENTS) Page ______ of _______ List the calibrated instruments and verify their calibration status during the execution of this protocol. Include a copy of the calibration certifications with this protocol. Instruments Calibration Instrument Model # Serial # Tag # Last Cal Date Cal Due Date Criteria Met? (Yes, No, NA) Acceptance Criteria The calibrated instruments are entered into a calibration program. The calibrated instruments have a current calibration sticker that is visible. The calibration standards are traceable to NIST. A copy of the calibration certification(s) for each instrument is attached. Comments: Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 19 Initials Date Initials Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 7 – HEPA FILTER INTEGRITY TEST VERIFICATION Document if the HEPA filter integrity testing performed meet the design specifications. Room 111 and MAU-1 Yes/No Initial/Date Actual Initial/Date Are copies of the Vendor testing report attached? Are the serial numbers documented in the report correct? Have any significant leaks been found and corrected? Do any corrections made using caulking silicone sealant exceed 5% of the filter area? Instrument used to perform the test is calibrated to NIST traceable standards? Description Testing performed by: Location of Original Report (s) Criteria Met? (Yes/No/NA) Acceptance Criteria All required documents are provided. Written justifications are provided for documents that could not be field verified. Comments Reference: FARR Clean Room Products Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 20 Initial/ Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 21 Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 8 – Verification of Operation – Exhaust Fan / Motor Verify and document the following information from the motor and Exhaust Fan : • Fan’s speed. • Motor’s supply voltage is within the motor specifications when operating under load. • Motor’s current draw is less than the motor full load amps when operating under load. • Fan’s Total Static Pressure. Parameters Expected Results Revolutions (RPM) 2252 ± 10% Nominal Voltage (V) 120 ± 10% Full Load Amperage (FLA) Not Specified Total Static pressure (I.W.) 1.5± 10% Actual Results Initial/ Date Pass (Yes/No) Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Justifications are provided for actual results that could not be field verified. The Fan’s speed is within ± 10% of the specified speed. The motor supply voltage is within ± 10% of the nominal when the voltage is operating under load. The motor current is less than the motor full load amps when operating under load. The total static pressure is within ± 10% of the specified total static pressure. Comments Reference: Raytheon Engineers & Constructors Dwg.No.H-02, rev –2,8/17/94 Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 22 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 9 – VERIFICATION OF OPERATION – PUMPS / MOTORS Pump #12 Pump Manufacturer: Expected Values Not Specified Chillers # 1 Actual values Initials/Dates Not Specified Series: 270 GPM Flow Rate: 92 FT Head: Motor Manufacturer Not Specified 10HP HP: 460 Voltage: 3 Phases: Hertz: Motor NEMA Classification: 60 Not Specified Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Justifications are provided for actual results that could not be field verified. The motor supply voltage is within ± 10% of the nominal when the voltage is operating under load. The motor current is less than the motor full load amps when operating under load. Comments Reference: Raytheon Engineers & Constructors Dwg.No.H-02, rev –2,8/17/94. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 23 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 10 – Verification of Operation – Cooling / Reheating Coils Verify and document the following information from the Reheating Coil: • • Enter Water Temperature (EWT). Leaving Air Temperature (LAT). Parameters Expected Results EWT NMT 180°F LAT 75°F Actual Results Initial/Date Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Justifications are provided for actual results that could not be field verified. Comments Reference: Raytheon Engineers & Constructors Dwg.No.H-02, rev –2,8/17/94. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 24 Initial/ Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 11 – Verification of Operation – Variable Air Volume Box Document the mechanical condition of the Variable Air Volume Box. Dampers Physical/Mechanical Condition Supply Air Opens (Yes/No):______ Initial/Date Operation* Closes (Yes/No:_______ *Operation may involve two positions, Normally Open (NO) and Normally Closed (NC), and floating or proportioning (modulating). Criteria Met? (Yes/No/NA) Acceptance Criteria The mechanical condition of the Variable Air Volume Box (VAV-A). Written justification is provided for actual results that could not be field verified. Comments Reference: Raytheon Engineers & Constructors Dwg.No.H-02, rev –2,8/17/94. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 25 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 12 – VERIFICATION OF OPERATION – SMOKE SENSOR Verify and document that the Smoke Sensor Inlet (DH-51), operates as specified (shuts off the supply air fan’s motor and trigger the alarm conditions at the fire alarm panel, when the presence of smoke is detected). Action Step Expected Results Actual Results Pass (Yes/No) Place the machine in operation and simulate a smoke condition inside the duct. Upon sensing smoke the Smoke Sensor Inlet (DH51) shall stop the AHU-6 and trigger the alarm condition at the fire alarm panel. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Initial/ Date Reference: Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 26 Initial/ Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 13 – SAFETY DEVICE(S) Verify and document the guarding requirements of the AHU-6 and MAU-1. AHU-6 - SPECIFIC GUARDING REQUIREMENTS Action Step Yes/No Step No. 1. 2. 3. 4. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Points of Operation Is there a guard or safety device provided for each point-of-operation of the machine? Do these guards allow the operators' hand, arms, or other body parts from making contact with hazardous machine parts by reaching over, under, around, or through the guard? Is there evidence that guards have been tampered with or bypass to make them ineffective (at the time of this review)? Are the guards firmly secured and not easily removed (fasteners should require the use of hand tools for removal)? Power Transmission Apparatus Are there any unguarded gears, sprockets, pulleys, flywheels, shafts, belts, couplings, or chain drives on the equipment? Do power transmission guards allow the operator’s hands, arm or other body parts to make contact with dangerous moving parts by reaching over, under, around, or through the guard? Are there any exposed sets of screws, keyways, collars, etc.? Are guards in good condition and firmly secured (fasteners should require the use of hand tools for removal)? Are starting and stopping controls within easy reach of the operator? If there is more than one operator station, are separate controls so located that the operators can see the entire operation? Are controls, including foot controls, guarded against accidental activation? Are controls labeled to identify their functions? Are controls similar in type and arrangement to other similar machines in the plant? Are emergency stop controls easily accessible and clearly identified? Is wired so that it must be manually re started if power is interrupted and then reapplied? Are two hands controls electrically wired to include the following: Concurrent use of both hands _______Anti-repeat ______Anti-holddown Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 27 Initial/Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 14 – VERIFICATION OF OPERATION – INTERLOCKS Page 1 of 2 Verify and document that each interlock shuts off AHU-6 and MAU-1. Verify that the AHU-6 and MAU-1can not be turned on with interlock open, verify on closure that machine must be reset. AHU-6 Interlock List Action Step Shuts Off (Yes/No) Verified By/ Date Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 28 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 14 – Verification of Operation – Interlocks Page 2 of 2 MAU-1 Interlock List Action Step Shuts Off (Yes/No) Verified By/ Date Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 29 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 15– VERIFICATION OF OPERATION – ALARMS Page 1 of 5 Verify and document the operational condition of each alarm in the AHU-6, MAU-1, Exhaust Fans and Utilities. AHU-6 Alarm Test Procedure Expected Results AHU-6Temperature Control Using the Metacomm station increase the temperature setpoint for each room (123125). The RHC-1, RHC-2 and VAV-A will increase and maintain temperature in rooms 123 and 125 at the new setpoint. The alarm condition will be indicated in the printed report. AHU-6 Temperature Control Using the Metacomm station decrease the temperature setpoint for each room (123125). The RHC-1, RHC-2 and VAV-A will decrease and maintain temperature in rooms 123-125 at the new setpoint. The alarm condition will be indicated in the printed report. AHU-6-Supply Smoke Alarms Test the smoke detection. Using smoke sticks, simulate smoke detection by the smoke detector in the AHU6. AHU-6 will shut down Test the smoke detection. Using smoke sticks, simulate smoke detection by the smoke detector in the AHU6. AHU-6 will shut down AHU-6-Return Smoke Alarms Initials/Date The alarm condition will be indicated in the printed report. The alarm condition will be indicated in the printed report. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Actual as expected? (Yes/No) Expected results provided by Company XFacilities Department. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 30 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 15 – Verification of Operation – Alarms Page 2 of 5 MAU-1 Alarm Test Procedure MAU-1-Smoke Alarm Test the smoke detection. Using smoke sticks, simulate smoke detection by the smoke detector in the MAU1. MAU-1 will shut down The alarm condition will be indicated in the printed report. MAU-1-Low Temperature Detection Check the low temperature detection thermostat. Simulate an air temperature below the low temperature detection thermostat setpoint. Fan shuts down. Outside damper closed MAU-1-Room Temperature Control MAU-1-Room Temperature Control Expected Results Actual as expected? (Yes/No) Initials/Date Chilled water valve closed The alarm condition will be indicated in the printed report. Using the Metacomm station The RHC-3-9, 19-21 and increase the temperature VAV-B-H, J-L will increase setpoint for each room: and maintain temperature in (120,121,122,113,114,111,118 rooms (120,121,122,113,114, ,117,119). 111,118,117,119) at the new setpoint. The alarm condition will be indicated in the printed report. Using the Metacomm station The RHC-3-9, 19-21 and decrease the temperature VAV-B-H, J-L will decrease setpoint for each room: and maintain temperature in (120,121,122,113,114,111,118 rooms (120,121,122,113,114, ,117,119). 111,118,117,119) at the new setpoint. The alarm condition will be indicated in the printed report. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 31 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 15 – Verification of Operation – Alarms Page 3 of 5 EXHAUST FANS Alarm Test Procedure Actual as expected? (Yes/No) Expected Results Shut off power to Exhaust Fan –EF-1 by cutting off the appropriate Electrical Breaker Switch. Fan shuts down. EF-2 Shut off power to Exhaust Fan –EF-2 by cutting off the appropriate Electrical Breaker Switch. Fan shuts down. The alarm condition will be indicated in the printed report. EF-3 Shut off power to Exhaust Fan –EF-3 by cutting off the appropriate Electrical Breaker Switch. Fan shuts down. EF-1 EF-4 EF-5 EF-6 EF-7 EF-8 EF-9 Shut off power to Exhaust Fan –EF-4 by cutting off the appropriate Electrical Breaker Switch. Shut off power to Exhaust Fan –EF-5 by cutting off the appropriate Electrical Breaker Switch. Shut off power to Exhaust Fan –EF-6 by cutting off the appropriate Electrical Breaker Switch. Shut off power to Exhaust Fan –EF-7 by cutting off the appropriate Electrical Breaker Switch. Shut off power to Exhaust Fan –EF-8 by cutting off the appropriate Electrical Breaker Switch. Shut off power to Exhaust Fan –EF-9 by cutting off the appropriate Electrical Breaker Switch. The alarm condition will be indicated in the printed report. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 32 Initials/Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 15 – Verification of Operation – Alarms Page 4 of 5 EXHAUST FANS Alarm EF-10 Test Procedure Shut off power to Exhaust Fan –EF-10 by cutting off the appropriate Electrical Breaker Switch. EF-11 Shut off power to Exhaust Fan –EF-11 by cutting off the appropriate Electrical Breaker Switch. EF-12 Shut off power to Exhaust Fan –EF-12 by cutting off the appropriate Electrical Breaker Switch. EF-16 Shut off power to Exhaust Fan –EF-16 by cutting off the appropriate Electrical Breaker Switch. EF-17 Shut off power to Exhaust Fan –EF-17 by cutting off the appropriate Electrical Breaker Switch. Actual as expected? (Yes/No) Expected Results Initials/Date Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Fan shuts down. The alarm condition will be indicated in the printed report. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 33 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 15 – Verification of Operation – Alarms – Utilities Services Page 5 of 5 UTILITIES SERVICES Alarm Hot Water Test Procedure Shut off power to supply pumps by cutting off the appropriate Electrical Breaker Switch. Expected Results Actual as expected? (Yes/No) Initials/Date The alarm condition will be indicated in the printed report. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 34 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 16 – ENVIRONMENTAL CONDITIONS VERIFICATION – STATIC CONDITIONS Temperature and Relative Humidity (T&RH) data collection points will be distributed inside the controlled space. Points distribution will be based upon the presence of heat sources, heat sinks, and the location of manufacturing equipment. T&RH data collection points will follow the numerical sequence and/or identification per area, specified in Attachment 1. Procedure: T&RH readings will be taken in designated points at work levels heights (4 to 5 feet). For this purpose, portable T&RH probe(s) will be used to obtain simultaneous readings of temperature and relative humidity at each predetermined location. The data acquisition will be performed at 6:00AM, 12:00PM, 6:00PM and 12:00AM with a time tolerance of plus/minus one hour per area, for three (3) consecutive days (the time intervals have been chosen considering general perceptive environmental changes of temperature and humidity). (Make copies of test form as needed.) Acceptance Criteria: Temperature and humidity are maintained within the specified design ranges (70oF ± 5oF and 20-80% RH) throughout the test period. Table 1: Temperature and relative humidity periodic readings recording Room 111 1st data collection Data Point ID. No. %RH T(°F) Initial/Date Pass/Fail 1 2 3 4 5 Test Stage Beginning End Date Hour Criteria Met? (Yes/No/NA) Acceptance Criteria All field verified results conform to system operating specified conditions.. Written justifications are provided for results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 35 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 TACHMENT 16 – Environmental Conditions Verification – Static Conditions Table 2: Temperature and relative humidity periodic readings recording Room 111 2nd data collection Data Point ID. No. %RH T(°F) Pass/Fail Initial/Date 1 2 3 4 5 Test Stage Beginning End Date Hour Criteria Met? (Yes/No/NA) Acceptance Criteria All field verified results conform to system operating specified conditions.. Written justifications are provided for results that could not be field verified. Comments Reference Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 36 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 16 – Environmental Conditions Verification – Static Conditions Page 3 of 40 Table 3: Temperature and relative humidity periodic readings recording Room 111 3rd data collection Data Point ID. No. %RH T(°F) Pass/Fail Initial/Date 1 2 3 4 5 Test Stage Beginning End Date Hour Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Reference Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 37 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 16 – Environmental Conditions Verification – Static Conditions Page 4 of 40 Table 4: Temperature and relative humidity periodic readings recording Room 111 4th data collection Data Point ID. No. %RH T(°F) Pass/Fail Initial/Date 1 2 3 4 5 Test Stage Beginning End Date Hour Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Reference Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 38 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 17 –DIFFERENTIAL PRESSURE VERIFICATION – STATIC CONDITIONS Page 1 of 1 To verify that the AHU-6 and MAU-1 maintain differential pressures where designed. Testing shall be performed in accordance with the NEBB requirements for “Enclosure Pressurization and Integrity Testing” as defined in Procedural Standards for Certified Testing of Cleanrooms. Acceptance Criteria: Operational Differential Pressure with all doors closed meets requirements for environmental performance qualification in Avecia’s facility. Procedure: Room differential pressures will be recorded from differential pressure monitors once a day under static conditions, with all doors closed, to ensure compliance with the design specifications. Verify and document that the AHU-6 and MAU-1 will maintain the differential pressure within Avecia’s specified operating ranges under static conditions. Room 111 Note: Not Less Than 0.005” W.C. in the specified direction With Respect To: Mechanical Corridor Design Actual Pass (Yes/No) Initial/Date 0.005” W.C. Acceptance Criteria Initial/Date All actual values conform to design results. Written justifications are provided for actual results that could not be field verified. Comments Reference: NEBB requirements for “Enclosure Pressurization and Integrity Testing Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 39 Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 18 – AIR CHANGES VERIFICATION Page 1 of 1 To verify that the operation of the AHU-6 and MAU-1 conform to design specifications for air changes per hour. Procedure: Testing and reporting shall be performed in accordance with the NEBB Standard Procedures. Acceptance Criteria: Air Change Rate meets requirements for environmental performance qualification in Avecia’s facility. These requirements are at least twenty (20) air changes per hour (CPH) for each room. Airflow readings should be taken from the Testing and Adjusting Balancing (TAB) Report, generated by a NEBB certified firm during the installation qualification. The TAB Report must be attached to the OQ Protocol. To verify and document that the operation of the AHU-6 and MAU-1 conforms to design specifications for air changes per hour. Equation Nactual = Qexhaust x 60 Vol. Where: Nrequired = Nactual = Qexhaust = Vol. = Room air changes per hour as per Avecia’s specifications Actual room’s air changes per hour Total air exhaust from room (CFM) Room’s volume (ft3) Air Changes for Room 111 Nrequired Qexhaust (CFM) Vol (ft3) Nactual (CPH) Pass or Fail Verified By/ Date Nactual ≥ _____ Criteria Met? (Yes/No/NA) cceptance Criteria All actual results conform to specified results. Written justifications are provided for actual results that could not be field verified. Comments Reference: Air Balance Report Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 40 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 19 – POWER LOSS AND RECOVERY Recovery of Environmental Conditions: To verify and document the response of the AHU-6 and MAU-1, when simulating a failure in the Chilled Water support utility. Procedure: Prior to power failure, record the set points in the table provided on the next page. Simulate power failure and record conditions until the readings of temperature and relative humidity are out of parameters, then restore power and continue recording until conditions returns to operational parameters. On the columns designated for In and Out Parameters Audit, write IN or OUT when the temperature and the humidity are in or out of parameters, respectively. During the power failure, field devices will be observed. In addition, the time elapsed for full restoration will be documented. Acceptance Criteria: On power failure, AHU-6 and MAU-1 goes to power off conditions. On power restoration, the AHU-6 and MAU-1 should pass the challenges stated on the test case form. In or Out of Parameters Audit Min/Max Readings %RH=20% to 80%, T= 70oF ± 5oF Time %RH T %RH T Min. Max. Min. Max. Min. Max. Min. Max. Condition Before Power Failure N/A Condition During Power Failure 10 min. 20 min. 30 min. 40 min. 50 min. 60 min. Condition After Power Failure 10 min. 20 min. 30 min. 40 min. 50 min. 60 min. Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to expected results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 41 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 20 – NON-VIABLE PARTICLE COUNT TEST Page 1 of 1 Verify and document that the MAU-1 and AHU-6 maintain the design non-viable particle count for controlled room environment area. Procedure: To ensure that the controlled manufacturing environments comply with the requirements stated in the engineering specifications and current revision of ISO-14644-1, “Classification of Air Cleanliness”. Non-viable particle counts will be taken for each room on each predetermined locations (see room Reference Attachment 1) for one (1) day under static conditions using a Met-One Particle Counter. Avecia’s Criteria: Data Point 3,520,000 particles/m³ of 0.5µ and 29,300 particles/m³ of 5.0µ Room 111 Non Viable Particle Count (As Found Results) 0.5 µ ID. No. Pass/Fail 5.0µ Initial/ Date 1 2 3 4 5 Criteria Met? (Yes/No/NA) Acceptance Criteria All data points results conform to expected results based on room classification.. Written justifications are provided for actual results that could not be field verified. Comments Reference:ISO14644-1 Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 42 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 21 SUPPORT UTILITIES VERIFICATION-CHILLED WATER Page 1 of 1 Test Objective: To verify that the operating chilled water inlet temperature meets design conditions. procedure: Chilled water coil temperatures shall be measured with a calibrated instrument and recorded a minimum of once every eight (8) hours over a period of three (3) consecutive days (shall be performed in conjunction with Environmental Verification at Dynamic Conditions). Acceptance Criteria: Chilled water coil inlet temperature meets design conditions (36 -48 oF) throughout the test period. EWT (oF) Time Expected Results Initial/Date As Found Results 36 – 48°F 36 – 48°F 36 – 48°F 36 – 48°F 36 – 48°F 36 – 48°F 36 – 48°F 36 – 48°F Criteria Met? (Yes/No/NA) Acceptance Criteria All results conform to design results. Written justifications are provided for actual results that could not be field verified. Comments Make copies of test form as required. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 43 Initial/ Date Operation Qualification Protocol Protocol No. MF/VAL/OQ/013/PRO Effective Date Title: HVAC AHU-6 and MAU-1 Issue No. Revision # 1 ATTACHMENT 22 SUPPORT UTILITIES VERIFICATION-HOT WATER Page 1 of 1 Test Objective: To verify that the operating hot water inlet temperature meets design conditions. Procedure: Hot water coil temperatures shall be measured with a calibrated instrument and recorded a minimum of once every eight (8) hours over a period of three (3) consecutive days (shall be performed in conjunction with Environmental Verification at Dynamic Conditions). Acceptance Criteria: Hot water coil inlet temperature meets design conditions (150-170oF ) throughout the test period. EWT (oF) Time Expected Results Initial/Date As Found Results 150 - 170°F 150 - 170°F 150 - 170°F 150 - 170°F 150 - 170°F 150 - 170°F 150 - 170°F 150 - 170°F Criteria Met? (Yes/No/NA) Acceptance Criteria All results conform to design results. Written justifications are provided for actual results that could not be field verified. Comments Make copies of test form as required. Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 44 Initial/ Date Operation Qualification Protocol Title: HVAC AHU-6 and MAU-1 Protocol No. MF/VAL/OQ/013/PRO Effective Date Issue No. Revision # 1 ATTACHMENT 23 SUPPORT UTILITIES VERIFICATION-COMPRESSED AIR Page 1 of 1 To verify that the compressed air inlet pressure meets control and equipment’s requirements. Procedure: Compressed air pressure shall be measured at system’s air pressure regulator valve’s inlet and recorded a minimum of once reading every eight (8) hours over a period of three (3) consecutive days (shall be performed in conjunction with Environmental Verification at Dynamic Conditions). Acceptance Criteria: Compressed air pressure meets control and equipment’s requirements (90-110 PSIG) throughout the test period. Time Pressure inlet (PSIG) Initial/Date Expected Results As Found Results 90-110 PSIG 90-110 PSIG 90-110 PSIG 90-110 PSIG 90-110 PSIG 90-110 PSIG 90-110 PSIG 90-110 PSIG Criteria Met? (Yes/No/NA) Acceptance Criteria All actual results conform to design results. Written justifications are provided for actual results that could not be field verified. Comments Completed by: Date: Reviewed by: Date: QA Approval: Date: Page 45 Initial/ Date