Proposed USP Chapter <797>

Changes are coming!

Published Sept 25, 2015

Presented by Eric S. Kastango, MBA, RPh, FASHP

Copyright © 2008-2016

1999 -2016CriticalPoint,

2008-2014

ClinicalIQ,

Clinical IQ,LLC®

LLC®

LLC®

- -All

All

- All

Rights

Rights

Rights

Reserved

Reserved

Reserved

I am speaking in my individual capacity and

not as a representative of any organization or committee regardless

of my status, membership or affiliations with any entity.

The views and opinions presented are entirely my own.

They do not necessarily reflect the views of any other organization I

may be associated with, nor should they be construed as an

“official” explanation or interpretation of any USP chapter or any

State Board of Pharmacy rule/law.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Scope of USP <797>

Compounded sterile preparations affected are:

• Injections

• Aqueous bronchial inhalations

• Baths and soaks for live organs and tissues

• Irrigation solutions for internal body cavities*

• Nasal/Sinus solutions does not have to be sterile, just clean (USP 795)

• Ophthalmics

• Implants

– Pellets

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

3

Who does the chapter apply to?

• Applies to

– all persons who prepare CSPs

– all places where CSPs are prepared

– pre-administration manipulations of CSPs including

storage, compounding, and transport

• Does not apply to administration!

• Specific chapter language:

– “shall” is a requirement (must)

– “should” is a recommendation

• Note: 503b outsourcing sterile compounding

facilities will be expected to comply with FDA cGMP

regulations

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Mission of Chapter: To Prevent Harm

• Microbial contamination

• Excessive bacterial endotoxins

• Variability in intended strength that

exceed monograph limits

• Use of ingredients of inappropriate quality

• Unintended physical and chemical

contaminants

Courtesy CBS News

This is a image of the fungus growing from a

sample taken from a patient’s spinal fluid.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

USP Chapter <797>

• Enforceable by the FDA and 28 State

Boards of Pharmacy (more or less)

• Based on current scientific information

and best sterile compounding practices

• Recognized as the national standard of

• Included in TJC and other accreditation

organization requirements only if their

standards address sterile compounding

• Minimum practice and quality standards

for compounding sterile preparations

practice

Published

11/2003

Official

1/2004

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Revision

released

12/2007

Official

6/2008

Out for Public

Comment

9/2015

Proposed USP <797>

Summary of Major Changes:

3 risk levels changed to 2 categories distinguished

by conditions under which they are made and time

within which used

Removal of HD handling section and cross-referenced

to USP 800

Quarterly requirement for Personnel Monitoring

(visual observation of hand hygiene and garbing,

MFT and ongoing GFS)

Monthly requirement for Viable Air sampling and

Surface sampling

BUD and Storage times changed with a maximum

BUD of 45 days regardless of sterility testing

Introduction of “In-Use time” (time before which

conventionally manufactured product or compounded

dilution bag must be used after it is punctured)

Master formulation and compounding records will

be required for all batch and non-sterile

compounding

New guidance for sterility testing of CSP prepared in

batch sizes of less than 40. (10% rule)

New placement requirements on use of isolators

Requirement for sterile gloves and sterile sleeves,

sterile wipers and cleaning tools that need to be resterilized but not sterile disinfectants

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Definitions and Practice Issues

• Current USP Chapter <797> rejects this statement

“Compounding does not include mixing, reconstituting, or similar acts that are

performed in accordance with the directions contained in approved labeling

provided by the product's manufacturer and other manufacturer directions

consistent with that labeling” [21 USC 321 (k) and (m)].

• For one patient for immediate administration a function of medication

administration

– This is fundamentally low-risk compounding

• Batching <797> applies

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Briefing of Proposed Changes

• Reorganized, redundancies eliminated, and requirements clarified

• Minor editorial changes have been made to update the chapter to current

USP style.

• Organized in a similar manner as 21 CFR Part 211 – US FDA CGMPs

• Key procedures placed in boxes for reference

• All sample documents and media procedures removed

• Hazardous Drug requirements referred to USP <800>

• Allergen extracts no longer given a carve-out

• Radiopharmaceuticals still need to comply with USP 797

• Administration is still out of scope – defer to CDC guidance

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Current BUD Paradigm

• Applied only to pre-administration activities (handling, compounding and

storage)

– Once CSP was administered, then USP 797 was no longer applicable

• Chemical Stability must be assured during the use of the CSP

• Not capped: USP 71 Sterility Test passed has allowed BUD to chemical

stability of the drug.

– Not Closure-Container Integrity Test required

• Current USP 797 is silent on the requirements for compounding multi-dose

vials/containers

– USP <51> Antimicrobial Effectiveness Test

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

New Proposed BUD Paradigm

• NEW DEFINITION: The date or time after which a CSP cannot be used and

must be discarded.

• The BUD is determined from the time the CSP is compounded.

– One day is equivalent to 24 hours.

• BUDs is capped to 42 days refrigerated

• Closure-Container Integrity Test required for frozen CSPs

• CSPs that are made as a MDV must undergo USP <51> Antimicrobial

Effectiveness Testing

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

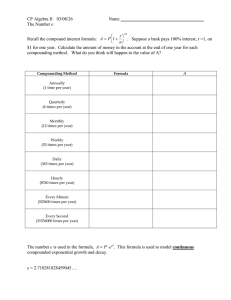

Flowchart of BUDs

1.

2.

3.

4.

5.

Aseptically-prepared or terminally-sterilized?

Sterility test performed?

Preservative added?

Only sterile components or any nonsterile component?

Storage temperature

A. Controlled Room Temperature

B. Refrigerator

C. Freezer

Changes in BUDs are based on increasing the frequency

of monitoring personnel and the environment

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Proposed USP 797: Category 1 CSPs

PEC placement

Not in ISO classified air

Sterility Testing

Not required

Endotoxin Testing

Not required

BUD

≤ 12 hours room temperature or ≤ 24 hours

refrigerated

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Proposed USP 797: Storage for Category 2 CSPs

PEC placement

Placed in ISO classified air

Sterility Testing

Based on BUD Assignment below

Endotoxin Testing Not required if sterile components

Storage

Method

Terminally

Sterilized CSPs

Aseptically

Prepared CSPs

BUD Assignment

> 12 hour room temperature or > than 24 hours refrigerated

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Sterility Testing

Preservative

Added

No

No

Controlled

Room

Refrigerated

Frozen

Made from 1 or more non sterile components

4 days

7 days

45 days

Made with only sterile components

Yes

No

Yes

6 days

9 days

Yes (USP 51)

28 days

42 days

No

28 days

42 days

Yes (USP 51)

42 days

42 days

No

14 days

28 days

Yes (USP 51)

28 days

42 days

No

28 days

42 days

Yes (USP 51)

42 days

45 days

45 days

45 days

In-Use Time

The time before which a conventionally manufactured

product used to make a CSP must be used after it has

been opened or punctured, or a CSP must be used after

it has been opened or punctured.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

In-Use Times

Conventionally Manufactured Products Opened, Stored, and Used for Sterile Compounding

in ISO Class 5 or Better Air Quality

Components

In-Use Time

Ampuls

Use immediately after opening and passing through a

sterile particulate filter

Pharmacy Bulk Package

As specified by the manufacturer

Single-dose container (e.g., bag, bottle,

syringe, or vial)

6 hours

Multiple-dose container

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

28 days, unless otherwise specified by the

manufacturer

In-Use Times

CSPs Opened, Stored, and Used for Sterile Compounding in ISO Class 5 or Better Air Quality

Components

In-Use Time

Compounded Single-Dose Container

Use for single patient immediately; discard remainder

Compounded Stock Solutions

6 hours

Compounded Multiple Dose Containers1

28 hours, unless otherwise specified by the original

compounder

1The particular

CSP formulation must pass antimicrobial effectiveness testing in accordance with (51) at the

completion of the sterility test (if conducted) or at the time of preparation (if sterility testing is not

performed). The test must be completed and the results obtained on the specific formulation before any of

the CSP is released or dispensed. The test needs to be conducted only once on each formulation in the

particular container–closure system in which it will be stored or released/dispensed.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Preparation of Dilutions: BUD Decision Tree*

General Example

*This example uses pooling however pooling is not always necessary.

OR

Step 1

Combine Single Dose

Vials

Copyright © 2008-2016 CriticalPoint, LLC® - All Rights Reserved

Step 2

SDVs combined to make Medium Risk CSP

This is source vial/bag for additional doses

Make it the right size so that it will be used up < 8 days

Step 3

Final CSP to Patient

Use within 24 hours and

do NOT recycle

Core Personnel Competencies

Training to establish the following competencies must be completed before

compounding:

• Hand hygiene and garbing

• Cleaning and disinfection

• Measuring and mixing

• Aseptic manipulation

• Proper clean room behavior

• Methods of sterilization and depyrogenation

• Use of compounding equipment

• Documentation

• Understanding air flow patterns

• Proper use of primary engineering controls

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

19

Personnel Garbing for Compounding

CSP Category

PEC type

Category 1

Any

Minimum Requirement

Non-cotton, low-lint, disposable gown or coveralls

Low-lint, disposable covers for shoes

Low-lint, disposable covers for head and facial hair that cover

the ears and forehead

Sterile gloves and sterile sleeves1

Laminar airflow

Non-cotton, low-lint, disposable gowns or coveralls

Category 2

system (LAFS) and

Low-lint, disposable covers for shoes

biological safety cabinet

Low-lint, disposable covers for head and

(BSC)

facial hair that cover the ears and forehead

Mask

Sterile gloves and sterile sleeves1

Eye shield is optional

RABS (CAI or CACI) or

Category 2

Non-cotton, low-lint, disposable gowns or coveralls

isolator

Low-lint, disposable covers for shoes and hair

Sterile gloves

1 Compounding or repackaging must not occur in worse than ISO Class 5 air.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Garbing changes/clarifications

• Remove all cosmetics because they shed flakes and particles

• Remove all hand, wrist, and other exposed jewelry or piercings (e.g., rings,

watches, bracelets, earrings, and lip or eyebrow rings) that can interfere with

the effectiveness of PPE (e.g., fit of gloves, cuffs of sleeves, and eye

protection)

• Cover any jewelry that cannot be removed (e.g., surgically implanted jewelry)

must be covered

• Ear buds, headphones, and cell phones, or other similar devices are not

permitted in the cleanroom

• Dry hands and forearms with either low-lint disposable towels or wipes. No

hand dryers mentioned

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Environmental Monitoring – Facility Related Metrics

Test

Current

Proposed

Non-viable air sampling

Every six months

Every six months

Viable air sampling

Every six months

Quarterly

Periodic

Monthly

Surface sampling

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Personnel Monitoring

Test

Media fill

Current

• Annually if only low/medium risk

compounded

• Semiannually if high risk

compounded

Failed test

• Requalification

Gloved fingertip test • Annually if only low/medium risk

(following initial

compounded

test)

• Semiannually if high risk

compounded

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Proposed

Quarterly

Any failed competency must

be repeated 3 times prior to

restarting

Quarterly

Primary Engineering Controls

• Laminar Air Flow Systems (LAFS)

– Laminar Air Flow Workbenches

– Laminar Air Flow zones

– Biological Safety Cabinets (BSC)

• Restricted Access Barrier System(RABS)

– Compounding aseptic isolator (CAI)

– Compounding aseptic containment isolator (CACI)

• Isolators

– Transfer ports

– Use sporicidal chemical decontamination

– Constant overpressure requirement

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Sterile gloves are

required when working

in a RAB or isolator!

Secondary Engineering Controls

• Segregated Compounding Area

• Category 1 CSPs

(SCA)

• Positive pressure buffer room with

access through a positive pressure

anteroom

• Category 2 CSPs

To meet Category 2, any PEC must be located in an ISO Class 7 area

The use of displacement airflow is NOT permitted

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Facility Design Requirements

• The surfaces of ceilings, walls, floors, fixtures, shelving, counters, and

cabinets in a classified area or in a segregated compounding area must be

smooth, impervious, free from cracks and crevices, and non-shedding,

thereby promoting cleanability and minimizing spaces in which

microorganisms and other contaminants can accumulate.

• The buffer area or area inside the perimeter of a segregated compounding

area cannot contain water sources (e.g., sinks) or floor drains.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Facility Design Requirements

• The room temperature must be maintained at 20° or

cooler and a humidity below 60% at all times.

– Temperature and humidity must be controlled

through an efficient heating, ventilation, and air

conditioning (HVAC) system rather than through

use of humidifiers and dehumidifiers, which can

contain standing water that can contribute to

microbial contamination

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Storage conditions

• Storage under frozen conditions places the container–closure under physical

stress, and the degree of stress may depend on the formulation and other

factors.

• Therefore, if a Category 2 CSP is to be stored in a freezer, the integrity of the

CSP in the particular container–closure system in which it will be stored must

have been demonstrated for 45 days at frozen storage.

• A container–closure integrity test needs to be conducted only once on each

formulation and fill volume in the particular container–closure system in

which it will be stored or released/dispensed.

• Once the CSP is thawed, the CSP must not be re-frozen.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

SOPS and Master Formulation and Compounding Records

• A Master Formulation Record is required

when CSPs are prepared in a batch for

multiple patients or when CSPs are

prepared from nonsterile ingredients.

• Compounding Record is required for every

CSP prepared and requires documentation

by all individuals involved in the actual

preparation of the CSP.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Urgent-Use CSPs (replaces Immediate-Use)

• A CSP may be prepared in worse than ISO Class 5 air quality (see 4.1

Protection from Airborne Contaminants) in rare circumstances when a CSP is

needed urgently (e.g., cardiopulmonary resuscitation) for a single patient,

and preparation of the CSP under conditions described for Category 1 or

Category 2 would subject the patient to additional risk due to delays in

therapy.

• In these circumstances, the compounding procedure must be a continuous

process not to exceed 1 hour, and administration of the CSP must begin

immediately upon completion of preparation of the CSP.

• Aseptic technique must be followed during preparation, and procedures

must be in place to minimize the potential for contact with nonsterile

surfaces, introduction of particulate matter or biological fluids, and mix-ups

with other CSPs.

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Technology advances

• The statement in the current chapter has

been removed:

– “The use of technologies, techniques,

materials, and procedures other than

those described in this chapter is not

prohibited so long as they have been

proven to be equivalent or superior with

statistical significance to those described

herein.”

• No reference to Rapid Microbiological

Methods as an alternative to USP Chapter

<71>

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

How to Provide Comments to USP

• Go to www.USP.org and search for USP <797>

• Download the proposed revisions

• Comments must be submitted on Comment Submission Template by email to

compoundingsl@usp.org by January 31, 2016

– Be sure to include line numbers for your comments

• If you have any questions, contact the Healthcare Quality Standards team

at CompoundingSL@usp.org

Copyright © 1999 -2016 Clinical IQ, LLC® - All Rights Reserved

Revisions to USP <797> Pharmaceutical

Compounding – Sterile Preparations

Tony Cundell

Consulting Microbiologist,

Scarsdale, NY

Copyright

© 2008-2014

CriticalPoint, LLC®

- All Rights

Reserved

Copyright

© 2008-2016

Tony

Cundell

- All Rights

Reserved

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Disclaimer

The opinions expressed in this presentation are

solely my own and are not representative of the

USP Microbiology Expert Committee, of which I

am a member, or my consulting clients.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Revisions to USP <797>

• Members of the USP Microbiology and Sterile Compounding Expert Committees in

collaboration with the FDA, after numerous meetings, have published the long-awaited

revisions to USP <797> Pharmaceutical Compounding – Sterile Preparations online at the

USP website September 25, 2015 with a 90-day comment period ending January 31, 2016.

• Eric Kastango and I strongly recommend, as stakeholders, you review and comment on the

revision.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Scope of the Chapter

• This chapter describes the minimum practices and quality standards to be followed when

preparing compounded sterile human and animal drugs CSPs.

• These practices and standards must be used to prevent harm, including death, to human

and animal patients that could result from:

1.

microbial contamination (non-sterility)

2.

excessive bacterial endotoxins

3.

variability from the intended strength of correct ingredients

4.

chemical and physical contaminants, and/or

5.

use of ingredients of inappropriate quality.

• Note: 503b outsourcing sterile compounding facilities will be expected to comply with FDA

cGMP regulations.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

USP <797> Revision

As a microbiologist I will discuss the following sections of the proposed revision:

• Competency Testing in Garbing and Hand Hygiene

• Environmental Monitoring

• Sterilization and Depyrogenation

• Release Testing

• Establishing Beyond-use Dating and In-use Times

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Presentation Structure

I will structure my commentary as follows:

• Summary of the requirements in the 2015 USP <797> revision

• Comparison to the 2008 USP <797> chapter

• Expert analysis of the intent and limitations of the USP <797> revisions

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Microbial Risk Analysis

Firstly, what are the major risks for CSP microbial and endotoxin contamination?

Personnel and Compounding Environment:

• Gloved Hands > Surfaces (Working) > Airborne > Surfaces (Non-working)

Compounding Operation:

• Non-sterile-to-sterile >> Sterile -to-sterile compounding

• Ingredient water > Compounding ingredients > Packaging materials

Sterilization Processes

• Sterile Filtration > Dry heat sterilization > Steam sterilization

• Aseptic compounding >> Terminal sterilization

• Multiple manipulations >> Single manipulations

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

39

Microbial Risk Analysis (continued)

What are the major risks for CSP microbial and endotoxin contamination?

Storage Temperature:

• Room temperature > Refrigeration >> Frozen

Storage Time:

• Short time > Longer time

Administration route:

• Intrathecal > Intravenal > Intramuscular

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

40

Hospital Usage of CSPs

Based on a 2012 FDA survey of acute-care hospitals that participated in Medicare the

following was found:

• 92% of the hospitals used CSPs

• Of those hospitals, 92% used sterile-to-sterile products and only 25% used higher risk nonsterile-to-sterile products.

• Non-sterile-to-sterile products composed less than 1% of the CSPs used.

• Of the hospital that used non-sterile-to-sterile CSPs, 85% outsourced at least some of

these products

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

41

Personnel Qualification

Revised USP <797>:

• Compounding personnel must gown and don gloves and have zero CFU on finger/thumb

sampling of both hands in an ISO 5 area, no fewer than three consecutive times, before

being allowed to compound.

• During quarterly sampling no more a total of 3 CFU from both gloved hands would be

acceptable.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

42

Fingertip Monitoring

• Gloved hand fingertip monitoring with a contact plate containing TSA plus lecithin and

Tween 20

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

43

Comparison of Personnel Testing Requirements

Personnel Qualification

Current

Proposed

Visual observation of

hand hygiene and

garbing

Finger-tip monitoring

Prior to compounding

and during media fill

testing

Quarterly

(category 1 & 2 CSPs)

Media Fill Testing

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Annually (low and

medium risk level)

Semi-annually

(high risk level)

Quarterly

(category 1 & 2 CSPs)

Personnel Qualification Analysis

Analysis of the proposed changes:

• The current chapter is more nuanced with the minimum requirements more closely

matching the risk level.

• As microbial contamination of the gloved fingertips is the greatest risk to CSP safety, glove

monitoring should be incorporated into environmental monitoring conducted monthly and

the technician removed from the compounding area, released CSPs evaluated, requalified, prior to returning to their duties, if they fail.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

45

Personnel Qualification: Analysis (continued)

Analysis of the proposed changes:

• Personnel qualification should be reduced to annually for sterile-to-sterile compounding

and semi-annually for non-sterile-to-sterile compounding.

• More emphasis should be given to the definition, observation and qualification of aseptic

technique in the USP <797> revision.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

46

Airborne Non-viable Particulate Monitoring

Revised USP <797>:

• For ISO 5 areas, the action level is ≥ 3,520

particles per m3 (1000 L) under typical

operating conditions (Semi-annually)

• Compounding will cease if the

requirements are not met.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

47

Airborne Non-viable Particulate Monitoring: Analysis

Analysis of proposed changes:

• What does typical operating conditions mean in practice?

• Does particulate monitoring distort the air flow patterns in a laminar

flow hood?

• Does semi-annual facility certification meet this requirement or not?

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

48

Viable Airborne Particle Monitoring

Revised USP <797>:

• For ISO 5 areas, the action level is ≥ 1 cfu/m3 (1000 L) during compounding operations

(monthly)

• If the action level is exceeded, investigate and take corrective action

• Trend below action levels for ISO 7 and 8 areas

• Identify action level isolates to species or at least genus and give greater emphasis to the

presence of pathogens in compounding areas

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

49

Active Viable Particulate Air Samplers

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

50

Viable Airborne Particle Monitoring

Action Levels for Viable Air Sampling

Air Cleanliness

Classification

Current

cfu/m3

Proposed

cfu/m3

ISO Class 5

>1

≥1

ISO Class 7

> 10

≥ 10

ISO Class 8

> 100

≥ 100

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

51

Viable Airborne Particle Monitoring: Analysis

Analysis of the proposed changes:

• Frequency from semi-annually to monthly which will allow for trending.

• Lower level of response, i.e. investigate and corrective actions, compared to non-viable

airborne particle monitoring.

• The action level in the revised USP <797> would be any isolation of microorganisms in the

ISO 5 area.

• Response related to pathogenicity of the isolated microorganisms.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

52

Viable Surface Monitoring

Revised USP <797>:

• For ISO 5 areas work surfaces, action level > 3 CFU/plate or 25 cm2 (monthly)

• Exceeding action levels requires an investigation and corrective actions but not ceasing

compounding.

• Reduce CSP beyond-use dating from Category 1 to 2

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

53

Viable Surface Monitoring

Action Levels for Viable Surface Sampling

Air Cleanliness

Classification

ISO Class 5

ISO Class 7

ISO Class 8

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Current

cfu/m3

Proposed

cfu/m3

>3

> 3 working

N/A non-working

>5

> 100

> 5 working

> 10 non-working

> 25 working

> 50 non-working

54

Viable Surface Monitoring: Analysis

Analysis of the proposed changes:

• Is the distinction between working and non-working surfaces useful?

• Given the analytical capability of the microbial method is there a real difference between 3

and 4 CFU/cm2 , i.e., a passing or failing result?

• Should compounding cease if the ISO 5 working surface action level is exceeded?

• Is the more stringent ISO class 8 action levels, i.e., 25 versus 100 CFU, justified?

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

55

Sterilization and Depyrogenation

• USP <797> references USP

<1229.4> Sterilizing Filtration

of Liquids, USP <1229.1> Steam

Sterilization by Direct Contact,

USP <1229.8> Dry Heat

Sterilization.

• Biological indicators are

included in routine steam and

dry heat sterilization cycles.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

56

Release Sterility Testing

Revised USP <797>:

• With aseptically prepared CSPs from non-sterile starting materials, the beyond-use dating

is extended from 4 to 28 days, if a USP <71> sterility test is performed.

• With aseptically prepared CSPs from only sterile starting materials, the beyond-use dating

is extended from 6 to 28 days, if a sterility test is performed.

• Storing the CSP at refrigerated temperature adds an extra 3 and 14 days to the beyond-use

dating respectively.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

57

Release Sterility Test: Analysis

Analysis of the proposed chapter <797>:

• The proposed revision to USP <797> should allow the use of

alternative methods to the USP <71> sterility test to reduce the

time to complete the test from 14 days to 7 day or within one

working shift using more rapid sterility testing methods.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

58

Release Endotoxin Testing

Revised <797> chapter:

• All category 2 CSPs made from one or more non-sterile ingredients, except those for

inhalation and topical ophthalmic, must be tested for bacterial endotoxin.

• Exceptions are when the certificates of analysis list the endotoxin level or the

compounding facility has a history of ingredient testing.

• In the absence of endotoxin limits in official USP monographs, the CSP must exceed the

limits calculated as described in USP <85>.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

59

Bacterial Endotoxin Requirements

Current

All high-risk CSPs, except for those

for inhalation and ophthalmic

administration, prepared in groups

of more than 25 SDPs or in MDVs or

that are exposed longer than 12

hours at 2 to 8˚ C or longer than 6

hours at room temperature before

they are sterilized shall be tested.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Proposed

All Cat 2 made from 1 or more non

sterile ingredients EXCEPT those for

inhalation or topical administration

must be tested.

Exception are if the non-sterile

ingredients have a COA listing

endotoxin bioburden or the

compounder has a testing history.

60

Release Endotoxin Testing: Analysis

Analysis of the proposed changes:

• A distinction is made between topical and intraocular ophthalmic administration in the

revised chapter.

• The testing is still directed towards high-risk CSPs

• The stated policy of the USP is to remove proscribed endotoxin limits for USP monographs.

• The clinician must communicate the patient dosage to the compounding pharmacy so they

can calculate the endotoxin limit.

• The small batch sizes, i.e. <25 SUVs are not exempt.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Comparison of Beyond-Use Dating

Proposed

Category

1

12 hours

Storage

Conditions

Current

Risk Levels

Room

48 hours (low)

30 hours (medium)

24 hours (high)

24 hours

Refrigerated

14 days (low)

9 days (medium)

3 days (high)

7 days (non-sterile to sterile)

9 days (sterile to sterile)

42 days (sterility tested)

Frozen

45 days

All risk levels

N/A

45 days

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Proposed

Category 2

4 days (non-sterile to sterile)

6 days (sterile to sterile)

28 days (sterility tested)

Beyond-use Dating: Analysis

Analysis of proposed changes:

• The preparation of Category 1 CSPs is actively discouraged by the short beyond-use dating,

i.e. 24 hours for RT storage.

• Release sterility testing gains an extra 8 and 21 days for room temperature and

refrigerated CSPs respectively.

• The beyond-use dating of sterile-to-sterile CSPs is extended from 48 hours to 6 days

(without sterility testing) and 28 days (with sterility testing) in the proposed USP <797>

revision.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

Beyond-Use Dating: Analysis (continued)

Analysis of proposed changes

• Preservatives are not typically included in IV drug products due to toxicity issues. However,

they may be included in pharmaceutical manufactured multiple-use products used as

starting materials in sterile compounding.

• Frozen storage is not commonly used in acute-cure facilities.

• Terminal sterilization is not a common practice in sterile compounding due to a lack of

steam sterilization capabilities. BUDs for terminally sterilized CSPs is limited to 45 days

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

64

In-Use Times

Revised USP <797>:

• USP <797> defines this new concept, the in-use time as the time before a manufactured

sterile product or CSP must be used after it is opened or needle-punctured.

• The in-use time assigned cannot exceed the expiration dating of the manufactured product

or BUD of the CSP.

• The regulators believe that the in-use time will depend on the type of product or CSP and

the environment where the manipulations occur, i.e. ISO 5 or worse.

• For manufactured products, the in-use times assigned for ampules, single-use container

and multi-dose containers manipulated in ISO 5 areas are use immediately, 6 hours and 28

days respectively.

• For CSPs, the in-use times assigned for compounded single-dose containers, compounded

stock solutions and compounded multi-dose containers that pass the Antimicrobial

Effectiveness Test manipulated in ISO 5 areas are 6 hours, 6 hours, and 28 days.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

65

In-Use Times: Analysis

Analysis of the proposed changes:

• The question must be asked where these in-use times came from and are they

scientifically justified?

• In-use time recommendations based on microbiological and physicochemical stability are

found in the package inserts of manufactured products. This labeling material is approved

by the FDA for each manufactured drug product using stability data submitted by the

manufacturer. They are not found in any GMP regulation or guidance document.

• It is presumed that the 28 days is derived by the longest time interval in the USP <51>

chapter.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

66

In-Use Times: Analysis (continued)

Analysis of the proposed changes:

• It is assumed that the administration time,

e.g. hang time for a IV bag, is not included

in the in-use time.

• Guidance for administration time would be

obtained from CDC recommendations and

ASHP guidelines

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

67

Conclusions

• Overall the changes to chapter <797> can be supported.

• There are opportunities for improvements especially if there is detailed and constructive

comments from stakeholders.

• Thanks for your attention. We will take questions as time permits.

Copyright © 2008-2016 Tony Cundell - All Rights Reserved

68