uc engineer - Mechanical and Materials Engineering

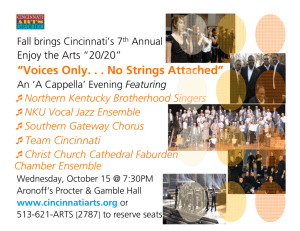

advertisement

UC ENGINEER M ,I N E echanical ndustrial and uclear ngineering 2005/2006 Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 UC ENGINEER is published by University of Cincinnati College of Engineering Department of Mechanical, Industrial and Nuclear Engineering 598 Rhodes Hall P.O. Box 210072 Cincinnati, Ohio 45221-0072 Telephone: 513.556.2738 Visit our Web site: www.min.uc.edu UC ENGINEER M ,I N E echanical ndustrial and uclear ngineering 2005/2006 Department Head’s Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Department News ABET Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Professor Frank Gerner moves to Associate Dean . . . . . . . . . . . . . MINE Creates Design Clinic Endowment . . . . . . . . . . . . . . . . . . . . . Industrial Advisory Board Established . . . . . . . . . . . . . . . . . . . . . . Faculty News 3 3 5 5 Faculty Research and Awards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Ohio Eminent Scholar Dr. Jay Lee . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Professor Emeritus Brown Wins SEM Award . . . . . . . . . . . . . . . . . 8 An Evening with Dr. Brown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Phillip C. Quo & Family Scholarship Fund . . . . . . . . . . . . . . . . . . 10 Professor Ronald Huston Retires . . . . . . . . . . . . . . . . . . . . . . . . . 10 Dr. Son Joins MINE Department . . . . . . . . . . . . . . . . . . . . . . . . . 10 Changes at UC-SDRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Research News Research Thrust Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Occupational Safety & Health Engineering Research Center . . . . Nanoengineering: Interdisciplinary Research . . . . . . . . . . . . . . . . . Cincinnati Radiation Society Hosts 50th Conference . . . . . . . . . IMS: Seeing Failure Before It Occurs . . . . . . . . . . . . . . . . . . . . . . 11 11 12 13 14 Robotics Team Responds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ASME Student Design Competition . . . . . . . . . . . . . . . . . . . . . . . . UC Forms Co-op Honor Society . . . . . . . . . . . . . . . . . . . . . . . . . . Bearcat Motorsport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 15 16 16 Student News Help Needed from Mechanical Engineers . . . MINE at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . How to Support MINE . . . . . . . . . . . . . . . . . . . . . . . inside back cover inside back cover inside back cover Department Head’s Messsage This has been a year of both change and growth in the Department of Mechanical, Industrial and Nuclear Engineering (MINE). We have been busy realigning our goals and plans to be consistent with UC|21; a new vision of the University of Cincinnati as the next premier urban research institution. Last summer Dr. Roy Eckart, who had served as MINE Head in the early nineties, was appointed to serve as the Interim Dean of the College of Engineering. Soon after that, Dr. Frank Gerner, who was the previous MINE Head prior to my current term, took over the position of Associate Dean for Undergraduate and Administrative Affairs left vacant by Dean Eckart. It was a great honor and a privilege for me to assume the Department Head position at the start of this year. Thus far, my experience has been extremely positive, despite the challenges ahead; fortunately with challenges come new opportunities. Professor Teik C. Lim Both undergraduate and graduate enrollment remains very strong, and the demand for our programs has never been higher. In fact, we are now the largest Department, by enrollment count, in the College of Engineering. Needless to say, we are extremely pleased with the quantity and quality of our applicants. Even though student interest in our programs remains high, we are persistent in our search for ways to continue to improve our curriculum and provide an exemplary education for our students. Our faculty and staff continue to come up with new and innovative teaching methods and materials. We have also been working in conjunction with our Industrial Advisory Board to re-define a new Design curriculum that will better prepare our students for the engineering demands of the 21st century. In order to keep up with the steady increase in enrollment, the Department has hired, and will be hiring more, new faculty. Just last spring, we recruited Dr. Jay Lee to be the new Ohio Eminent Scholar and L.W. Alter Chair Professor in Advanced Manufacturing. Dr. Lee is responsible for the recent establishment of the NSF Industry/University Cooperative Research Center on Intelligent Maintenance Systems (IMS) in our Department. At the same time, Drs. Adrian Miron (Nuclear Engineering) and Hai Qiu (Intelligent Maintenance Systems) both joined us as Research Assistant Professors. They were most recently followed by Dr. Sang Young Son (Thermal-Fluids Science), who just came on board as an Assistant Professor. For those who have followed news publications issued by the Department in the past, you will notice that we have adopted a new and improved look in this issue. This new look is intended to better highlight our recent progress, and display our continued growth and renewed focus. We have no doubt that you will find this new style interesting and informative. As you read through the pages, whether the article is about faculty updates or research news, ranging from intelligent systems to nanoengineering, please let us know what you think. We are always glad to hear from you. The Department, College and University are indeed undergoing change and thus the opportunities for improvement are plentiful. The MINE Department is fundamentally very strong, possessing a solid student base, first rate faculty and staff, and very rigorous programs. Therefore we are in an excellent position to make a significant leap forward. We are committed to excellence and will do everything in our power to ensure that both our academic, and research based endeavors continue to thrive. We are proud of, and grateful for, the state of our Department, and we hope all of you feel the same. Happy reading! Teik C. Lim, Ph.D., P.E., Professor and Department Head Teik.Lim@uc.edu 513.556.4450 (phone) 513.556.3390 (fax) www.min.uc.edu (department Web site) 2005/2006 UC ENGINEER University of Cincinnati College of Engineering DEPARTMENT NEWS ABET Review In October of 2004 all programs in the College of Engineering were reviewed by the Accreditation Board for Engineering and Technology (ABET). This is the first time that the College has been reviewed using the new ABET 2000 criterion. ABET 2000 is a process where programs set goals for their graduates and then, by using surveys, attempt to determine if the graduates are meeting those goals. The process starts by writing a mission statement. The mission statement for the Mechanical Engineering Programs is: The mission of the Mechanical Engineering Program of the University of Cincinnati is to educate students in the fundamentals of engineering and help them develop their full potential as competent engineers, leaders and responsible citizens of a global society. Primary goals are the enhancement of the ability of graduates to apply knowledge to engineering situations, to function competently in multidisciplinary situations, to communicate effectively and to understand professional and ethical responsibility. This mission must be consistent with the mission of the University of Cincinnati: The University of Cincinnati is a public comprehensive system of learning and research. The excellent faculty have distinguished themselves world wide for their creative pedagogy and research, especially in problem solving and the application of their discoveries. The University system is designed to serve a diverse student body with a broad range of interests and goals. It is a place of opportunity. In support of this mission, the University of Cincinnati strives to provide the highest quality learning environment, world-renowned scholarship, innova- tion and community service, and to serve as a place where freedom of intellectual interchange flourishes. Additionally, it must be consistent with the mission of the College of Engineering. The College of Engineering’s Mission is to: • Provide education, discover new applied knowledge, serve the stakeholders • Provide students with the fundamental knowledge, intellectual skills, and practical experience to become leaders in engineering • Perform significant research • Provide practicing engineers with upto-date graduate study • Provide technical services Using the mission statement as a starting point, the department next defines its educational objectives. These objectives are a statement of what we would like for our alumni 5 to 10 years after they have received their degree. The Mechanical Engineering educational objectives are: • Our students will be prepared for successful careers, for graduate studies and for lifelong learning. • Our students will have an understanding of the fundamental tools of mechanical engineering analysis, including a solid foundation in the mathematical, computational and fundamental science knowledge necessary for engineering problem solving. • Our students will develop the skills pertinent to the design process, including the ability to formulate problems, to analyze and synthesize information, to think creatively, to make informed decisions, to communicate effectively, and to work in multidiscicontinued on page 4 Professor Frank Gerner Accepts Associate Dean Position As many of you know, in Autumn quarter 2004, I accepted the position of Associate Dean for Undergraduate and Administrative Affairs for the College of Engineering. During Autumn quarter I served as both Associate Dean and Department Head for MINE. I was both relieved and extremely pleased when Dr. Teik Lim became Department Head at the beginning of Winter quarter 2005. When we hired Teik three years ago from the University of Alabama, I was aware that he was an outstanding researcher and teacher. Working with him for the past three years, I have learned that he is punctual, unself- Professor Frank Gerner ish, hardworking and a team player. All qualities that will make him an exceptional Department Head for MINE. We are very lucky to have him as Department Head. As I step down as Department Head, I wish to thank the students, staff and faculty of MINE for all of their support. As those of you with administrative experience realize, a department head is unable to implement any significant changes on his own. The only thing that one can do is assist and support the faculty and staff as they serve our students. We have made significant progress during the past four years. Our most important accomplishments include the hiring of nine truly outstanding faculty members, including an Eminent Scholar and our new Department Head. The faculty has greatly expanded our research base and our course offerings. With the help of the College and central administration, we greatly improved our instructional and research space and improved our laboratories. As some of you are aware, hiring and retaining faculty is becoming increasingly competitive. Fortunately, we were able to obtain equity adjustments for our exceptional faculty and raises for some of our outstanding staff. While it was not without pain, the suspension of admissions to our Industrial Engineering B.S. program will allow us to concentrate our limited resources and build centers of excellence. In summary, MINE has an exceptional faculty and staff. Our students are second to none. Under Dr. Lim’s leadership, I am confident that our research and educational program’s will become even more excellent. While I am now in College Administration, I will always be proud of the fact that I am a faculty member in Mechanical, Industrial and Nuclear Engineering. Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 DEPARTMENT NEWS ABET Review Continued from page 5 plinary teams. • Our students will learn to use stateof-the-art experimental and data analysis techniques necessary for engineering applications. • Our students will understand the relationship of engineering and the global society and will have an understanding of their professional and ethical responsibilities. Using the educational objectives as a guide, the department must then establish its program outcomes. The program outcomes define the attributes that our graduating seniors must posses if they are to meet our educational objectives. These outcomes start with the ABET a-k objectives and are supplemented with our own additional objectives. Specifically, graduates of the Bachelor of Science in Mechanical Engineering k.an ability to use the techniques, skills, and modern engineering tools necesprogram must have: sary for engineering practice. a.an ability to apply knowledge of l. knowledge of chemistry and calculus mathematics, science and engineerbased physics with depth in a least ing one, b.an ability to design and conduct ex- m.ability to apply advanced mathematperiments, as well as to analyze and ics through multivariate calculus and interpret data differential equations, c.an ability to design a system, com- n.familiarity with statistics and linear ponent, or process to meet desired algebra, needs o.the ability to work professionally in d.an ability to function on multi-disciboth thermal and mechanical systems plinary teams including the design and realization e.an ability to identify, formulate, and of such systems. solve engineering problems f.an understanding of professional and Accreditation ethical responsibility ABET sends a team of evaluators for g.an ability to communicate effectively a site visit. The evaluators review the h.the broad education necessary to College and Department self-study and understand the impact of engineer- course material. They talk to faculty, stuing solutions in a global and societal dents and staff. At the end of their visit context they provide with a preliminary report i.a recognition of the need for, and an of their findings. ability to engage in lifelong learning j.a knowledge of contemporary issues Results The ABET visit for Mechanical Engineering went very well. The ME ABET Team (Dave Brown, Bob Rost, Teik Lim) assembled all of the necessary documentation for the review. The review team identified 4 program strengths. Summarized, they are: 1.The strength of the co-op program 2.The quality of the students 3.The quality of the faculty 4.The improvements in the facilities The review team also identified one area that they thought we could be doing better. The evaluators would like to see us have more information from graduates, both recent (0 – 5 years after graduation) as well as long term graduates. They would also like us to collect more data from employers. How you can help The department needs the help of our alumni to maintain an up-to-date curriculum and to assure that we continue to graduate high quality undergraduate and graduate students. Our alumni can help in several ways. 1. Help us keep our Alumni Database up-to-date. You can update your data on our Web site survey (see below). 2. Take a few minutes to answer the questions about our educational objectives. The survey is on-line at http://mie4.uc.edu/abetsurvey/. 2005/2006 UC ENGINEER University of Cincinnati College of Engineering MINE to Create Engineering Design Clinic Endowment The MINE Department announces the creation of a special endowment fund to raise at least $2.0 million to generate income to support the project-based educational activities of the Design Clinic and to maintain the learning facility. The Design Clinic offers a multi-disciplinary capstone design course sequence for engineering students in the Mechanical, Materials, Chemical, Computer and Electrical undergraduate degree programs. The present Director of the Design Clinic is Professor Bob Rost. In creating the Design Clinic Endowment, the Department seeks to establish long-term partnerships with external stakeholders, including employers, foundations, alumni, and interested individuals and groups through the formation of an Advisory Council to help enhance the learning experience of engineering students. The Advisory Council will advise the Department on educational matters related to the Design Clinic, offer design project ideas, and collaborate with the engineering students enrolled in the Design Clinic. Fundraising will target companies currently supporting the Design Clinic projects as well as other engineering companies in Cincinnati and the Midwest, corporate foundations, alumni, and individuals and groups with interest in the Design Clinic. Major donors contributing majority of the endowment will earn the naming rights to the Design Clinic. Other significant donors to the endowment will also earn a membership in the Advisory Council. All contributors will be recognized on the commemorative donor plaque that will be prominently displayed outside the Design Clinic learning facility. If you are interested in learning more about the Design Clinic, please contact Tom Curtis, director of industrial relations, at (513) 556-1169 or curtistc@ucmail.uc.edu . Industrial Advisory Board Established in Mechanical, Industrial and Nuclear Engineering The Mechanical, Industrial and Nuclear Engineering Industrial Advisory Board (IAB) had their first meeting on April 2, 2004. The IAB that comprised of engineering leaders in the areas represented in MINE was established to advice and collaborate with the faculty to achieve excellence in its academic and research programs at both the undergraduate and graduate levels. Within the IAB, several subcommittees were also created to focus on Concurrent Product and Process Development, ABET, Recruiting and Scholarships, and Research. Al Klosterman, Co-Chair SDRC (retired) Multiple Board of Directors Jim Bossart Quebecor World Gary Conley TechSolve, Inc. (President) Bill Kramer General Tool Co. Bill Lower Rotex, Inc. Gary Armstrong Rotex, Inc. Bob Ryan, Co-Chair Consultant John Procario Cinergy Services Suna Polat Procter & Gamble Company Art Koehler Procter & Gamble Company Jeannie Rinckel FENOC Robert E. Schafrik GE Aircraft Engines Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 FACULTY NEWS Faculty Research and Awards Randall Allemang, Ph.D., Professor • Shock and Vibration Testing of Penetrator, General Dynamics • Improved Parameter Identification for Transient Excitation Data, Boeing • BP Faculty Excellence Award Rupak Banerjee, Ph.D., Associate Professor • Influence of Guide-Wire Catherer on Pulsatile Flow Rate-Pressure Drop Diagnostics in Significant Coronary Stenoses, American Heart Association • Calculations of Intra-Aortic Hemodynamic Forces on Endografts, Cleveland Clinic • Bio-Transport and Metabolism under Microgravity Supporting Human Physiologic Processes, NASA John Christenson, Ph.D., Professor • Building an Effective Educational Bridge between Tuskegee University and the University of Cincinnati Nuclear and Radiological Engineering Program, South Carolina State University • Collaborative Utility University Project, AEP & FENOC • Program Simulator Interfaced Light Water Reactor Instruction and Research, DOE Ashraf Genaidy, Ph.D., Associate Professor • An Occupational Epidemiology Study of Forklift Operators, NIOSH • Lab Safety Best Practices, Ohio University Frank Gerner, Ph.D., Professor and Associate Dean • Proof of Concept Micro Loop Pipe, NASA • Development of a Micro Loop Heat Pipe Using Novel Coherent Porous Silicon: A System for Thermal Management of Space Solar Power, NSF Urmila Ghia, Ph.D., Professor • Three-Dimensional, Three-Temperature Computational of Leading Edge Film Cooling with Pulsed Coolant Flow, DAGSI • BP Faculty Excellence Award • AIAA Fellow Sam Huang, Ph.D. Associate Professor • A Fully Integrated Corporate Experience Based Manufacturing Education Strategy, NSF • Integrated and Computerized Set-Up Planning and Fixture Design, NSF • A Scalable and Adaptive Tool for Rapid Process Mod- eling, OAI Whine, Ford • Adaptation of Health Monitoring Techniques for • Driveline NVH Modeling, Dana Evidence-based Patient Care, University Research • Development of an Acoustic Transfer Function Active Council Control System for Automotive Powertrain Noise, • 2005 Society of Manufacturing Engineers Robert A. Ford Dougherty Outstanding Young Manufacturing Engi- • Active Acoustic Noise Control of High-speed MRI neer Award Scanner, COM Dean’s Discovery Fund • SAE (Society of Automotive Engineers) Arch T. Colwell Milind Jog, Ph.D., Associate Professor Merit Award, 2005 • Sigma Xi, Outstanding Young Investigator Award • SAE (Society of Automotive Engineers) Excellence in Technical Paper Presentation Award, 2005 Michael Kazmierczak, Ph.D. Associate Professor Yijun Liu, Ph.D., Associate Professor • Measurement of the Heating of Cryocooled Samples • Fast Simulation of Complex MEMS Structures with from Synchroton X-Ray Beams Advanced Photon the Boundary Element, Finite Element and Fast MulSource, Argonne National Laboratory tipole Methods, NSF • Chunhui Fellowship of the Ministry of Education of Jay Kim, Ph.D., Associate Professor China • Measurement of Sound Power and Sound Pressure • JSPS (Japan Society for the Promotion of Science) SeLevels from Various Pieces of Electrically-Powered nior Researcher Fellowship Tools, NIOSH • Modification of Hearing Protector Fit Test Software, Ivan Maldonado, Ph.D., Associate Professor NIOSH • Boiling Water Reactor Assembly Optimization for • Hot-Rolled Steel Plate Analysis, POSTECH Minor Actinide Recycling, DOE • Measurement and Characterization of Noise from • Development of Assumptions and Criteria for the Power Tools, NIOSH High Flux Isotope Reactor, UT-Batelle Oak Ridge Na• Tau Beta Pi Eminent Engineer Award tional Laboratory • Collaborative Project for a Program Simulator InterJay Lee, Ph.D., Professor and Ohio Eminent faced Light Water Reactor Instruction and Research, Scholar DOE • NSF Industry-University Cooperative Research Center • Building an Effective Educational Bridge between on Intelligent Maintenance Systems, NSF & over 40 Tuskegee University and the University of Cincincompanies nati Nuclear and Radiological Engineering Program, • Informatics Platform for Prognostics and MainteSouth Carolina State University nance Optimization, NSF • Collaborative Utility University Project, AEP & • Predictive Infotronics Agent for Integrated Product FENOC. Life Cycle Support, NSF • Program Simulator Interfaced Light Water Reactor • Unified Prognostics Approach for Vehicle Electronics Instruction and Research using Physics-of-Failure Driven Sensor Fusion, NSF • Presidential US-Canada Joint Task Force on Northeast Power Outage Teik C. Lim, Ph.D., Professor and Department Head Adrian Miron, Ph.D., Research Assistant Pro• Development of Hypoid Gear Load Distribution Professor gram, Gearlab Consortium • Argonne National Laboratory Pacesetter Award for • Rotorcraft Cabin Noise Quality Analysis, Sikorsky excellence in achievement and performance • Hypoid Gear Tooth Wear, Visteon • Federal Emergency Management Agency (FEMA) • Hypoid Gear Mesh and Dynamics Consortium, Arvinevaluator for radiological emergency preparedness Meritor, Visteon, AAM, JohnDeere, Caterpillar & exercises Dana • Curriculum Development and Training for Envi• Modeling Tools and Methodology for Rear Axle Gear ronmental Restoration/Waste Management, DOE National Nuclear Security Administration (NNSA) 2005/2006 UC ENGINEER University of Cincinnati College of Engineering Ohio Eminent Scholar Dr. Jay Lee Woojin Park, Ph.D., Assistant Professor • Development of Memory-based Motion Simulation Program, University of Michigan Allyn Phillips, Ph.D., Research Associate Professor • HPE 143x Demonstration Software, ATA Engineering • AFP LM Drive Model, Boeing • Structural Analysis Software Enhancement, Boeing • HP-SDF to MatLab/API Reader Development, Los Alamos National Laboratory • Improved Parameter Identification for Transient Excitation Data, Boeing Dong Qian, Ph.D., Assistant Professor • Interplay Between Mechanical Deformation and Electronic Properties in Carbon Nanostructures, NSF • National Science Foundation Summer Institute Young Investigator Fellowship Robert Rost, Ph.D., Associate Professor • Robert E. Hundley Award for Excellence in Teaching Mark Schulz, Ph.D., Associate Professor • Material Characterization, Clean Technologies • Artificial Neural System for Wind Tunnel Blades, North Carolina A&T State University • Telescoping Nanotube Arrays, NSF • College of Engineering Neil Wandmacher Teaching Award for Young Faculty Richard Shell, Ph.D., Professor • Educational Resource Center Pilot Project Research Training Program, NIOSH Dr. Jay Lee is Ohio Eminent Scholar in Advanced Manufacturing and L.W. Scott Alter Chair Professor at the Univ. of Cincinnati. Previously, he held a position as Wisconsin Distinguished Professor and Rockwell Automation Professor at the Univ. of Wisconsin-Milwaukee and is founding director of National Science Foundation (NSF) Industry/University Cooperative Research Center (I/UCRC) on Intelligent Maintenance Systems (IMS). Prior to joining UW-Milwaukee, he served as R&D Director for Product Development and Manufacturing Department at United Technologies Research Center (UTRC), E. Hartford, CT, and was responsible for the strategic direction and R&D activities for next-generation products and manufacturing, and service technologies. During 1991-1998, he served as Program Director for a number of programs at NSF, including the Engineering Research Centers (ERCs) Program, the Industry/University Cooperative Research Centers (I/UCRCs) Program, and the Materials Processing and Manufacturing Program (MPM). In addition, he had served as an adjunct professor for a number of academic institutions, including Johns Hopkins University, where he was an adjunct faculty member for the School of Engineering and Applied Science as well as for the Hopkins Technical Management Program during 1992-1998. He conducted research work at the Mechanical Engineering Lab. of the Ministry of International Trades and Industry (MITI) as a Japan Science and Technology Agency (STA) Fellow in 1995, a Japan Society for Promotion of Science (JSPS) Fellow at the Univ. of Tokyo in 1997, and a visiting professor at Swiss Institute of Technology (EFFL), Lausanne, Switzerland in July 2004. Henry Spitz, Ph.D., Professor • Bioassay Standards for Fernald, Fluor Daniel Fernald Inc. • Direct and Indirect Bioassay Standards, Fluor Daniel Fernald Inc. • Developing a Readiness Program for Radiation Instruments Used in Emergency Radiological Response, NIOSH His current research focuses on IT-enabled smart products, self-maintenance machine, and E-manufacturing technologies including design of smart machine, remote monitoring, embedded prognostics and nearzero breakdown production systems. Recently, he has extended his research to smart healthcare/homecare systems and advanced gerontics engineering. Kumar Vemaganti, Ph.D., Assistant Professor • Mechanical Properties of Living Cells: Atomic Force Microscopy Studies, Modeling and Education, NSF • A Microstructural Approach to Modeling the Nonlinear Mechanics of Soft Tissue,Honda America R & D Currently, he serves as member of the Board on Manufacturing and Engineering Design (BMAED) of National Research Council (NRC)/National Academy of Engineering. Previously, he served as member of the Board of Directors for the National Center for Manufacturing Science (NCMS), the chairman of the Manufacturing Professor Jay Lee Engineering Div. And Materials Handling Engineering Div. of ASME, and committee member for a number of the National Research Council (NRC) study committees. He had served as editorial board and associated editor for a number of journals, including the ASME Journal on Manufacturing Science & Engineering, IEEE Transaction on Systems, Man, and Cybernetics, International Journal on Quality, Reliability, and Safety, etc. He has authored/co-authored over 100 technical publications, edited two books, contributed numerous book chapters, three U.S. patents, 2 trademarks, and had delivered numerous invited lectures and speeches, including over 60 invited keynote and plenary speeches at major international conferences. Dr. Lee received his B.S degree from Taiwan, a M.S. in Mechanical Engineering from the Univ. of WisconsinMadison, a M.S. in Industrial Management from the State Univ. of New York at Stony Brook, and D.Sc. in Mechanical Engineering from the George Washington University. He received the Milwaukee Mayor Technology Award in 2003 and was a recipient of SME Outstanding Young Manufacturing Engineering Award in 1992. He is also a Fellow of ASME and SME. Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 FACULTY NEWS Professor Emeritus Dave Brown Wins SEM Award The Society of Experimental Mechanics (SEM) again has chosen to recognize Professor Brown for his accomplishments during his research and academic career by honoring him with the M.M. Frocht Award. The award recognizes “outstanding achievement as an educator in the field of experimental mechanics.” This year’s presentation was made by SEM President Jose Freire at the Honors and Awards Luncheon held at the International Modal Analysis Conference (IMAC) in Orlando, Florida on February 2, 2005. The Frocht Award was also announced at the Honors and Awards Luncheon held at the SEM Annual Conference in Portland, Oregon on June 8, 2005. The following is a little background on the award. The M.M. Frocht Award was established in 1967 to honor Mr. Max Mark Frocht for his professional accom- Society of Experimental Mechanics President Jose Freire (right) presents Dr. Dave Brown with the Frocht Award. plishments by the Society of Experimental Mechanics. The award recognizes “outstanding achievement as an group of experimentalists, development engineers, educational institutions. More information about SEM educator in the field of experimental mechanics,” and is design engineers, test engineers and technicians, and and its awards can be found at the Society’s Web site research and development scientists from industry and (www.sem.org). presented annually to the “Educator of the Year.” Dr. Frocht’s work on photoelasticity research on stress concentration factors and 3-D techniques and his twovolume treatise on photoelasticity is considered a classic and has been translated into Russian, Spanish, and Chinese. Dr. Frocht was a student of Steven Timoshenko and many of his own students have made important contributions to the field of experimental mechanics. He presented papers and lectures on photoelasticity and experimental stress analysis in all parts of the world. Dr. Brown has previously been recognized by the Society of Experimental Mechanics. Dr. Brown was honored with the B.J. Lazan Award in 1987 for “outstanding original technical contributions to experimental mechanics” and by the D.J. DeMichele Award for “exemplary service and support of promoting the science and educational aspects of modal analysis technology” in 1992. The Society for Experimental Mechanics, originally called The Society for Experimental Stress Analysis, was founded in 1943 as a nonprofit scientific and educational organization with the original goal to “further the knowledge of stress and strain analysis and related technologies.” In the years since its founding, SEM has continued to adapt itself to the needs of the members in the experimental mechanics community. The members of SEM encompass a unique An Evening with Dr. Brown Even though Professor David Brown retired as of September 1, 2004, the UC Structural Dynamics Research Lab (UC-SDRL) and the Department waited until June 18, 2005 to have an official retirement party. Professor Brown was still very active over the last year, teaching System Dynamics Analysis again and working as one of the two ABET Coordinators for the Department, together with Professor Rost, to organize the ABET accreditation visit that took place in October 2004. Therefore, there was no real hurry in having an appropriate party as this sort of event requires much planning. Also, this gave the UC-SDRL an opportunity to get the word out at IMAC 2005 in February so that a maximum number of friends and former students would get a chance to hear about the event and hopefully plan to attend. undergraduate engineering class, friends from Belgium as well as former students from all over the country. With some of Dave’s favorite songs playing in the background, pictures of Dave with friends, family and former students were projected on a large screen to remind everyone about various events during Dave’s career at UC. This early part of the evening was filled with stories and fellowship and this was before the official program for the evening began. The main event was an electronic presentation of the highlights of Professor Brown’s career with the required elaboration concerning the number of publications, keynote speeches and awards that Dave has complied over the forty years of teaching and research at UC. As the event invitation promised, this was truly a celebration of his teaching and research career. The presentation took The event was billed as “An Evening with Dr. Brown” somewhat of a turn toward a roast as the need for “telland was held on campus at the Russell C. Myers Alum- ing the rest of the story” became the focus of the next ni Center. A number of attendees were curious about two hours. appropriate attire for the evening, knowing Dave’s disdain for the suit and tie. Naturally, we encouraged Professor Allemang emceed the presentation with able everyone to arrive in Hawaiian shirts or fishing attire assists from Mike Lally from The Modal Shop, Bill Fladung in Dave’s honor. Around 90 friends and former students from Los Alamos National Labs and Professor Emeriwere able to attend, including several friends from his tus William Shapton from Michigan Tech. The program 2005/2006 UC ENGINEER University of Cincinnati College of Engineering included stories about the deer botfly, the green flash, drugs in Wyoming and the first use of electronic presentations. A number of Dave Brown-isms were presented along with definitions based upon Professor Brown’s unique ability to mispronounce certain words but have everyone know exactly what he means. At the end of the program, a number of parting gifts were lavished on Dr. Brown. The required rocking chair as well as another electronic gadget for Dave to play with came from the UC-SDRL. A “Modal Man” statue, made from sensors from PCB Piezotronics, Inc., was a gift presented by Jim Lally, CEO of PCB in recognition of Dave’s work with PCB on sensor development over the last thirty years. Mike Lally from The Modal Shop presented Dave with a plaque that included a gold plated impact hammer in recognition of Dr. Brown’s development of the impact testing method of FRF testing. Numerous gifts from former students included several cases of applesauce (Dave frequently, when paying for lunch with several students, would indicate that their obligation in return for lunch involved feeding him applesauce when he was in the rest home.) The evening’s program concluded with the reading of well wishes and anecdotes from a large number of friends and former students who sent their regards via cards, letters or e-mail. Dr. Brown was given a chance to get in the last word but kept his remarks short, agreeing that most of what had been said was substantively true. While an attempt to reach all of those who wanted to attend was made via over 300 direct e-mails and word of mouth, we know that a number of you who would have wanted to attend were probably not contacted. For that, we apologize. For those of you who did not hear about the event or for those of you who could not attend, we have developed a Web page with pictures and a copy of the electronic presentation on the UC-SDRL Web site (WWW.SDRL.UC.EDU). If you would like to extend your well wishes to Dr. Brown, he can still be reached here at the Department or via his e-mail (David.L.Brown@ UC.EDU). Clockwise from top: Rocking Chair Gift from UC-SDRL, Dave Brown Portrait from Early in his Career, Golden Hammer Gift from The Modal Shop, Modal Man Gift from PCB Piezotronics, Inc. Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 FACULTY NEWS Phillip C. Quo and Family Scholarship Fund Professor Phillip Quo has recently established a scholarship fund in the Mechanical, Industrial and Nuclear Engineering Department. Professor Quo joined the University of Cincinnati in 1968 as an Adjunct Professor and as a Professor in Mechanical Engineering in 1985. He came from A. M. Kinney where he was a Vice President for 13 years. Professor Quo’s area of expertise was in CAD/CAM . He was invited to make a presentation at the International Conference on CAD/CAM and Factories of the Future from the Academy of Sciences of Russia in St. Petersburg, Russia in 1993. Later in the year, Prof. Quo was elected to the National ASME Distinguished Lecturer on Manufacturing Technology and was the keynote speaker during engineer’s week at the University of Kentucky in Lexington and the University of Nevada in Reno. Prof. Quo’s honors and awards are too numerous to mention, however his contribution to his field, and to the University of Cincinnati have been outstanding. Upon retiring in 2001, Prof. Quo donated 112 books to the engineering library. With this act of kindness, he made certain that he could better enhance the understanding and knowledge of future students that have and will attend the engineering program at the University of Cincinnati. His generosity continues to benefit the University of Cincinnati, and especially the Mechanical, Industrial and Nuclear Engineering Department with his most recent endowed scholarship fund which will serve as a perpetual gift to the department. Prof. Quo now lives in Palo Alto, California with his wife and family. He has maintained his residence in Cincinnati as well to keep in touch with his many friends and colleagues. Professor Ronald Huston Retires Professor Ronald Huston is retiring after 43 years of dedicated service to the University of Cincinnati. Dr. Huston is Professor of Mechanics in the Department of Mechanical, Industrial and Nuclear Engineering at the University of Cincinnati. In addition, he received the title of Distinguished Research Professor at the university level for his outstanding work in the research area. He is also Director of the University’s Institute for Applied Interdisciplinary Research. He received a B.S. degree in Mechanical Engineering from the University of Pennsylvania in 1959. He received an M.S. in Civil Engineering in 1961 and a Ph.D. in Engineering Mechanics in 1962, also from the University of Pennsylvania. He has been a Licensed Professional Engineer in Ohio since 1966. Dr. Huston joined the University of Cincinnati in 1962, and has been teaching, conducting research and performing outstanding service ever since. In 1977-78, he was a Visiting Professor at Stanford University, and in 1979-80 he served as Division Director for the Division of Civil and Mechanical Engineering at the National Science Foundation. In 1985 he served as a Visiting Professor at service universities in China. Dr. Sang Young Son joins MINE Department Dr. Sang Young Son, Assistant Professor of Mechanical Engineering, comes from NASA Glen Research Center in Cleveland Ohio where he was a Staff Scientist before coming to UC. He was responsible for Interfacial Transport and Capillary Flow Laboratory. Dr. Son received his Ph.D. and M.S. from Texas A&M University in Mechanical Engineering and his B.S. from Sogang University, Seoul, Korea in Chemical Engineering. His primary research interests cover a broad range of topics of thermal and fluid science ranging from microscopic multi-phase to single-phase thermal and fluid flow. 10 2005/2006 UC ENGINEER University of Cincinnati College of Engineering Professor Ronald Huston Dr. Huston is the author of over 200 technical papers and journal articles. He is an author of three textbooks and editor of four other volumes. He has been an active member of numerous technical societies and service organizations, locally, statewide and nationally, including ASME, SAE, AAUP, Human Factors and Ergonomics Society, the Ohio Academy of Science and the Chancellors Advisory Committee to the Board of Regents. His technical interests are in multibody dynamics, robotics, human factors, and accident reconstruction. Dr. Huston’s contributions to engineering research have produced unique advances in fundamental aspects of engineering, in theoretical and applied mathematics, and in engineering mechanics and analysis. His engineering practice has been directed toward practical, innovative applications of his analytical and computational discovery in almost every arena: space, oceans, transportation, manufacturing, and biomedicine. He is best known for his work in classical mechanics. More than 20 years ago, he developed methodologies that simplified the dynamic analysis of chained and connected bodies ­now known as “multibody dynamics.” Dr. Huston’s method simultaneously employed lower body arrays, differentiation algorithms, partial velocity vectors, and Kane’s equations. This led to a remarkably efficient and auto­mated analysis of multibody systems. When first conceived, the efficiency of the method enabled solutions of RESEARCH NEWS Research Thrust Areas dynamics problems that had previously exceeded the available computer power. Today, the techniques make possible the near real-time graphic simulation of such complex dynamical systems as the human spine, multi-arm robots, long towing cables, space station cranes, and full form human body models. Less well known is his work in such areas as gear manufacturing. For example, he has developed a theoretical basis for the manufacture of spiral bevel gears which recognizes the effects that load imparts to the mating surfaces of the gears in service conditions. He has developed the exact theoretical gear surface topologies for these service-deformed surfaces using tensor notation and differential geometry. This is an enabling technology whose implementation is changing the way that industry produces this gear form. As a result of all these endeavors, Dr. Huston has developed expertise in biomechanics, accident victim simulation, and accident reconstruction. He is a nationally recognized consultant in these areas. Although Dr. Huston has officially retired, we are very fortunate that he will continue to be involved at the department, college and university level as he has for 43 years. Changes at UC-SDRL The Directors of the UC-SDRL have decided to honor Professor Emeritus David Brown with the title of Director Emeritus of the UC-SDRL to reflect his newly retired status and his reduced role in the operation of the Lab. With this change, Professor Randy Allemang will now serve as Director of the UC-SDRL and Associate Professor Bob Rost will move into the position of Associate Director. Congratulations to all! In Spring 2005, the MINE faculty established six major research thrusts in the effort to increase research, foster collaboration, enhance graduate education and advance relevant state of the art engineering technologies. Each thrust areas are led by an appointed chair: • Structural Dynamics, Vibro-Acoustics and Controls (Chair: Prof. Randall Allemang) • Solid Mechanics and Nano/Bio Mechanics (Chair: Prof. Yijun Liu) • Thermal and Fluid Systems (Chair: Prof. Raj Manglik) • Intelligent Manufacturing and Design (Chair: Prof. Sam Anand) • Safety and Health Engineering (Chair: Prof. Richard Shell) • Nuclear and Radiological Engineering (Chair: Prof. John Christenson) For more information, please see www.min.uc.edu Occupational Safety and Health Engineering Research Center In collaboration with Ohio University, the University of Louisville and TechSolve®, the Safety & Health group within the Department at the University of Cincinnati is working to establish the Occupational Safety and Health Engineering (OSHE) Research Center. The OSHE Research Center will assist different technology groups in various markets such as manufacturing and distribution, healthcare, construction, and service industries for small, medium, and large organizations. The Center can handle both existing and new issues and concerns pertaining to safety and health engineering. MINE faculty involved in the Center includes Professors Shell, Genaidy, Park, and Hall. For more information please contact us at: OSHE@UC.Edu” Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 11 RESEARCH NEWS NANOENGINEERING: Interdisciplinary Research with Enormous Potential and Challenge Nanoengineering is a crosscutting field where engineers improve electromechanical systems by taking advantage of the properties of nanoscale materials. Working with nanoscale materials poses great challenges and can bring surprises. This article describes some of the research performed this past year in the Smart Materials and Nanobioengineering Laboratory in the MINE department at UC. In this lab students combine their mechanical, materials, electrical and chemistry skills to develop new and improved materials based on carbon nanotubes. Carbon nanotubes are nanometer diameter, micron long cylinders of carbon that have great electromechanical and electrochemical properties due to their small size, tremendous surface area, large aspect ratio, high strength, and electrical conductivity. The first application of nanotubes pursued in the lab was to reinforce polymers and to make them electrically conductive. Dispersing nanotubes and achieving a good bond with the polymer matrix proved to be a great challenge. Significant improvements in elastic properties and electrical conductivity were achieved, but the improvement was far below what theory predicts. The nanotube materials being developed, however, turned out to have extraordinary sensing and actuation properties. Different polymer materials laced with nanotubes were found to have piezoresistive properties. This means the electrical resistance of the composite changes with strain. A long continuous film sensor was formed using this material and was shown to be a good sensor for structural health monitoring. Figure 2. Concept medical device application overlaid on a mm long carbon nanotube array. The response of this sensor on a composite beam is shown in Figure 1(A). While testing, this sensor was found to be very susceptible to electromagnetic interference. This led to an experiment in which an electrically charged plastic strip was oscillated transversely across the sensor. Figure 1(B) shows the resulting response of the nanotube film and the high sensitivity to the changing intensity of the electric field. A similar behavior was shown by vibrating the sensor in an ionic fluid. Applications for this type of sensor might be to shield components from Figure 1. Response of nanotube sensors: (A) measuring the strain vibration of a beam in the healthy condition and then with damage; (B) sensor response due to an oscillating electric field crossing the sensor; and (C) electrochemical impedance spectra illustrating the supercapaci- 12 2005/2006 UC ENGINEER University of Cincinnati College of Engineering electromagnetic interference, stealth, energy harvesting, and replacing electrical wires with nanofilm to make lightweight motors. The high sensitivity to electric fields is thought to be due to the large surface area of the nanotubes, which may be equivalent to a wire that is one hundred times the size of the surface of the nanotube film. Finally, the most exciting sensing property of nanotubes may be their electrochemical transduction. Nanotube films and arrays were tested dry and in electrolytes such as saline solution. The dry nanotubes have a small capacitance, but their capacitance increases by two orders of magnitude when the nanotubes are placed in an electrolyte. This behavior is being taken advantage of to develop micro-scale bioelectronic sensors. Figure 1(C) illustrates the electrochemical impedance spectra and supercapacitance behavior of the nanotube sensor. Our hope is that this sensor will be sensitive enough for label free detection of cancer. Medical doctors Zhongyun Dong and Abdul Jazieh in the College of Medicine and Professors William Heineman and Brian Halsall in tance of the nanotube sensor for DC potentials of 0.2 V(a), 0.4 V(b), and 0.6 V(c) at frequencies between 0.05 Hz and 100 KHz. Cincinnati Radiation Society hosts the 50th Anniversary Conference on Bioassay, Analytical, and Environmental Radiochemistry the Department of Chemistry at UC are helping to develop the biosensor. Finally, the nanotube covalent bonds expand due to double layer charge injection. This principal is being used to develop promising wet and dry actuators and potentially a structural material that actuates. A concept application of the actuator material is shown in Figure 2 at left. These array type nanotubes are grown at UC and also at First Nano, Inc. Students working in the Smart Materials and Nanobioengineering lab are Goutham Kirikera, Yun Yeo-Heung, Vishal Shinde, Swathi Balaji, and Ram Gollapudi. Students recently graduating from this laboratory are Sachin Jain, Atul Miskin, Suhasini Narasimhadevara, and Inpil Kang. Dr. Jon Wong Lee, a visiting scholar from Korea, also works in the lab. Dr. Mark Schulz (Mechanical Engineering) and Dr. Vesselin Shanov (Chemical and Materials Engineering) direct the lab. Dr. Yijun Liu and Dr. Dong Qian are other faculty members in the MINE department working in the area of nanotechnology. Their expertise is in the area of computational and theoretical nanomechanics. They are using multi-scale modeling and simulation to predict the performance of nanocomposite materials. A goal is to gain understanding of nanoscale material behavior and to improve the elastic properties of nanostructured composite materials. More information on nanotechnology research in the MINE Department can be found in the Web sites: http:// www.min.uc.edu/~mschulz/smartlab/smartlab.html, http://urbana.mie. uc.edu/CAELab.htm, and in the edited book “Nanoengineering of Structural, Functional and Smart Materials,” CRC Press, Editors: Mark J. Schulz, Ajit Kelkar, and Mannur Sundaresan, 2005. Henry Spitz Cincinnati Radiation Society University of Cincinnati Nuclear and Radiological Engineering Program Health Physics Program Director 598 Rhodes Hall Cincinnati, OH 45221-0072 513.556.2003 phone henry.spitz@uc.edu The Nuclear and Radiological Engineering (NRE) Program co-hosted the 50th Annual Conference on Bioassay, Analytical, and Environmental Radiochemistry at the Hilton Netherland Plaza Hotel in downtown Cincinnati. Other conference hosts included the Cincinnati Radiation Society (CRS) and the National Institute for Occupational Safety and Health (NIOSH). This was a significant undertaking for the NRE Program, considering how much time was required to plan and actually facilitate a technical conference for over 225 people from national and international organizations. A series of technical workshops on radiation measurements, radiochemistry, and radiological emergency response were also arranged prior to the formal conference. There were 36 oral and 25 poster presentations arranged into topical sessions that included radiochemistry, direct and indirect bioassay, mass spectrometry, internal dosimetry, quality control/assurance, numerical methods, and environmental analysis. Dr. Naomi Harley, from New York University Medical Center, was the keynote speaker for the Conference and also one of three recipients of the Founders Award. The two other recipients were Norman Cohen and Richard Blanchard. The 50th Anniversary Conference celebration was held at the new National Freedom Center and Underground Railroad Museum. A unique feature of the Bioassay Conference is that it is planned and facilitated wholly by volunteers. There is only an informal formal charter that describes the objective of the annual Conference. There are no officers or board members. Since institutional memory fades quickly when there is no formal institution to keep records, each new volunteer organizing committee begins anew with Conference organization. The venue for the Conference changes each year depending upon the location of the volunteers and what deal they can make with a nearby hotel. However, some traditions are hard to break. For example, the Conference returns to Cincinnati (the city of its origin) every ten years. The UC NRE program also hosted the Conference in 1994. Graduate students in the NRE Program also contribute to the Conference organization and deliver technical presentations at the meeting. The first conference began as a meeting at Fernald in 1954 involving about 25 chemists and analysts from the National Labs and the U.S. weapons complex who met to discuss the problems associated with reliably analyzing small amounts of uranium and plutonium in biological and environmental samples. presentations can be lengthy and sometimes quite animated. Persons honored as session chairs sometimes need to have experience in the martial arts to keep the Conference on schedule. In order to preserve the working objective of the Bioassay Conference, no formal publication or proceedings have ever been published other than a booklet of abstracts and Conference schedule. This practice insures that presenters are free to discuss and share problems and challenges they have confronted or resolved. It is expected that knowledge gained at the conference through a very active and lively, but highly constructive, peer review process is beneficial to the presenter and the audience. Recognition of a 50-year anniversary is an important historical event. However, the 50th anniversary of the Bioassay Conference is more than just a chronological milestone. This event demonstrates how important it is for professionals in any field to volunteer their time and effort to sustain those activities that make a profound impact on their profession. The co-chairs of the 50th Bioassay Conference were Henry Spitz and Samuel Glover, both faculty in the UC NRE Program. One can only conclude that the concept of a small amount of activity has a very different meaning today than that discussed in 1954. Many presentations at the Bioassay Conference are truly works in progress where the author is soliciting comments and recommendations from the conference participants. The discussion following some of the Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 13 RESEARCH NEWS NSF Industry/University Cooperative Research Center on Intelligent Maintenance Systems Center Re -located to UC Seeing Failure Before it Occurs Most machine maintenance today is either purely reactive (fixing or replacing equipment after it fails) or blindly proactive (assuming a certain level of performance degradation, with no input from the machinery itself, and servicing equipment on a routine schedule whether service is actually needed or not). Both scenarios are extremely wasteful. To human beings, it often seems that machines fail suddenly, but in fact machines usually go through a measurable process of degradation before they fail. Today, that degradation is largely invisible to human users, even though a great deal of technology has been developed that could make such information visible. It may come as a surprise to many people that most state-of-the-art manufacturing, aircraft engine, mining, farming, and service machines (e.g., elevators) are actually quite “smart” in themselves. Many sophisticated sensors and computerized components capable of delivering data about the machine’s status and performance. beyond mere “predictive maintenance” to intelligent “prognostics”—the process of pinpointing exactly which components of a machine are likely to fail, and when and autonomously trigger service and order spare parts. Figure 1 shows the system elements of an “Intelligent Maintenance Systems (IMS).” The Center for Intelligent Maintenance Systems (IMS) is a National Science Foundation Industry/University Cooperative Research Center which was founded in 2001 as a multi-campus Center of Excellence between the Univ. of Wisconsin-Milwaukee and the Univ. of Michigan. The Center is aimed at developing predictive tools and embedded/remote monitoring technologies to enable products and machines to achieve nearzero-downtime performance. Its mission is to serve as a center of excellence for the creation and dissemination of a systematic body of knowledge in intelligent e-maintenance systems and ultimately to impact next-generation The problem is that little or no practical use is made of most of this data. We have the devices, but we do not have a continuous and seamless flow of information throughout entire processes. Sometimes this is because the available data are not rendered in useable form. More often, no infrastructure exists for delivering the data over a network, or for managing and analyzing the data even if the devices were networked. When smart machines are networked and remotely monitored, and when their data is modeled and continually analyzed with sophisticated systems, it is possible to go 14 2005/2006 UC ENGINEER University of Cincinnati College of Engineering product, manufacturing, and service systems with six-sigma quality. It serves as a catalyst as well as enabler to assist company members to transform their operation strategies from today’s “Failto-Fix/Fly-to-Fix (FAF)” to “Predict-andPrevent (PAP)” performance. In addition, the Center has developed Design for Zero-Breakdown (DF0B) methodology to help industry eliminate unexpected downtime and improved productivity. For the past five years, the IMS team has been pursuing frontiers research in partnership with over 40 industry members including Toyota, GM, Ford, DaimlerChrysler, Rockwell Automation, Intel, United Technologies, Harley-Davidson, Mitsubishi Heavy Industry, Omron, Komatsu, Siemens, ITRI (Taiwan), etc. Dr. Lee and his team have pioneered many advances in advanced prognostics and remote monitoring technologies including the coined Watchdog Agent™ which is a prognostics toolbox-based “digital doctor.” It consists of different prognostics tools for predicting the degradation or performance loss on devices, process, and systems. The algorithms include neural network based, time-series based, wavelet-based and hybrid joint time-frequency methods, etc. Assessment of performance degradation is accomplished through several modules including the processing of multiple sensory inputs, extraction of features relevant to description of product’s performance, sensor fusion and performance assessment. Each of these modules is realized in several different ways to facilitate the use of Watchdog Agent™ in a wide variety of products and applications, with various requirements and limitations with respect to the character of signals, available processing power, memory and storage capabilities, limited space, power consumption etc. The key research activities are focused on four fundamental areas: 1.) transform data to information to knowledge and synchronize decision with remote systems; 2.) intelligent embedded prognostics algorithms for performance degradation assessment and prediction; 3). develop software and hardware platform for smart prognostics in a tethered and tether-free environment; 4.) closed-loop product design and optimization through the use of product embedded service information. Many of the developed tools and technologies have been validated through industry testbeds and contracted research activities. STUDENT NEWS UC Robot Team Responds to DARPA Grand Challenge The UC Robot Team, hosted by the MINE Department but open to any UC student and supported by sponsorships, placed 5th out of 37 teams in the navigation event at the Intelligent Ground Vehicle Contest on June 1, 2005 at Grand Travers City, Michigan. Dr. Jay Lee are joining Ernie Hall as faculty advisors and coaches from MINE along with other faculty from ECECS, DAAP, OCAS, Biology and Geography as well as other volunteers to try to win this national event and develop autonomous ve- hicle technology that can be used, not only for the military, but also for manufacturing and medical applications. Please send ideas to any of the faculty advisors and donations to the UC Robot Team (www.robotics. uc.edu). Thirteen students attended this event even though it was after graduation and a challenging outdoor contest. The Bearcat Cub was designed and fabricated by UC students and worked very well. The software has been developed in C# and will continue to be developed for the 2006 IGVC (www.igvc. org). The Cub was working so well that the team also entered the DARPA Grand Challenge (www.darpa.mil/grandchallenge) and made it past the first two screenings but were not selected for the semifinals because their robot was too small and slow. So, they are now seeing the support of the US Army, TACOM and hope to receive an MP Hybrid vehicle to run in the 2006 contest. If they win the $2,000,000 prize they have agreed to donate the money to the UC Foundation to start scholarships for robotics engineering students. Other sponsors are needed. Dr. Teik Lim, Department Head, Vice President Sandra Degan and Deans Roy Eckart, Paul Bishop and Frank Gerner are helping form a “dream team.” Professors Randy Allemang, Bob Rost, Ronald Huston, Richard Shell and Eminent Scholar Robotics Team ASME Student Design Competition Senior University of Cincinnati Mechanical Engineering students, Dean Clodfelder, Billy Mertz and Sarah Jones, represented the university at the American Society of Mechanical Engineers (ASME) Student Design Competition in April 2005. Unlike many other well known student engineering competitions, the SDC presents a new challenge each year. This year’s challenge was to design and create a scaled model of a robotic Bulk Material Transporter. The robot could make multiple trips while carrying rice over a series of steps and around turns to deposit the load in a receiving container within a ten minute period of time. A creative design and robust device was necessary to be successful in the competition. The team created a radio controlled robot, Bulkie, which was propelled by 2 cordless screwdriver motors. The large cargo bay was able to hold a maximum of 12 pounds of rice per trip, until it remotely released the hatch which allowed the rice to cascade into the depository. The team completed 4 trips but was only able to deliver 3 ½ loads due to time constraints. The design outperformed all but one other robot which allowed the team to place a very close 2nd in a competition of 19 teams. Department of Mechanical, Industrial and Nuclear Engineering UC ENGINEER 2005/2006 15 STUDENT NEWS UC Forms Co-op Honor Society MINE students can now be recognized on a national level for their co-op experiences. The Division of Professional Practice has established a local chapter of the national co-op honor society to recognize those students that have succeeded both in the classroom and in the workplace. Kappa Theta Epsilon Society, KTE, established the Phi Chapter here at the University of Cincinnati in March 2004. In less than a year, this organization boasts more than 50 initiated members. With a minimum GPA of 3.3 needed for membership, these students are the leaders in their respective academic programs and have remained in good standing with the Division of Professional Practice for their co-op quarters. KTE was founded at the Virginia Polytechnic Institute in 1956 by two Cooperative Education coordinators and a group of their senior students. They initiated the first class of the Alpha chapter the following year. Since that time, Kappa Theta Epsilon has grown to 19 chapters nationally. This year the National Convention will be held at Virginia Tech, where this honor society began almost fifty years ago. Co-op Student delegates from all chapters will convene in Blacksburg, Virginia for three days to share informa- tion and ideas ranging from reviewing officer reports, leadership development activities, breakout sessions and social events. basketball games this winter brings together students of many different majors with a common connection of co-op. The Phi Chapter at UC develops programming that will not only provide opportunities for professional development to its members, but the entire University community. There are two sets of officers for the chapter, one to represent each section of co-op. With the guidance of the faculty and staff advisors, the officers have already hosted a university-wide professional night with a lively panel discussion by co-op employers to discuss career paths and how co-op helped to get them where they are today. KTE chapter members also served on committees within the Division of Professional Practice and provided leadership to freshman through presentations on the co-op program and by sharing their personal experiences with the program. Kappa Theta Epsilon Society members serve as ambassadors of the co-op program as leaders within their programs, colleges and the university. The new tradition of KTE here at the University of Cincinnati through professional development programming, networking opportunities, leadership development and peer to peer connections provides a forum for co-op students to promote experiential learning through co-op. For more information on Kappa Theta Epsilon, please visit their Web site, www.kappa-theta-epsilon.org Through presenting both the challenges and the rewards to younger students, KTE members have found a way to give back to the University of Cincinnati. They hope to encourage these students to stay at the UC so they can participate in the co-op program. A variety of social events ranging from a hayride in the fall to Bearcat Motorsports 2005 UC Formula SAE Car Thirty-five dedicated and hardworking engineering student members of the Bearcat Motorsports teamed up again this year to design, build, and race a formula-style race car as part of an annual competition 16 2005/2006 UC ENGINEER University of Cincinnati College of Engineering sponsored by the Society of Automotive Engineers. The team’s leadership includes a Team Leader, a Technical Committee and a Business Manager. Other team members work on designing and constructing all aspects of the race car including the frame, suspension, body, engine, drive train and electrical systems. By applying state-of-the-art computer aided engineering technology in combination with the hands-on welding and machining experiences, students are able to translate classroom knowledge into real life application. Aside from designing and fabricating the race car, students also participate in the business side of the project, which includes program management, sponsorship, scheduling, planning and cost analysis. MINE at a Glance Faculty and Staff Professor Associate Professor Assistant Professor Eminent Scholar (Professor) Research Faculty Adjunct Faculty Professor Emeritus Visiting Scholar Post-Doctoral Researcher Full-time Staff 12 12 4 1 3 7 14 6 3 10 Academic Programs B.Sc. Mechanical Engineering Undergraduate Minors: Industrial & Manufacturing Engineering (IME) Nuclear & Radiological Engineering (NRE) Accelerated Engineering Degrees (ACCEND): B.Sc. ME & M.Sc. NRE B.Sc. ME & M.B.A. M.Sc. & Ph.D. Mechanical Engineering M.Sc. & Ph.D. Industrial Engineering M.Sc. & Ph.D. Nuclear & Radiological Engineering M.Sc. Health Physics Ph.D. Medical Physics Students Undergraduate (ME) Graduate: Mechanical Industrial Nuclear & Radiological 420 284 184 81 19 Research Active Projects ($3.5million) Research Thrust Areas Research Laboratories Research Centers 45 6 19 2 If you are interested in supporting the Department of Mechanical, Industrial and Nuclear Engineering financially, please mail check payable to UC Foundation to: Attn: MINE Dept Head University of Cincinnati 598 Rhodes Hall, PO Box 210072 Cincinnati, OH 45221-0072. You may simply contribute to the general academic fund or designate your contribution to one or more of the following specific needs in the Department: • Engineering Design Clinic • Undergraduate Student Scholarships • Graduate Student Scholarships • Hundley Excellence in Teaching • Others (please state intent) Please be sure to include your name, address, phone and/or e-mail so that we may thank you and also stay in touch with you. Your generous contribution would most certainly benefit the engineers of tomorrow. Thank you for your support. Mechanical Engineering Alumni WE NEED YOUR HELP Remember when you had your ME senior composite picture taken? We have all but 4 classes since the 1949 graduating class displayed in the 5th floor hallway. W are missing four composites from the 1950, 1970, 1999 and 2002 graduating classes. If you have your composite picture and would be willing to lend it to us for a short time, we will copy it and return it immediately. We also have the composites from the 1942 and 1943 graduating classes and would be interested in collecting and displaying any others that we can get copies of. Please e-mail bob.rost@uc.edu or call him at 513-556-0420 if you have one of those years and are willing to help us. It’s amazing how many times we have visitors who look at these pictures looking for classmates or faculty. Thank you for your help. ! UC2830 University of Cincinnati College of Engineering Department of Mechanical, Industrial and Nuclear Engineering 598 Rhodes Hall P.O. Box 0072 Cincinnati, Ohio 45221-0072