TECHNICAL BULLETIN

TB-105

November 2014 (Expires 11/2016)

Garage Floor Design Guidelines

In North America, design load requirements for residential garage floor applications can be found in model building codes including

the International Building Code (IBC), International Residential Code (IRC), and National Building Code of Canada (NBCC), as well as

the American Society of Civil Engineers (ASCE) standard ASCE/SEI 7-10 Minimum Design Loads for Buildings and Other Structures.

These documents generally consider uniform live load and/or concentrated load cases and are summarized in this document.

Provisions for commercial garages, vehicle repair facilities, driveways, bridges, and garage floors accommodating large trucks or

busses are not included in this technical bulletin.

In Canada, garage floor joists are not covered in Part 9 of the NBCC and therefore require the services of a professional engineer.

Some municipalities, such as Burnaby and Surrey in British Columbia, Canada do not allow wood members to support garage floors.

In the United States, some jurisdictions, such as Oregon, have specific load conditions that must be considered. Before designing,

check local code jurisdictions for design requirements.

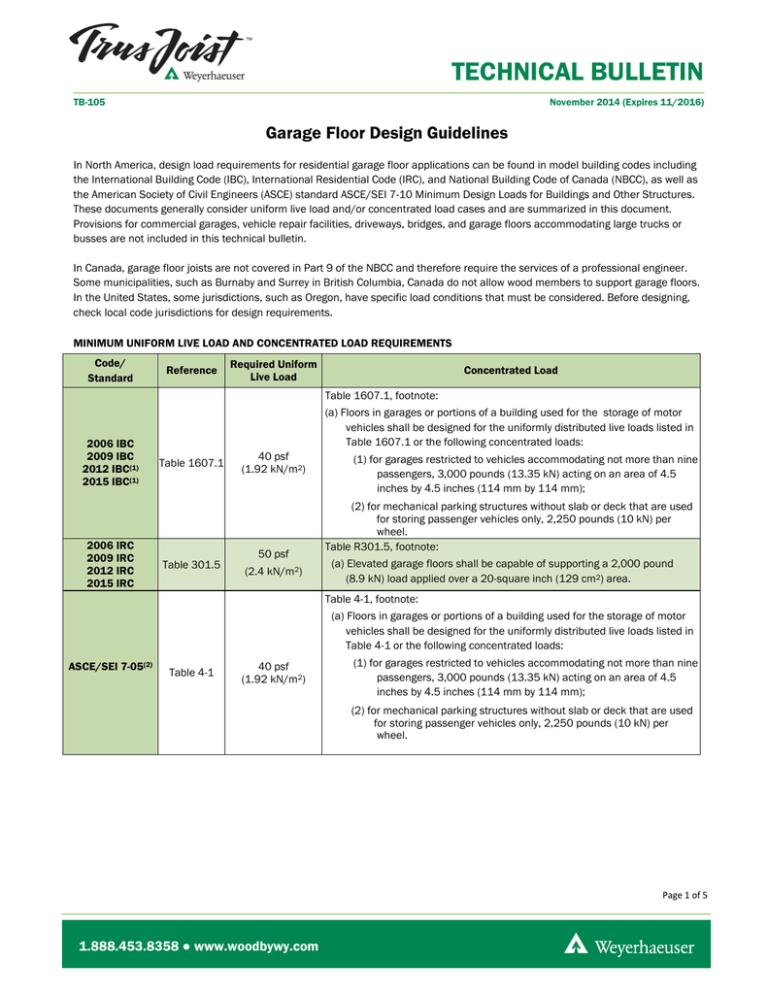

MINIMUM UNIFORM LIVE LOAD AND CONCENTRATED LOAD REQUIREMENTS

Code/

Standard

Reference

Required Uniform

Live Load

Concentrated Load

Table 1607.1, footnote:

2006 IBC

2009 IBC

2012 IBC(1)

2015 IBC(1)

2006 IRC

2009 IRC

2012 IRC

2015 IRC

(a) Floors in garages or portions of a building used for the storage of motor

vehicles shall be designed for the uniformly distributed live loads listed in

Table 1607.1 or the following concentrated loads:

Table 1607.1

Table 301.5

40 psf

(1.92 kN/m2)

50 psf

(2.4 kN/m2)

(1) for garages restricted to vehicles accommodating not more than nine

passengers, 3,000 pounds (13.35 kN) acting on an area of 4.5

inches by 4.5 inches (114 mm by 114 mm);

(2) for mechanical parking structures without slab or deck that are used

for storing passenger vehicles only, 2,250 pounds (10 kN) per

wheel.

Table R301.5, footnote:

(a) Elevated garage floors shall be capable of supporting a 2,000 pound

(8.9 kN) load applied over a 20-square inch (129 cm2) area.

Table 4-1, footnote:

(a) Floors in garages or portions of a building used for the storage of motor

vehicles shall be designed for the uniformly distributed live loads listed in

Table 4-1 or the following concentrated loads:

ASCE/SEI 7-05(2)

Table 4-1

40 psf

(1.92 kN/m2)

(1) for garages restricted to vehicles accommodating not more than nine

passengers, 3,000 pounds (13.35 kN) acting on an area of 4.5

inches by 4.5 inches (114 mm by 114 mm);

(2) for mechanical parking structures without slab or deck that are used

for storing passenger vehicles only, 2,250 pounds (10 kN) per

wheel.

*

1.888.453.8358 ● www.woodbywy.com

Page 1 of 5

TECHNICAL BULLETIN

TB-105

November 2014 (Expires 11/2016)

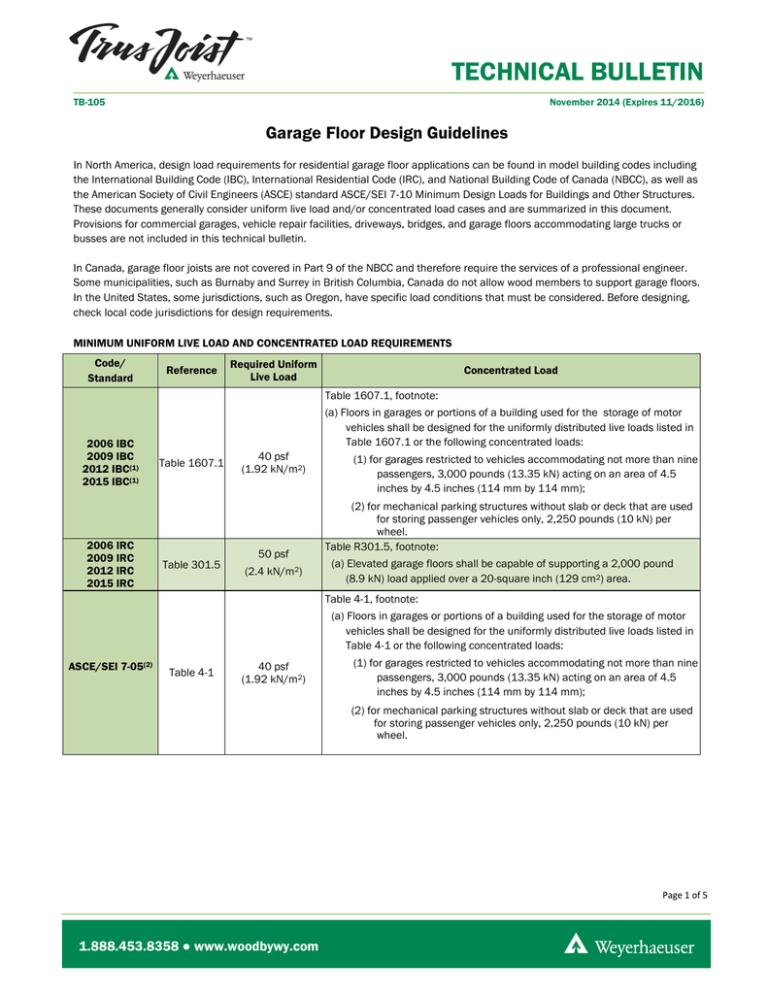

MINIMUM UNIFORM LIVE LOAD AND CONCENTRATED LOAD REQUIREMENTS (CONTINUED)

Code/

Standard

Reference

Required Uniform

Live Load

Concentrated Load

Table 4-1, footnote:

(a) Floors in garages or portions of a building used for the storage of motor

vehicles shall be designed for the uniformly distributed live loads of Table 4-1

or the following concentrated loads:

ASCE/SEI 7-10(3)

Table 4-1

40 psf

(1.92 kN/m2)

(1) for garages restricted to vehicles accommodating not

more than nine passengers, 3,000 pounds (13.35 kN)

acting on an area of 4.5 inches by 4.5 inches

(114 mm by 114 mm); and

(2) for mechanical parking structures without slab or deck that are

used for storing passenger vehicles only, 2,250 pounds (10 kN)

per wheel.

2005 NBCC

Section 4.1.5.10:

- Floor used by passenger cars:

Table 4.1.5.3 For Passenger Cars Load = 2,480 lbs. (11 kN)

Section

LL = 50 psf (2.4 The specified live load due to possible concentrations of load resulting from

4.1.5.10

the use of an area of floor or roof shall not be less than that listed in Table

kPa)

4.1.5.10. applied over an area of 29.5 inches by 29.5 inches (750 mm by

750 mm) located so as to cause maximum effects.

2010 NBCC

Vehicles not

exceeding

8,820

Table 4.1.5.3

lbs (4,000 kg)

Section

4.1.5.10

LL = 50 psf (2.4

kPa)

Section 4.1.5.9:

- Floors used by vehicles not exceeding 8,820 lbs (4,000 kg):

Load = 4,046 lbs. (18 kN)

Loaded Area = 4.72 inches by 4.72 inches (120 mm by

120 mm)

(1) The 2012 & 2105 IBC prohibits live load reductions for garage floors except for members supporting two or more floors (see Section 1607.10.1.3).

(2) The ASCE/SEI 7-05 prohibits live load reductions for garage floors except for members supporting two or more floors (see Section 4.7.4).

(3) The ASCE/SEI 7-10 prohibits live load reductions for garage floors except for members supporting two or more floors (see Section 4.8.3).

*

1.888.453.8358 ● www.woodbywy.com

Page 2 of 5

TECHNICAL BULLETIN

TB-105

November 2014 (Expires 11/2016)

Design Considerations

When checking concentrated loads, the uniform live load is removed and replaced with a single concentrated point load to simulate

a jack load. The majority of a vehicle's weight (80%) is in the engine. The concentrated load provision of 40% of the gross vehicle

weight contained in codes prior to 2003 stems from the weight of the engine supported on two wheels. The minimum load of 2,000

lbs in the IRC is the equivalent of a 5,000-lb automobile. Sport utility vehicles, passenger vans, and light trucks have increased in

size each year. For example, a Chevrolet Suburban weighs approximately 5,700 lbs, while a Ford Excursion weights 7,600 lbs.

Because of these heavier vehicles, the concentrated load of 3,000 lbs in the 2006, 2009 and 2012 IBC and ASCE/SEI 7-05 and 710 is recommended. The designer must ensure that the structure is capable of supporting loads that can be reasonably expected.

In addition, the condition of concentrated or uniform live load which produces the greatest stresses shall govern.

When checking concentrated load requirements, floor joists should be analyzed with as many concentrated loads as are feasible for

the garage, with one concentrated load used for each parking space. Depending on the joist layout and support locations, it may be

possible to have a single joist supporting two parking spaces. Concentrated loads shall be located where they cause the worst

stresses, and will change depending upon the design property. For example, concentrated load locations for determining maximum

bending moment will be different than those for shear, bearing, and deflection.

Weyerhaeuser structural frame software employs safe-load checks for commercial products. The commercial concentrated load

provision (safe-load) in software assumes a single 2,000 lb concentrated load acting over 2½ square feet, which does not comply

with the live load requirements or the appropriate footprint for garage floors. Therefore, safe-load design in Weyerhaeuser software

should not be relied upon to properly size and analyze garage floor joist members.

Keep in mind that a garage floor may have a significant dead load associated with its design. The IBC and IRC have provisions

requiring that floor surfaces be made of a noncombustible material, and many times, the material of choice may be a concrete

topping layer. For more on floor surface requirements, see below.

It is important to use particular caution and judgment when designing garage floors. This is one application that will regularly

support full design live loads.

Finally, a directly applied ceiling will improve the bottom flange stability of garage floor members. If a ceiling finish is directly

fastened to the garage floor joists, it is important to strictly limit live-load deflection to minimize cracking in the ceiling finish. Also,

because of the long-term loads involved, the effects of creep must be considered. Comparably speaking, TJI® joists have relatively

low reaction and shear capacities, so using Trus Joist® Microllam® LVL, TimberStrand® LSL, or Parallam® PSL for garage floor

framing members often provides a better solution.

*

1.888.453.8358 ● www.woodbywy.com

Page 3 of 5

TECHNICAL BULLETIN

TB-105

November 2014 (Expires 11/2016)

Consider 4 load cases for a simple span garage floor to determine member. Whichever load case produces the greater load effect

shall be used to size the supporting member.

Case 1: Uniform live load + Uniform dead load

Case 2: Uniform dead load + live load located

at mid-span (Design professional may design reinforced

concrete, and determine some load sharing for this case)

Case 3: Uniform dead load + pounds live load located

the depth of the joist + ½" from face of bearing.

(no load sharing this case)

Case 4: Bearing Length/Hanger Check- Uniform dead load

+ live load located ½" from face of bearing

Floor Surface Requirements

As mentioned above, garage floor parking surfaces must be made from noncombustible and nonabsorbent materials. Many times,

a concrete topping layer is used and can significantly add to the dead load of the floor system. Concrete topping layers should be at

least 3 inches thick and reinforced to prevent cracking due to cyclic wheel loads and shrinkage. If a concrete topping layer is used,

then long term loading must be addressed.

IBC, Section 2304.12 addresses long-term loading of wood members. It requires that wood members supporting concrete, masonry,

or similar materials be checked for long-term loading using the provisions of the AF&PA NDS. The total deflection, including the

effects of long-term loading, shall be limited in accordance with Section 1604.3.1 for these supported materials. One exception to

Section 2304.12 is horizontal wood members supporting a masonry or concrete nonstructural floor or roof surfacing not more than

4 inches thick (102 mm), which need not be checked for long-term loading. For more information on long term loading and creep,

see Technical Bulletin, TB-101.

Hanger Considerations

If connection details require hangers to sit on a treated plate on top of the foundation or connect to a treated ledger other than

TimberStrand® StrandGuard® LSL, additional corrosion resistance may be required for the hangers. For additional hanger

information please refer to Simpson Strong-Tie and USP catalogs.

*

1.888.453.8358 ● www.woodbywy.com

Page 4 of 5

TECHNICAL BULLETIN

TB-105

November 2014 (Expires 11/2016)

Sheathing Requirements

In some regions it is not uncommon for builders to prefer building an elevated garage floor over wood framing rather with a

structural concrete slab. While the design of the support joist framing is relatively straightforward, the calculations for garage

flooring materials (wood structural panels covered by other materials) are more complex. Historically, sheathing and panel industry

associations have provided several systems that have been deemed to be adequate in these applications. However, building code

load requirements have significantly increased recently. Therefore, it is Weyerhaeuser's recommendation that users consult with a

registered design professional to provide a site specific design.

Additional Recommendations

Adequate ventilation, drainage, and detailing are necessary to ensure that wood products remain dry, particularly at the interface

between the driveway and the garage. A waterproof membrane should be installed between the sheathing and the concrete topping

layer. In addition, provisions should be made for draining water that might collect on top of the membrane. Moisture conditions

above those at dry-service conditions will increase initial deflection, increase creep deflection due to sustained loads, and reduce

the strength of the wood.

If you have any questions, please feel free to contact your Weyerhaeuser representative.

,’Weyerhaeuser,’Forte,’Javelin,’Microllam,’Parallam,’Silent’Floor,’TimberStrand,’TJI,’TJ,’Trus’Joist,’Edge,’and’Edge’Gold’are’registered’trademarks’and’TJPro’is’a’trademark’of’Weyerhaeuser’NR.’©’2014’Weyerhaeuser’NR’Company.’All’rights’reserved.

1.888.453.8358 ● www.woodbywy.com

Page 5 of 5