Uncontrolled Copy

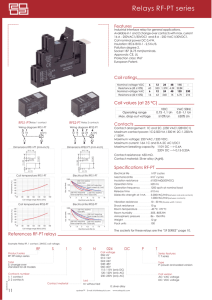

advertisement

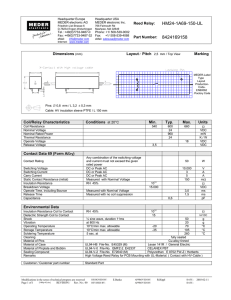

Hellermann Deutsch Ltd. HDSS half crystal can relay BS9151 F0026 Resonance free contact system for extreme environments Fast operation Th e HDS5 half crystal can size , 2 pole changeover relay has been in UK production longer than any other comparable relay. Its all welded construction dynamically balanced armature , fus ion welded seal and special resonance free contact system ensure satisfactory performance under extreme environmental conditions. The fini shed relay is contaminant free , assured by ultrasonic cleaning , vacuum de-gassing , sealing into a sta inless steel can by fusion welding and filling of the relay enclosure with inert dry nitrogen . op y Special relays are available with coil transient suppression incorporated by the fitting of diodes. In this case polarity has to be observed when connecting the relay into circuit and this is indicated by the reference HDP6. As a result of incorporating diodes in this way release time, weight and overall height are slightly increased. pF . normally closed contacts and pF . contact sets 0.3 pF . coil and case 22 pF . Temperature Range -65°C. to +125°C. Ambient. tro Contact rating/life 2 Amps at 28YDC resistive load, 100,000 operations . 4 Amps at 28VDC resistive load, 10,000 operations . 1 Amp at 28VDC inductive load, 100,000 operations. 2 Amps at 115vac, 400 Hz. resistive load, 100,000 operations. (case ungrounded) Low level , 10 6 operations For DC inductive loads an adequate spark quench should be fitted . Contact resistance 50 milliohms initial. 100 milliohms after rated life. Operate Time 4 milliseconds max. at 25°C with nominal voltage . case 1.5 Between case 2.5 Between Between lle d Specification Contact form 2 pole changeover (2PDT) C The contact resistance of every relay is checked at each of 5,000 operations with a measuring circuit, the source voltage which does not exceed 10 millivolts. U nc on Vibration 0.12 inch DA, 10-60Hz, 20g . 50-2000Hz. Release time 4 milliseconds max at 25°C with nominal voltage . (not applicable to HDP6) Bounce time 3 milliseconds max . at 25°C with nominal voltage . Insulation resistance Not less tha:1 500 Megohms at 500 volts. Dielectric strength 500 VRMS at 50Hz. at sea level. 350 VRMS at 70 ,000 ft. Capacitance (Typical) Between open contacts 0.38 pF . Between normally open contacts and Shock 50g . 11 milliseconds. Weight HDS5- 8 gm. max (style 21 , other styles vary with brackets etc .) Coil data Minimum operate power: 220 milliwatts. Power dissipation at nominal voltage 800 milliwatts . Maxi mum permissible coil dissipation 1.4 watts at 25°C and 1 watt at 125°C. Finish HDSS The stainless steel can is finished with a black epoxy paint. Identification is in white indelible ink. Relay header is hot tin dipped. HOPS Relay header and terminals are gold plated . Special Modifications To contacts, operating characteristics, mountings, terminations, finish etc ., may be obtained to special order. If your requirements are not satisfied by a standard relay consult your Hellermann Deutsch Rep resentative or contact our Sales Office . Schematic diagram HDSS HDP6 Termination variants HD BS A 8 c H L 11 s 12 Dimension X mm. Solder hooks Type ln. Straight Straight Straight Hooks Straight Straight 0.312 0 .500 1.00 07.92 12.70 (Consult Factory) 25.40 (Consult Factory) 3.00 0 .200 76.20 (Consult Factory) 05.08 Straight leads Q_l f Lw Qj~~-~~ If X PIN DIA. :0 · 0 30 (0·76) ~····~ (5 "08) 0 · 200 Notes: 1. Term ination type S suitable for use with relay sockets 4223-1 and 420204 (5·08) Mounting variants BS STYLE 01 HD STYLE 26 BS STYLE 02 ·:,::ci HD STYLE 34 1·325 (33 ·63) MAX 0 ·375 (9·53) 0 · 030 (0·76) op ,C:"--""""<=i BS STYLE 03 BS STYLE 04 C HD STYLE 22 BS STYLE 05 H ~ nc on 1 · 320M~X ,0 · 120 DIA (3 ·05) tro HD STYLE 25 lle d 0·206 q~p (5·23) l y HD STYLE 21 0 ·020 t 0·370 0·128 DIA (3·25) 0·128 DIA U (3·25) 1 1 ·078 (27. 38) • HD STYLE 23 BS STYLE 07 HD STYLE 24 r 1· 320 MAX 0·020 1 ~ 0·189 (Q.51 J J - u J(4 ·8'0) . TTIIT-. BS STYLE 08 1 ·078 (27·38) - 1 ~~ ,;,~, (9·40) 0·128 DIA 0·020 ~ (3·25) (o·5 1 lL~ '1. Dimensions throughout are in inches w ith metric equivalents in brackets unless otherwise stated 1 ·320 MAX (33·53) j • blue bead Coil Data HD Coil Nominal Operate Voltage VDC Coil Resistance Ohms ±10% AT 25°C Must Operate Voltage VDC Must Drop Out Voltage VDC H2 C2 4.5 6 6 12 12 18 20 24 26.5 32 48 25 42 60 210 320 430 700 1250 830 1300 2800 2.5 3.2 3.6 6.8 7.2 9.5 10.6 14.4 13.5 16.8 25.5 0.2 0.3 0.3 0.6 0.6 0.9 0.9 1.2 1.2 1.4 2.5 E2 M2 K2 F3 F2 J2 G2 BS Coil 02 03 05 06 15 09 08 11 HOW TO ORDER HDS5S·F2-K22 y BS9151·F0026·02·08·05·12 C op L.....-----------'----+----+--TERM I NATION VARIANT tro lle d ~-------------+----'--- MOUNTING VARIANT nc on ~------------__,___ _ _ COIL VARIANT BS HD 11 12 s A 01 21 02 26 03 34 04 05 22 07 08 23 24 02 C2 25 03 05 06 E2 08 09 F2 F3 G2 11 U H H2 M2 J2 15 CONTACT ~-------------- RATING Superseded NATO stock numbers against items previously supplied to DEF-5165 SM5U BS 9151·F0026 Direct Equivalent NATO Stock Number DEF-5165 Item NATO Stock Number 5945-99· 014·2584 014-2585 014·2586 014-2587 Style Reference SM5 U SM5U SM5U SM5U · · · · N1 N2 N3 N4 5945-99· 017-2850 017-2859 017-2868 017·2877 02 K2 Miniature relay bases Specification Contact Rating Dielectric strength 3 amps 1400 volts at sea level Temperature range Contact resistance 50 milliohms Material Contacts Glass filled phenolic (4223-1 is diallylphthalate). Gold plated e All relay base contacts are identified in numerical sequences. MOUNTING • Th ese idents differ in some cases from those on relay schematic diagrams . Care should be taken to avoid confusion when detailing circuit diagrams and wiring diagrams . • Bases are supplied complete with set of mounting hardware. 1·320 • Bases with crimped contacts suppl ied with full complement of contacts ; (33·53) versions with rear-grommet supplied with 3 filler plugs . • Gasket is supplied with 420204. No2-56UNC • Other mounting styles can be used with these bases if suitable 2Ascrew adaption to the installation is made. INFORMATION ·062 (1·58) panel * 208 (5·8) , 4223·1 SOLDER BASE Base screw No 4-40 UNC 2A thread y When panel is assembled at rear of base .062 spacer suppl ied should be used to maintain th is dimension. .203 Max (5 16) op 1 · 062 (27·0) ·400 (1 0· 2) . 200 1 062 (27·0) 2 Holes · 128 (3 · 25) DIA ·_±+:H- - - - t- 1 lle d 1 (5:8) C r-~~l$] j__ ~- 1·344 (34·4) --IH-t+--. ·425 (10·80) · 070 (1 · 78) rad. or can be square tro 420204 CRIMPED ENVIRONMENTALLY SEALED BASE .234 (6.0) PANEL CUT-OUT MOUNTING INFORMATION No 2 _ 56 UNC 2Ascrew Relay(ref . only) ·234 * on No 2-56 U NC 2A screw I U nc spacer , Rear grommet Socket contact Rear grommet Contact re ta ining clip *When panel is assembled at rear of base .062 spacer supplied should be used to maintain this dimension . 1 ·078 (27·48) ;;~ 0~ 6 -, - i---'---7:::--'-:C.::..,-::!--c:--i-:--..; ·406 (1 .815(20.70) oc_ '----"-::;-:::L.+::._:_--'---' .070(1.78) Rad . I I , '"" "" "'"'"~ PANEL CUT-OUT 2 Holes · 125 (3·18) DIA I jJr/ I,,~~~ Assembly Tooling, Contacts & Filler Plugs Base Part Number Contact Part Number Suitable Wire Gauge Crimp Tool Crimp Tool Locator Contact Insertion Tool Contact Removal Tool Filler Plug Gasket Wire 0/D Range 420204 420280 20.22 HD1 6/20-15500 15500-20/29 M15570-20 M15570-20 419206 420282 .040" - .083. HeUermann Deutsch Ltd., lmberhorne Way, East Grinstead, West Sussex, RH19 1RW. Telephone: East Grinstead (0342) 27411 Telex: 95118 A member of the Bowthorpe Holdings PLC IIDS5 RELAY DATA SHHE'........,....,..f HDSSIBS91Sl F0026 2PDT HALF CRYSTAL CAN RELAY • Hermetically sealed • BS9000 approval Wiring Schematic • Low level capability • Small size for high density packaging y Specifications op GENERAL CONTACT ARRANGEMENT 2 POLE CHANGEOVER (2PDD BREAK BEFORE MAKE WEIGHT C 8.7 g (mounting variant 01) MATING BASES lle d SOLDER CONTACTS- ORDER PART NO. 4223-1 CRIMP CONTACTS - ORDER PART NO. 420204 tro PERFORMANCE 2A RESISTIVE, 10' OPERATIONS AT 28 VDC 1A RESISTIVE, 1 OPERATIONS AT 115 VRMS 400 Hz LOW LEVEL, 10 OPERATIONS (typical 5 VDC, 10 rnA) CONTACT RATING/LIFE nc on r' 5 X 10' OPERATIONS OPERATE TIME 3.5 ms nominal, 5 ms max (excluding bounce) RELEASE TIME 1 ms nominal, 5 ms max (excluding bounce) U MEAN MECHANICAL UFE BOUNCE TIME 3 msmax All measurements at 25°C and nominal voltage ENVIRONMENTAL TEMPERATIJRE RANGE 2 SHOCK* 490 m/s for 11 +/- 1 ms VIBRATION* 60 to 2000Hz at 196 m/s acceleration 10 to 60Hz at 1.5 mm amplitude 2 •Applies to mounting style 01 A UNEAR ACCELERATION 980 m!s' BUMP 4000 bumps at 390 m/s , 6 ms duration CUMATIC BS 2011 test Z/ABDM procedure 1 SALT MIST BS 2011 part 2.1 Kb severity 2 S T E P 2 AHEAD I N TECHNOLOGY ELECTRICAL Code 01 contacts 50 miliohms max. measured at open circuit voltage of 5V and current of 10 rnA. Code 02 contacts 50 miliohms max. measured at open circuit voltage of 10 mV and current of 10 rnA. INSUlATION RESISTANCE 500 Megohms min. - between any two isolated terminals. 500 Megohms min. - between terminals and case. Measured at 500 VDC and 25°C. VOLTAGE PROOF 500 VRMS 50 Hz, at sea level, between terminals and case, between the two sets of contacts, and between open contacts. 350 VRMS 50 Hz, at 20 millibar air pressure, between all terminals and case. CAPACITANCE Closed contacts to case Open contacts to case Between contacts of a set Between the two contact sets COIL D ISSIPATION The maximum operate power that can be applied to the coil is l.OW at 25 •c de-rated linearly to 0.8W at 125•c. HD U nc on tro lle d C op y CONTACT RESISTANCE BS 'X' mm 1YPE Straight 7.92 B Straight 12.70 c Straight 25.40 Hooks 5.08 Straight 76.20 Straight 5.08 A H 11 L s Solder Hooks 12 Straight Leads 5.08 4pF 2pF 2pF 4pF HD Ref21 BS Ref01 BS Ref03 HDRef 34 ., 20.6 max ,~ HD Ref26 BS Ref 0 2 "·'·n CO L. -- ..J L. -- ..J 3.25 @0@@ 1.00 •r-c:=======:J 34.0 max I I -- ..J tro L. 27.4 3.25 3.25 @@@@ @0@@ 1~: .I HD Re f23 BS Ref 0 7 HD Ref22 lle d lu J 0.7 f BS Ref 0 5 C HD Ref25 BS Ref04 op y 5.23 nc on Cl U 10.4max @@@@ @0@@ @@@ @) 274 .I HD Ref24 BS Ref08 34 0 max .,lf bl_j ... - - ..J 27.4 J 9.40 [ 5.08 480 t t 3.25 3.25 9.40 [ 07 l 27.4 Tolerances +/- 0.25 unless otherwise stated. All dimensions are in nun unless otherwise stated. fl . . 34.0 max ORDERING INFORMATION BS9151-F0026 -01 -08 -05 -12 HDS5S -F2 -K22 Terminatio n Variant BS HD II H 12 s (refer to page 2) Mounting Variant BS HD 01 02 03 04 05 07 08 21 26 34 25 22 23 24 (refer to page 3) Coil Variant HD 02 05 08 09 C2 E2 F2 F3 G2 H2 M2 J2 K2 y BS op II Con tact Rating Light Duty Rating Low Level tro lle d C 15 (refer to table below) H2 C2 E2 M2 Coil resistance Nominal operate voltage Ohms +/-10% Must operate voltage VDC Must drop out voltageVDC BS Coil 4.5 25 2.5 0.2 6.0 42 3.2 0.3 02 12.0 2 10 6.8 0.6 05 18.0 430 9.5 0.9 U HD Coil nc on COB. VARIANTS AND OPERATING CHARACI'ERISTICS K2 20.0 700 10.6 0.9 15 F3 24.0 1250 14.4 1.2 09 08 F2 26.5 830 13.5 1.2 J2 32.0 1300 16.8 1.4 G2 48.0 2800 25 .5 2.5 11 All values are measured at 25°C --------------LTD-------------Birches Industrial Estate, Imberhorne Lane East Grinstead, W. Sussex RH19 1RW England Tel: 01342 410055 Fax: 01342 410005 Kenspeckle: HDS5