Version 1.10 Change`Air Product Catalog Sophomore Series

advertisement

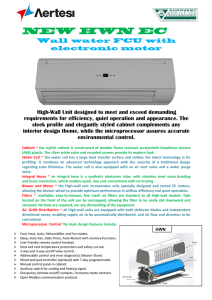

Change’Air Product Catalog Version 1.10 Sophomore Series For a complete catalog contact your local representative. Engineered Excellence for Greener Classrooms NOTE: Change’Air reserves the right to make changes to Unit specifications without prior notice. The performance of each Unit may vary based on site conditions and installation. 3.0 Sophomore Series 3.1 3.2 3.3.1 3.3.2 3.4 3.5 3.6 3.7 3.8 3.9 Features Sophomore Series Cabinet Size Selection Physical Data Tables (Cabinet “O”) Physical Data Tables (Cabinet “P”) Sophomore Series Air Source Heat Pump (ASHP) Classroom Air Handler Heating Options Cooling Options Power Relief Energy Recovery ASHP Energy Recovery Wheel Sophomore Series SELF CONTAINED A/C & AIR SOURCE HEAT PUMP 3.1 Features The Change’Air Sophomore Series classroom air handler has a wide range of features. It is available in two of our cabinet sizes (O & P ) with supply air capacities ranging from1000 to 2200 cfm. standard features IN the Sophomore Series Include: - Raised condenser intake design with a single wall penetration above a sill - High efficiency design including ECM supply fan assembly - Staged scroll compressors - 2 to 5 ton capacities available with efficient R410a refrigerant In addition to the standard features the Sophomore Series options includes: - Air source heat pump operation - Energy Recovery Wheel (ERW) with economizer damper - Hot gas reheat for effective dehumidification When cooling and heating is required and high efficiency is a priority, the Change’Air self-contained, packaged air source heat pump may be the answer. This is designed to standard CSA 22.2 NO. 236-05 UL 1995 certified by the Electrical Testing Laboratories (ETL) and bears the label indicating it has been tested to the current safety standards for both the United States and Canada. Standard ECM supply fan assembly Aluminum fresh air dampers Quiet and reliable modulating spring return actuators Condenser Fan(s) Super quiet and efficient staged scroll compressors C 3.0 Sophomore Series Sophomore 3.2 Sophomore Series Cabinet Size Selection “O” Cabinet 44 32 Basic Features, Design Options and Capacities. ! ! ! ! ! ! ! ! ! ! High condenser intake cabinet (44” x 32” x 91”) Supply air up to 1600 CFM. Primary or supplementary heating capacity (Hot water up to 90 Mbtuh or two stage Electric up to 15KW. Optional air source heat pump operation. Cooling capacity through self-contained A/C with capacities from 24 to 36 Mbtuh. (2, 2.5 or 3 Ton) Standard condensing/relief fan option Energy recovery wheel (ERW) with or without an outside air economizer damper (optional to only a standard outside air damper). Hot gas reheat coil (optional). Two step scroll compressors standard. 91 Insulation and Acoustics The cabinet front incorporates two fully insulated full size service panels. The cabinet panels are thermally and acoustically insulated with 1”(2.54 cm) thick flexible acoustic insulation. This insulation is covered in the air stream with a black coated mat. The flexible, thermal and acoustical liner includes the specification compliance ASTM C1071, HN-1545B, NFPA 90A and NFPA 90B. “P” Cabinet 48 Basic Features, Design Options and Capacities. ! ! ! ! ! ! ! ! ! ! High condenser intake cabinet (48” x 32” x 91”) Supply air up to 2200 CFM. Primary or supplementary heating capacity (Hot water up to 110 Mbtuh or two stage Electric up to 15KW). Optional air source heat pump operation. Cooling capacity through self-contained A/C with capacities from 42 to 60 Mbtuh. (3.5, 4 or 5 Ton) Standard condensing/relief fan option Energy recovery wheel (ERW) with or without an outside air economizer damper (optional to only a standard outside air damper). Hot gas reheat coil (optional). Two step scroll compressors standard. 91 Cabinet Construction Each cabinet is manufactured using galvanized steel with a powder coat baked enamel-textured finish. The internal frame supports all the internal metal pans and components so that the external panels do not carry any of the weight. The external cabinet panels are attached so that there are no visible screws, rivets or fasteners. 32 Enamel Finishes Each cabinet has the highest quality, powder coat baked enamel finish. For architectural and design purposes, Change’Air provides three standard colors: white, antique white, and gray. C 3.0 Sophomore Series 3.3.1 Physical Data Table - Cabinet “O” 2, 2.5 & 3.0 Ton SOPHOMORE “O” CABINET OPTIONS PRIMARY OR SUPPLEMENTARY ELECTRIC HEAT (E) HEATING HOT WATER COIL (H) OPTIONAL HEAT PUMP HEATING AIR SOURCE HEATING CAPACITY COOLING SELF-CONTAINED COOLING CAPACITY VALUE OR CAPACITY RELIEF FANS ECM AC CENTRIFUGAL FANS FILTERS SUPPLY DESIGNATION DESIGNATION Low Capacity(LC) 10KW 12KW 15KW 16” X 26”, 1 row 55 Mbtuh 16” X 26”, 2 row 90 Mbtuh 2.0 Ton 2.5 Ton 3.0 Ton Standard Capacity(SC) High Capacity(HC) Standard Capacity (SC) Standard Capacity (HC) Nominal 24 Mbtuh (AHP) Nominal 30 Mbtuh (AHP) Nominal 36 Mbtuh (AHP) Nominal 24 Mbtuh (RCI) Nominal 30 Mbtuh (RCI) Nominal 36 Mbtuh (RCI) 2.0 Ton 2.5 Ton 3.0 Ton SUPPLY FANS COMPATIBILITY TABLE Standard Capacity SC-D - ½ hp (2 fan bodies) High Capacity HC-D - 3/4 hp (2 fan bodies) 1200 cfm 1400 cfm 250 - 1600 cfm (2) 1” Disposable (2) 2” Disposable Relief fan option using condensing fans 18” x 18” (2) Permanent Washable “B” “C” “D” “E” 18” x 18” 18” x 18” YES SUPPLY VOLTAGES 208/3/60 208-230/1/60 277/1/60 460/3/60 HOT GAS REHEAT All Models YES YES ENERGY RECOVERY WHEEL (no economizer) All Models YES ENERGY RECOVERY WHEEL (with economizer) All Models YES YES YES AIR FLOW DESIGN Draw Through Heating YES WEIGHT 2 & 2.5 Ton 3.0 Ton 850 lb 875 lb All weights are calculated on the maximum available options. Performance: rated in accordance with AHRI Standard 390 (Formerly ARI Standard 390) 1 - Cooling capacity rated at standard conditions - 80/67°F indoor air, 95°F outdoor air 2 - Heating capacity rated at standard conditions - 70°F indoor air, 47/43°F outside air NOTE: Change’Air reserves the right to make changes to air handler specifications without prior notice. The performance of each air handler may vary based on site conditions and installation. 3.0 Sophomore Series 3.3.2 Physical Data Table - Cabinet “P” 3.5, 4.0, 5.0 Ton SOPHOMORE “P” CABINET OPTIONS PRIMARY OR SUPPLEMENTARY ELECTRIC HEAT (E) HEATING HOT WATER COIL (H) OPTIONAL HEAT PUMP HEATING AIR SOURCE HEATING CAPACITY COOLING SELF-CONTAINED COOLING CAPACITY VALUE OR CAPACITY RELIEF FANS ECM AC CENTRIFUGAL FANS FILTERS SUPPLY DESIGNATION DESIGNATION Low Capacity(LC) 10KW 12KW 15KW 16” X 30”, 1 row 70 Mbtuh 16” X 32”, 2 row 110 Mbtuh 3.5 Ton 4.0 Ton 5.0 Ton Standard Capacity(SC) High Capacity(HC) Standard Capacity (SC) Standard Capacity (HC) Nominal 42 Mbtuh (AHP) Nominal 48 Mbtuh (AHP) Nominal 60 Mbtuh (AHP) Nominal 42 Mbtuh (RCI) Nominal 48 Mbtuh (RCI) Nominal 60 Mbtuh (RCI) High Capacity HC-D - 3/4 hp (2 fan bodies) 3.5 Ton 4.0 Ton 5.0 Ton SUPPLY FANS COMPATIBILITY TABLE 1800 cfm 2200 cfm Extra High Capacity XHC-D - 1 hp (2 bodies) 250 - 1600 cfm (2) 1” Disposable (2) 2” Disposable Relief fan option using condensing fans 18” x 18” 18” x 18” (2) Permanent Washable “B” “C” “D” “E” 18” x 18” YES YES YES SUPPLY VOLTAGES 208/3/60 208-230/1/60 277/1/60 460/3/60 HOT GAS REHEAT All Models YES YES ENERGY RECOVERY WHEEL (no economizer) All Models YES ENERGY RECOVERY WHEEL (with economizer) All Models YES AIR FLOW DESIGN Draw Through Heating WEIGHT 3.5 & 4.0 Ton 5.0 Ton YES 920 lb 950 lb All weights are calculated on the maximum available options. Performance: rated in accordance with AHRI Standard 390 (Formerly ARI Standard 390) 1 - Cooling capacity rated at standard conditions - 80/67°F indoor air, 95°F outdoor air 2 - Heating capacity rated at standard conditions - 70°F indoor air, 47/43°F outside air NOTE: Change’Air reserves the right to make changes to air handler specifications without prior notice. The performance of each air handler may vary based on site conditions and installation. Sophomore 3.0 Sophomore Series 3.4 Sophomore Series Packaged A/C and Air Source Heat Pump Classroom Air Handler (Raised Condenser Intake) Supply Fan Fig.4b The Sophomore Series raised condenser intake design achieves maximum efficiency through its many unique features. This self contained cooling system can easily be upgraded to an air source heat pump so that it can be used effectively in the heating season by reversing the refrigerant flow. If required, additional supplementary heat can be added with electric, hot water or steam making the Sophomore extremely flexible. Evaporator Coil Outside Air Damper Condensing Coil & Scroll Compressor Compartment Standard features include staged compressors, power relief of room air using the condensing fans and EC supply fan motor. Additional options available include an energy recovery wheel (ERW) with or without an outside air economizer damper, or hot gas reheat coil for dehumidification. C 3.5 Heating Options 3.6 Cooling Options AIR SOURCE HEAT PUMP The Sophomore Series (ASHP) has primary heating available through an air source heat pump. The capacities range from 2 to 5 ton and all units include quality two stage scroll compressors as standard equipment. Safety features included are an automatic high pressure switch, evaporator freeze protection and line dryers to ensure a long operating life. The Sophomore Series (RCI) has the self-contained A/C to achieve efficient cooling. The capacities range from 2 to 5 ton and all units include quality two stage scroll compressors as standard equipment. Safety features included are an automatic high pressure switch, evaporator freeze protection and line dryers to ensure a long operating life. Other features are items such as a condensing coil pre-filter along with optional stainless steel or insulated drain pans and other cooling upgrades. HOT WATER HEAT SOURCE: The hot water heating coil is constructed in an air over water configuration and provides either primary or supplementary heat by way of a fin tube water coil. Built to dependable, design conscious standards all our coils have a self closing bleeder to facilitate start-up. Valve packages are available factory installed for a simple site startup. ELECTRIC HEAT SOURCE: Electric heat source as primary or supplementary heat consists of multi-stage electric resistance elements offered in several voltage/phase and kilowatt configurations. They come integral to the unit and are located on the leaving side of the evaporator. 3.7 Power Relief The Sophomore Sereis includes the option of using the condensing fans as power relief for stale room air. The balancing dampers direct airflow from the room out through the condensing fans at the same rate as the supply fan is drawing outside air into the unit. The condensing fans operate at multiple adjustable speeds and in mechanical cooling operation the mixed room and outside air being drawn across the outside air coil moderate the temperature adding efficiency to the system. 3.8 Energy Recovery An energy recovery wheel is available as an option and compatible with all other features. It is a 19” diameter wheel 1" or 2” thick and is available with or without an outside air damper providing additional un-recovered fresh air or economizer cooling when applicable. A typical application of 450cfm would have an effective recovery rate of 63.8% in cooling season and 66.4 % in heating season. 3.0 Sophomore Series Sophomore 3.9 ASHP Energy Recovery Wheel Energy recovery wheels (ERW) rotate through both the outside incoming air stream and the relief air stream. As the wheel rotates, it transfers a portion of the sensible and latent energy from one air stream to the other. As a result the incoming air stream is pre-conditioned reducing the thermal gradient across the conditioning equipment thereby reducing energy consumption. Fig.4c Supply Air Summer Conditions Supply Air Outdoor Air 95°F DB 78°F WB 81°F DB 68°F WB Cooling Coil Mixed Air Return Air Relief Air Outside Air Damper (on Energy Recovery Wheel Section Only) 89°F DB 73°F WB 75°F DB 63°F WB Heating Coil Energy Recovery Wheel Outside Air Fig.4d Exhaust/Relief Air Winter Conditions Supply Air 53°F DB 40°F WB Outdoor Air 7°F DB 6°F WB Condenser Coil Return Air Return Air 72°F DB 54°F WB Relief Air Floor Level 27°F DB 20°F WB Ground Level Effectiveness (%) SCFM 350 S L T Clg 74.1 66.1 69.6 ΔP T Htg (in.w.c) 71.2 0.42 400 72.1 64.1 67.7 69.2 0.48 450 70.1 62.1 65.7 67.2 0.54 Rated in accordance with ARI Standards 1060 Manufactures Recommended Cleaning Wash the segments or small wheels with a non-acid based (evaporator) coil cleaner or alkaline detergent solution. Non-acid based coil cleaner such as KMP Acti-Clean AK-1 concentrate in a 5% solution has been demonstrated to provide excellent results. Do not use acid based cleaners, aromatic solvents, temperatures in excess of 170 °F or steam; damage to the wheel may result. Soak in the cleaning solution until grease and tar deposits are loosened. An overnight soak may be required to adequately loosen heavy deposits of tar and oil based contaminants. NOTE: Change’Air reserves the right to make changes to the specifications without prior notice. The performance may vary based on site conditions and installation.