0 to 25 Percent Manual Fresh Air Hood

advertisement

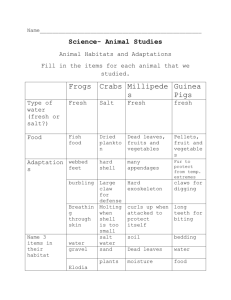

Installer's Guide Customer Propety: Contains wiring and service information. Please retain. DMPR-IN-28F 18-HE60D26-5 Library Service Literature Product Section Unitary Product Model Unitary Accessories Econs, Dmprs, Motors, Low Ambient Literature Type Installer's Guide Sequence 28F Date File No. June 1999 SV-UN-ACC-DMPR-IN-28F 06/99 Supersedes Models : Used With: BAYDMPR029C TCD036-300 TCH048-300 YCD036-300 YCH048-300 WCD036-240 WCH048-240 DMPR-IN-28E 0-25 % Manual Fresh Air Hood General Information The manual fresh air adjustment panel with the hood is designed to provide up to 25 percent outside air. Once the adjustable panel is set and the hood is installed, they will allow a fixed quantity of outside air to be introduced into the conditioned space. Shipping Inspection Visually inspect for shipping damage when it arrives. If damage is evident, file a claim with the carrier immediately. Specify the type and extent of the damage on the "bill of lading" before signing. Inspect the components for concealed damage as soon as possible after delivery, before it is stored. Concealed damage must be reported within 15 days. If concealed damage is discovered, stop unpacking the shipment. Do not remove damaged material from the receiving location. Take photos of the damage, if possible. The owner must provide reasonable evidence that the damage did not occur after delivery. Notify the carrier’s terminal of damage immediately by phone and by mail. Request an immediate joint inspection of the damage by the carrier and the consignee. Note: Do not attempt to repair any damaged parts until the parts are inspected by the carrier’s representative. Open and lock the unit disconnect switch before installing this accessory. Failure to do so could result in severe injury or death due to electrical shock or contact with moving parts. Installation Table 2 Maximum Fresh Air CFM Unit YC,TC(D,H) 103, 103 YC,TC,WC(D,H) 120, 121 YC,TC,WC(D,H) 150, 151 YC,TC,WC(D,H) 180 YC,TC(D,H) 181, 210, 211 YC,TC,WC(D,H) 240, 241 YC,TC(D,H) 300 1. Open the unit disconnect switch. 2. Remove screws securing the fresh air adjustment panel to the unit's end panel. 3. Adjust the amount of fresh air desired by changing the position of the fresh air panel. Refer to Table 1 to determine the correct opening for the specified amount of fresh air, based on the operating return static pressure. 4. Secure the fresh air adjustment panel to the unit end panel with 2 screws.(Remaining screws to be used in step 8.) Max CFM 850 1000 1250 1500 1750 2000 2500 Note: Install the filter/mist eliminator with the arrow pointing in the direction of the airflow. The filter/mist eliminator can be taken out for cleaning by removing the screws installed in step 6. 5. Using the provided screws, assemble the fresh air hood, as illustrated in Figure 1. 7. Install the provided gasket onto the hood mounting flange. 6. Install the filter/mist eliminator into the fresh air hood and secure it in place using three screws in each side, as illustrated in Figure 1. 8. Install the fresh air hood onto the end panel of the unit using the six screws removed in step 2, as illustrated in Figure 1. Table 1 Fresh Air CFM vs. Return Static Pressure 9. Close the unit disconnect switch and start the supply fan. (036-060) Manual Fresh Air Accessory Airflow Inches Return Static -- inch W. G. Open -0.05 -0.1 -0.2 -0.3 -0.4 -0.5 -0.6 -0.7 1 70 100 120 160 190 230 280 270 2 140 200 240 330 380 460 570 550 3 200 270 330 450 520 600 740 730 4 250 330 420 560 650 750 900 910 5 300 390 510 680 790 890 6 350 450 600 790 920 6½ 380 490 650 860 1000 Do not operate Do not operate 3 or 4 ton 3 ton in this area. in this area. To prevent injury or death from electrocution or contact with moving parts, it is the responsibility of the technical to recognize these inherent hazards and use extreme caution when performing service procedures with the electrical power energized. 10. Measure the full load amps of the supply fan motor. If the amperage exceeds the motor nameplate value, system CFM may be too high. Make the necessary adjustments to lower the motor amperage to the nameplate value, by; readjusting the fresh air damper or adjusting the fan RPM. (061-091) Manual Fresh Air Accessory Airflow Inches Return Static -- inch W. G. Open -0.05 -0.1 -0.2 -0.3 -0.4 -0.5 -0.6 -0.7 1 110 160 190 260 300 370 380 440 2 200 260 350 440 530 600 640 740 3 280 360 500 530 750 830 900 1040 4 340 440 600 790 930 1040 1140 1280 5 400 530 700 960 1100 1250 1370 6 450 640 890 1120 1300 1460 7 500 760 1080 1270 1500 w/Open 520 780 1120 1320 Do not operate 6 ¼ ton in this area. Figure 1 YC,TC(D,H)102-300 (8.5-25 Tons) WC(D,H)102-240 (8.5-20 Tons) Manual Fresh Air Accessory Airflow* Inches Open 1" 2" 3" 4" 5" 6" 7" W/Open Return Static -- inch W. G. -0.1 -0.2 -0.3 -0.4 -0.5 -0.6 80 159 195 221 277 292 197 296 361 415 498 511 318 432 528 610 720 731 431 569 694 804 941 950 471 680 830 959 1086 1174 511 791 965 1113 1231 1398 598 910 1095 1268 1422 1592 707 1058 1258 1462 1661 1835 -0.7 352 586 819 1053 1289 1525 1731 1989 -0.8 383 636 890 1143 1401 1659 1886 2170 -0.9 378 656 933 1211 1458 1705 1958 2275 -1.0 438 717 997 1276 1573 1870 2115 2422 * Before utilizing CFM’s listed in the shaded area, refer to Table 2 for maximum allowable fresh air for the unit. © American Standard Inc. 1999 Technical Literature Printed in USA 2