265634-UAI-A-0906

YKIEC18

ACCESSORY KIT INSTALLATION INSTRUCTIONS

ECONOMIZER DAMPER AND HOOD

MODELS 2EE04702024 / 2EE04703824 / 2EE04703924

2MD04702524 / 2MD04702624 / 2MD04702824 / 1EH0411 / 1EH0412

FOR 15, 17.5, 20, AND 25 TON ROOFTOP UNITS

General

This instruction provides the necessary information to

properly field-install economizer dampers and hood

assembly on 15, 17 ½, 20 and 25 ton single package

rooftop units.

The damper accessory provides the return air and outdoor

air dampers and actuator for economizer operations.

Contained in this kit are all rain hood components.

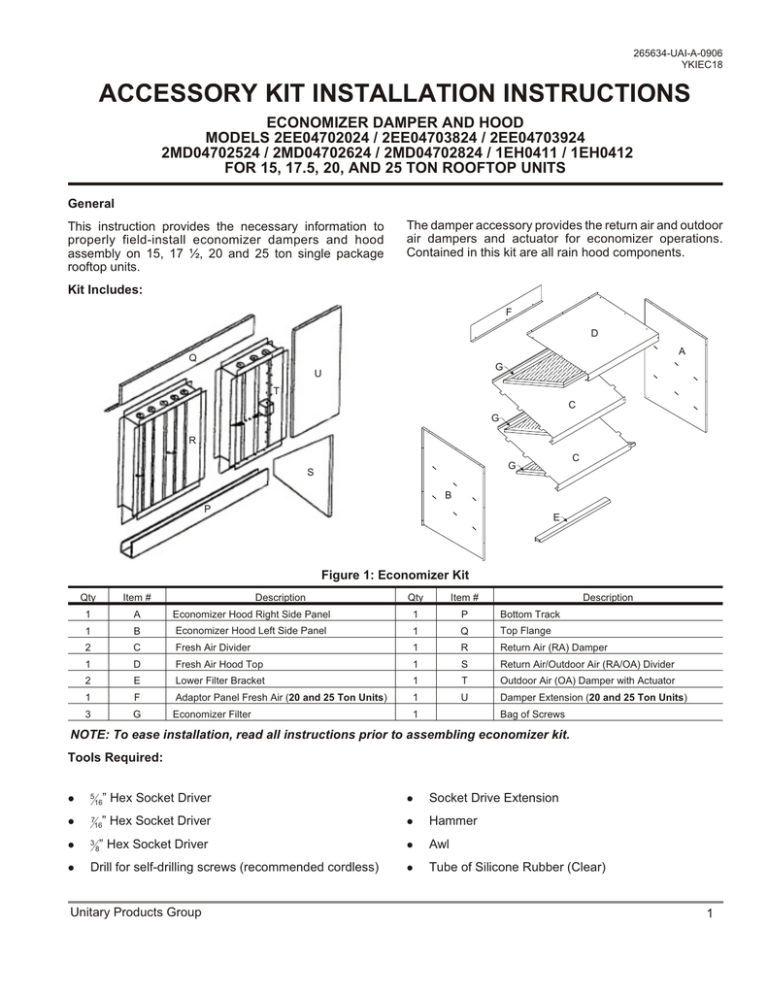

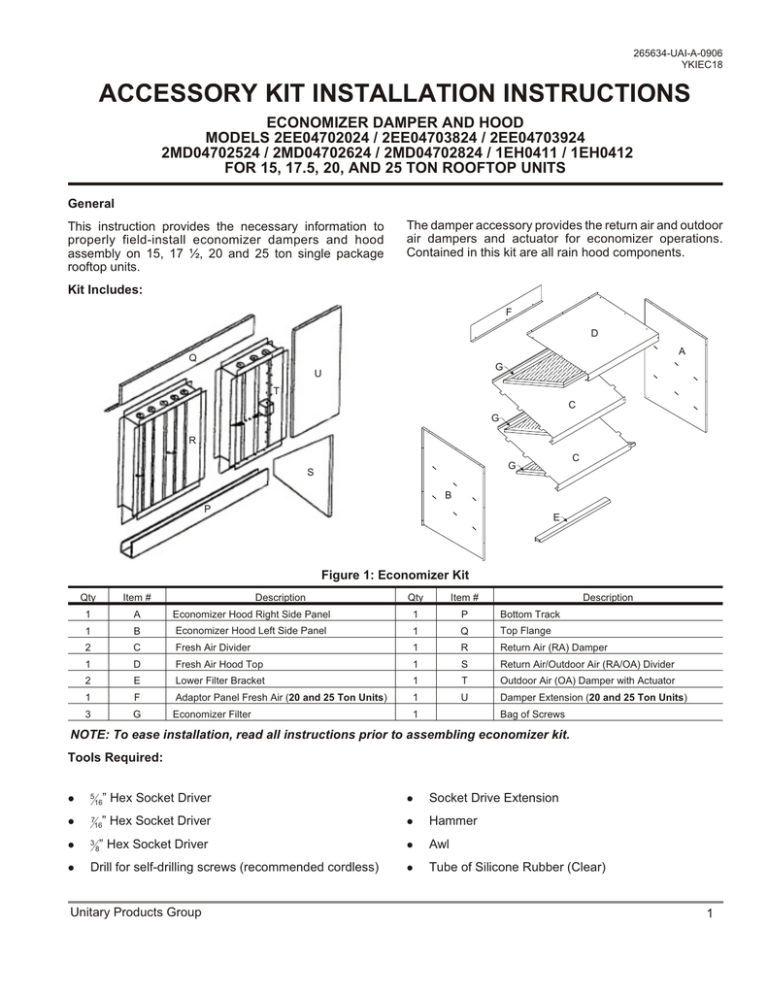

Kit Includes:

F

D

A

Q

G

U

T

C

G

R

C

G

S

B

P

E

Figure 1: Economizer Kit

Qty

Item #

Description

Qty

Item #

Description

1

A

Economizer Hood Right Side Panel

1

P

Bottom Track

1

B

Economizer Hood Left Side Panel

1

Q

Top Flange

2

C

Fresh Air Divider

1

R

Return Air (RA) Damper

1

D

Fresh Air Hood Top

1

S

Return Air/Outdoor Air (RA/OA) Divider

2

E

Lower Filter Bracket

1

T

Outdoor Air (OA) Damper with Actuator

1

F

Adaptor Panel Fresh Air (20 and 25 Ton Units)

1

U

Damper Extension (20 and 25 Ton Units)

3

G

Economizer Filter

1

Bag of Screws

NOTE: To ease installation, read all instructions prior to assembling economizer kit.

Tools Required:

” Hex Socket Driver

l

Socket Drive Extension

” Hex Socket Driver

l

Hammer

l

Awl

l

Tube of Silicone Rubber (Clear)

l

5

l

7

16

l

3

l

Drill for self-drilling screws (recommended cordless)

16

” Hex Socket Driver

8

Unitary Products Group

1

265634-UAI-A-0906

YKIEC18

Damper Assembly Procedures

CAUTION

When installing dampers, use care to avoid damage

to filters or coils located in the adjacent

compartment.

1. Remove the four access panels (two OA, one RA, and

one filter shown in Figure 2) by using a 716" hex socket

to loosen he screws securing the rotating latches and

a 516" hex socket to remove the four screws on the

bottom of each panel.

Figure 4: Panel Latch

Note: Retain the "O" rings which provide the seal

between the panel and unit bottom.

WARNING

RETURN AIR ACCESS DOOR

If the return air duct cover has been removed, install

a covering over the open hole to prevent personal

injury or equipment damage.

2. Remove the support brackets on 20 and 25 ton

rooftop units.

FILTER ACCESS

DOOR

FRESH AIR ACCESS DOOR

Figure 2: Rooftop Unit

Figure 5: Removing Support Bracket

Figure 3: Installed Components

2

l

Use a 516" hex socket to remove the top screws

securing the support bracket located between the

return air and outdoor air compartments.

l

Use a 516" hex socket to remove the top screws

securing the corner support bracket.

Unitary Products Group

265634-UAI-A-0906

YKIEC18

l

Use a 3 8" hex socket to remove the two inside top and

bottom screws. Save the screws and bracket for

installation later.

CAUTION

l

Position the bottom track so that clearance holes in the

bottom track can match the unit hole pattern. Use and

awl to align the holes.

4. Remove the RA Damper and the top flange from their

packing materials.

Lift the roof when removing the support bracket to

prevent tearing the roof seal.

Figure 8: Installing Top Flange

Figure 6: RA Duct and Screw Locations

l

Remove the RA duct panel covering the RA opening if

it has not already been removed by the installing

contractor.

5. Install the RA Damper:

l

Inside the top lip, align the holes of the top flange with

the holes in the lip.

l

Use the self-drilling screws provided to secure the top

flange to the lip. Install the screws from outside the unit

as shown in Figure 8.

3. Install the bottom track:

l

Refer to Figure 6 and remove the 8 screws for 15

tons or 11 screws for 20 and 25 ton units, securing

the drip and bottom pans along the bottom inside of the

unit. Save the screws for installation later.

Figure 9: Connecting Linkage

Figure 7: Installing Bottom Track

Unitary Products Group

l

Remove the nuts attached to the swivel ball joints on

the linkage arm. Retain for future use.

l

Align the two swivel ball joints attached to the linkage

arm with the crank arms attached to the RA damper

blades.

l

Insert the swivel ball joints into the top holes of the

crank arms and secure with nuts.

3

265634-UAI-A-0906

YKIEC18

l

Use two 716" wrenches to tighten and secure the swivel

ball joints.

6. Install the OA Damper:

l

Remove the outdoor air damper from the packing

material.

Figure 10: Installing Return Air Damper

l

With the identification label facing up in the lower left

corner of the damper, position the lower edge of the

damper on the bottom pan.

l

Slide the RA Damper on the edge of the bottom pan

until the bottom flange of the damper is past the bottom

track.

l

Lift the RA Damper up past the top flange and pull the

RA Damper towards you until the damper is positioned

in the bottom track.

l

Rest the RA Damper on the top flange.

Figure 13: Installing OA Damper

l

With the identification label facing up in the lower left

corner of the damper, set the bottom of the OA damper

into the bottom track from the filter access area.

l

Lift the top of the OA damper up past the top flange and

push the damper towards the RA damper along the

bottom track, and rest it on the top flange.

Figure 14: Initial Damper Frame Alignment

l

To aid the installation of the damper assembly, slide

the OA damper to the left until the frame overlaps the

RA damper frame as shown in Figure 14.

Figure 11: Positioning Return Air Damper

l

Slide the RA Damper to the left until the seal contacts

the heating compartment wall.

Figure 12: Securing Damper to Top Flange

l

4

Fasten the Damper to the top flange using pilot holes

and self-drilling screws provided. Refer to Figure 12.

No fastening to the bottom track is required.

Figure 15: Re-Installing Center Support Bracket

Unitary Products Group

265634-UAI-A-0906

YKIEC18

7. On 20 and 25 ton units install the two support

brackets previously removed.

Note: At this time, the RA and OA damper frames will

not overlap.

l

CAUTION

Fasten the OA damper to the top flange using the

self-drilling screws and pilot holes provided. Use an

awl to align the holes.

Lift the roof when installing the support brackets to

prevent tearing the roof seal.

l

Align the bottom holes, lift the roof and rotate the

bracket to a vertical position.

l

Use the screws previously removed from each bracket

to secure.

8. Securing the OA Damper:

Figure 19: Connecting Linkage Rod

l

Remove and keep the nut attached to the swivel ball

joint on the linkage arm.

l

Align the swivel ball joint attached to the actuator

linkage arm with the crank arm attached to the damper

blade. This procedure will open the RA damper blades

while the OA damper blades will remain in the closed

position.

Figure 16: Foam Tape Installation Location

l

Using the 18" foam tape supplied, measure and cut a

length that will fit the long edge of the damper frame

that will rest against the access panel.

Note: FOR 25 TON Units, Attach Damper Extension

Arms (provided) to the Actuator Crank Arm and

Outdoor Damper Pivot Arm.

l

Insert the swivel ball joint into the bottom hole of the

crank arms and secure with nut.

l

Use two 716" wrenches to tighten and secure the swivel

ball joint.

Figure 17: Positioning OA Damper

Figure 20: Flange Screws

Figure 18: Damper Frame Alignment

Unitary Products Group

5

265634-UAI-A-0906

YKIEC18

9. Use a 516" driver to remove the 2 screws located in the

floor flange between the return air and outdoor air

compartments and save for future use.

l

Use 4 self-drilling screws to secure the RA/OA divider

to the RA damper frame using the pilot holes provided.

l

Fill the gap at the base of the divider with ¾” foam tape

provided.

l

On single enthalpy units, mount the enthalpy sensor to

the metal surface on the RA/OA divider. On dual

enthalpy units, mount the second enthalpy sensor on

the opposite surface in the return air. Use two

self-tapping screws to secure.

Figure 21: Applying Tape to Divider

10. Install the RA/OA divider:

l

Remove the return air/outdoor air divider from its

packing material.

l

Using the 18" foam tape supplied, apply a length that

will fit on the diagonal edge of the RA/OA divider.

Figure 23: Installing Cable Assemblies

11. Mounting Sensors and wire harness:

l

Cut the wire tie securing the cable harness to the

damper.

l

Insert the 15 pin connector to the unit economizer plug

near the filters.

Figure 22: Installing Divider

l

Use the 2 screws removed in step 9 to secure the

RA/OA divider to the floor flange.

l

Use two self-drilling screws to secure the OA/RA

divider to the support bracket.

6

Figure 24: Routing Cables

Unitary Products Group

265634-UAI-A-0906

YKIEC18

l

Uncoil the remaining wiring harness and route through

the round hole in the top flange. Allow the wires to hang

in the OA compartment.

l

Locate the discharge air sensor mounting location on

the heating section wall. Mount the sensor bracket

provided using one self-tapping sheet metal screw.

Figure 25: Component Location on RA/OA

TABLE 1: Sensor Connection Table

Sensor Type

(Terminal)

Figure 27: Grommet Installation Locations

15, 17.5, 20 and 25

Ton Units

(Wire Color)

Logic Module

(Terminal)

PURPLE

+o

l

Insert the wire harness into split grommets and push

the grommets through each hole that the wires pass.

l

Use tie wraps to bundle the wires and secure to the top

flange and RA/OA divider as shown in Figure 24 on

page 6.

Enthalpy

O.A. (+)

l

O.A. (-)

RED

So

R.A. (+)

BLUE

+R

R.A. (-)

ORANGE

SR

Discharge Air

Temperature

2 Leads

T

T1

Make all wiring connections as shown in Table 1.

IMPORTANT

When using the wire harness, insert a loop between

the two tie wraps so that the wire harness does not

rub on the damper frames during operation.

Figure 28: Installing Blank-Off Section

Figure 26: Installing Discharge Air Sensor

Unitary Products Group

7

265634-UAI-A-0906

YKIEC18

12. For 20 and 25 ton units only:

l

Remove the blank-off section from the packaging.

l

Using the 18” foam tape supplied, apply a length that

will fit on the long edge of the blank-off section which

contacts the access panel.

l

Insert the blank-off section through the side access

opening of the OA compartment.

l

Use the pilot holes on the top flange for the self drilling

screws provided to secure the top of the blank-off

section to the top flange.

l

Install ¾” foam tape around the cut-out for the vertical

support bracket.

13. Damper Assembly is now complete. Proceed to the

hood assembly instructions.

Note - Place 18 x ½ gasket as shown in Figure 29 to both

side panels (A,B) before installing.

3. Install the economizer hood right side panel (A)

aligning the matching holes in flange with the holes on

the right side of fresh air access door. Insert and fasten

five screws supplied with the hood kit. Use a 516" drive

to tighten screws. See Figure 29.

4. Install the economizer hood left side panel (B) aligning

the matching holes in flange with the holes on the right

side of fresh air access door. Insert and fasten five

screws supplied with the hood kit. Use a 516" drive to

tighten screws. See Figure 29.

5. Remove the packing materials from parts. Align lower

filter bracket (E) holes against inside of hood right side

panel (A) and hood left side panel (B). Secure with

#10-½" x 16 screws provided. See Figure 29.

Economizer Hood Assembly Procedures

Note - To ease installation, read all instructions prior

to assembling economizer hood kit.

CAUTION

Care must be take when using cordless drivers that

the screws do not strip the metal take holes.

A

LOCATION OF GASKET

FRESH AIR ACCESS DOOR

LOCATION OF GASKET

B

C

C

A

Figure 30: Installing Divider Panels

Note - Place 18 x ½ gasket as shown in Figure 30 to both

hood sides over slots where fresh air dividers

(C) are inserted.

B

COVER PANEL REMOVED

E

Figure 29: Installing Economizer Hood Side Panels

1. Remove the cover panels by using a 516" hex drive to

remove the screws securing the cover panels. See

Figure 29.

2. Remove the economizer hood parts from the inside of

fresh air section of unit and remove the packing

materials from parts.

8

6. Remove the packing materials from parts. Insert upper

fresh air divider panel (C) between hood right side

panel (A) and hood left side panel (B). See Figure 30.

7. Align tabs of divider panel (C) and insert into slots in

hood right side panel (A) Repeat for hood left side

panel (B). See Figure 30.

Note - Do Not forget the gasket material that should

have been applied before Step 4.

8. Repeat Step 6 and 7 for installing upper fresh air

divider panel (C). See Figure 30.

Unitary Products Group

265634-UAI-A-0906

YKIEC18

11. Take the fresh air access door with hood assembly

and place back in position and secure in place with

hardware removed in Step 1. See Figure 32.

LOCATION OF GASKET

D

A

C

D

F

B

G

C

B

BEND TABS DOWN

G

G

Figure 31: Installing Fresh Air Hood Top

Note - Place 18 x ½ gasket as shown in Figure 31 to

flange that are against the unit on fresh air hood

top (D) before installing.

9. Place fresh air hood top (D) over hood right side panel

(B) and secure with #10-½" x 16 screws provided. See

Figure 31.

10. Bend tabs down on divider panels (C) either by hand or

gently tapping with a rubber mallet. This must be done

to assure the hood structure. See Figure 31.

Figure 33: Installing Adaptor Panel & Filters

12. Install adaptor panel fresh air (F) under unit top panel

and over the flange of the fresh air hood top (D).

Secure with two #10-½" x 16 screws provided. See

Figure 33. (20 & 25 Ton Units)

13. Seal all seams and edges with silicone caulk (not

provided).

14. Install the economizer filters (G) inside the three

sections of the economizer hood assembly. See

Figure 33.

D

A

C

B

C

Figure 32: Installing Assembled Fresh Air Hood

Unitary Products Group

9

265634-UAI-A-0906

YKIEC18

10

Unitary Products Group

265634-UAI-A-0906

YKIEC18

Unitary Products Group

11

Supercedes: 035-19854-000-B-0105

Subject to change without notice. Printed in U.S.A.

Copyright © by Unitary Products Group 2005. All rights reserved.

Unitary

Products

Group

265634-UAI-A-0906

YKIEC18

5005

York

Drive

Norman

OK

73069