Document

advertisement

*

I

I

q

t

1

I

By David Phillips,

Heyl & Patterson lnc.

ecause an industrial dryer is a

major capital investment lor any

organization,

it

pays

to

select

and test the unit carefully. Dryer life can

be measured in decades, so the selection

of inefficient equipment can have a longterm impact on the economic health of

the facility that houses it. The selection

of drying equipment is predominantly

an exercise in which knowledge, experience and science all play important roles.

of the complexitv of the drying

many

factors need to be considprocess,

Because

ered and weighed.

Before choosing an industrial dryer, con-

duct a preliminary analysis of your drying

needs. Ask questions about your material,

the production and final product quality

requirements, and your plant.

Think about the characteristics of the material to be dried. ls it wet or dry? What is

the particle size distribution? A material's physical or handling characteristics will

eliminate some dryers from consideration.

www.process-heating.com

. June 2013

|

27

Material. \\'hrrt ule rh., nr.rreri.rl's plrlsirrei ,,r tlrIi \\'lt.rt

is rhr prrrticlc sizc clisrribrrtionl I: rlre nrar.,rirri toric, ilrrnrrrrrtble. corrosir r' ,,r' .r1-i rr:ir e?

Drying Requirements. is rh. nr.rrcr.i.rls

nr()i\tLlr( briirnrl (chenr icallr' rr.rIlre.l i nri.]e

rlre P111j61111. rrn[rorrnrl 1n()t ilttirLlle(l t()

rlre p.rrriele', nhiclr is rrlso crrlletl lree

Ill()i\lLlt('l or ltotlr: \\'hrrt.r|e rhc nt.rterirrl's

initirrl .rn.1 linrrl nroistLrre corrr(lrrs? \\'llrr

lrr' ilr(' nr.i\rnrLur perntissible rlli inq Lcnt,

periltLlre.trlLl |111111111. cllving rirtrc liir thc

nrrrrrri.rli \\ lr.ri I' rltc tlrlinq ctrrvr: \\'i]l

tlrc tlrr irrg ri nr|!'r.1tLlrr ne('(1 to ilLrctu,rrc

rni.11,.,, lrrr ,.r- . r.. .lr,'rr,1 l'r,,.r'.,:

Production Requirements. l)ocs

c.t] ehar,rcrcristics rrh.'rt

I

t':,

rd

F,

st

tl

it

I

fq

iH

t J.-

$t

!'-

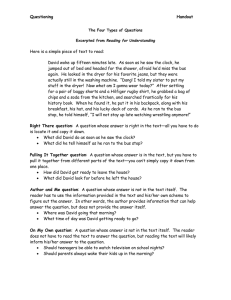

When sele Ct ing a new dryer, consider whether existing ancillary items can handle the

pacity.

ncrea sed

i

f

rH /iJ } l r i" l;i f 2t; r -f;jil..

,r."H li.,;**-i r f { }.:; ;/i*: "f i,

a"$FWl

{euir-.

h,

!-a

.qb

H

@

o'

t

28

lLr

ne 2013.

,.

i1

*

6

U

rirc nr;ttclirrl nert] ro

1,c [..rtclt or eon,

pro.e"..i: \\ h.rr tlrL.rnrin of

nrlttcrirrl nlrr\r llr. .l rrir hrurtlle ;rer

IrriLrr'? \\'het rcl.nii()ir riir. ,r ill ,rchitvc

rr high-rluirlirr' f inrrl pr,,.1Lr.r: Hos u ill

tlre l.roccsscs bcf,rr. .rr.l .rlter rllvinq

lffcer thc rlrvt'r choii.l

rinr.rorrslr'

Final Product Quality Requirements.

(.rn tlre ntilrcriil] rltr inli. tlt,lr..rtle. or..r-

dry or become contaminated during drying? How uniform must its final moisrure content be?'lrhat should the final

product temperature and bulk density

be? W'ill the dried material give off dust

or require solvent recovery?

Plant. How much space is available in

the plant? How warm, humid and clean is

the plant air?'$7hat fuel and power sources,

wet feed sources and exhaust gas outlets are

available in the plant? 'What levels of noise,

vibration, dust and heat loss are permis-

in the plant according to local zoning

and environmental regulations?

By answering these questions, vou rvill

rule out many dryers that are not suitable

for your application. For instance. a matesible

rial's physical or handling characteristics

will eliminate some dryers. A sterrm-tube

rotary dryer is not a good choice fbr a s'et,

sticky material such as mica. The dn,er

moves material by rotating and rolline it,

and such passive convevinq cannot move

a

sticky material our of the inlet area befbre

it cakes on the r.essel rvall and steam tubes.

A screw conveyor or indirect multiple

disc dryer is a better choice. Either unit

provides positive displacement that can

quickly move the mica away from the

inlet and toward the outlet.

Next, consider the footprint or

required floor space of the remaining

dryers that meet your requirements. Rule

out any dryer that does not fit the existing space or would require a costly plant

renovation or expansion. Compare the

capital and operating costs and performance of the remaining candidates.

If you are selecting a high-performance dryer ro upgrade your existing

drying process, consider whether existing ancillary items such as storage and

receiving equipment, conveyors and pollution control equipment can handle the

new dryer's increased capacity.

Once the field o[dryer choices has been

narrowed, test the dryers with your material under your operating conditions.

Dryer tests can be conducted in a pilot

plant lab faciliry and should establish:

.

The optimal operating conditions for

your material.

.

.

.

How well each dryer handles the material's physical characreristics.

The materialk qualiry and characteristics

after drying.

The appropriate dryer size.

Based

on these results, a dryer manu-

Facturer can develop detailed recommen-

dations for equipment that will meet

your drying needs. \With recommendations in hand, you can select a dryer

and drying options. Factors to discuss

include the dryer's installation and operating costs, the dryer's operation and

maintenance requirements. Pll

David Phillips is manager, marketing and

communications, at Heyl & Patterson lnc.,

Pittsburgh, a manufacturer of thermal processing systems, including rotary calciners

and dryers. For more information lrom Heyl

& Patterson lnc., call (412) 788-9810 or visit

www.heylpatterson.com.

MultiTherm's

Heat Transfer Fluids

Keep All Systems

Run your system more efficiently,

for longer periods, with less down time.

Make System Maintenance a Priority!

1-800-339-7549

www.process-heatrng.com. June

2013

|

29