Application Specification

114-106118

POWER TRIPLE LOCK (PTL)

Connector System

24 AUG 16 Rev F

NOTE

All numerical values are in metric units [with U.S. customary units in brackets]. Dimensions are in millimeters. Unless

otherwise specified, dimensions have a tolerance of ±0.13 and angles have a tolerance of ±2°. Figures and illustrations are

for identification only and are not drawn to scale.

For an overview of the PTL connector system, view the video on www.te.com.

1. INTRODUCTION

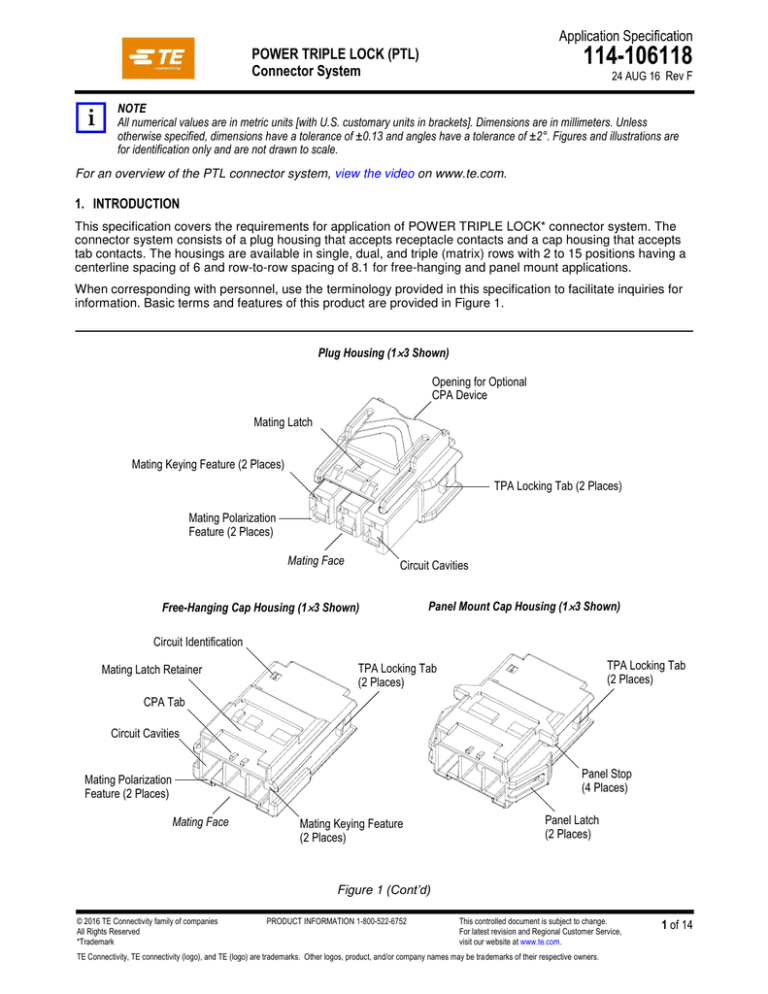

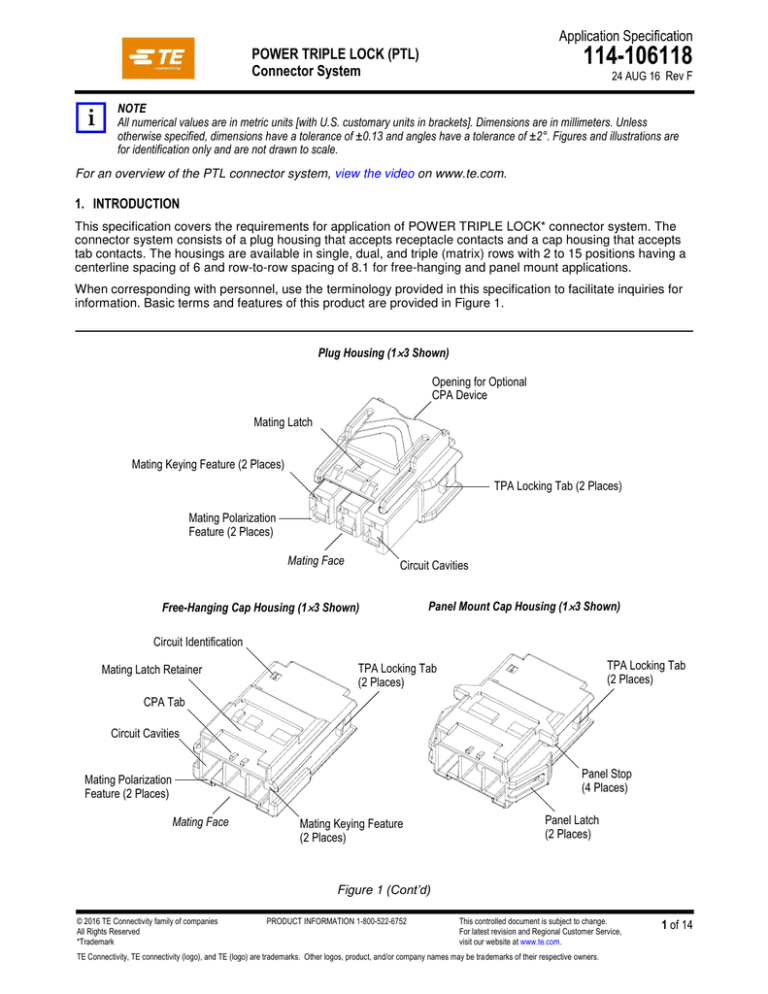

This specification covers the requirements for application of POWER TRIPLE LOCK* connector system. The

connector system consists of a plug housing that accepts receptacle contacts and a cap housing that accepts

tab contacts. The housings are available in single, dual, and triple (matrix) rows with 2 to 15 positions having a

centerline spacing of 6 and row-to-row spacing of 8.1 for free-hanging and panel mount applications.

When corresponding with personnel, use the terminology provided in this specification to facilitate inquiries for

information. Basic terms and features of this product are provided in Figure 1.

Plug Housing (13 Shown)

Opening for Optional

CPA Device

Mating Latch

Mating Keying Feature (2 Places)

TPA Locking Tab (2 Places)

Mating Polarization

Feature (2 Places)

Mating Face

Circuit Cavities

Free-Hanging Cap Housing (13 Shown)

Panel Mount Cap Housing (13 Shown)

Circuit Identification

Mating Latch Retainer

TPA Locking Tab

(2 Places)

TPA Locking Tab

(2 Places)

CPA Tab

Circuit Cavities

Panel Stop

(4 Places)

Mating Polarization

Feature (2 Places)

Mating Face

Mating Keying Feature

(2 Places)

Panel Latch

(2 Places)

Figure 1 (Cont’d)

© 2016 TE Connectivity family of companies

All Rights Reserved

*Trademark

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

1 of 14

114-106118

Optional Connector Position Assurance (CPA) Device

Optional Terminal Position Assurance (TPA) Device

(13 Shown)

Receptacle Contact

Tab Contact

Contact Stabilizer

Contact Stabilizer

Wire Barrel

Wire Barrel

Insulation Barrel

Side Key

Center Key

Mating End

Insulation Barrel

Side Key

Latch Opening

(Not Shown)

Mating End

Latch Opening

(Not Shown)

Figure 1 (End)

The housing features contact cavities each having a keying feature, mating polarization feature, a mating latch

(plug) or mating latch retainer (cap) that provides positive mating. The ribs surrounding the mating latch prevent

wires from becoming caught underneath the latch. The polarization feature prevents mating housings of

different sizes and keying configuration. The housings have a mating keying feature available in 4 configurations

(A, B, C, and D) to prevent mis-mating. The housings are also color coded for 4 available housing materials:

standard, high temperature, glow wire, and hot wire. In addition, the panel mount cap housing features panel

stops and flexible panel latches. In use, the panel latches secure the housing to a panel without the use of

mounting hardware.

Optional connector position assurance (CPA) device and terminal position assurance (TPA) device (also called

locking plate) are available to install onto the housing. These devices provide added security to ensure that the

mated housings remain together and ensure proper contact insertion and retention in the circuit cavities. The

CPA device prevents the plug housing mating latch from being accidentally depressed.

Each contact features a wire barrel, insulation barrel, contact stabilizer, and center key (plug) or side keys (tab).

The underside at the mating end of the contact has a latch opening that engages the housing contact cavity

latch and secures the contact to the housing. The key(s) only allow the contact to be inserted into the

associated housing.

2. REFERENCE MATERIAL

2.1. Revision Summary

Revisions to this application specification include:

Revised Figure 1 drawings to include rectangular stabilizer and proper width after crimping wire

Revised Figure 3. Changed Crimp height for 2238066 and 2238067. Show 0.70mm² wire is #19 AWG.

Revised Figure 3. Changed Detail A dimensions for Rear Bellmouth.

Section 2.4 added a reference to 408-143020 Instruction Sheet

Rev F

2 of 14

114-106118

2.2. Customer Assistance

Reference Product Base Part Number 1971779 (receptacle contact) and 1971238 (tab contact) and Product

Code L755 are representative of PTL connector system. Use of these numbers will identify the product line and

help you to obtain product and tooling information, which can be obtained by visiting www.te.com or by calling

the number at the bottom of page 1.

2.3. Drawings

Customer drawings for product part numbers are available from www.te.com. Information contained in the

customer drawing takes priority. Also available for this product is:

1969744

PTL Receptacle Contact Continuity Test Fixture Design Guidelines

1969745

PTL Tab Contact Continuity Test Fixture Design Guidelines

2.4. Instructional Material

Instructional material that pertains to this product is:

408-10389 Ocean Side-Feed Applicators 2151741-1, 2151742-1, 2151743-1, 2151744-1, 2151745-1,

and 2151746-1

408-32082 SDE-SA Commercial Hand Tools 2217266-1 and 2217267-1

408-32083 SDE-SA Commercial Hand Tool 2217268-1

408-32084 SDE-SA Commercial Hand Tool 2217208-1

408-32184 Guidelines for PTL Receptacle Contact Continuity Test Fixture Design and Probing

408-32187 Guidelines for PTL Tab Contact Continuity Test Fixture Design and Probing

408-32206 Re-Work Procedure for Power Triple Lock (PTL) Connector System

408-143020 Procedure for Vertical Force Testing PTL Cap Housings

409-5128

AMP-O-LECTRIC* Model “K" Terminator Machine 1-471273-2

409-5842

AMP-O-LECTRIC Model “G” Terminating Machines 354500-[ ]

409-10047 AMP 3K* Terminating Machines 1725950-[ ] and AMP 5K* Terminating Machines 1725900-[ ]

409-10099 AMP 3K/40* Terminating Machines 2119683-[ ] and AMP 5K/40* Terminating Machines

2119684-[ ]

2.5. Specifications

Product Specification 108-106118 provides product performance requirements and test information. When

mating single row Caps with POWER TRIPLE LOCK* PC Board headers refer to specifications 108-32090 and

114-32136

3. REQUIREMENTS

3.1. Storage

A. Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the product

material.

B. Shelf Life

Contacts are shipped on continuous reels and housings are supplied in plastic bags in cartons. The

product should remain in the shipping containers until ready for use to prevent deformation to components.

The product should be used on a first in, first out basis to avoid storage contamination that could

adversely affect performance.

Rev F

3 of 14

114-106118

C. Reels

When using reeled contacts, store coil wound reels horizontally. When storing partial reeled contacts, the

end of the strip should be secured to the flange using a wire tie or similar method.

D. Chemical Exposure

Product must not be stored near any chemical listed below as they may cause stress corrosion cracking in

the material.

Alkalies

Amines

Ammonia

Carbonates

Citrates

Nitrites

Phosphates Citrates

Sulfur Nitrites

Sulfur Compounds

Tartrates

NOTE

Contacts that contain brass must not be stored or used in environments where these chemicals exist.

3.2. Wire Selection and Preparation

The contacts accept 1 stranded copper wire sizes 0.34 to 3.30 mm2 [22 to 12 AWG] or 2 stranded copper wires

sizes 0.34 to 0.89 mm2 [22 to 18 AWG] with an insulation diameter range of 2.00 to 4.25.

Each wire must be stripped to the dimension given in Figure 2.

CAUTION

Care must be taken not to nick, scrape, or cut any part of the wire during the stripping operation.

Note: Not to Scale

4.5±0.3

Strip Length

Figure 2

3.3. Contact Crimp

A. Cutoff Tab and Burr

The cutoff tab is the remaining portion of the carrier strip after the contact is cut from the strip, and the

burr is the result from the cutoff tab shearing. The cutoff tab and burr must not exceed the dimension

given in Figure 3.

B. Wire Barrel Crimp

The crimp applied to the wire barrel portion of the contact is the most compressed area and is most critical

in ensuring optimum electrical and mechanical performance of the crimped contact. The crimp must be

centered on the closed wire barrel. The crimp must result in an “F” crimp where the wire barrel forms a

closed seam with no evidence of loose wire strands or wire strands visible in the seam. The crimp height

and width must be within the dimensions provided in Figure 3.

C. Insulation Barrel Crimp

The crimp applied to the insulation barrel of the contact must result in either an “F” crimp where the

insulation barrel forms a closed seam with no evidence of wire insulation in the seam or an overlap crimp

where the tips of the insulation barrel wraps overlap each other and wrap firmly around the wire insulation

without cutting into the wire insulation. The crimp height and width must be within the dimensions provided

in Figure 3.

Rev F

4 of 14

114-106118

D. Contact Stabilizer

The contact stabilizer must not be crimped or deformed in any way. The width of the stabilizer must be

within the dimension given in Figure 3. Otherwise, in addition to reducing the function of the stabilizer, a

deformed stabilizer will cause the TPA to be ineffective.

E. Wire Barrel Flash

Wire barrel flash is the formation that may appear on both sides of the wire barrel as the result of the

crimping process. It must not exceed the dimension provided in Figure 3.

F. Twist and Roll

There should be no twist or roll of the wire barrel or mating portion of the crimped contact that would

cause overstress or impair usage. See Figure 3.

G. Wire End Extrusion

The wire conductor ends must extend beyond the end of the wire barrel within the dimensions given in

Figure 3.

H. Bellmouths

The front bellmouth and rear bellmouth shall be evident and conform to the dimensions given in Figure 3.

Rev F

5 of 14

114-106118

Wire Barrel Seam (“F” Crimp) Closed with No Wire Strands Showing

Wire Conductors and Insulation

Visible Within This Area

0.1-1.5

Wire End Extrusion

Insulation Barrel

Width (See Table)

No Damage or Distortion

to Mating End

Wire Barrel Crimp Centered

on Closed Wire Barrel

Front Bellmouth 0.3 Max

(Except #22 AWG 0.5 Max)

X

Insulation Barrel Seam

(“F” Crimp Shown) (Refer to Table)

Stabilizer Width at Top:

4.50-5.20

See Detail A

Y

Insulation Barrel Height

(See Table)

X

See Detail B

Stabilizer Must Not Be Crimped

5.0 REF

Y

Detail A

SECTION Y-Y

Detail B

Rear Bellmouth

Wire Size Range (AWG)

0.2 - 0.5 Max

22-12 (1 wire)

0.2 - 0.6 Max

22-18 (2 Wires)

0.13 Max

Burr

0.51 Max

Cutoff Tab

Section X-X

Wire Barrel Crimp Width

(See Table below)

Avoid Twist and Roll

5° Max

0.13 Max

Wire Barrel Flash

Front of Contact

5° Max

Wire Barrel Crimp Height

(See Table)

Wire Barrel

Figure 3 (Cont’d)

Rev F

6 of 14

114-106118

CONTACT CRIMP (“F” Crimp Except Where Indicated OV—Overlap Crimp)

WIRE

USING HAND TOOL

Wire Barrel

NO. OF

SIZE

CONDUCTORS mm² [AWG]

0.34 [22]

0.56 [20]

0.70 [19]

1

0.80 [18]

INSULATION

DIAMETER

RANGE

Width

1.14-2.70

1.40

1.14-2.70

2.00-3.30

2.65-2.95

USING APPLICATOR

Insulation Barrel

Wire Barrel

Height

(Ref)

Width

Height

0.98

2.79

+0.03/-0.06

2.2

1.40

0.98±0.03

2.79

2.2

1.40

1.05±0.03

2.5

1.40

1.05±0.03

2.79

2.5

2.03

1.08

3.56 OV

+0.04/-0.08

2.5

2.03

1.08±0.04

3.56 OV

2.5

2.03

1.21

3.56 OV

+0.04/-0.08

2.7

2.03

1.21±0.04

3.56 OV

3.2

3.56

2.7

‡—‡

Height

‡—‡

Width

2.79

‡—‡

‡—‡

3.56

3.6

1.63±0.05

4.06

3.3

3.05

1.87±0.05

4.83

4.2

—

2.03

1.07±0.04

3.56 OV

4.0

4.7

2.03

1.28±0.04

3.05

4.7

2.29

1.48±0.05

3.3

1.37

3.56 OV

+0.04/-0.08

3.2

2.03

1.37±0.04

2.10 [14]

3.40-3.70

2.29

1.52

+0.05/-0.1

4.06

3.3

2.29

3.30 [12]

3.85-4.25

3.05

1.87

+0.05/-0.1

4.83

4.2

0.34 [22]

2.03 Max

—

—

0.56 [20]

2.40-2.70

2.03

1.28

3.05

+0.04/-0.08

2.29

1.40±0.10

0.80 [18]

2.69-2.99

(0.84 Thickness)

‡ 2.7 ‡

3.2

2.03

2.65-2.95

(0.76 Thickness)

Height

(Ref)

3.56 OV

3.00-3.30

—

Width

‡ 2.03 ‡ ‡ 0.99±0.03 ‡ 3.56 OV ‡

1.27 [16]

2

Insulation Barrel

4.9

3.3

4.9

5.0

5.0

For contacts 1971783 and 1971784. Refer to product customer drawing for minimum cross-sectional area (CMA).

‡ For contacts 2238066 and 2238067. Crimp Height shown applies to all wire types except #18 UL3071, UL3173 and UL3252 which are to

have a Crimp Height =1.07+/-0.05.

Figure 3 (End)

I. Mating End

There must be no damage or distortion to the mating end of the contact. See Figure 3.

J. Wire Location

All conductors must be held firmly inside the wire barrel. No strands can be folded back over the wire

insulation. The wire insulation must be inside the insulation barrel, but must not enter the wire barrel.

The wire conductors and insulation must be visible within the area between the wire barrel and insulation

barrel as shown in Figure 3.

K. Contact Length

The contact length measured from the front of mating end to the back of the contact stabilizer (not

including the carrier strip cutoff tab) must be within the dimensions given in Figure 4.

NOTE

Exceeding the contact length given may prevent the TPA from engaging the housing.

Rev F

7 of 14

114-106118

Contact Length (After Crimping)

16.80+0.50/-0.10

Contact Stabilizer

Receptacle Contact

Datum Line

0.80±0.10 Ref

12.00+0.50/-0.10

Tab Contact

Contact Stabilizer

Datum Line

0.80±0.10 Ref

Figure 4

L. Bend Allowance

The bend allowance between the wire barrel and cable is acceptable within the limits given in Figure 5.

Side-to-Side Bend Allowance

3° Max

Datum Line

Ref

3° Max

Up-and-Down Bend Allowance

1.5° Max

Datum Line

(Bottom of Wire Barrel)

1.5° Max

Ref

Figure 5

3.4. Keying

A. Contact Keying

The key(s) of the contact must match the contact keying feature of the circuit cavity to allow insertion into

the associated housing.

B. Housing Mating Keying Feature

Only plug housings and cap housings with identical keying configuration will mate; for example, key A will

only mate with key A, etc. The TE Connectivity customer drawing provides keying configurations.

Rev F

8 of 14

114-106118

3.5. Contact Insertion and Extraction

A. Insertion

Each contact must be aligned with the appropriate circuit cavity from the wire end of the housing so that

the contact key(s) faces the housing mating latch (plug housing) or latch retainer (cap housing) for the first

and third rows, and for the second row, the contacts must be inverted. The orientation of the contacts

must alternate from row to row. Refer to Figure 6.

The contact must be inserted into the circuit cavity until the contact internal latch locks onto the circuit

cavity locking finger. See Figure 7.

NOTE

Gently pulling on the wire after the contact has been inserted will ensure that the contact is locked.

Note: For clarity, the optional TPA device and contacts

are shown outside of the housing.

Wire End of

Plug Housing

(23 Shown)

Mating Face of

Panel Mount

Cap Housing

(23 Shown)

Circuit

Identification

Side Keys of

Tab Contact

Latch Retainer

Mating

Latch

Optional

CPA

Locking Latch

(2 Places)

Center Key of

Receptacle Contact

Panel Stop

(4 Places)

Circuit

Identification

Optional

TPA

Optional

TPA

Locking Latch

(2 Places)

Panel Latch

(2 Places)

Keying Feature

(2 Places)

TPA Locking

Tab (2 Places)

TPA Locking Tab

(2 Places)

Polarizing Feature

(2 Places)

Figure 6

Cross-Section of Contact Insertion

Contact Internal Latch Locked onto

Circuit Cavity Locking Finger (Ref)

Contact Cavity

Housing Row 1

Wire

Housing Row 2

Note: Contacts in Row 2 are inverted

as compared to rows 1 and 3

Housing Row 3

Figure 7

Rev F

9 of 14

114-106118

B. Extraction

If the optional TPA device is used, the contacts cannot be removed until the TPA is removed from the

housing. Contacts must be removed individually from the housing using the extraction tool given in

Paragraph 5.4 and the instructions for removing a contact given in 408-32206. After extraction, the

contact must be inspected for damage or deformation; if evident, the contact must be replaced.

NOTE

If the contact has been pushed or pulled out of the housing, the rework procedure given in 408-32206 must be followed.

3.6. Optional TPA and CPA Devices

An optional TPA device is available for the plug housing and cap housing, and an optional CPA device is

available for the cap housing.

The following requirements apply for installation (refer to Figure 6):

NOTE

All contacts must be inserted before the devices can be installed into the housing.

— The CPA device must be fully inserted into the opening at the top of the wire end of the plug housing

until the latch engages the plug housing. There should be an audible click. After installation, the tips of the

legs must be visible at the top of the mating face of the plug housing.

— The TPA device must be installed onto the wire end of the housing so that the latches are secure to the

housing TPA locking tabs. There should be an audible click. If the latches do not reach the locking tabs,

this indicates that one or more contacts has not been fully inserted or the contact internal latch has not

locked onto the circuit cavity.

The following requirements apply for removal (refer to Figure 6):

— The CPA device must be removed by depressing the tips of the legs, and sliding the CPA device out of

the housing.

— The TPA device must be removed by lifting each latch so that it clears the housing TPA locking tab,

and pulling the TPA device straight from the housing.

3.7. Continuity Testing

For continuity testing of the housing, design guidelines for the test fixture and pogo pin (probe) must be

considered (refer to Paragraphs 2.3 and 2.4); otherwise damage to the contacts may occur.

All contacts must be inserted and locked into the housing prior to placing the housing into the test fixture.

To avoid deformation to the contact, it is extremely important to ensure specific probe location. See Figure 8.

Plug Housing

Cap Housing

See

Detail

See

Detail

Detail

Circuit

Cavity

Circuit

Cavity

Mating

Face

Mating

Face

Receptacle

Contact

Probe Location:

Bottom Edge of

Receptacle Contact

Probe Location:

Top Edge or

Bottom Edge

of Tab Contact

Tab

Contact

Figure 8

Rev F

10 of 14

114-106118

3.8. Panel Mounting

Recommended panel cutout dimensions are provided on the customer drawing for the specific cap housing.

The cap housing must be inserted through the panel in the same direction that the cutout was punched until the

panel stops sit against the panel so that the flexible panel latches engage the panel. No hardware is required.

See Figure 9.

To remove the cap housing from the panel, both latches must be simultaneously depressed, then the cap

housing must be gently pulled straight out of the panel. If there is no damage to the cap housing, the cap

housing can be re-mounted.

Direction of Punch of Cutout

Panel Cutout

Wire (Ref)

Panel Latch (2 Places) Engaged to Panel

Panel Stop (4 Places) Against Panel

Cap Housing

Figure 9

3.9. Mating and Unmating

The mating face of the cap housing must align with the mating face of the plug housing, then the housing must

be pushed together until the mating latch is secured to the latch retainer. There should be an audible click.

Refer to Figure 6.

To unmate the housings, if used, the CPA device must be withdrawn (but not removed). The plug housing

mating latch must be depressed until it is released from the latch retainer, then the housings can be pulled

straight apart.

CAUTION

These housings are not intended to be used as an electrical interruption device. To avoid degradation to the contacts, there

must be no current flow when unmating.

3.10. Strain Relief and Wire Dress

Wires can be bundled together and supported using cable ties or electrical tape. The wires must remain

perpendicular to the housing and avoid an excessively sharp bend radius. The wire bundle must be at least 76

[3.0] from the back of the housing before bending in any direction. Do not bend unsupported wires as this may

cause strain on the contacts.

3.11. Replacement and Repair

Damaged or defective product must not be used. The housings, contacts, CPA device, and TPA device are not

repairable.

A contact can be removed using the extraction tool given in Paragraph 5.4. The contact can be re-inserted into

the housing provided there has been no deformation or damage to the contact latch opening or housing

internal latch. Refer to Paragraph 3.5.B for contact extraction and insertion information. If the contact has been

pushed or pulled out of the housing, the rework procedure given in 408-32206 must be followed.

4. QUALIFICATION

The POWER TRIPLE LOCK* connector system is Recognized by Underwriters Laboratories Inc. (UL) in File

E28476.

Rev F

11 of 14

114-106118

5. TOOLING

Tooling part numbers and instructional material packaged with the tooling are given in Figure 10.

5.1. Machine (Power Unit)

The machine provides the force required to drive an applicator for crimping the contacts. These machines can

be set up to automatically measure, cut, strip, and terminate the wire.

5.2. Applicator

The applicators are designed to crimp tape-mounted contacts onto pre-stripped wire. The applicators accept

interchangeable die assemblies and must be installed onto a power unit.

SDE-SA Commercial Hand Tools

2217266-1 and 2217267-1 (408-32082)

2217268-1 (408-32083)

2217208-1 (408-32084)

AMP-O-LECTRIC Model “K"

Terminator Machine

1-471273-2 (409-5128)

AMP 3K/40 Terminating Machines

2119683-[ ] and AMP 5K/40

Terminating Machines 2119684-[ ]

(409-10099)

Ocean Side-Feed Applicators

(Atlantic Style and Pacific Style) 2151741-1,

2151742-1, 2151743-1, 2151744-1,

2151745-1, and 2151746-1 (408-10389)

AMP-O-LECTRIC Model “G”

Terminating Machines

354500-[ ] (409-5842)

Extraction Tool 2217301-1

(408-32206)

HDE Applicators

1552992-2, 1552993-2, 1552994-2,

1552995-2, 1552996-2, and 1552511-2

(No Document Available)

Model “T” Terminating Units

694620-[ ] (409-5207) or

458000-4 (409-5289)

PTL Receptacle Contact

Continuity Test Fixture

(Customer Supplied)

(408-32184)

(Design Guidelines

Drawing 1969744)

AMP 3K Terminating Machines

1725950-[ ] and AMP 5K

Terminating Machines

1725900-[ ] (409-10047)

PTL Tab Contact

Continuity Test Fixture

(Customer Supplied)

(408-32187)

(Design Guidelines

Drawing 1969745)

Figure 10 (Cont’d)

Rev F

12 of 14

114-106118

WIRE

NO. OF

CONDUCTORS

APPLICATOR

OCEAN (US/EMEA Only)

HAND TOOL

Pacific Style

HDE

(AP Only)

2151744-1

2-2151744-1

1552995-2

2217267-1

2151744-1

2-2151744-1

1552995-2

2217267-1

SIZE

(mm² [AWG])

INSULATION

DIAMETER RANGE

Atlantic Style

0.34 [22]

1.14-2.70

2.40-2.70

0.56 [20]

0.70 [19]

1

2151743-1

2.00-2.70

2151743-1

2-2151743-1 1552994-2

2-2151743-1 1552994-2

2217208-1

2217208-1

0.80 [18]

2.65-2.95

1.27 [16]

3.00-3.30

2.10 [14]

3.40-3.70

2151742-1

2-2151742-1

1552993-2

2217266-1

3.30 [12]

3.85-4.25

2151741-1

1552992-2

2217268-1

0.34 [22]

2.03 Max

2151743-1

2-2151741-1

0.56 [20]

2.40-2.70

2151746-1

2-2151746-1

1552511-2

2217267-1

2151745-1

2-2151745-1

1552996-2

2217266-1

2

0.80 [18]

2.65-2.95

(0.76 Thickness)

2.69-2.99

(0.84 Thickness)

2-2151743-1 1552994-2

—

For contacts 1971783 and 1971784. Refer to product customer drawing for minimum cross-sectional area (CMA).

This applicator will produce an overlap (OV) crimp on the contact insulation barrel.

Figure 10 (End)

5.3. Hand Tool

The hand tool consists of a tool frame and die assembly that has two crimping chambers. The tool features a

ratchet (crimp height) adjustment wheel and locator.

5.4. Extraction Tool

The extraction tool must be used to remove a contact from the housing. The extraction tool is designed to lift

the contact latch opening from the housing internal latch without causing deformation or damage. Refer to

Paragraph 3.5.B for contact extraction information.

5.5. Test Fixture

The test fixture is used for continuity testing of the housing. The design guidelines drawing provides geometry

and instruction of component assembly. Models are available upon request. For information concerning

continuity testing of the housing, call the number at the bottom of page 1.

Rev F

13 of 14

114-106118

6. VISUAL AID

The illustration below shows a typical application of PTL connector system. This illustration should be used by

production personnel to ensure a correctly applied product. Applications which do not appear correct should be

inspected using the information in the preceding pages of this specification and in the instructional material

shipped with the product or tooling.

FREE-HANGING APPLICATION

PLUG HOUSING LATCH

MUST BE SECURE UNDER

CAP HOUSING RETAINER

THERE MUST BE NO

DAMAGE TO HOUSINGS

IF USED, TIPS OF LEGS OF

CPA MUST BE VISIBLE

WIRES MUST NOT BE

DAMAGED IN ANY WAY

IF USED, CPA MUST BE

FULLY INSERTED INTO

PLUG HOUSING

WIRE CONDUCTORS

MUST NOT BE VISIBLE

WIRE CONDUCTORS

MUST NOT BE VISIBLE

HOUSINGS MUST BE

FULLY SEATED AGAINST

EACH OTHER

IF USED, EACH TPA LATCH

(2 PLACES) MUST BE ENGAGED

WITH TPA LOCKING TAB

IF USED, EACH TPA LATCH (2

PLACES) MUST BE ENGAGED WITH

TPA LOCKING TAB

REQUIREMENTS ABOVE

ALSO APPLY

PANEL-MOUNT APPLICATION

DIRECTION OF

PUNCH OF

CUTOUT

CAP HOUSING MUST BE

MOUNTED IN SAME

DIRECTION AS PUNCH

OF CUTOUT

EACH CAP HOUSING PANEL LATCH

MUST BE ENGAGED TO PANEL

EACH CAP HOUSING PANEL STOP

(4 PLACES) MUST SIT AGAINST PANEL

FIGURE 11. VISUAL AID

Rev F

14 of 14