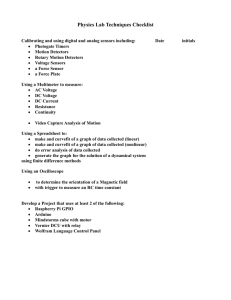

Current Sensors Voltage Sensors

advertisement