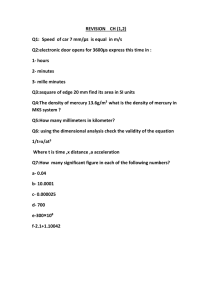

The paragraph 29 study

advertisement