VARIABLE FREQUENCY DRIVE

LIFE CYCLE EXTENSION PROGRAM

THE PROBLEM

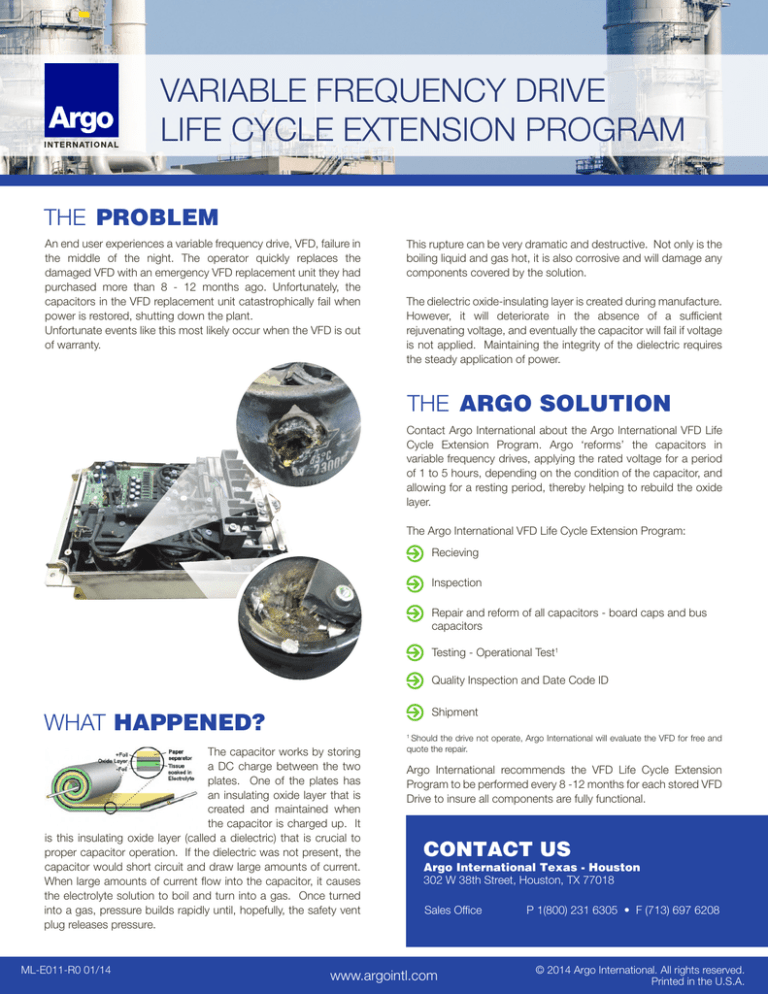

An end user experiences a variable frequency drive, VFD, failure in

the middle of the night. The operator quickly replaces the

damaged VFD with an emergency VFD replacement unit they had

purchased more than 8 - 12 months ago. Unfortunately, the

capacitors in the VFD replacement unit catastrophically fail when

power is restored, shutting down the plant.

Unfortunate events like this most likely occur when the VFD is out

of warranty.

This rupture can be very dramatic and destructive. Not only is the

boiling liquid and gas hot, it is also corrosive and will damage any

components covered by the solution.

The dielectric oxide-insulating layer is created during manufacture.

However, it will deteriorate in the absence of a sufficient

rejuvenating voltage, and eventually the capacitor will fail if voltage

is not applied. Maintaining the integrity of the dielectric requires

the steady application of power.

THE ARGO SOLUTION

Contact Argo International about the Argo International VFD Life

Cycle Extension Program. Argo ‘reforms’ the capacitors in

variable frequency drives, applying the rated voltage for a period

of 1 to 5 hours, depending on the condition of the capacitor, and

allowing for a resting period, thereby helping to rebuild the oxide

layer.

The Argo International VFD Life Cycle Extension Program:

Recieving

Inspection

Repair and reform of all capacitors - board caps and bus

capacitors

Testing - Operational Test1

Quality Inspection and Date Code ID

Shipment

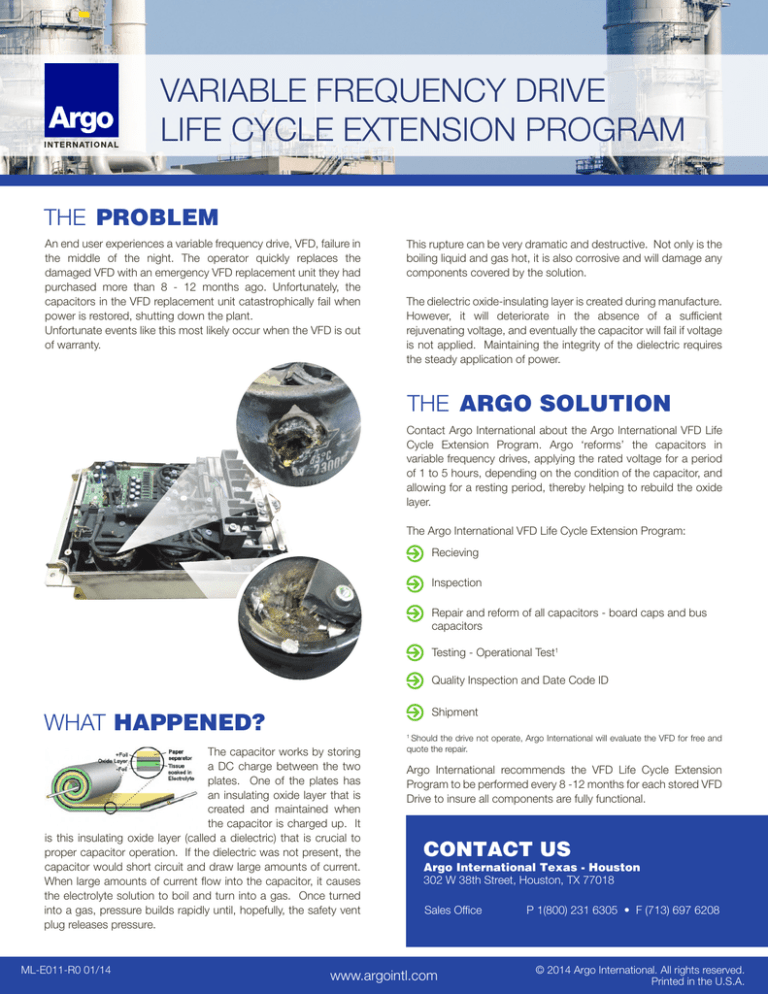

WHAT HAPPENED?

ML-E011-R0 01/14

Should the drive not operate, Argo International will evaluate the VFD for free and

quote the repair.

1

The capacitor works by storing

a DC charge between the two

plates. One of the plates has

an insulating oxide layer that is

created and maintained when

the capacitor is charged up. It

is this insulating oxide layer (called a dielectric) that is crucial to

proper capacitor operation. If the dielectric was not present, the

capacitor would short circuit and draw large amounts of current.

When large amounts of current flow into the capacitor, it causes

the electrolyte solution to boil and turn into a gas. Once turned

into a gas, pressure builds rapidly until, hopefully, the safety vent

plug releases pressure.

Argo International recommends the VFD Life Cycle Extension

Program to be performed every 8 -12 months for each stored VFD

Drive to insure all components are fully functional.

CONTACT US

Argo International Texas - Houston

302 W 38th Street, Houston, TX 77018

Sales Office

www.argointl.com

P 1(800) 231 6305 • F (713) 697 6208

© 2014 Argo International. All rights reserved.

Printed in the U.S.A.