INTEGRATED VARIABLE-FREQUENCY DRIVES (VFDs)

advertisement

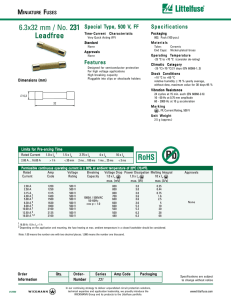

Custom-Engineered Electrical Equipment INTEGRATED VARIABLE-FREQUENCY DRIVES (VFDs) For Underground-Potash and Other Harsh Mine-Duty Applications Description Variable-frequency drives have been used in a variety of industries for years to start motors, optimize load control, and achieve energy savings. Unfortunately, the mining industry has not been able to fully realize these benefits as the combination of the electronics used in VFD’s and the dirty or harsh environments found in underground and open-pit mining tends to decrease the drive’s reliability and expected life. Littelfuse has solved this problem by designing a low-maintenance modular system that keeps the critical components of the VFD isolated from the harsh mining conditions, yet meets the thermal cooling requirements of the VFD. One of the benefits of the modular design is the ease in which the unit can be transported, installed, or replaced. Once the unit is moved to the operational area of the mine, it can be quickly connected to the load using cable couplers, programmed, and put into service, minimizing commissioning and/or downtime. Patent Pending The Littelfuse Custom Products engineering team will assist with your design. All designs are viewed by engineers prior to quoting. Low Maintenance, Plug and Play Design Variable-Frequency Drive This Littelfuse-designed package has been engineered to minimize the need for regular maintenance. As a result of the convenient filter-less design, maintenance is limited to the simple periodic clearing of dust or debris from the heat sink on the back section. Littelfuse modular VFD units incorporate a third-party, high-quality three-phase variable-frequency drive, selected to give maximum performance in harsh mining conditions. Cooling is provided through the use of a flange-mounted heat sink. This is desirable as it allows the drive’s electronics to be sealed away from the dusty or harsh environments. Mine-Duty Enclosure Enclosures are rugged, mine-duty, and are built to NEMA 4 or NEMA 12 standards. The modular VFD package is designed for portability with a runner-style or flat-bottom tub and optional forklift pockets. Trailer-mount units are also available. Typical construction consists of the following: Main frame 4” x 2” x 1/4” rectangular tubing A36 hot-rolled, mild-steel plate, sized as follows: 1/2” flat base plate, 1/4” removable top covers (as applicable), 3/16” outer skin and internal partitions, 10 ga doors Plated or stainless-steel hinges, latches, and hardware Sandblasted and covered with a heavy-duty powder coating Features include: For use on 600 V loads, up to 350 HP Wide input supply voltage range ack-channel VFD cooling removes up to 90% of heat losses B from the electrical compartment, which improves reliability and prolongs life by dramatically reducing temperature rise and contamination of the electronic components. Standard white interior and exterior; other colours available DC fan eliminates the need for the heat sink fan transformer Quick-connect couplers for incoming and outgoing cables as per customer specification IP 54 sealed electronics Low-voltage compartment doors feature heavy-duty freezer-style latches. Key-interlocked systems and provisions for padlocking are provided as required. Doors are formed, gasketed, and hinged. Where applicable, doors can have wired-glass viewing windows. Polycarbonate viewing windows are optional. © 2016 Littelfuse Custom-Engineered Electrical Equipment Littelfuse.com/CustomProducts All serviceable parts removable from the front of the drive Output Filter Rev: 1-C-051016 Custom-Engineered Electrical Equipment INTEGRATED VARIABLE-FREQUENCY DRIVES (VFDs) For Underground-Potash and Other Harsh Mine-Duty Applications Options HMI screen provides a graphical interface for control of the VFD. Additional graphics can be added to display heating and flow status.Trending screens, drawings, manuals and maintenance videos are also available with the HMI option. R egenerative VFD option returns energy to the grid. When an electric motor is driven by a VFD, electric power delivered to the motor is regenerated while the motor decelerates. Reduced harmonic drives available. Single Motor Applications (Ventilation, Pumping, Crushers, Conveyors, etc.) Built-in variable-frequency drive controls allow programming to optimize performance and control for variable-speed requirements such as flow control for pumping and ventilation. Multiple-Motor Applications (Conveyors, Pumping, Ventilation, etc.) For multiple motor applications, such as on conveyors, multiple units (one master and multiple slaves) can be linked together for load sharing, load shedding, and speed control. Wiring All wiring and buswork is copper. High-voltage wiring is secured to withstand both thermal and mechanical stress. Wiring to components is terminated with compression lugs. Wires are bundled for neatness, reliability, and ease of duct or bundle maintenance. Control wiring is labeled with heat shrink permanent markers. A continuous copper grounding bus extends the length of the enclosure and it is fitted with hardware for customer connections. Documentation Complete documentation is included with each power centre. Documentation includes three sets of prints and three sets of manuals containing schematics, layouts, wiring diagrams, bill of material, recommended spare-parts list, and technical information on any purchased equipment. The drawings are available in AutoCAD format. Testing and Warranty Littelfuse custom equipment must pass an extensive qualityassurance inspection. Control operation is verified and all functions are tested. Dielectric and high-voltage tests comply with applicable standards. Warranty is 24 months from the date of shipping. Codes, Standards, & Regulations Portable modular VFD systems are designed and manufactured to meet or exceed CSA standards, including CSA M421 when required. Ordering Information 3714 Kinnear Place Saskatoon, SK S7P 0A6 Canada Tel: +1 306 373 5505 Email: Customproducts@littelfuse.com Nameplates Doors, receptacles, assemblies, and major components are labeled with Lamicoid nameplates. Customer equipment numbers are added to the exterior of the unit if desired. All compartments are labeled with appropriate warning labels. © 2016 Littelfuse Custom-Engineered Electrical Equipment Littelfuse.com/CustomProducts Rev: 1-C-051016