2 QUESTION N° : 2-17

advertisement

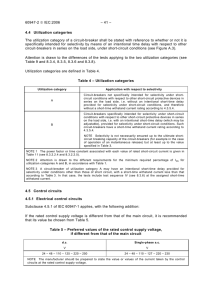

NAME : Mirko Palazzo COUNTRY : Switzerland REGISTRATION NUMBER : 397 GROUP REF. : A3 PREF. SUBJECT : 2 QUESTION N° : 2-17 Duties of generator circuit-breakers and related requirements for application Generator circuit-breakers (at least those for short-circuit currents of 50 kA and above) are a complex piece of equipment and are more comparable to high-voltage circuit-breakers than to medium-voltage circuit-breakers. Furthermore when comparing different power station layouts there is an immediate interest in the reliability figures of both generator circuit-breakers and high-voltage circuit-breakers. In contrast to general purpose highvoltage circuit-breakers, the very steep transient recovery voltages which generator circuit-breakers have to deal with are associated with currents of very high magnitude. Therefore it is interesting to investigate how the design and the stresses associated with the location of installation affect the reliability of circuit-breakers. In order to analyse the difference in the hazard rate of generator circuit-breakers and high-voltage circuitbreakers it is important to identify the duties of those circuit-breakers. The main duties of a generator circuitbreaker are as follows: • synchronise the generator with the main system; • separate the generator from the main system; • carry and interrupt load currents (up to the full load current of the generator); • interrupt system-source short-circuit currents; • interrupt generator-source short-circuit currents; • interrupt fault currents due to out-of-phase conditions. For high-voltage circuit-breakers the shunt reactor switching is associated with a substantially higher hazard rate compared to other switching duties. The hazard rate is especially higher in case of live tank circuit-breakers. On the other hand the high-voltage circuit-breakers operating on shunt reactors represent only approximately 1% of the surveyed service experience. It is also to be mentioned that approximately 45% of the surveyed population of high-voltage circuit-breakers is of live tank design and 87% of the total population is installed outdoor. High-voltage circuit-breakers, if air insulated, are subject to environmental conditions which can lead to especially severe stress. The hazard rate of live tank high-voltage circuit-breakers is approximately 0.48 major failures per 100 circuit-breakers years (i.e. about 3 times higher compared to GIS or dead tank equipment). Generator circuit-breakers are normally installed inside enclosures that protect them from atmospheric conditions. Therefore a generator circuit-breaker even in case it is installed outdoor operates under indoor conditions. Hence these stresses will not be imposed on it. In addition, the relative difference between the withstand voltage and the rated maximum voltage of generator circuit-breakers is higher than the relative difference between the withstand voltage and the rated voltage of high-voltage circuit-breakers. Another relevant aspect is that the requirements imposed on generator circuit-breakers greatly differ from the requirements imposed on general purpose circuit-breakers. Due to the location of installation of a generator circuit-breaker high technical requirements are imposed on the circuit-breaker with respect to: • rated current; • system-source short-circuit currents; • generator-source short-circuit currents; • fault currents due to out-of-phase conditions; • transient recovery voltages. The stresses imposed on generator circuit-breakers differ from the stresses imposed on general purpose circuitbreakers mainly in the following respects: • the relatively long d.c. time constant of the system-source short-circuit current results in a degree of asymmetry at contact separation in the order of 70% to 80% within a practical range of contact parting times; • the degree of asymmetry of the generator-source short-circuit current at contact separation is in the order of 120% to 150% within a practical range of contact parting times, i.e. the generator-source shortcircuit current exhibits delayed current zeros (degree of asymmetry > 100%); • the rate-of-rise of the transient recovery voltage appearing after the interruption of a system-source short-circuit current may be as high as 6.0 kV/μs and the corresponding time delay as short as 1 μs; 1 • • the rate-of-rise of the transient recovery voltage appearing after the interruption of a generator-source short-circuit current may be as high as 2.2 kV/μs and the corresponding time delay as short as 0.5 μs; a generator circuit-breaker shall be capable of interrupting fault currents due to out-of phase conditions with extremely severe transient recovery voltages. The test quantities given for general purpose circuit-breakers for the short-circuit and out-of-phase current switching tests do not adequately cover the above requirements. The only standard which covers the requirements for generator circuit-breakers is IEEE Std C37.013-1997 (R2008) with its amendment IEEE Std C37.013a-2007. This standard in particular covers the requirements imposed on generator circuit-breakers regarding the degree of asymmetry of the fault currents (including the case of fault currents with delayed current zeros) and the characteristics of the transient recovery voltages (rate-of-rise, time delay and peak value). The positioning of a generator circuit-breaker between the generator and the step-up transformer, where its performance directly influences the output of the unit, places high demands on its reliability. The required equipment quality and reliability can only be achieved by exhaustive testing of all the relevant aspects. In case of air-blast generator circuit-breakers it has to be mentioned that some major failures characterised by "does not operate on command" and "locking in open or closed position" are caused by the interrupting chamber. A failure of the main seal which is located in the interrupting chamber leads to a loss of the operating medium (i.e. air) and hence to a situation where the circuit-breaker cannot be operated any longer. 2