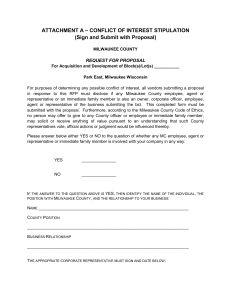

EMCW 2015 Conference - E

advertisement

EMCW 2015 Conference Wisconsin Convention Center 400 W. Avenue, Milwaukee, WI 53203 Wednesday, May 13, 2015 9:00am – 4:00pm Chair Dan M. Ionel, Regal Beloit Corp., and Marquette University Co-Chairs Gennadi Sizov, Rockwell Automation Nathan Weise, Marquette University Conference, Milwaukee, WI, Wednesday, May 13, 2015 9:00 am Electromagnetic and Thermal Design Considerations for High Performance Servo Permanent Magnet Synchronous Motors Gennadi Sizov, Rockwell Automation In this presentation aspects related to electromagnetic and thermal design of servo permanent magnet synchronous motor design will be discussed. Servo motors are designed at the thermal limits of the materials used in the construction of the electromagnetic core. This presents additional design challenges. Practical issues related to thermal-EM motor design and motordrive system design will be highlighted. Detailed FEA-based motor-drive system simulation including the effects of PWM will be used to analyze the motor-drive interaction and its effects on thermal performance. Gennadi Sizov received the B.S., M.S., and Ph.D. degrees in electrical engineering from Marquette University, Milwaukee, WI, in 2005, 2007, and 2013, respectively. He is currently working as a Senior Motor Development Engineer at Rockwell Automation, Mequon. He had previously worked with R&D departments of A. O. Smith, ABB Low Voltage Drives, and Bucyrus International (Caterpillar Mining). His areas of interest include the analysis, modeling, design, and condition monitoring of electric machines and adjustable-speed drives. Dr. Sizov is Co-Chair of the 2015 EMCW Conference. 2 Conference, Milwaukee, WI, Wednesday, May 13, 2015 9:30 am Simulation of Efficiency Maps for Synchronous Permanent Magnet and Induction Machines Mark Solveson and Emad Dlala, ANSYS Accurate calculation of electric machine efficiency over a torquespeed range is a valuable tool for machine engineers. It allows them to better determine design trade-offs, such as reducing magnet size and cost versus a potential reduction in efficiency or increase in torque ripple throughout the operating speed. A description of the simulation approach using magnetic Finite Element Analysis will be presented for a Synchronous Permanent Magnet machine and includes validation with a measured efficiency map. In addition, methods for calculating efficiency maps for induction machines will also be presented. Mark Solveson is Lead Application Engineer with ANSYS, Inc., where he specializes in simulation using electromagnetic finite-element analysis and multi-domain system simulation software for power distribution, automotive, off-road vehicle, healthcare, aerospace and renewable energy industries. Prior joining ANSYS, he acquired eleven patents with the Research and Development group at Eaton Corporation as well as an M.S.E.E from Marquette University. 3 Conference, Milwaukee, WI, Wednesday, May 13, 2015 10:00 am Rotational Cutting as an Alternative in the Processing of Electrical Steel Strip Markus Hubert and Jörg Franke, Friedrich-AlexanderUniversität Erlangen-Nürnberg (FAU) Improving the efficiency in production is always the aim. In many applications where progressive stamping approaches the technological limits, rotational cutting is successful. Relevant applications to name are the processing of paper, card boxes, packaging and simple perforated steel profiles. The main limiting factors of the stamping technology are the accelerations and decelerations in sheet feed and stamping motion. In contrast rotational cutting is a continuous process that leads to greater speeds and higher output. While performing the electrical steel strip between two cylindrical tools in stamp and die arrangement, the laminations are cut out. Rotational cutting in the manufacture of laminations is a great challenge and researched at the Bavarian Technology Center for Electric Drives at the FAU. This presentation provides the main technological differences between progressive stamping and rotational cutting regarding the process structure. Furthermore the geometric and technical parameters of the rotational cutting process are described mathematically. Finally, a sophisticated device for the tooling setup is introduced and the first cutting results of laminations are presented. Markus Hubert received a diploma in Mechanical Engineering from the Georg Simon Ohm University of Applied Sciences Nuremberg. Since 2012 he is working at the Institute for Factory Automation and Production Systems (FAPS) of the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Germany. Jörg Franke heads the Institute for Factory Automation and Production Systems (FAPS) at the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) since 2009. In FAPS he focuses the research on manufacturing of mechatronic products, starting from packaging of electronic circuits, structured metallization of circuit carriers, surface mount technology, assembly of electric motors, automation solutions and ending with engineering, planning and simulation of complex mechatronic systems. Previously, Prof. Dr.-Ing. Franke held different management positions with global responsibilities e.g. at McKinsey&Co, Robert Bosch GmbH, ZF AG, Schaeffler AG and ABM Greiffenberger AG. 4 Conference, Milwaukee, WI, Wednesday, May 13, 2015 10:30 am Alternative Manufacturing Method for Concentrated Wound Machines Jason Kreidler, Regal Beloit Corp. As the price and availability of rare earth materials came into question an effort into maximizing the use of this material in a PMAC machine became critical. In order to achieve power density in the stator which matches the power density of rare earth materials higher slot fills needed to be achieved. To meets these criteria Regal Beloit embarked on a project to construct an automated stator manufacturing line capable of maximum slot fills. This paper will discuss the benefits and challenges of design, and implementation of an automated stator line. Jason Kreidler manages the Enabling Technology Team for Commercial and Industrial Motors at Regal Beloit Corporation. Jason started his career in electric motors 19 years ago working in various development engineering roles. He received his degree in Mechanical Design form Lakeshore Technical College and is currently enrolled at University of Wisconsin – Stout studying Business Management. 5 Conference, Milwaukee, WI, Wednesday, May 13, 2015 11:00 am Unbalanced Magnetic Force and Vibration Characteristics of Flux Switching Permanent Magnet Machines with and without Eccentricity Silong Li and Bulent Sarlioglu, University of Wisconsin Madison The flux switching permanent magnet (FSPM) machine, which has both magnet and armature winding on the stator, and has a salient pole rotor similar to switched reluctance machine (SRM), become very popular in recent years. The research on FSPM machines is mainly focused on electromagnetic performances analysis, but the mechanical and structural analyses are very limited. However, the salient pole rotor structure of FSPM machine is prone to produce high vibration and acoustic noise. Additionally, manufacturing issues such as eccentricity and bearing defect could also lead to unbalanced magnetic force (UMF) and vibration in the FSPM machine. In order to fill this knowledge gap, this presentation/paper will investigate the UMF and vibration characteristics of FSPM machine both with and without eccentricity. Simulations with 2D and 3D FEA 2 will be presented. Silong Li received the B.S. degree in electrical engineering & automation from Xi’an Jiaotong University, Xi’an, China in 2011, and the M.S. degree from University of Wisconsin Madison, in 2014. He is currently working toward the Ph.D. degree in electrical and computer engineering at the University of Wisconsin-Madison. His research interests include novel permanent magnet machines design, and high performance electric machine drives. Bulent Sarlioglu is a Professor at University of Wisconsin–Madison, and Associate Director of Wisconsin Electric Machines and Power Electronics Consortium (WEMPEC). He received the Ph.D. degree from University of Wisconsin–Madison. Dr. Sarlioglu spent more than ten years at Honeywell’s aerospace division, most recently as a staff systems engineer, earning Honeywell’s technical achievement award in 2003 and an outstanding engineer award in 2011. He contributed many internally or externally funded R&D programs and realization of many technology development programs for many platforms including Boeing 7E7 (787), Airbus A350 and A380. Dr. Sarlioglu is the inventor or co-inventor of sixteen US patents. His current research interests include novel electric machines, high-speed electric machines, and wide bandgap device based power electronics. 6 Conference, Milwaukee, WI, Wednesday, May 13, 2015 11:30 am Rapid Estimation of Induction Machine Stator Core Losses Sreekanth Narayana Pillai and Ian P. Brown, Illinois Institute of Technology An induction machine finite element analysis technique for the estimation of stator core losses using a series of magneto-static simulations is presented. This technique unites two previously proposed simulation procedures: one for determining the average torque in the induction machine under field oriented conditions and another for the rapid analysis of synchronous machine core losses. Stator winding and sinusoidally distributed rotor bar currents are imposed at discrete rotor positions where a magneto-static finite element solution is computed. Electric and magnetic symmetries are exploited to reconstruct or approximate the stator flux density waveforms. From the reconstructed or approximate waveforms the stator core loss is estimated. Sreekanth Narayana Pillai graduated with a Bachelor in Technology in Electrical and Electronics Engineering degree from Mahatma Gandhi University, Kottayam, Kerala, India in 2008. Ian P. Brown received the B.S. degree in engineering from Swarthmore College, Swarthmore, PA, USA, in 1999 and the M.S. and the Ph.D. degrees in electrical engineering from the University of Wisconsin, Madison, WI, USA, in 2003 and 2009, respectively. Since 2012, he has been with the Illinois Institute of Technology, Chicago, IL, USA. Previously, he was with the Corporate Technology Center, A. O. Smith Corporation, Milwaukee, WI, USA. His main research interests are high-performance electrical drives and the design of electric machines. 7 Conference, Milwaukee, WI, Wednesday, May 13, 2015 1:00 pm High-Frequency “Airgap” Windings for High-Power Density Electrical Machines Jonathan Martin and Kiruba Haran, University of Illinois Urbana Champaign The University of Illinois is currently working on high-power density megawatt-scale electrical machines for aerospace applications. One key feature is the use of very high-frequency armature windings ranging from 3 kHz to 10 kHz. The high frequency currents, especially in an “airgap”-winding configuration pose significant AC loss challenges, and thereby require highly stranded Litz conductors. This presentation will discuss detailed AC loss calculations that have been performed, as well as review results from manufacturing trials and bench tests carried out to refine the machine design. Jonathan Martin graduated with a B.A. in Physics from Colgate University in 2014. He is currently pursuing a M.S. degree in electrical engineering under Professor Kiruba Haran with focus on electric machines at the University of Illinois, Urbana-Champaign. Kiruba Haran obtained a BS in Electrical Engineering from OAU, Nigeria, in 1994, and a PhD in Electric Power Engineering from RPI, Troy, NY in 2000. He is currently an Associate Professor and Associate Director of the Grainger Center for Electric Machinery at the University of Illinois at Urbana-Champaign. He moved to UIUC in 2014 after 13 years at GE Research. At GE, Dr. Haran was the manager of the research group developing advanced electrical machine technology for all of GE’s industrial businesses, including Wind, Oil & Gas, Aviation, Transportation and Energy Services. Dr. Haran has 35 US patents, several more global patents, and has published 20 journal papers and given dozens of conference presentations. He is a registered PE in NY, and is a fellow of the IEEE. 8 Conference, Milwaukee, WI, Wednesday, May 13, 2015 1:30 pm Linear actuators: A Very Diverse Landscape Bruno Lequesne, E-Motors Consulting, LLC Many mechanisms ultimately require linear motion, from fuel injection to aircraft launches. The presentation will provide an overview of the many technical solutions developed for such applications. An important distinction will be made between devices where the motive force is perpendicular to the airgap, as opposed to parallel. This distinction exists in the rotary world as well but is seen much less frequently. For linear actuation it generally separates shorter from longer motions. For longer travels, the option of retaining a rotary machine, paired with a rotary-to-linear mechanism has many advantages in a number of cases. Ultimately, choosing one approach over another involves both a deep understanding of electromagnetic force generation as well as a system approach. Bruno Lequesne received the Certified-Engineer degree from the Ecole Supérieure d'Electricité (CentraleSupélec), France, in 1978, and the PhD degree in electrical engineering from the Missouri University of Science and Technology, Rolla, MO, USA, in 1984. He worked for 30 years in the automotive industry with General Motors, Delphi, and Eaton on transportation electrification research before starting his own consultancy, E-Motors Consulting, LLC, in 2014. Dr. Lequesne holds 49 patents with 4 more pending, primarily on sensors, linear actuators, and automotive applications. He is the recipient of ten Best Paper Awards, seven from the IEEE Industry Applications Society (IAS), and three from the Society of Automotive Engineers. He was elected an IEEE Fellow in 1997. He is also past president (2011-2012) of the IEEE IAS and is currently on the steering committee of the IEEE Transportation Electrification Community. 9 Conference, Milwaukee, WI, Wednesday, May 13, 2015 2:00 pm Modern Heat Extraction Systems for Electrical Machines – A Review Mircea Popescu, Motor Design, Ltd. The thermal stress on the electrical machines is created by the losses dissipated in the system which will heat different components of the machine, like windings, rotor cages, magnets, and needs to be dissipated. One can thermally protect the electrical machines by reducing the local losses, i.e., the induced eddy-current losses in the electrical conducting regions, iron cores, magnets, retaining sleeves, and/or using an efficient cooling system. Depending on the application, cooling systems can be employed with natural convection (totally enclosed nonventilated), forced convection (air or liquid cooling), or radiation cooling (in the case of electrical machines, operating in vacuum environment). Heat can be extracted through conduction, convection (natural and forced) and radiation. The thermal management of electrical machines is a 3-dimensional problem which requires complex heat extraction phenomena to be addressed; e.g., heat transfer through complex composite components such as the wound slot, temperature drop across interfaces between components and complex turbulent air flow within the end-caps. This study presents modern various solutions for an efficient heat extraction or thermal management of the electrical machines. Mircea Popescu is the Engineering Director of Motor Design, Ltd., a software and consultancy company headquartered in the UK and with offices in the US, and has more than thirty years of engineering experience. Earlier in his career, he was with Helsinki University of Technology (now Aalto University) in Finland and with the SPEED Lab at University of Glasgow, UK. Dr. Popescu published more than one hundred papers and his publications have received three IEEE best paper awards. His consultancy contributions for industry are incorporated in many state-of-the-art products. Current major projects include electrical machines and drives for hybrid/electrical vehicles, and formula-e racing cars. An IEEE Fellow, Dr. Popescu is the Chair of the IEEE Industry Application Society (IAS) Electrical Machines Committee and a Distinguished Lecturer for IEEE IAS Region 8. 10 Conference, Milwaukee, WI, Wednesday, May 13, 2015 2:30 pm Synchronous Reluctance and PM Assisted Motors Steven J. Stretz, Regal Beloit Corp. Synchronous reluctance machines and their PM assisted varieties, which incorporate magnets in the flux barriers, are being considered for variable speed power electronic converter -fed applications. The presentation will cover fundamental concepts, optimal computer-aided design, and practical demonstrations of the technology. The advantages of employing PM assisted rotor topologies with cost competitive ferrites will be quantified in terms of improved power factor, specific power, and efficiency. Numerical and experimental results for a 10hp 1,800rpm typical rating will be discussed. Steven J. Stretz is Chief Engineer with Regal Beloit Corporation and is based in Grafton, WI. He received the B.S. degree in electrical engineering from the University of Wisconsin Milwaukee followed by post graduate studies in Engineering Management. Mr. Stretz has more than 40 years of experience in various engineering and management roles in the electric machine industry and introduced to manufacturing many new products. He has been a working member of IEEE and NEMA involved in the development of standards for electric machines. 11 Conference, Milwaukee, WI, Wednesday, May 13, 2015 3:00 pm Permanent Magnets for Electric Machines: Current Performance and Research Trends Melania Jasinski, Heeju Choi, and Jinfang Liu, Electron Energy Corp. In this presentation we will review the performance of permanent magnets for electric machine applications and discuss the tradeoff between the performance and cost, density of magnetic flux and thermal stability, etc. We will also present lesser known magnet grades, such as ultra-high temperature Sm-Co magnets, temperature compensated Sm-Co magnets, sequentially laminated magnets, and new grades of Nd-Fe-B magnets. The latest research activities in the US, recently funded by the Advanced Research Projects Agency-Energy, as well as worldwide major research programs on rare earth and non- rare earth magnets and their objective-accomplishment status, will be discussed in the context of preparing the engineering community for possible new generations of permanent magnets. Melania Jasinski is the Manager of Process Technology at Electron Energy Corporation. She received her PhD in Physics in 2003, from A.I.Cuza University, while also working as a researcher at the National Institute for Research and Development, in Iasi, Romania. She joined EEC in 2007, leading the R&D group in material research activities under more than a dozen government and industry funded projects. Dr. Jasinski co-authored more than 50 peer-reviewed papers and 8 patent applications and serves as a reviewer for several journals and government research-funding agencies. 12 Conference, Milwaukee, WI, Wednesday, May 13, 2015 3:30 pm Common-Mode Voltage Mitigation in MultilevelInverter-based Adjustable Speed Motor Drives Chad Somogyi and Nabeel A.O. Demerdash, Marquette University The three-level neutral-point-clamped (NPC) ASD is a popular multilevel inverter topology used in low- and medium-voltage regenerative/non-regenerative motor drive applications because of its ability to produce lower levels of total harmonic distortion (THD) and withstand higher voltages while preserving rated output power compared to two-level ASDs. While multilevel PWM schemes to mitigate or eliminate CMV have been proposed in literature, many of these methods do not consider real-world conditions and requirements, such as switch dead-time, polarity reversals in the output line voltage, etc., for safe and efficient operation of three-level ASDs and motor loads. This paper will review the harmful effects of CMV and introduce several carrierbased multilevel PWM strategies that reduce and/or eliminate CMV produced by three-level NPC motor drives. Simulation and experimental results based on a laboratory scale 7.5 kVA threelevel NPC ASD will be presented to verify the introduced PWM strategies for mitigating the CMV in ASDs. Chad Somogyi received a B.S. in electrical engineering technology from Milwaukee School of Engineering University, Milwaukee, Wisconsin in 2012. He is currently working on his M.S. in electrical engineering at Marquette University, with a research focus on common-mode voltage mitigation for multilevel-inverter-based adjustable speed motor drives. Nabeel A. O. Demerdash has pioneered since the 1970’s finite element techniques for low frequency electromagnetics and their applications for electric machines and drives. In the 1980’s as part of a NASA project he designed and built one of the very first rare-earth brushless DC motor drives for electric vehicles. He has published more than 100 IEEE Transactions papers, and is the winner of the 1999 IEEE Nikola Tesla Technical Field Award, which represents the highest IEEE recognition for work on electrical machine topics. Professor Demerdash is an IEEE Life-Fellow, a member of the American Society of Engineering Education, the Sigma Xi, and the Electromagnetics Academy. 13 Conference, Milwaukee, WI, Wednesday, May 13, 2015 http://www.coilwinding.org/ http://electricalmanufacturing.org/ Dan M. Ionel, EMCW 2015 Conference Chair, is Chief Engineer with Regal Beloit Corp. and Research Professor with Marquette University in Milwaukee, WI. After completing postdoctoral research with the SPEED Laboratory, University of Glasgow, he worked in industry and academia in the UK and the US. An IEEE Fellow, Dr. Ionel was granted more than thirty patents and has published more than one hundred papers, including two winners of IEEE IAS best paper awards. He is the Editor-in-Chief of the Electric Power Components and Systems Journal, the Chair of the IEEE PES Electric Motor Subcommittee and of the IEEE Milwaukee Power Electronics Chapter. Nathan Weise, EMCW 2015 Conference Co-Chair, is an Assistant Professor with Marquette University in Milwaukee, WI. He received the Ph.D. from University of Minnesota, Minneapolis, MN and worked in industry as an electrical engineer at Cummins Power Generation and General Electric Global Research. Before joining Marquette University in 2014, he was an Assistant Professor at the University of Maine, Orono, ME. His current interests include power electronics, electrification of transportation, control of renewable energy sources, motor drive systems, wave energy converters, HVDC, and grid connected converters. Ver. 2015 0321 14