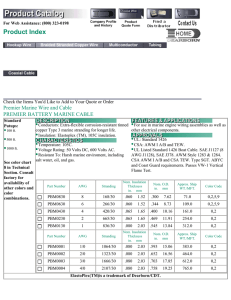

product catalog

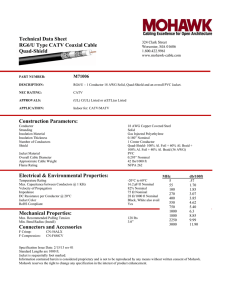

advertisement