Electrical Regulations

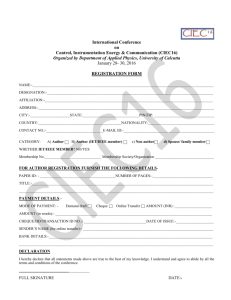

advertisement

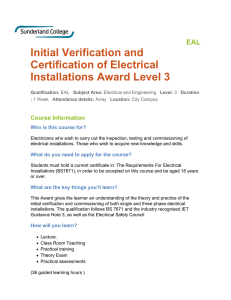

Page 1 of 3 Electrical Regulations Electrical Wiring and Safety Regulations are contained in the newly amended BS 7671:2008 Incorporating Amendment No. 3: 2015 Requirements for Electrical Installations, IET Wiring Regulations, 17th Edition. The “yellow book” has now replaced both the “red book” and the “green book” as the current standard for all electrical installations. The following extracts from the Regulations are intended to assist Members, but please note that SPATA would anticipate that all Members should have access to the above named British Standard to gain a full understanding of the requirements. Please note this Standard is not available to SPATA members at a discount price: Filter pump connection 552.1.2 Every electric motor having a rating exceeding 0.37 kW shall be provided with control equipment incorporating means of protection against overload of the motor. (BS 7671:2008+A3:2015 Requirements for Electrical Installations, IET Wiring Regulations, 17th Edition. Institution of Engineering & Technology (IET), p. 177). The SPATA Technical Committee considers that all motors of 0.37kW or greater should be covered by this Regulation due to the risk of the motor over running due to the loss of prime and therefore the resistance to rotation of the impellor. Spray protection 522.3.1 A wiring system shall be selected and erected so that no damage is caused by condensation or ingress of water during installation, use and maintenance. The completed wiring system shall comply with the IP degree of protection relevant to the particular location. NOTE: Special considerations apply to wiring systems liable to frequent splashing, immersion or submersion. (BS 7671:2008+A3:2015 Requirements for Electrical Installations, IET Wiring Regulations, 17th Edition. Institution of Engineering & Technology (IET), p. 127). The SPATA Technical Committee considers that there is a high risk of water ingress, condensation and spray in all plant rooms. Page 2 of 3 Pool shell bonding 702.415.2 Additional protection: Supplementary equipotential bonding. All extraneous-conductive-parts in zones 0, 1 and 2 shall be connected by supplementary protective bonding conductors to the protective conductors of exposed-conductive-parts of equipment situated in these zones, in accordance with Regulation 415.2. NOTE : The connection with the protective conductor may be provided in the proximity of the location, e.g. in an accessory or in a local distribution board. (BS 7671:2008+A3:2015 Requirements for Electrical Installations, IET Wiring Regulations, 17th Edition. Institution of Engineering & Technology (IET) p. 213). It has long been considered that the risk to bathers within the pool shell, whether swimming or getting in or out, merits the elimination of transmitted earthing faults; hence handrails and ladders are not considered to be extraneous-conductive-parts and, therefore, need not be connected to the main earthing terminal by main protective bonding conductors. There is no particular requirement to install a metal grid in solid floors. However, where a PME earthing facility is used for the swimming pool, an earth mat or earth electrode is recommended and it is suggested that this should be low in resistance, i.e. in the order of 20 Ohms and be connected to the local protective equipotential bonding. (BS 7671:2008 (2011) Requirements for Electrical Installations, IET Wiring Regulations, 17th Edition. Institution of Engineering & Technology (IET) regulation 702.410.3.4.3 p. 212). The view expressed to the SPATA Technical Committee in the past, by experienced wet leisure industry electrical engineers, is valid in that the reinforcement in the pool shell does not require bonding as it is not “extraneous”. The exception MAY be when that reinforcement is linked to the reinforcement of the whole enclosing building. However, the only scenario where the reinforcement could be touched, is if the shell is being drilled to retrofit handrails etc. In this case the pool would be empty and low voltage drills etc. cover by RCD’s would be used. Page 3 of 3 Control Panels Following the publication of the third amendment to the 17th Edition of the IET Wiring Regulations BS 7671:2008+A3:2015, there is now a requirement (since 1st January 2016) for consumer units and similar switchgear for use in dwellings to have their enclosures made from non-combustible materials. There is an understanding that swimming pool plant room control panels are likely to be required to be made from noncombustible materials for safety reasons. A Fire Risk Assessment may be suitable if a combustible material is going to be considered for the control panel and the pool plant room is in a garden out building well away from any habitable building. Any deviation from using a non-combustible control panel should be discussed with a competent electrician and the client, with responses received in writing. Future Work SPATA is discussing the feasibility of producing a publication with electrical specialists that provides guidance on electrical matters relating to the wet leisure industry. Permission to reproduce extracts from BS 7671:2008+A3:2015 is granted by the Institution of Engineering and Technology (IET) and The British Standards Institution (BSi). SPATA acknowledges that where the standard is updated and/or if there is a requirement for further reproduction of extracts, SPATA will need to make a new application to use the material in this factsheet. This publication can be purchased in hardcopy format from the IET website http://electrical.theiet.org/ and the BSI online shop: http://shop.bsigroup.com and is available in ebook format as part of the Wiring Regulations Digital suite: http://electrical.theiet.org/wiringregulations/digital/index.cfm SPATA reminds its members that no responsibility can be taken by SPATA, its employees or agents in respect of any errors or omissions from this factsheet. This version of M35 dated 11 May 2016