MEIGaN - Voltimum

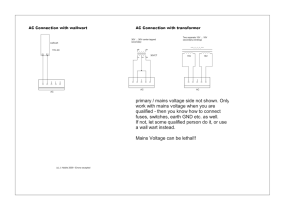

advertisement