General Purpose Transformers

advertisement

SOLA/

HEVI-DUTY

General Purpose Transformers

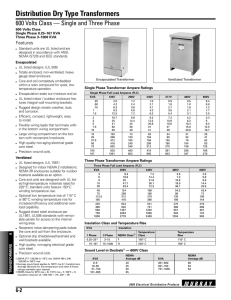

Selection Tables: Single Phase

Listed

Group IA - 240 x 480 Volt Primary, 120/240 Secondary, 60 Hz (Encapsulated)

. Certified

Height

(inch)

Width

(inch)

Depth

(inch)

Ship Weight

Approx. (Ibs)

Design

Style

Elec

Conn

Primary

Amps

Secondary

Amps

HS1B50

7

4

3

3

2

1

.208/.104

.416/.208

.075

HS1B75

7

4

3

3

2

1

.31 21. 156

.625/.312

.100

HS1B100

7

4

3

4

2

1

.417/.208

.833/.417

.150

HS1B150

7.5

5

4

5

2

1

.625/.313

1.25/.625

.250

HS1B250

7.5

5

4

8

2

1

1.04/.512

2.08/1.04

.500

HS1F500B

10

6

5

22

3

1

2.08/1.04

4.16/2.08

.750

HS1F750B

10

6

5

23

3

1

3.13/1.56

6.25/3.13

Catalog

Number

KVA

.050

HS1F1BS

10

6

5

28

3

2

4.17/2.08

8.33/4.17

HS1F1.5AS

13

10

7

39

4

2

6.25/3.13

12.5/6.25

2

HS1F2AS

13

10

7

47

4

2

8.33/4.17

16.7/8.33

3

HS5F3AS

13

10

7

55

4

3

12.5/6.25

25.0/12.5

5

HS5F5AS

17

14

9

104

4

3

20.8/10.4

41 .6/20.8

1

1.5

7.5

HS5F7.5AS

17

14

9

135

4

4

31.3/15.6

62.5/31.3

10

HS5F10AS

28

14

9

156

4

4

41 .7/20.8

83.3741. 7

Ship Weight

Approx. (Ibs)

Design

Style

Elec

Conn

Primary

Amps

Note: See Section 7 for Higher KVA encapsulated units.

Group IB - 240 x 480 Volt Primary, 120/240 Secondary, 60 Hz

KVA

Catalog

Number

NEMA3R

Weather

Shield

Height

(inch)

Width

(inch)

Depth

(inch)

•Secondary

Amps

15

S5H15S

WS-01

23

14

16

160

1

5

62.5/31.3

125/62.5

25

S5H25S

WS-15

28

16

16

230

1

5

104/52.1

208/104

37.5

S5H37S

WS-17

31

18

18

310

1

5

156/78

313/156

50

S5H50S

WS-17

31

18

18

380

1

5

208/104

416/208

75

S5H75S

WS-09

44

23

21

555

1

5

313/156

625/313

100

S5H100S

WS-09

44

23

21

650

1

5

41 7/208

833/417

167

S5H167S

WS-16

46

26

24

905

1

5

695/348

1 392/695

250*

S5H250S

N/A

65

36

35

1580

1

5

1042/521

2083/1042

Design

Style

Elec

Conn

Primary

Amps*

Secondary

Amps

* Not UL or CSA Approved

Group II - 120/208/240/277 Volt Primary, 120/240 Secondary, 60 Hz

NEMA3R

Weather

Shield

Height

(inch)

HS12F1BS

N/A

HS12F1.5AS

N/A

2

HS12F2AS

3

5

Width

(inch)

Depth

(inch)

Ship Weight

Approx. (Ibs)

10

6

5

29

3

9

3.6

8.33/4.17

13

10

7

40

4

10

5.4

12.5/6.25

N/A

13

10

7

60

4

10

7.2

16.7/8.33

HS12F3AS

N/A

13

10

7

66

4

10

10.8

25.0/12.5

HS12F5AS

N/A

17

14

9

104

4

10

18.0

41 .6/20.8

7.5

HS12F7.5AS

N/A

17

14

9

135

4

10

27.1

62.5/31.3

10

HS12F10AS

N/A

17

14

9

156

4

10

36.1

83.3/41.7

KVA

1

1.5

Catalog

Number

15

S12H15S

WS-01

23

14

16

200

1

11

54.2

125/62.5

25

S12H25S

WS-15

28

16

16

250

1

11

90.3

208/104

* Amperage calculated at 277 Volts on primary.

72

Fax-on-Demand #: (877) 888-9329, Document #: 8332

Contact Technical Services at (800) 377-4384 with any questions.

General Purpose Transformers

• Copper lead wire terminations.

Single Phase: .05-.250 KVA Features

• Units 1 -10 KVA are encapsulated with electrical grade

silica sand and epoxy for rugged applications.

• Nonmetallic nameplates list all rating data. Wiring

diagram strategically located on inside of wiring

compartment cover.

• UL-3R enclosure for indoor or

outdoor service.

• Fast, easy installation.

Mounting holes built into the

enclosure.

• Low temperature rise, UL

class 105°C insulation

system, 55°C temperature

rise under full load. Can be

banked for three phase service.

• Nonmetallic nameplates list

all rating data. Wiring diagram

strategically located on

inside of wiring

(Ml Listed

compartment cover.

Single Phase: 15-250 KVA

Three Phase: 15-500 KVA Features

Certified

• Conduit knockouts for side entry into roomy wiring

compartment.

• Copper lead wire terminations.

• Quiet operation.

Single Phase: .500-10 KVA

Three Phase: 3-9 KVA Features

• UL-3R enclosures for indoor or outdoor service.

• Fast, easy installation.

• Electrostatically shielded for quality power on sizes

1 KVA and larger.

• Efficient operation. UL class 180°C insulation system,

115°C temperature rise under full load. Can be banked

for three phase service.

• Conduit knockouts for side entry into roomy wiring

compartment.

• UL class 220°C insulation system, 150°C temperature

rise under full load.

• Electrostatically shielded for quality power.

• Front connected terminal board and spacious wiring

compartment.

• UL-3R outdoor enclosures when used with optional

weather shields (order separately).

• Panel enclosure design reduces labor time. Remove

only two bolts for entry. Wiring diagram on inside front

cover.

• Core and coil completely isolated from enclosure by

means of vibration dampening pads to provide quiet

operation.

Accessories and Design Styles

• Wall mounting brackets - for ventilated design units,

single and three phase, 15 to 75 KVA. The catalog

number for all wall brackets is WB-1C.

• Totally enclosed non-ventilated designs are available

for sizes 15 KVA and larger.

• Core and coil designs are available for sizes 15 KVA

and larger.

• Surge Suppression Devices (page 5) provide additional

protection and longevity to any electronic equipment.

• Weather Shields.

Design Styles

w

W

H

H

CD

Style 1

70

Style 2

Fax-on-Demand #: (877) 888-9329, Document #: 8331

Contact Technical Services at (800) 377-4384 with any questions.

SOLA/

HEVI-DUTY

General Purpose Transformers

Construction Features

• Free Shielding

• Easy Installation

UL-3R Enclosures

Fast Delivery

• 10 Years+2 Warranty

High impact powder paint finish

UL-3R Enclosure

(with optional weather

srueld)

Shielded for

quality power

Remove two bolts for

interior access, front

or rear.

Easily accessed

tap connections.

Coils

Vibration and sound

dampening pad.

Fiberglass terminal

board relieves cable

stress.

Enclosure bottom

designed for ventilation

and rodent protection.

Large, easy to read

wiring diagram

inside front cover.

Flexible ground strap

(included but not shown).

Fax-on-Demand #: (877) 888-9329, Document #: 8331

Contact Technical Services at (800) 377-4384 with any questions.

71

General Purpose Transformers

Electrical Connections (Single Phase)

H1

240 X 480 Volt Primary 120/240 Volt

Secondary Taps: 2, 21/2% FCAN & FCBN

240 X 480 Volt Primary

120/240 Volt Secondary Taps: None

240 X 480 Volt Primary

120/240 Volt Secondary Taps: None

1

H3

H1

H2

H3 H4

H5

L>^A_A_X_A_X>J

Connect Lines to

Primary

Voltage

Interconnect

H1 to H3

Connect Lines to

H1 to H3

H2 to H4

H2 to H4

Secondary

Voltage

Connect Lines to

Secondary

Vottage

Interconnect

X1 to X3

X1 & X4

X2 to X4

240 X 480 Volt Primary,

120/240 Volt Secondary

Taps: 2, 21/2% FCAN; 4, 21/2% FCBN

H1

H2H3H4H5

A

H1

H6H7H8H9

H10

240 X 480 Volt Primary,

1 20/240 Volt Secondary

Taps: 2, 21/2% FCAN; 4, 21/2% FCBN

LAJv-A-XJ

UUJv-Aj

X1

X3

X2

Interconnect

Connect Lines to

504

H5 to H6

H1 & H10

492

H4 to H6

H1 & H10

480

H4 to H7

H1 & H10

468

H3 to H7

H1 & H10

456

H3 to H8

444

Connect Lines to

504

H4 to H5

H1 & H8

492

H3 to H5

H1 & H8

480

H3 to H6

H1 & H8

468

H2 to H6

H1 & H8

456

H2 to H7

H1 & H8

H1 to H5

H1 & H8

H4 to H8

240

H1 to H6

H3 to H8

H1 & H8

228

H1 to H7

H2 to H8

H1 & H8

Secondary

Voltage

Interconnect

Connect Lines to

X1 & X4

X2 to X3

X1 , X2 & X4

H1

H2

120

X1 to X3

X2 to X4

X1 & X4

(1

0

2 4 6 8

^_A_/^^AAAA_AA>J

V>^AAAAAAAAAA_.

\('

X1

Primary

Voltage

X3

SHIELD

X2

600 Volt Primary, 120/240 Volt Seco ndary

Taps: None

X4

Interconnect

Connect Lines to

1 to 2

H1 & H2

2 to 3

H1 & H2

480

3 to 4

H1 & H2

468

4 to 5

H1 &H2

H1 & H10

456

5 to 6

H1 & H2

H2 to H8

H1 & H10

444

6 to 7

H1 & H2

432

H2 to H9

H1 & H10

432

7 to 8

H1 & H2

252

H1 to H6

H5to H10

H1 & H10

252

H1 to 2

H2to1

H1 & H2

240

H1 to H7

H4to H10

H1 & H10

240

H1 to 4

H2to3

H1 & H2

H3to H10

Interconnect

X2 to X3

504

H1 to H8

X4

240

492

228

X2

120/240

X4

Primary

Voltage

'1

I SHIELD

i*

**

7 5 3 1

-L o^rVv^,

rv-vVv^

~

^xr

SHIELD I

r-^S

I

3

Primary

Voltage

Connect Lines to

120/240

rv'YVv'V'w^

X3

252

X1 to X3

X2 to X4

H8

r^S

X1

Primary

Voltage

H7

UV>LA_/LA^AJ

prv>^rS^w~\

I

H6

H1

t•

H2

4i

>~A_A^A_^A-A^A_A^VAA-A--VA^

t

X1

Primary

Vottage

i

X3

X2

Interconnect

X4

Connect Lines to

600

H1 & H10

228

H1 to 6

H2to5

H1 & H2

6

H1 & H2

Secondary

Voltage

Interconnect

Connect Lines to

240

X2 to X3

X1 & X4

216

H1 to H9

H2to H10

H1 & H10

216

H1 to 8

H2to 7

H1 & H2

120/240

X2 to X3

X 1 , X2& X4

Secondary

Voltage

Interconnect

Connect Lines to

Secondary

Voltage

Interconnect

Connect Lines to

120

240

X2 to X3

X1 & X4

240

X2 to X3

X1 & X4

120/240

X2 to X3

X1.X2&X4

120/240

X2 to X3

X1.X2&X4

X1 &X4

120

X1 to X3

X2 to X4

X1 &X4

120

78

X1 to X3

X2 to X4

X1 to X3

X2 to X4

Note: 1 through 2 KVA units have

electrostatic shielding.

Fax-on-Demand #: (877) 888- 9329, Document #: 8334

Contact Technical Services at (800) 377-4384 with any questions.

X1 &X4

SOLA/

HEVI-DUTY

General Purpose Transformers

Specification Guide for Low Voltage, General Purpose,

Dry Type Transformers (600 Volt Class) -15 KVA and larger

General

Single and three phase distribution transformers

(600 Volt and below)

• Provide and install, as referenced on the electrical

plans, enclosed dry type transformers as manufactured

by Sola/Hevi-Duty or approved equal.

Standards

• Transformers must be listed by Underwriters

Laboratory, certified with Canadian Standards

Association and designed, constructed and rated in

accordance with NEMA ST 20, ANSI C89.2 and

applicable IEEE & OSHA specifications.

Construction

Cores

• All transformer cores shall be constructed of low loss,

high quality, electrical grade laminate steel. By design,

the flux density is to be kept well below the saturation

level to reduce audible sound level and minimize core

losses. The core volume shall allow operation at 10%

above rated primary voltage at no load without

exceeding the temperature rise of the unit.

Coils

• Coil conductors shall be either aluminum or copper and

must be continuous. The entire core and coil assembly

shall be impregnated with a thermal setting varnish and

cured to reduce hot spots in the coils and seal out

moisture. Coils with exposed magnet wire will not be

acceptable. Transformers shall have common core

construction.

• All transformers shall incorporate a faraday

(electrostatic) shield between primary and secondary

windings for the attenuation of voltage spikes, line

noise and voltage transients.

• Transformers shall be provided with six 2.5% full

capacity taps - two above and four below primary rated

voltage.

Enclosures

• Transformer enclosures shall be constructed of heavy

gauge sheet steel and coated with a grey powder paint

finish (ANSI 6 1 ) . Ventilated transformer enclosures

shall be UL/NEMA Type 2 rated and UL/NEMA Type

3R rated for outdoor use with the addition of a

weathershield. This information must be listed on the

transformer nameplate.

• Maximum transformer enclosure temperature will

not exceed 65°C rise above a 40°C ambient under

full load.

• Transformers must have vibration isolators located

between the core and coil assembly and the

transformer enclosure to reduce audible sound levels

caused from magnetostriction of the transformer core.

No externally located vibration dampening pads shall

be used as they tend to increase audible noise.

Ventilated transformers are to be floor mounted to a

concrete pad.

• The transformer enclosure must be grounded by the

installer in accordance with the latest edition of the

National Electric Code and any local codes or

ordinances.

Performance

• Audible sound levels will not exceed limits established

in NEMA/ANSI Standard C89.2:

10 to 50 KVA

51 to 150 KVA

151 to 300 KVA

301 to 500 KVA

• Transformers, 15 KVA to 500 KVA, shall incorporate a

UL recognized 220°C insulation system and exhibit a

maximum 150°C temperature rise above a maximum

ambient of 40°C under full load.

• General purpose transformers are classified as

isolation transformers.

84

45 db

50 db

55 db

60 db

Fax-on-Demand #: (877) 888-9329, Document #: 8336

Contact Technical Services at (800) 377-4384 with any questions.