Issue 14 - 15 November 2013

advertisement

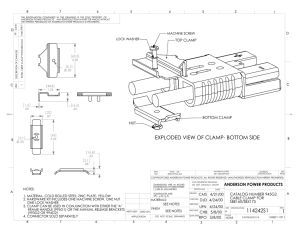

ISSUE 14 – 19 December 2013 INDEX 1. NEW TERMITE PROTECTION KIT FJ0025 FOR HV XLPE STRAIGHT JOINTS (JIMI VO) ............................................................... 3 2. NEW MINI PILLAR HOUSING ONLY STOCK NUMBER FB0060 CREATED (JIMI VO)..................................................................... 4 3. NEW LV CONSAC TRANSITION JOINT KIT (FJ0009) (JIMI VO) ....................................................................................................... 5 4. RDA TO DELTA CONSTRUCTION - CORRECT CONDUCTOR TRANSITIONING (NIALL MCNAMARA) ........................................ 6 5. CHANGE TO 22KV POLE TOP SWITCH – GS0115 TO GS0120 (NIALL MCNAMARA) .................................................................... 7 6. LABELLING STANDARD UPDATED 7. INTERMEDIATE HV CROSS-ARM, KING BOLT DIAMETER INCREASED TO 20MM (NIALL MCNAMARA) .................................. 8 8. FAULT TAMER FUSE – LATEST UPDATES (NIALL MCNAMARA & ROY ENGLISH) ..................................................................... 9 9. INTRODUCING: THE FIRE SAFE - SURGE ARRESTER (NIALL MCNAMARA) ............................................................................. 10 (NIALL MCNAMARA) ........................................................................................................... 8 10. DISTRIBUTION DESIGN CATALOGUE - (DDC) UPDATE (NIALL MCNAMARA)........................................................................... 11 11. NEW STOCK ITEM - ARMOUR ROD FOR 7/16 GALVANIZED STEEL CONDUCTOR - CF0257 (YOW CHIA) ........................... 12 12. WHERE TO USE AN ISOLATOR AND A LIVE LINE CLAMP (YOW CHIA) ...................................................................................... 13 13. EARTH ROD AND CLAMP (YOW CHIA) .......................................................................................................................................... 14 DM# 11512037 Page 1 of 29 ISSUE 14 – 19 December 2013 14. COMPRESSION (CRIMP) FITTINGS AND COPPER HELICAL SPLICE – RECALL OF CABAC AND NON-UTILUX SLEEVES (YOW CHIA).................................................................................................................................................................................. 15 15. ELECTRICAL CLAMP FOR 7/16 GALVANISED STEEL WIRE (YOW CHIA) ................................................................................... 16 16. ORIENTATION OF CONDUCTORS CONNECTED BY A CLAMP (YOW CHIA) ............................................................................... 17 17. INSTALLATION OF INSULATORS ACCORDING TO THE POLLUTION SEVERITY (NIKOLA BOROVAC) .................................. 18 18. POSITIONING OF MPS TRANSFORMERS ON CONCRETE CULVERT (CHRISTO NIEMAND) ..................................................... 19 19. NEW STANDARD FOR REPLACEMENT OF STREETLIGHT SWITCHWIRE WHEN THERE IS NO LV MAINS AVAILABLE (ROY ENGLISH) ........................................................................................................................................................................... 20 20. UPDATE ON ABB EDO DROP OUT FUSES (ROY ENGLISH) ......................................................................................................... 21 21. ABB CAPACITOR BANK REPLACEMENT PROGRAM (PAUL SEILER) ........................................................................................ 22 22. BROKEN PLASTIC KEYHOLE COVERS ON SCHNEIDER RM6 RMU FACIA (CHRIS HON) ......................................................... 25 23. SEPARATION OF SCHNEIDER RM6/FLUSARC KIOSK & SUPPORT STAND (CHRIS HON) ........................................................ 26 24. THE CORRECT INSTALLATION PROCEDURE OF HOUSE SERVICE CONNECTION CLAMP FC0110 (YOW CHIA) ................. 27 25. INSTALLATION INSTRUCTION UPDATED FOR RM6 SWITCHGEAR SEPARABLE CONNECTORS (FC0294) (JIMI VO) .......... 28 DM# 11512037 Page 2 of 29 ISSUE 14 – 19 December 2013 1. NEW TERMITE PROTECTION KIT FJ0025 FOR HV XLPE STRAIGHT JOINTS (JIMI VO) Currently, we do not have a HV XLPE joint with termite protection. This leaves joints vulnerable to termite attack. A new kit FJ0025 was developed to apply over standard HV XLPE straight joints to protect against termite attack when installed with termite protected cable. Figure 1.1 below shows the layout of the termite protection joint kit being applied over the HV straight joint: FJ0025 is neither a straight joint kit nor supplied with the straight joint kit. It is a stand alone kit which needs to be applied over a constructed straight joint when termite protection is required. It is recommended to use termite protection kit FJ0025 on straight joints that join termite protected cables (i.e. Termiticide or Double Brass Tape cables) only. FJ0025 is suitable for all existing HV XLPE straight joints with ranges from 35 to 400sqmm in the following CUs: CU ID HU1 HU2 HU13 HU14 HU56 HU58 DESCRIPTION STRAIGHT JOINT - 1 X 1 CORE 95 TO 400MM STRAIGHT JOINT - 3 X 1 CORE 95 TO 400MM STRAIGHT JOINT 35/95MM 1X1 CORE STRAIGHT JOINT 35/95MM 3X1 CORE STRAIGHT JOINT 50 3 X 1 CORE 19.1/33KV STRAIGHT JOINT 50 1 X 1 CORE 19.1/33KV The new CU for the termite protection joint kit has been created as HU110 which is included in the Distribution Design Catalogue in the link below: Figure 1.1: Termite protection for straight joint(FJ0025) The installation instruction is included in the kit packaging. http://www.westernpower.com.au/documents/ldd/ddc/HU-high-voltageunderground.pdf DM# 11512037 Page 3 of 29 ISSUE 14 – 19 December 2013 2. NEW MINI PILLAR HOUSING ONLY STOCK NUMBER FB0060 CREATED (JIMI VO) A new stock item FB0060 consisting of mini pillar base and lid has been created without the terminal board as shown in Figure 2.1 for the following purposes: A separate stock number for lid and base housing only has not been created for the uni pillar. This is because both the terminal board and housing of the uni pillar are often damaged together and the complete unit needs replacing. 1. damaged pillar replacement (where the lid and the top part of the base housing are damaged but not the inside terminal board); Hence, a similar stock arrangement for a uni pillar is not warranted. 2. temporary cover for street light cables while waiting for new street light pole replacement; 3. temporary cover for low voltage cable working end. If a completed mini pillar (FB0059) is issued when only the housing (lid and base) is required, it is wasteful to discard the termination boards. Hence the creation of the mini pillar lid and base housing as new stock item FB0060. The lid only option (FB0058) is issued where only the lid is damaged. Below is the summary of pillar stock codes: STOCK CODE FB0058 FB0059 FB0060 FB0855 FB0856 DESCRIPTION Mini Pillar (lid only) Mini Pillar (complete with lid, base and terminal board) Mini Pillar (lid and base housing only) Uni Pillar (complete with lid, base and terminal board) Uni Pillar (lid only) Note: when replacing the pillar housing, all cable connections must be checked to ensure a sound connection exists. Figure 2.1: Mini pillar housing only (lid and base) (FB0060) DM# 11512037 Page 4 of 29 ISSUE 14 – 19 December 2013 3. NEW LV CONSAC TRANSITION JOINT KIT (FJ0009) (JIMI VO) Currently, there is no existing standard joint kit to join LV Concentric Neutral Solid Aluminium Conductor (CONSAC) cable with LV XLPE (wavecon) cable. A new fit for purpose cable “transition joint kit” has been developed and supplied by IPD under Western Power stock code FJ0009. Figure 3.3 shows a completed transition joint using FJ009 kit. The main purpose of the kit is to transition LV CONSAC cable to LV XLPE cable. However, the design of the conductor connector in the kit also allows it to be used as a straight and/or tee-off joint for LV CONSAC cables. Design of conductor connector incorporates a service insert module which allows a service cable to connect to the main cable as shown in Figure 3.1. Figure 3.3 Completed Transition Joint FJ0009 Summary of jointing applications for the joint kit FJ0009: Left Cable LV CONSAC LV CONSAC Right Cable LV XLPE LV CONSAC Service Cable tee-off The allowable cable sizes for the above applications are: Figure 3.1 Conductor connector with Service insert. Figure 3.2 Sicame line tap NET/1. Figure 3.2 is the neutral/earthing connector included in the transition joint kit FJ0009. Its purpose is to connect the Aluminium neutral sheath (of LV CONSAC cable) with the copper screen wires of LV XLPE cable. Cable Type LV CONSAC LV XLPE Service cable Conductor ranges 2 120-300mm 2 185-240mm 2 2 10-16mm , 25mm Core Conductor 3 cores 3 single cores single core, 3 cores FJ0009 is a new transition joint kit and does not replace any existing kit. The connector part number is called “Sicame line tap NET/1” and is only approved to use in FJ0009 kit only. Consultation with Plant & Assets Design Section is required for other uses. DM# 11512037 Page 5 of 29 ISSUE 14 – 19 December 2013 4. RDA TO DELTA CONSTRUCTION - CORRECT CONDUCTOR TRANSITIONING (NIALL MCNAMARA) RDA structures are used when line deviation angles become significant, typically greater than 20 degrees. Conductors that transition from horizontal to vertical,i.e. from a delta or flat (horizontal) configuration to the RDA (vertical) stucture have historically been built three possible ways: Centre phase of Delta to Top phase of RDA (preferred, most used in recent past) or No easy method exists to re-configure the phases of existing transition spans as the conductor lengths will be impacted, needing to be cut and joined. However, a method to improve the Delta to RDA conductor separation without reconfuring the network is achieved by increasing the phase separation on the Delta structure. Installing the Anti-swan cross-arm is ideal for this application however due to the different configurations, the appropriate cross-arm needs to be used: Centre phase of Delta to Middle phase of RDA (not preferred, used in past) Centre phase of Delta to Bottom phase of RDA (not preferred, very rarely used) Centre to Top – CB0111 (Long raiser) Centre to Middle – CB0114 (Short raiser) All new designs are to be constructed using the Centre to Top phase attachment approach, see Figure 4.1. Additionally, in all cases the inside phase (of the deviation angle) on the delta or flat construction must go to the bottom phase attachment on the RDA structure, as illustrated by the blue phase in Figure 4.1. For more information please see: Section 3.6.1.2 of the Distribution Overhead Line Design Manual (DOHLDM), Clearances Chapter, DM#9692585 Figure 4.1. Correctly configured Delta to RDA to Anti-Galah Section 3.3 of the Long Bay Solutions for Existing Overhead Power Lines Chapter of the DOHLDM, DM#9945161. Using a Centre (horizontal) phase to Top (vertical) approach gives a 50% larger phase to phase clearance compared to the Centre to Middle and Centre to Bottom phase approaches, thus significantly reducing the chances of conductor clashing. DM# 11512037 Page 6 of 29 ISSUE 14 – 19 December 2013 5. CHANGE TO 22kV POLE TOP SWITCH – GS0115 TO GS0120 (NIALL MCNAMARA) The 22kV pole top switch (PTS) first installed on Western Power networks in the early 70’s has been through many changes during its life time. In March 2012, in order to reduce the risk of midspan clashing of conductors and to achieve larger span lengths, it was decided to increase the phase separation of the 22kV PTS. The inter phase separation has been increased from 800mm to 1000mm, making the PTS 400mm wider and heavier. See examples of the old and new PTS Figure 5.1. Once Stock levels of the old PTS GS0115 have been depleted, the Distribution Design Catalogue (DDC) and Ellipse/DQM will be updated with the new Stock Code. In the short term, while stock of the older PTS is still available, Designers wishing to make use of the larger span lengths achievable using the wider PTS should specifying the new 22kV PTS on their designs. The raiser frame for the combination PTS, shown below in Table 5.1, attaches to the outside of the PTS, typically used when the network continues over the PTS, e.g. HV11, HV13, H14-1, H17-1 etc. has also been made wider. This new raiser frame is available as Stock Code CB0480. See the table below for matching the raiser to the PTS. 22kV PTS PTS Raiser frame Inter-phase separation Stock Code Stock Code 800mm (old) GS0115 CB0478 1000mm (new) GS0120 CB0480 Table 5.1 Matching table – PTS to raiser frame Figure 5.1 Old and new PTS with increased phase separation indicated. Changing of the PTS necessitated a new Stock Code viz. GS0120. All other attachments, e.g. contact heads, braids, rod extensions etc. available as individual replacement parts on the old 22kV PTS have remained the same and fit both old and new 22kV PTS’s (GS0115 and GS0120). Increasing the inter phase separation is the only change to the PTS, making it fully interchangeable with any of the older versions. DM# 11512037 Page 7 of 29 ISSUE 14 – 19 December 2013 6. LABELLING STANDARD UPDATED (NIALL MCNAMARA) The Distribution Equipment Labelling – Network Standard NS 05, DM# 5211952, is a document regularly amended and updated with relevant changes as required. Some of the recent changes are: Cattle tags used on cables, given in NS05 Section 7.2 , see Figure 6.1 below. Location of the equipment label over the Danger plate, given in NS05 Section 5.5 , see Figure 6.2 below. Minimum and maximum font size of equipment labels amended, given in NS05 Section 5.9, to accommodate longer pole numbers and remain legible. 7. INTERMEDIATE HV CROSS-ARM, KING BOLT DIAMETER INCREASED TO 20mm (NIALL MCNAMARA) To prevent possible failure, under certain conditions, the size of the king bolts will be increased to 20mm and the grade of steel increased to Grade 8.8 on the HV intermediate cross-arms CB0109, CB0111 and CB0114. WITHDRAWN for re-evaluation The size of holes in the HV cross-arms will also be increased to accommodate the larger diameter bolt. To implement the change to the cross-arms and the introduction of larger, stronger bolts as efficiently as possible, the cross-arm manufacturer will attach the required bolts to the cross-arms. Stock codes of these cross-arms will not be changed. The existing 16mm bolts will be removed from the CU’s when stock levels of the older cross-arms are exhausted. To ensure that the required bolts are used on the newer version of the cross-arm, the following: Figure 6.1 Cattle tags for cables Figure 6.2 Equipment labels over Danger plate Please note that the Labelling Standard NS 05 is amended periodically. Registered users will be notified of the new updates via e-mail. To register to receive e-mail notification of changes to the standards and manuals, please e-mail distribution.assets@westernpower.com.au DM# 11512037 The larger diameter, stronger bolts will have the head painted blue to be visible from the ground Cross-arms will have a sticker on the lower section of the raiser to indicate the newer version. (a permanently marked solution is not required, it only needs to remain visible until shortly after the cross-arm is installed) Using these two methods to identify the newer cross-arms and bolts will make it easily visible from ground level and simple to audit. Page 8 of 29 ISSUE 14 – 19 December 2013 8. FAULT TAMER FUSE – LATEST UPDATES (NIALL MCNAMARA & ROY ENGLISH) New Stock Code (NIALL MCNAMARA) The FT fuse assembly GF1913 , as shown in Figure 8.1, will now be available as three individual items, viz. GF1923 – FT Fuse Base and stand-off insulator GF1915 – FT Current Limiter GF2015 – FT carrier (commonly referred to as the tube or barrel) The Distribution Design Catalogue (DDC) has been updated accordingly together with Ellipse and DQM. Figure 8.1 Fault Tamer fuse – Stock Codes DM# 11512037 Handling Reminder (ROY ENGLISH) A reminder on the handling of the fault tamer units is provided following recent failed fault tamers which had severe burnt conditions around the area of the joining of the two sections. The units concerned have been sent back to America for further investigation with the supplier. As described in the video at DM#8211739, caution must be taken when handling these units particularly with the metal contact clip on the side of the fuse tube unit. This must not be damaged. To prevent damage: The fuse tube must be aligned carefully with the current limiter element, ensuring the keys of the fuse tube are aligned with the notches in the exhaust control section of the current limiter. Never rotate the fuse tube when inserting it into the current limiter else the contact clip will be damaged. When putting the two units together, ensure that the knurled screw tightening ring on the fuse unit has engaged correctly with the thread of the main body before fully screwing the two sections together tightly. Once the whole fault tamer has been assembled, a continuity test using a multimeter or continuity buzzer is essential to ensure the fuse cartridges, contact clip and current limiter are correctly making contact. After a fault operation ensure any debris is cleaned out from the current limiter tube before re-inserting the carrier. Figure 8.2 Photograph of the Metal Clip on the base of the fuse link unit Page 9 of 29 ISSUE 14 – 19 December 2013 9. INTRODUCING: THE FIRE SAFE - SURGE ARRESTER (NIALL MCNAMARA) Approximately two years ago Western Power entered into a contract with Siemens for the supply of distribution surge arresters, mentioned in Issue 12 of the Distribution Equipment Bulletin – 27 September 2011, DM# 8670433. amount of energy transferred to the failed surge arrester which prevents sparks being emitted. Stock Codes were amended accordingly from the GA3000 series to the GA4000 series. For this reason, the new SPC-A surge arresters may be used on the network in High and Extreme fire risk areas when not located downstream of a fuse, typically on Reclosers, LBS’s, some cable terminations etc. These surge arresters were a like for like replacement and are classified under AS1307.2 - 1996 as Spark Production Class C (SPC-C). SWER and single phase transformers on a group fused network, the SPC-C surge arrester may be used regardless of the fire risk area. The Technical Tender Evaluation also evaluated “spark-less” surge arresters, referred to as Spark Production Class A (SPC-A) surge arresters. The Stock Codes involved are listed in the Table 9.1, below: These types of surge arresters are intended to reduce the possibility of starting a bushfire as they do not emit sparks if they fail. They make use of a static “spark spinner” located at each end of the arrester to achieve the SPC-A rating, as shown in Figure 9.1 below. Network Voltage (single/3 phase) Stock Code SPC-C New Stock Code SPC-A 6.6kV GA4000 GA4010 11kV GA4001 GA4011 12.7/22kV GA4002 GA4012 19.1/33kV GA4003 GA4013 Table 9.1 New Spark Production Class A surge arresters – Stock Codes CU’s will be updated in the DDC and Ellipse for selection when required. Designers to replace the SPC-C arresters with SPC-A if required on CU’s that don’t typically require SPC-A arresters, .e.g. transformers. Figure 9.1 SPC-A surge arrester with Spark Spinners Testing confirmed that surge arresters are not expected to fail destructively when located downstream of a fuse. The speed of the fuse operation limits the DM# 11512037 Page 10 of 29 ISSUE 14 – 19 December 2013 10. DISTRIBUTION DESIGN CATALOGUE - (DDC) UPDATE (NIALL MCNAMARA) Earlier this year a new version of Pole n Wires (PnW) was rolled-out which incorporated Limit State Design Principles as required by AS/NZS 7000:2010. The PnW database was amended accordingly and included the introduction of a table containing the pole top construction dimensions. The data contained in the Constructions Database allows the Designer to accurately model the mechanical and electrical characteristics of a structure and line. The Distribution Design Catalogue (DDC) has been amended to reflect the dimensions in the Constructions Database of Poles n Wires, as illustrated below, see red arrow: Figure 10.1 Construction dimensions in the DDC and PnW (red arrow) and Structural limits (blue arrow) In addition, the Structural limitations of the Cross-arm and Insulators, by limiting the span lengths and deviation angles, have also been added to the DDC, shown with the blue arrow. These limitations will also be amended in the Distribution Construction Standards Handbook (DCSH), in due course. DM# 11512037 Page 11 of 29 ISSUE 14 – 19 December 2013 11. New Stock ITEM - Armour Rod for 7/16 Galvanized Steel Conductor - CF0257 (YOW CHIA) Section 3 (Design Summary) and Section 12.2.2 (The Use of Armour Rods on Conductors) of the Conductors and Fittings Chapter of the Distribution Overhead Line Design Manual, provides guidelines on the use of armour rods. The following are extracts from the Manual. SECTION 3. DESIGN SUMMARY Armour rods must be fitted on all bare conductors when using non urban tensions (18% design tension or greater). The higher tensions allow for longer spans and therefore require fewer structures. SECTION 12.2.2 The Use of Armour Rods on Conductors Armour Rods should be used at tied supports and are effective in sacrificing their surface to abrasion instead of the conductor’s outside surface. They distribute the bending stresses imposed on the conductor at line angles whilst they also distribute compression forces under clamps. Armour rods are not designed to suppress line motion though they do to a limited extent. Conductors that have armour rods installed have many times the life expectancy of bare conductors. Armour rods are to be installed on bay lengths using non urban tensions and all bays where SC/AC conductor is used as armour rods allow for higher tensions without conductor damage and therefore fewer poles are used. Figure 12.3: Photo showing conductor installed with armour rod for protection Selection of the correct size armour rod is important to ensure adequate protection. This is not a problem when building a new line from scratch but care should be taken to identify the correct conductor size if using armour rods when retrofitting a new structure to an existing line. CF0257 is a new stock item for an armour rod created for the use on 7/16 galvanized steel conductor. DM# 11512037 Page 12 of 29 ISSUE 14 – 19 December 2013 12. Where To Use An Isolator and A Live Line Clamp (YOW CHIA) Isolator Live Line Clamp An isolator is generally used in the HV networks to isolate pole mounted equipment such as voltage regulators, reclosers, etc, for maintenance purposes. An example of the use of an isolator is depicted below in Figure 12.1 and Figure 12.2, as per the Distribution Construction Standards Handbook drawing number H16 and H33. A live line clamp is generally used in the HV networks on single phase distribution lines in the country regions where infrequent isolation is required. Its primary function is the same as for the isolator, but it is a much cheaper method of isolation compared to the isolator. A live line clamp should not be attached directly to the main conductor as some conductors may not be suited to the clamping force of the live line clamp. Instead, a bail should be fitted to the main conductor so that a live line clamp can be attached or detached to/from this bail as required. An example of the live line clamp application is depicted below in Figure 12.3 as per drawing H48 in the Distribution Construction Standards Handbook. Figure 12.3 Live line clamp attached to bail Guidelines on the use of a live line clamp. 1. A live line clamp is used on the single phase networks in the country area downstream of a fuse rated at 5A or less and is only operated on average less than 5 times per annum. Figure 12.1 Recloser Isolator Figure 12.2 Voltage Regulator Isolator 2. A live line clamp should NOT be used in the metro regions due to the high fault levels or connecting to the main line in rural locations when > 5A is transferred. 3. Where isolation is required and the live line clamp is unsuitable, isolators must be fitted. DM# 11512037 Page 13 of 29 ISSUE 14 – 19 December 2013 13. Earth Rod And Clamp (YOW CHIA) Discontinued Stock Code Replacement Stock Codes CE0300 and CE0055 CE0135 & CE0058 CE0300 was a “kit” set that consisted of an earth rod 12.7 mm in diameter and 1.4m long, together with an earth clamp CE0055. This was used mainly for pillars. The replacement earth rod CE0135 is 14.2 mm in diameter and 1.5 m long. The earth clamp CE0058 can accommodate cable size ranging from 16 sqmm to 70 sqmm. This is used for most earthing applications. Comments The original kit CE0300 consisted of a “domestic” earth rod and earth clamp CE0055. To reduce inventory and standardize on the earth rod clamp, CE0058 was chosen. The old clamp CE0055 still can be used in domestic installations but it will be discontinued once this stock is exhausted. Correct position of rod and conductor in clamp See R6, in the DCSH. DM# 11512037 Page 14 of 29 ISSUE 14 – 19 December 2013 14. Compression (Crimp) Fittings and Copper Helical Splice – Recall of Cabac and non-Utilux sleeves (Yow Chia) Compression (Crimp) Fittings – aka “full tension” sleeves Copper and Steel Helical Splices Sleeves should always be used for joining two separate bare overhead conductors together. When incorrect sleeves or dies are used, it can result in the joint overheating and failure. The correct use of sleeves and dies is shown in Table 14.1 below. Helical splices are available for joining both copper and steel conductors, however under no circumstances, shall a termination fitting (deadend) be modified to use as a splice. Broken low voltage conductors should not be joined with helical splices due to the high resistive material that bonds the individual helical splice strands together. This caused problems with high resistance neutral joints in the past. The Table below shows the helical splice in WP stock. With High Voltage steel conductors there is no alternative as the only option for jointing either SCGZ or SCAC is the helical line splice. Hazard Incident A hazard incident recently occurred when the die and sleeve used to join two conductors were not of the same brand. Also use of the wrong size die contributed to the conductor separating at the joint and falling to the ground. Recalling all non Utilux sleeves should eliminate the incorrect use of dies. Recall of Cabac and Non Utilux Sleeves ALL CABAC AND NON UTILUX SLEEVES MUST NOT BE USED AND SHALL BE RETURNED TO THE JANDAKOT STORE, HOPE ROAD. Table 14.2 Stock Codes for helical splices Figure 14.1 Copper helical splice Table 14.1 Matching table for Conductors, sleeves and dies Also see CN17, in the Distribution Design Catalogue DM# 11512037 Page 15 of 29 ISSUE 14 – 19 December 2013 15. Electrical Clamp For 7/16 Galvanised Steel Wire (YOW CHIA) This article is published here because of an incident where a PG clamp was used incorrectly on a 7/16 SCGZ conductor. The correct clamp for 7/16 SCGZ is the Transverse Wedge Clamp (TWC). Table 15-1 on the right of this page details the four stock codes used for TWC. A TWC comprises of two separate ‘J’ shaped members held together by a single bolt. Each ‘J’ member has two groove sizes, a small groove and a large groove as shown in Figure 15.1. The BB4 ‘J’ member is the only exception with one groove as shown in Figure 15.2. By selecting the correct groove size, the conductors are clamped within these grooves according to the diameters of the respective conductors. AA1 to AA3, BB3 and BB4 designate the ‘J’ members of TWC. J member AA1 Letter “L” designates Large groove s L The single bolt must be tightened to 40Nm for AA J-Clamps or 50Nm for both BB series and combinations of AA/BB J-Clamps. One Groove only J member BB4 Letter “S” designates Small groove J member BB3 J member AA3 Large groove Small groove Figure 15.1 – Transverse Wedge Clamp Type AA3 – AA1 DM# 11512037 Figure 15.2 – Transverse Wedge Clamp Type BB3-BB4 Table 15-1 : Selection Chart for the use of TWC ‘J’ member 1 ‘J’ member 2 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (BB3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (BB3 – S ) 7/16 SCGZ (BB3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 7/16 SCGZ (AA3 – S ) 6/1/2.50 ACSR (AA1 – S ) 6/1/2.75 ACSR (AA1 – S ) 6/1/3.00 ACSR (AA1 – L ) 6/4.75 & 7/1.6 ACSR (BB4 ) 7/2.50 AAAC ( AA1 – S ) 7/3.00 AAAC ( AA1 – L ) 7/3.75 AAAC ( AA2 – L ) 7/4.50 AAAC ( AA3 – L ) 7/4.75 AAAC ( BB4 ) 19/3.25 AAAC ( BB4 ) 7/16 & 7/1.75 HDBC ( AA3 – S ) 7/14 & 7/2.00 HDBC ( AA2 – S ) 19/16 &19/1.63 HDBC (AA1 – S ) 19/14 & 19/2.00 HDBC ( AA2 – L ) 95 sqmm ABC Tap (AA2-L) Stock CC0492 & CC0494 150 sqmm ABC Tap (AA3-L) Stock CC0493 & CC0496 Bail – stock code FC0105 ( AA2 – S ) Page 16 of 29 Stock Code CC0128 CC0126 CC0126 CC0126 CC0129 CC0126 CC0126 CC0127 CC0128 CC0129 CC0129 CC0128 CC0127 CC0126 CC0127 CC0127 CC0129 CC0127 ISSUE 14 – 19 December 2013 16. Orientation of Conductors Connected By A Clamp (YOW CHIA) When connecting two conductors with dissimilar metals, they should be located in the clamp as depicted in the diagrams on the right. This is to minimize galvanic corrosion. Therefore when connecting an aluminium conductor to a copper conductor, the copper conductor should be located at the bottom of the pg clamp as shown in Figure 16.1. Aluminium or SCAC Similarly when connecting galvanized steel wire to an aluminium conductor, the aluminium conductor should be located at the bottom of the PG clamp as shown in Figure 16.2. Recommended Torque is embossed here For 7/16 SCGZ wire, a transverse wedge clamp is the correct clamp for this size wire and the aluminium/SCAC or copper conductor must be located at the bottom as shown in Figure 16.3. Figure 16.1 – Bi-Metallic PG Clamp Copper Aluminium PG clamp SCGZ IMPORTANT NOTES A successful connection made with a pg clamp or transverse wedge clamp depends critically on the following factors. 1. All conductors must be thoroughly cleaned. Aluminium and copper conductors generally have an oxidized layer which must be cleaned by brushing and then immediately apply the appropriate grease to the conductors because oxidation can take place within a minute 2. Steel conductor should be lightly cleaned to remove surface contaminants with care taken not to remove the galvanizing layer. 3. Apply even pressure across the plates of the pg clamp by tightening up the bolts alternately till the recommended torque is achieved. Recommended torque is embossed here Aluminium or SCAC Figure 16.2 - Aluminium PG Clamp tee dS lv Ga ze ani l ini um lum A Figure 16.3 – Transverse Wedge Clamp DM# 11512037 Page 17 of 29 ISSUE 14 – 19 December 2013 17. INSTALLATION OF INSULATORS ACCORDING TO THE POLLUTION SEVERITY (NIKOLA BOROVAC) Environmental and industrial pollution defines the type of insulator to be used in a particular location. Pollution of the insulator is a significant factor that affects the reliability of overhead power systems. The main types of pollution are salt (marine and salt lakes), mineral sand/dust and ash (industrial). The coexistence of two or more pollution types, as well as moisture (dew, fog, drizzle rain) is an unfavourable combination for the operation of insulators. The presence of electrolytic particles and moisture forms a conductive path along an insulator’s surface, which leads to the increased flow of leakage currents which can lead to pole top fires and tracking with the potential for insulator flashover. Insulators with Stock Code IC0086 shall be used within 5km of the coast in the Perth Metro area and in the South Country area, and within 20km of the coast in the North Country area and 5km around industrial areas. The very heavy pollution areas are presented with the brown shade in Figure 17.3. Western Power uses the following line post insulators on the overhead distribution network: polymeric epoxy resin (grey) insulator (Stock Code IC0073) (Fig 17.1) and polymeric composite (red) insulator (Stock Code IC0086) (Fig 17.2). SUPERSEDED See DEB Issue 15 – 1 December 2013-12-17 DM#11590391 Figure 17.3 Identified Very Heavy Pollution areas within Western Power’s network Figure 17.1 IC0073 Figure 17.2 IC0086 Note: All insulators north of Yanchep within 20km from the coast shall be additionally sprayed with silicon to achieve the satisfactory insulating performance due to severe marine pollution. Insulators with Stock Code IC0073 shall be used in medium to heavy pollution areas, which covers the non coastal area of Western Power’s network. DM# 11512037 Page 18 of 29 ISSUE 14 – 19 December 2013 18. POSITIONING OF MPS TRANSFORMERS ON CONCRETE CULVERT (CHRISTO NIEMAND) MPS transformers are supplied on a galvanised base or plinth. The plinth has been fitted with steel “feet” (a flat piece of steel welded to the front support beam of the plinth). The plinth feet raise the plinth by 8mm at the front support beam; refer to Figure 18.1. This results in the front part of the plinth angling slightly upward when installed correctly. Doing so will prevent the front cubicle from pulling away from the transformer as in Figure 18.2. The MPS transformer shall be installed on the culvert so that the plinth “feet” are set back 50mm from the front edge of the culvert; refer to Figure 18.3. Any closer to the edge may cause the concrete to fracture, damaging the culvert. Refer to DSM-4-02 for full installation guide. 50x70x5 mm Angle Plinth ‘feet’ Align Galvanised Plinth 50 Concrete culvert Figure 18.1 Plinth ‘Feet’ Figure 18.2 LV cubicle pulling away from Tx DM# 11512037 Figure 18.3 Correct landing of a MPS Transformer Page 19 of 29 ISSUE 14 – 19 December 2013 19. NEW STANDARD FOR REPLACEMENT OF STREETLIGHT SWITCHWIRE WHEN THERE IS NO LV MAINS AVAILABLE (ROY ENGLISH) Where bare aerial streetlight switchwire is being replaced, it is preferable to connect the streetlights directly to the low voltage mains supply and update the streetlight control to an individual photocell. Where there is no LV mains 2 on the same pole, the switch wire is to be replaced with 2 core 16mm insulated service cable. A new LV strain clamp (wedge clamp) has been introduced to support the insulated service cable for spans over 30m, stock code CC0112. Its use and application is the same as the smaller LV strain clamp. Work Practice 6.25 and Network instructions for this construction. The new construction is detailed in drawing S19 Standard DM#10442869, includes The higher winds in the region around Geraldton require the use of slightly shorter spans for this insulated service cable. Existing LV Strain Clamp - CC0111 2 – suitable for 2 x 6 to 4 x 35mm cable Changes to the Distribution Construction Standards Handbook - Drawings to be used for maintenance only - S1, S4 - Drawings Added - S19, S20 New LV Strain Clamp - CC0112 2 - suitable for 2 x 6 to 2 x 25mm cable Changes to the Distribution Design Catalogue - CU’s available for maintenance only - SL1, SL4, SL19, SL22, RE4, RE5 - CU’s Added DM# 11512037 - SL23, SL24, RE7, RE8 Page 20 of 29 ISSUE 14 – 19 December 2013 20. UPDATE ON ABB EDO DROP OUT FUSES (ROY ENGLISH) There are a number of issues with the ABB EDO that are being investigated with the help of ABB Head Office. Your continuing detailed reporting of issues found with drop out fuses is much appreciated and very helpful in these investigations. Fuse Carriers burning out. A successful fault clearance fuse operation relies on the expulsion of the arc fault which in turn relies on the delicate inner lining of the fuse link carrier which creates the expulsion gases. ABB have requested that the interior of the fuse carrier be examined for cleanliness and excessive wear before replacing the fuse link to ensure it remains in a serviceable condition – the sides of the internal tube should be smooth and free of any debris or thinning / thickening along the length (examples of poor tubes in Figure 20.1). The factory installed bolt holding the head assembly to the base. There have been cases of this bolt shearing off which causes the head to become loose and the fuse carrier to drop. The reporting of this condition is a recent occurrence and seems very limited, possibly to the exposed severe coastal areas. Investigations continue, but your feedback on this problem is vital to understand its cause and solution (Figure 20.2). Nuts on the bolts holding the line connector clamps bind on tightening / un-tightening. Stainless steel is prone to binding if there is rapid movement of the nut, or if over-tightened. Use of the correct tool to ease both conditions is recommended (results shown in Figure 20.3). A Prolink fuse has been found that had different rating stamped on its metal head to that listed on the nylon sleeve. As a caution, both the sleeve and head stamp must be read to ensure they give the same figure rating. Return any that do not match to Standards for further action (Figure 20.4). Figure 20.1 Figure 20.2 Figure 20.3 Figure 20.4 Feedback directly to: roy.english@westernpower .com.au or via incident reporting. DM# 11512037 Page 21 of 29 ISSUE 14 – 19 December 2013 21. ABB CAPACITOR BANK REPLACEMENT PROGRAM (PAUL SEILER) There have been multiple PS25 capacitor switch failures on the overhead network. The root cause was found to be problems with the circuit board inside the PS25 switches. The supplier ABB has now changed the design of the circuit board to a new solid state switch relay to resolve the problem and has agreed to replace the faulty units with new switches on a one for one exchange of new for old. Figure 21.1 Typical ABB Pole Mounted Capacitor Bank with PS25 vacuum switches. DM# 11512037 ABB PS25 Vacuum Switch Page 22 of 29 ISSUE 14 – 19 December 2013 REPLACEMENT PROCESS (PAUL SEILER) Bill Corti (Service Delivery team) is coordinating a program to remove the faulty units from the field and return them to ABB in exchange for replacement switches. All PS25 switches that DO NOT have yellow reflective tape placed around the circumference of the tank (See Figure 21.2) must be shipped back to ABB through the replacement program at Peel Depot, not through stores. An RFR (Request for Repair) must be completed in order to generate a job in DQM only for switches without yellow tape identification. It must be noted in DQM that the switches “are subject to warranty replacement”. If it is necessary to return a non-modified PS25 switch before it is scheduled to be changed out through the program, please contact Paul Seiler or Bill Corti to arrange release of replacement switches. Care should be taken to ensure the switches being returned are not damaged in any way as ABB will not accept damaged units for exchange with new PS25 switches. Packaging supplied by ABB will be given at time of pickup of replacement switches at Peel Depot. The replacement switches with yellow tape shall be installed on the capacitor bank and the old switch shall be repackaged and delivered back to Peel Depot. Figure 21.2 Replacement PS25 vacuum switch DM# 11512037 Page 23 of 29 ISSUE 14 – 19 December 2013 There are a number of older ABB capacitor banks still on the network which do not have ABB PS25 switches; instead they have “Maysteel” or “Trinetics” units. See Figure 21.3. At the time of manufacture, ABB did not offer switches on their capacitor banks and used third party switches (Maysteel or Trinetics) to supply switching. These units are not part of the ABB replacement Program and should not be returned to Peel Depot. Figure 21.3 Typical “Trinetics” switch. Trinetics (Hubbell Inc.) bought Maysteel which explains why either name occurs on older ABB capacitor bank switch nameplates. DM# 11512037 Page 24 of 29 ISSUE 14 – 19 December 2013 22. BROKEN PLASTIC KEYHOLE COVERS ON SCHNEIDER RM6 RMU FACIA (CHRIS HON) It has been reported that plastic keyhole covers on Schneider RM6 ring main switchgear have been broken while in service. This can be attributed to rough and incorrect handling by the use of the steel operating handle to flip open the plastic cover bending the plastic cover piece beyond its maximum open position. Plastic Keyhole Cover Tips to minimise breakage of the plastic keyhole cover: 1. Do not use operating handle to flip open plastic keyhole cover. Lift open the plastic cover by gripping the cover piece using your thumb and forefinger only 2. Do not insert operating handle into keyhole that has a padlock attached (ref. Figure 22.1) 3. Take due care when inserting operating handle into fuseswitch keyhole as the plastic keyhole cover flips open upwards. Only insert the operating handle parallel to the top cover of the fuse compartment. Do not tilt operating handle upwards as this action can break the plastic keyhole cover. (ref. Figure 22.2) Operating Handle 4. Take due care when lifting the fuse compartment top cover ensuring that it does not to come into contact with the open plastic keyhole cover as physical contact with the metal lid can cause the plastic keyhole cover to break off. Top Cover of Fuse Compartment Figure 22.1 SW/DC and E/SW DM# 11512037 Figure 22.2 FS/SW and E/SW Page 25 of 29 ISSUE 14 – 19 December 2013 23. SEPARATION OF SCHNEIDER RM6/FLUSARC KIOSK & SUPPORT STAND (CHRIS HON) Guardian Action ACT1005575 requires Western Power to communicate to the total operational workforce the safe method to disengage a Ring Main Unit (RMU) kiosk from the support stand that was identified from the documented risk assessment in action ACT1005574. (Guardian Action ACT1005574 concerns an installer with a suspected back injury sustained while separating a Schneider RM6 RMU kiosk and support stand.) Safe practice for separation of Schneider 24kV RM6 / 36kV FLUSARC RMU kiosk and support stand are as follows 1. Wear appropriate PPE. 2. Before working on the kiosk and stand separation ensure the RMU is deenergised and earthed. 3. Maintain good communication and coordination between team members separating the kiosk and stand 4. Clear obstructions behind and around the kiosk and maintain safe walk/work area adjacent to kiosk and stand 5. Minimum 3 persons are required to shift RM6 / Flusarc RMU kiosk with controlled actions to separate kiosk and stand (25-35mm separation is required) aided by use of appropriate tool (e.g. lever) if required and using a crane, rated straps/chain for lifting kiosk. 6. Lift kiosk from designated lifting points using crane and rated straps/chain (Ref. DM# 6323270, 8519709 and 10283501) DM# 11512037 Figure 23.1 Schneider RM6 RMU kiosk and support stand Kiosk - stand separation procedure 1) Remove all kiosk-stand mounting bolts and nuts. 2) Remove the wiring loom and earth wires (inside kiosk) which Push interconnects T200H RTU, RMU, antenna, street light cutout, kiosk and stand and kiosk door switch in preparation for the kiosk and stand separation. 3) 3 persons then push on front of kiosk simultaneously such that the kiosk moves evenly backwards about 25mm to 35mm when the kiosk “tongue” separates from the support stand “groove” (Ref. Fig.2). 4) Lift the kiosk using crane to separate from stand. Schneider 5-way RM6 aluminum kiosk Schneider 5-way RM6 galv. steel support stand Figure 23.2 Tongue-in-groove kiosk and stand inside arrangement at back of kiosk where the kiosk back panel attaches to the support stand Page 26 of 29 ISSUE 14 – 19 December 2013 24. The Correct Installation Procedure of House Service Connection Clamp FC0110 (Yow Chia) There are reports of the house service connection clamp(Stock Code FC0110) being cracked while tensioning the clamp keeper to the recommended torque of 35 Nm. Setting the correct torque is very important to achieve the best electrical connection regardless of whether it is a pg or house service connection clamp. As an example, the Kincrome metric calibration is not as straight forward as the imperial unit. The coarse adjustment for the metric calibration jumps from 13.6 to 27.1 to 40.7 ...... and so on. This means there's 13.6 Nm between each coarse adjustment. The fine adjustment on the handle is calibrated in one tenth of a unit. This means for every unit, it is equal to 13.6/10 = 1.36 Nm. Now, with the coarse adjustment set at 27.1 Nm, to achieve 35 Nm, it needs another 7.9 Nm and this is equal to approx 5.8 "notches" on the fine calibration. i.e. 5.8 x 1.36 = 7.9 Nm. With the coarse adjustment of 27.1 Nm and the fine adjustment of 7.9 Nm, the sum of these two will yield 27.1 + 7.9 = 35 Nm. If your torque wrench has only imperial calibration, then it should be set to 25.8 ft lb (foot-pound). Correct installation is achieved with the house service connection clamp held perpendicular to the conductor axis whilst installation torque is reached as shown in Figure 24.1. Tests carried out by Tyco demonstrated that using this method of installation, torques of between 6080Nm were achieved without failure of the clamp keeper. If installation is attempted with the house service connection clamp NOT kept perpendicular to the conductor axis then rotation of the connector will occur in relation to the conductor and uneven stress is placed on the clamp keeper resulting in failure of the keeper at between 40-50Nm. This is still greater than the installation torque but at a lesser safety margin. Figure 24.1 Correct Technique Note: If set at 35 ft lb, this is equivalent to 47.5 Nm which is greater than the torque required to break the clamp keeper. If the clamps are still failing after the torque wrenches are set correctly and the installation technique was followed as described herewith, please retain the failed clamps and return to the Conductor Performance Manager in the Asset Performance Section. Figure 24.2, shows the result of not keeping the house service connection clamps perpendicular to the conductor when being installed. This resulted in failure of the keepers at the lower torque loads. These three clamp keepers failed at 45Nm, 43Nm, and 45Nm respectively. Figure 24.2 Incorrect Technique DM# 11512037 Page 27 of 29 ISSUE 14 – 19 December 2013 25. INSTALLATION INSTRUCTION UPDATED FOR RM6 SWITCHGEAR SEPARABLE CONNECTORS (FC0294) (JIMI VO) FC0294 is the current standard separable connector kit to terminate cable onto RM6 switchgear. Its installation instruction (IS) has been updated recently to reflect a change in torque setting requirement. The torque setting change is located in Step 2 of the “Connector Installation On Bushing” instruction on page 5 of the IS. The detail of the change is described and shown in Figure 25.1 as below: This is the only update which is an evolutionary development to reduce the risk of damaging the inner thread of the bushing due to over tightening the bushing stud. The stud function is to hang the cable connected to the lug and does not carry any current. An amendment notice in yellow background paper and updated installation instruction will be included in the future kits that are supplied to Western Power from 15 NOV 2013. The amendment is as below: The existing instruction (issued on 20 SEP 2011) specifies to use a torque range of 30Nm up to 50Nm to tighten the bushing stud. The updated instruction (issued on OCT 2013) specifies a torque setting of 30Nm only. Figure 25.1 Existing and Updated instruction on page 5, Step 2. All cable termination onto RM6 switchgear shall follow the new torque setting requirement as per updated installation instruction. DM# 11512037 Page 28 of 29 ISSUE 14 – 19 December 2013 Distribution List: Email or Group name DQM Internal DQM - Everybody@Western_Power DQM External DQM - External UserContacts@Western_Power Horizon Power delia.leonhardt@horizonpower.com.au, supply.management@horizonpower.com.au DDP West Coast Energy (Wally Huia) Thiess Services (Rick Sage) Wally.HUIA@westcoastenergy.com.au RSage@thiess-services.com.au Future Grid Future Grid - Management@Western_Power, Power Training services (PTS) Power Training Services Operational Standards Operational.Standards@Western_Power Procurement Procurement.Operations@Western_Power Logsys c/o Contracts Manager (Sam Harris) Supply Chain Chain@Western_Power, CSV Group Commercial-Supply Perth Powerlines c/o Contracts Manager (Sam Harris) Vemco c/o Contracts Manager (Sam Harris) Distribution Group DD Everyone Electrix c/o Contracts Manager (Sam Harris) Networks Group NWK Everyone Cranelines c/o Contracts Manager (Sam Harris) System Management SM Everyone Customer Service Network Connections CUS Cust Network Connections-Bentley Customer Service Customer Assist CUS Customer Assist CEVA Logistics adam.walsh@cevalogistics.com Customer Service Metering CUS Metering Design Consultants: SKM APD rdavey@globalskm.com, mnewton@globalskm.com apd.admin@alliancepoweranddata.com.au VEMTEC khuvemtec@vemco.com.au, kmillane@vemco.com.au, CVillan@vemco.com.au, DMcLagan@vemco.com.au Balpara tnguyen@balpara.com.au, sross@balpara.com.au, aopiraporia@balpara.com.au Peracon fcloete@peracon.com.au, cvanheerden@peracon.com.au; 3E Consulting Engineers admin@3ece.com.au, jhutton@3ece.com.au DM# 11512037 Page 29 of 29