Microwave Office®

Application Note

INTRODUCTION

The X-band frequency range has been designated for critical military and

public safety applications such as satellite communications, radar, terrestrial

communications and networking, and space communications. It is important to

ensure that these signals deliver quality, reliable, and secure communications.

This application note describes the design and realization of a complex X-band

transmission analyzer for use in real-time material testing.

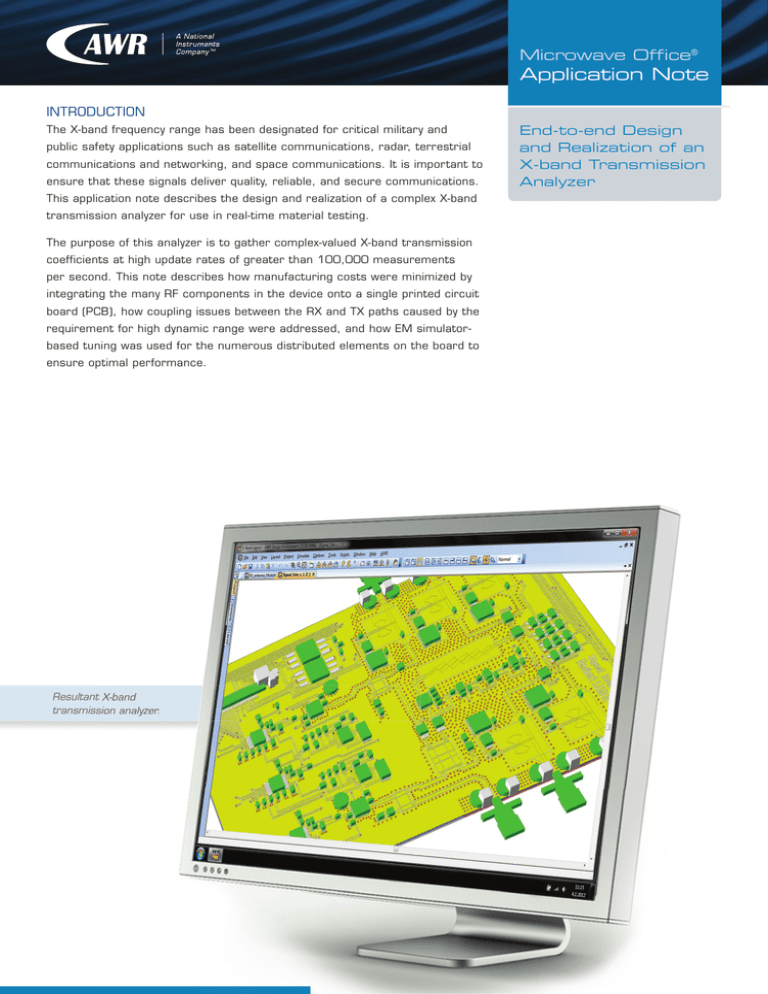

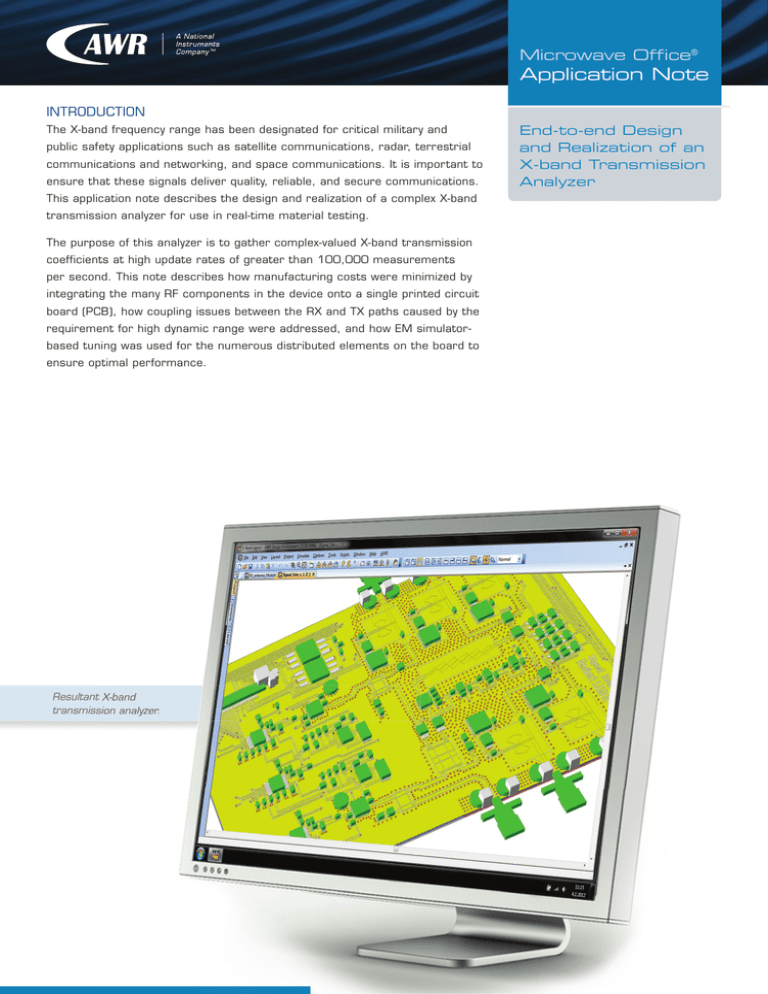

The purpose of this analyzer is to gather complex-valued X-band transmission

coefficients at high update rates of greater than 100,000 measurements

per second. This note describes how manufacturing costs were minimized by

integrating the many RF components in the device onto a single printed circuit

board (PCB), how coupling issues between the RX and TX paths caused by the

requirement for high dynamic range were addressed, and how EM simulatorbased tuning was used for the numerous distributed elements on the board to

ensure optimal performance.

Resultant X-band

transmission analyzer.

End-to-end Design

and Realization of an

X-band Transmission

Analyzer

THE DESIGN FLOW

The design team at the Vienna University of Technology was tasked with designing from

scratch and realizing this X-band transmission analyzer. The design flow involved the

design and optimization of several breeds of circuits, including critical elements such as

bias-T and microstrip filters, all of which were designed using AWR’s circuit, system, and

EM analysis software within the single, integrated AWR Design Environment™.

The PCB layout was done entirely within AWR’s Microwave Office® circuit design

software. Additionally, AWR’s Visual System Simulator™ (VSS) communication system

design software was used to find an optimal RX chain and to estimate the phase locked

loop’s (PLL) phase noise properties. The PLL’s loop filter characteristics were optimized

using the exact same schematic that was also used for carrying out the PCB layout.

Finally, AWR’s AXIEM® 3D planar EM software was utilized for simulating the varied

distributed element circuits, as well as to tackle shielding issues in the final PCB design.

(Figure 1 shows all relevant RF-circuits that were investigated during this project in order

to design the resulting final, outstanding overall system.)

Figure 1: PCB topologies investigated

during the design flow.

Because all AWR’s technologies are integrated into a single design environment, the

team was able to easily reuse structures and circuits from system models down to

PCB layout structures. For example, EM simulations of the actual PCB traces could be

checked against VSS models to see whether the designed shielding was sufficient. This

approach enabled the designers to reuse highly optimized sub circuits in the final PCB

design (Figures 2 and 3).

Figure 2: Final design layout shown within the AWR software environment.

Figure 3: Final manufactured prototype.

THE BIAS-T

Microwave Office software enables users to readily tune circuits based upon EM

simulations. In this case, the design required that the X-band RF link, the high-speed

serial bus, and the DC power supply be combined onto the same cable, thus requiring

a bias-T for each and every X-band cable interface.

In order to reduce assembly complexity and manufacturing costs, the circuit

was realized using distributed elements. A classic radial stub approach was

determined to be the best, considering tradeoffs between PCB real estate,

circuit performance, and board complexity. For reasons emerging from signal

post-processing, two different-sized radial stubs were used to ensure that the

circuit would perform consistently over about 30 percent bandwidth (Figure 4).

Using two unequal stubs made it possible to achieve constant low RF leakage

over a broad frequency range, however, this architecture was more challenging to design because placing resonant structures in close proximity resulted

in significant coupling effects. Typically this is less of a problem when dealing

with multiple structures, all operating at the same frequency. Yet in this case,

the coupling effects tended to disrupt the phase relations if not all length ratios

were close to optimum.

LF +DC

λ/4 @ flow

low RF stub

λ/4 @ flow

RF

λ/4 @ fhi

high RF stub

λ/4 @ fhi

combined RF + LF +DC

LF - block

It was clear to the team that this issue could not be resolved using closed form

approximations or simple models. For this reason, AXIEM and the Microwave Office

optimizers were the weapons of choice. Numerous runs were necessary to find a

proper solution and to answer questions like “what’s the required clearance to the

surrounding ground?” In the end, the same circuit was reused several times within

the overall design without any issues.

The inner workings of the circuit could

be understood using the current density

derived by AXIEM (Figure 5). The current

density’s maximum, which is equal to the

phase center of the RF reflect, shifted

with respect to the excitation frequency.

This resulted in a frequency-independent

virtual RF open exactly at the branch line

intersection with the RF path. This was

observed as current density minimum

at this position. Therefore, the branch

Figure 5: Bias-T standing wave current

density.

line was virtually “invisible” for the RF

signal. All the RF leakage measurements

Figure 4: Bias-T dimensions.

as well as the simulations were combined, as shown in Figure 6. The final circuit

indeed shows the desired flat frequency response in leakage over a broad band and

at constant low leakage.

0

Bias-T RF leakage (dB)

-10

-20

-30

-40

Figure 6: Measured data vs. simulation.

-50

measured - both stubs

- only high stub

- only low stub

- no stub

-60

-70

8

9

10

Axiem

11

Model Based

12

13

14

Frequency (GHz)

THE MICROSTRIP FILTER

The microstrip filter design was carried out by deriving an equivalent lumped circuit

from the design’s specifications. This representation can easily be reformulated in

terms of characteristic impedances, which is the starting point for any distributed filter

design. After that, it is up to the designer to choose a transmission line topology that

1) can realize all the desired impedances, 2) enables a compact setup, and 3) can be

manufactured with an available PCB process. In this situation, the Microwave Office

software environment assisted the design team with various tools like TX-Line® and

simple transmission line models available for many topologies. It further enabled the

designers to quickly gauge whether a certain substrate, topology, and tolerance mix

could work. These decisions are critical to the overall success of the design and must

be carefully considered.

The challenge with designing the microstrip filter for this project was that the

substrate needed to be quite thin in order to achieve a compact design in a 50Ω

microstrip stack up. It was also problematic for the PCB manufacturer to deal

with very narrow coupling gaps. The design team needed to find an alternative to

the classic edge-coupled microstrip design. The resultant design utilized two lines

with higher characteristic impedance in parallel instead of a single line, which

resulted in a larger range of achievable characteristic impedances. Figure 7 shows

the two filters in stop-band and pass-band excitation. Even though the design was

complex due to the extensive use of circuit parameters, the simulation power as

Figure 7: X-band filters (standing wave

current density).

well as the hierarchical design capabilities of the Microwave Office software made

it possible to run the same optimization routines on both circuits. This not only

reduced the design team’s time and effort, but also meant that the two blocks

were exchangeable in the final design.

CONCLUSION

This application note illustrates a complete design flow for the end-to-end design

and realization of an X-band transmission analyzer. The ability to not only design

and optimize several different circuits on a single PCB but also to work through

many design iterations and verification steps at different abstraction layers was

critical to achieving the project’s ambitious performance goals. Keeping design

changes and parameter variations consistent through all abstraction layers was

a challenging task that was made possible and ultimately successful with the

help of the AWR Design Environment that offered complete integration of all the

constituent design and verification steps.

Final prototype of the X-band

transmission analyzer.

AWR would like to thank Norbert

Leder, Dipl.-Ing., lead engineer from

Vienna University of Technology to his

contributions to this application note.

Dr. Holger Arthaber

Head of Microwave Engineering,

Project leader

holger.arthaber@tuwien.ac.at

Dipl.-Ing. Norbert Leder,

System architect, Lead engineer

norbert.leder@tuwien.ac.at

Copyright © 2013 AWR Corporation. All rights reserved. AWR, Microwave Office, AXIEM, and TX-Line are registered

trademarks and the AWR logo, AWR Design Environment, and Visual System Simulator are trademarks of AWR

Corporation. Other product and company names listed are trademarks or trade names of their respective companies.

AN-TUV-MWO-2013.2.14

AWR Corporation | www.awrcorp.com

info@awrcorp.com | +1 (310) 726-3000