APPLICATION NOTE

SKYA21004: PCB Layout Guidelines

Introduction

PCB layout design is essential to better performance, reliability

and manufacturability. Malfunctions from noise, which may hurt

the system stability, have become an increasing problem, and

may therefore generate more failures and reliability malfunctions

in production lines.

In this document, several considerations and guidelines for

SKYA21004 PCB layout design are presented to improve

performance, reliability, and manufacturability.

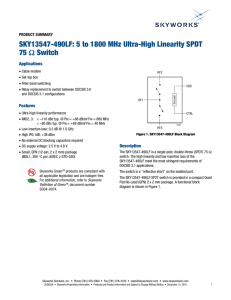

Guidelines for Land Pattern and Thermal Vias on

the SKYA21004

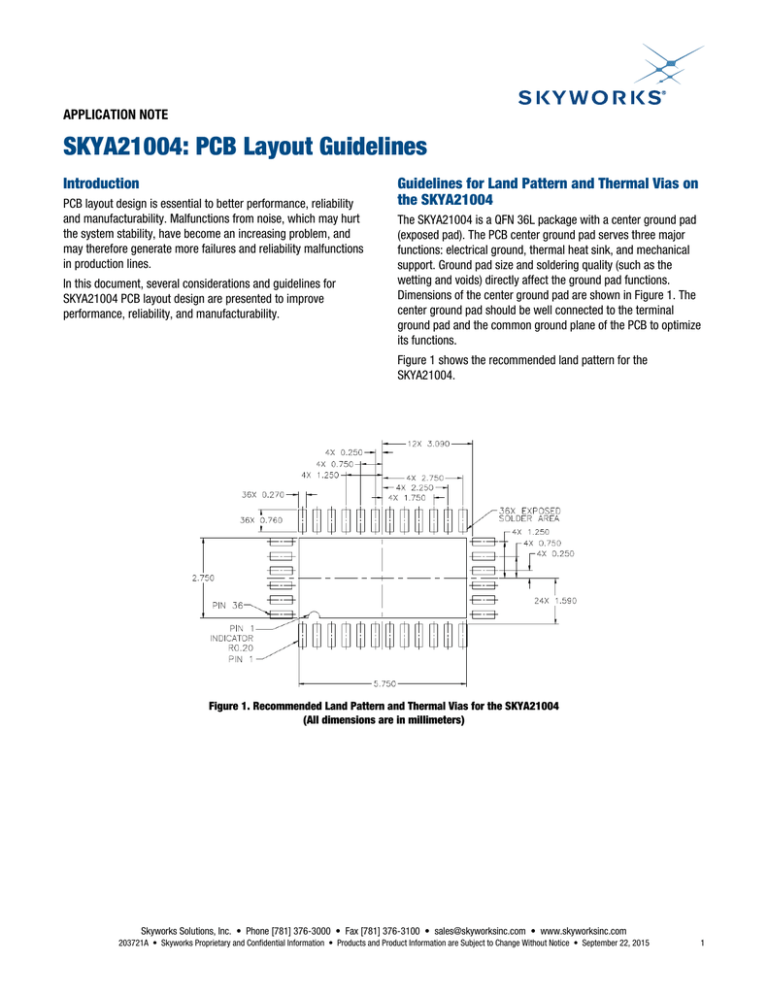

The SKYA21004 is a QFN 36L package with a center ground pad

(exposed pad). The PCB center ground pad serves three major

functions: electrical ground, thermal heat sink, and mechanical

support. Ground pad size and soldering quality (such as the

wetting and voids) directly affect the ground pad functions.

Dimensions of the center ground pad are shown in Figure 1. The

center ground pad should be well connected to the terminal

ground pad and the common ground plane of the PCB to optimize

its functions.

Figure 1 shows the recommended land pattern for the

SKYA21004.

Figure 1. Recommended Land Pattern and Thermal Vias for the SKYA21004

(All dimensions are in millimeters)

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

203721A • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • September 22, 2015

1

APPLICATION NOTE • SKYA21004: PCB LAYOUT GUIDELINES

Electrical and Thermal Performance

To improve thermal and electrical performance of a mounted

SKYA21004, an array of thermal vias placed on the area of the

ground pad should be connected to the internal and bottom

common ground copper planes of the PCB. In general, there is a

direct correlation between the thermal via cross-sectional area

and the heat dissipation rate. However, large and excessive

thermal vias may introduce more voids in the solder joint and

actually reduce overall heat dissipation performance.

Recommended thermal vias are 0.30 mm to 0.33 mm in diameter,

and via barrels should be plated with 1 oz. of copper to plug the

vias. The thermal via array should be arranged evenly with a pitch

of 0.5 mm to 1.0 mm. For the exposed region of the ground pad,

if the plating thickness is not sufficient to effectively plug the

barrel of the via when plated, solder mask should be used to cap

the vias with a minimum dimension equal to the via diameter plus

0.1 mm. This will prevent solder wicking through the thermal via

during the soldering process, resulting in voiding.

In the SKYA21004 layout, it is recommended to arrange 24ea vias

evenly with a pitch 0.6 mm, as shown in Figure 1.

For more detailed information refer to the Skyworks Application

Note #101752I.

Guidelines for the Boost Section for LED

Backlight Driving and LCD Bias Power

The SKYA21004 is divided into two blocks as its operating

purpose. One is a LED Backlight Driving Boost Section and the

other is an LCD Bias Power Boost Section. To prevent interactive

noise between two individual power blocks (LCD Bias Power and

LED Driver), use independent planes for PGND (power ground for

LCD Bias Power) and WPGND (power ground for LED Driver).

Another way to plug thermal vias uses solder mask tenting on the

bottom of the copper plane. Solder mask tenting must completely

cover the vias.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

2

September 22, 2015 • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • 203721A

APPLICATION NOTE • SKYA21004 LAYOUT GUIDELINES

OUT

470 nF

0.1 μF

VIN

LCD Supply Input

0.22 μF

10 μF

8 nF

100 pF

COMP

19

20

FB

21

AGND

VL

IN

22

FB

24 SCL

23

SCL

25

DGND

26

OVP

OUT

BL_EN

28

27 OVP

WEN

WCOMP

18

17

DRVN

GND

FBN

FB

11 kΩ

14

5V

13 VDD

0.1 μF

1 μF

0.22 μF

0.1 μF

BL Supply Input

0.1 μF

00.22 μF

0.22 μF

D1

NC

2.2 μF

2.2 μF

301 kΩ

FBP

10 kΩ

37.4 kΩ

0.22 μF

OVP

NC

6.04 kΩ

OUT (up to 28 V)

1 MΩ

VGH

0.1 μF

4.7 μH

4.7 μF

226 kΩ

NC

15 EN_LCD

VDD

12

11

10

REF

GND

9

WLX

8

WLX

6

7

WPGND

WPGND

NC

2.2 μF 2.2 μF 2.2 μF 2.2 μF

16 FBP

DRVP

5

36

LX

PGND

EN

CS56

1

X

SKYA21004

CS34

PWM

LED3 35

4.7 μH

FBP

4

LED2 34

AVDD

200 kΩ

CS12

GND

22 kΩ

FOSC

PWM 3

LED1 33

SDA

ISET

32

SGND

31

2

34.8 kΩ

29

30 SDA

10 kΩ

0.22 μF

2.2 μF

VGL

45.3 kΩ

AVDD

VDD

Y2380

Figure 2. SKYA21004 LED Driver Boost Section

Layout of LED Driver Boost Section Procedure

1. Connect the inductor and diode as close to the WLX node as

possible.

2. Connect CIN capacitor close to the inductor and COUT capacitor(s)

close to the diode.

3. Connect the COUT ground return and IC WPGND with direct wide

and short trace. If needed, connect the ground return on

multiple layers with multiple vias connected.

4. Make the PCB traces between CIN and inductor, inductor and

WLX pin, WLX pin and diode, diode and COUT as wide and as

short as possible.

5. The trace should be wider than 1.5 mm.

6. Isolate the WPGND return from the AGND, DGND, SGND, and

GND. Connect the WPGND to the system ground near the

system input.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

203721A • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • September 22, 2015

3

APPLICATION NOTE • SKYA21004: PCB LAYOUT GUIDELINES

OUT

470 nF

0.1 μF

VIN

LCD Supply

pp y Input

p

0.22 μF

10 μF

8 nF

100 pF

COMP

19

20

FB

21

AGND

VL

IN

22

FB

24 SCL

23

SCL

25

DGND

27 OVP

BL_EN

28

26

OUT

18

PGND

17

DRVN

GND

11

FB

11 kΩ

14

5V

13 VDD

0.1 μF

1 μF

0.22 μF

0.1 μF

BL Supply Input

0.1 μF

0.22 μF

0.22 μF

NC

OUT (up to 28 V)

2.2 μF

2.2 μF

301 kΩ

FBP

10 kΩ

37.4 kΩ

0.22 μF

1 MΩ

NC

6.04 kΩ

D1

OVP

VGH

0.1 μF

4.7 μH

4.7 μF

226 kΩ

NC

N

15 EN_LCD

VDD

12

REF

FBN

10

GND

9

WLX

8

7

WLX

6

WPGND

5

WPGND

4

NC

2.2 μF 2.2 μF 2.2 μF 2.2 μF

16 FBP

DRVP

PWM

36

LX

EN

CS56

1

X

SKYA21004

CS34

GND

LED3 35

4.7 μH

FBP

2

LED2 34

2000 kΩ

CS12

PWM 3

22 kΩ

OVP

FOSC

AVDD

WEN

32

LED1 33

WCOMP

ISET

SDA

31

SGND

34.8 kΩ

29

30 SDA

10 kΩ

0.22 μF

2.2 μF

VGL

45.3 kΩ

AVDD

VDD

Y2381

Figure 3. SKYA21004 LCD Bias Power Boost Section and Charge Pump Section

Layout of LCD Driver Boost and Charge Pump Section

Procedure

1. Connect the inductor and diode as close to the LX node as

possible.

2. Connect CIN and COUT capacitor(s) as close to the IC as

possible.

3. Connect the COUT ground return and IC PGND as close as

possible.

4. Make the PCB traces between CIN and inductor, inductor and

LX pin, LX pin and diode, diode and COUT as wide and as

short as possible.

5. Trace should be wider than 1.5 mm. Connect all grounds of the

charge pump to PGND.

6. Isolate the PGND return from the AGND, DGND, SGND, and

GND.

7. Connect the PGND to the system ground near the system input.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

4

September 22, 2015 • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • 203721A

SDA

WCOMP

WEN

OVP

OUT

DGND

SCL

VL

IN

AGND

FB

COMP

30

29

28

27

26

25

24

23

22

21

20

19

APPLICATION NOTE • SKYA21004 LAYOUT GUIDELINES

ISET

31

18

FOSC

32

17

PGND

CS12

33

16

FBP

CS34

34

15

EN

CS56

35

14

DRVP

NC

36

13

VDD

1

2

3

4

5

6

7

8

9

10

11

12

SGND

GND

PWM

WPGND

WPGND

WLX

WLX

GND

REF

FBN

GND

DRVN

EP

LX

t0095

Figure 4. SKYA21004 Pinout

Figure 5. SKYA21004 Layout Example (Boost Section)

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

203721A • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • September 22, 2015

5

APPLICATION NOTE • SKYA21004: PCB LAYOUT GUIDELINES

Guidelines of Analog and Feedback Section

isolated from the noise of the boost and charge pump section.

Grounds for the analog and feedback sections should be

connected to the plane of AGND, DGND, SGND, and GND.

The Analog and Feedback section is an important block for stable

system operation. For stable operation, these sections should be

OUT

470 nF

0.1 μF

VIN

LCD Supply Input

0.22 μF

10 μF

8 nF

100 pF

20

19

COMP

AGND

FB

21

22

IN

VL

23

FB

24 SCL

SCL

25

26

DGND

OVP

OUT

BL_EN

28

27 OVP

WEN

18

17

DRVN

GND

FBN

FB

11 kΩ

14

5V

13 VDD

0.1 μF

1 μF

0.22 μF

0.1 μF

BL Supply Input

0.1 μF

0.22 μF

0.22 μF

D1

2.2 μF

301 kΩ

FBP

NC

10 kΩ

37.4 kΩ

0.22 μF

OVP

NC

6.04 kΩ

OUT (up to 28 V)

1 MΩ

VGH

0.1 μF

4.7 μH

4.7 μF

226 kΩ

NC

15 EN_LCD

VDD

12

11

10

REF

GND

9

8

WLX

WLX

7

6

WPGND

WPGND

5

NC

2.2 μF 2.2 μF 2.2 μF 2.2 μF

16 FBP

DRVP

PWM

36

LX

PGND

EN

CS56

1

X

SKYA21004

CS34

4

LE

LED3 35

4.7 μH

FBP

GND

LE

LED2 34

AVDD

200 kΩ

CS12

2

22 kΩ

FOSC

PWM 3

LED1 33

LE

WCOMP

ISET

32

SDA

31

SGND

34.8 kΩ

29

30 SDA

10 kΩ

2.2 μF

0.22 μF

2.2 μF

VGL

45.3 kΩ

AVDD

VDD

Y2382

Figure 6. SKYA21004 Analog Section

Layout of Analog Section Procedure

Feedback Layout Design Considerations

1. Connect the resistors and capacitors for IN, OUT, VL, COMP,

WCOMP, ISET, FOSC, and OVP as close to the IC as possible.

Feedback sensing points – All feedback points including FB,

FBP, FBN, and OVP should be sensed from the output capacitor

for stable and precise output feedback.

2. Connect to DGND ground plane for ground return.

3. Use the same ground plane for AGND, DGND, SGND, and GND.

Routing of the feedback line – To avoid coupling effects,

sensitive lines should not be routed on top of the digital or

switching signal. Sensitive lines also should not be placed in

parallel with a digital or switching signal.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

6

September 22, 2015 • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • 203721A

APPLICATION NOTE • SKYA21004 LAYOUT GUIDELINES

OUT

470 nF

0.1 μF

VIN

LCD Supply Input

0.22 μF

10 μF

8 nF

100 pF

19

COMP

20

FB

21

AGND

VL

IN

22

FB

24 SCL

23

SCL

OUT

DGND

26

25

BL_EN

28

27 OVP

OVP

18

PGND

17

DRVN

FB

11 kΩ

14

5V

13 VDD

0.1 μF

1 μF

0.22 μF

0.1 μF

BL Supply Input

0.1 μF

0.22 μFF

0.22 μF

D1

NC

22.2 μF

2.2 μF

301 kΩ

FBP

10 kΩ

337.4 kΩ

0.22 μF

OVP

NC

6.04

0 kΩ

OUT (up too 28 V)

1 MΩ

VGH

0.1 μF

4.7 μH

4.7 μF

226 kΩ

NC

C

15 EN_LCD

VDD

12

GND

11

FBN

10

REF

GND

9

8

WLX

WPGND

WLX

7

6

WPGND

5

4

NC

2.2 μF 2.2 μF 2.2 μF 2.2 μF

16 FBP

DRVP

PWM

36

LX

EN

CS56

1

X

SKYA21004

CS34

GND

LED3 35

4.7 μH

FBP

PWM 3

LED2 34

200 kΩ

CS12

SGND

22 kΩ

AVDD

A

AV

DD

WEN

FOSC

LED1 33

WCOMP

ISET

32

SDA

31

2

34.8 kΩ

29

30 SDA

10 kΩ

0.22 μF

2.2 μF

VGL

45.3 kΩ

AVDD

VDD

Y2383

Figure 7. SKYA21004 Feedback Section

Layout of Feedback Section Procedure

1. Connect the OVP resistors to the OUT capacitors with a

dedicated ground shielded trace to avoid interference from

other signals. This trace is used as a feedback for the WLED

boost regulator.

3. To avoid coupling effects, sensitive lines should not be routed

on top of the digital or switching signal.

4. When connecting nodes from the other layer, use at least four

0.4 mm hole diameter, 0.7mm pad diameter vias (conductive

filled via is preferred).

2. Connect the AVDD/VGH/VGL feedback resistors to the OUT

capacitors with a dedicated ground shielded trace.

Figure 8. Example of Routing the Sensitive Line

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

203721A • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • September 22, 2015

7

SDA

WCOMP

WEN

OVP

OUT

DGND

SCL

VL

IN

AGND

FB

COMP

30

29

28

27

26

25

24

23

22

21

20

19

APPLICATION NOTE • SKYA21004: PCB LAYOUT GUIDELINES

ISET

31

18

LX

FOSC

32

17

PGND

CS12

33

16

FBP

CS34

34

15

EN

CS56

35

14

DRVP

NC

36

13

VDD

1

2

3

4

5

6

7

8

9

10

11

12

SGND

GND

PWM

WPGND

WPGND

WLX

WLX

GND

REF

FBN

GND

DRVN

EP

t0095

Figure 9. SKA21004 Pinout

Figure 10. SKYA21004 Layout Example (Analog and Feedback Section)

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

8

September 22, 2015 • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • 203721A

APPLICATION NOTE • SKYA21004 LAYOUT GUIDELINES

Copyright © 2015 Skyworks Solutions, Inc. All Rights Reserved.

Information in this document is provided in connection with Skyworks Solutions, Inc. (“Skyworks”) products or services. These materials, including the information contained herein, are provided by

Skyworks as a service to its customers and may be used for informational purposes only by the customer. Skyworks assumes no responsibility for errors or omissions in these materials or the

information contained herein. Skyworks may change its documentation, products, services, specifications or product descriptions at any time, without notice. Skyworks makes no commitment to

update the materials or information and shall have no responsibility whatsoever for conflicts, incompatibilities, or other difficulties arising from any future changes.

No license, whether express, implied, by estoppel or otherwise, is granted to any intellectual property rights by this document. Skyworks assumes no liability for any materials, products or

information provided hereunder, including the sale, distribution, reproduction or use of Skyworks products, information or materials, except as may be provided in Skyworks Terms and Conditions

of Sale.

THE MATERIALS, PRODUCTS AND INFORMATION ARE PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE, INCLUDING FITNESS FOR A

PARTICULAR PURPOSE OR USE, MERCHANTABILITY, PERFORMANCE, QUALITY OR NON-INFRINGEMENT OF ANY INTELLECTUAL PROPERTY RIGHT; ALL SUCH WARRANTIES ARE HEREBY EXPRESSLY

DISCLAIMED. SKYWORKS DOES NOT WARRANT THE ACCURACY OR COMPLETENESS OF THE INFORMATION, TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS. SKYWORKS

SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING BUT NOT LIMITED TO ANY SPECIAL, INDIRECT, INCIDENTAL, STATUTORY, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION,

LOST REVENUES OR LOST PROFITS THAT MAY RESULT FROM THE USE OF THE MATERIALS OR INFORMATION, WHETHER OR NOT THE RECIPIENT OF MATERIALS HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

Skyworks products are not intended for use in medical, lifesaving or life-sustaining applications, or other equipment in which the failure of the Skyworks products could lead to personal injury,

death, physical or environmental damage. Skyworks customers using or selling Skyworks products for use in such applications do so at their own risk and agree to fully indemnify Skyworks for any

damages resulting from such improper use or sale.

Customers are responsible for their products and applications using Skyworks products, which may deviate from published specifications as a result of design defects, errors, or operation of

products outside of published parameters or design specifications. Customers should include design and operating safeguards to minimize these and other risks. Skyworks assumes no liability for

applications assistance, customer product design, or damage to any equipment resulting from the use of Skyworks products outside of stated published specifications or parameters.

Skyworks, the Skyworks symbol, and “Breakthrough Simplicity” are trademarks or registered trademarks of Skyworks Solutions, Inc., in the United States and other countries. Third-party brands

and names are for identification purposes only, and are the property of their respective owners. Additional information, including relevant terms and conditions, posted at www.skyworksinc.com,

are incorporated by reference.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

203721A • Skyworks Proprietary and Confidential Information • Products and Product Information are Subject to Change Without Notice • September 22, 2015

9