DONN Brand Ceiling Suspension Accessories

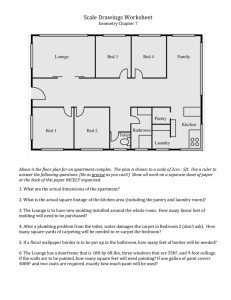

advertisement

Donn® Brand Suspension Systems Accessory Product Guide Since 1957, DONN brand suspension systems have set the standard worldwide for the ceiling suspension industry. Donn suspension systems are readily available in all markets, install faster than any other suspension system, and maintain modularity (squareness) better than any other system. The following pages represent USG’s most popular suspension system accessory items, which are designed to assist you in installing perfect ceilings with minimum effort. If you are in doubt about the application of any of our accessory items or any of our other products, please call our Technical Service Department, 1 800 USG.4YOU, or your local USG Sales Representative. ® Installing Perfect Ceilings User’s Guide Use this brochure to design, specify, bid and install USG Donn suspension systems. Pages Moldings 4 Angle Molding Shadow Molding US Channel Wall Molding "F" Molding Molding Accessories Grid Installation Accessories 6 7 Outside Corners Inside Corners Galvanized Hanger Wire Stabilizer Bars Partition Attachment Grid to Primary Support Seismic Compression Posts Hold-Down Clips Grid to Molding Tee Accessories FINELINE® Accessories Tee to Tee Light Fixture Accessories 12 Light Fixture Clip Miscellaneous Accessories 13 Cross Tee Hole Punches Touch-Up Paint Air Diffusers Separation Joints 14 Tee-Face Sleeves Expansion Joint Moldings 3 Accessory Product Guide Donn Suspension Systems Moldings Angle Molding Use for standard ceiling perimeters. Angle Molding w/Gasket M12CE Use in cleanroom applications with Donn CE suspension system. Shadow Molding For creating reveals at ceiling perimeters. Also helps to hide imperfections in drywall partitions and bulkheads. A B C D Length x A x B x C x D Shadow Molding Catalog Number M71 M7OL M7A M7-10 M7SS M7Z M91 M9-10 M12 MC11A25 M12CE M20SM M20SM-2 M202 MS124 Length x A x B x C x D (See illustration above) MS134 Angle Molding MS144 MS1543 MS164 MS1743 MS274 Description 12 x 7/8 x 7/8 Wall Molding 12 x 7/8 x 7/8 Overlapping Wall Molding 12 x 7/8 x 7/8 Aluminum Wall Molding 10 x 7/8 x 7/8 Wall Molding 12 x 7/8 x 7/8 Stainless Steel Wall Molding 12 x 7/8 x 7/8 Hot-Dipped Galvanized Steel Wall Molding 12 x 9/16 x 15/16 Wall Molding 10 x 9/16 x 15/16 Wall Molding 10 x 1 x 1 1/2 Wall Molding 10 x 1 x 1 Aluminum Cap Wall Molding 10 x 1 x 1 1/2 Wall Molding w/ gaskets 10 x 1 x 2 Wall Molding 10 x 2 x 2 Wall Molding 10 x 1 x 2 Wall Molding 12 x 15/16 x 1/4 x 5/16 x 15/16 Shadow Molding (Option 1) 12 x 15/16 x 5/16 x 1/4 x 15/16 Shadow Molding (Option 2) 12 x 9/16 x 1/4 x 5/16 x 3/4 Shadow Molding (Option 1) 12 x 3/4" x 5/16 x 1/4 x 9/16 Shadow Molding (Option 2) 12 x 3/4 x 3/8 x 1/2 x 3/4 Shadow Molding (Option 1) 12 x 3/4 x 1/2 x 3/8 x 3/4 Shadow Molding (Option 2) 12 x 7/8 x 3/4 x 3/4 x 7/8 Shadow Molding 12 x 3/4 x 3/4 x 3/4 x 3/4 Shadow Molding 12 x 7/8 x 3/8 x 3/8 x 9/16 Shadow Molding (Option 1) 12 x 9/16 x 3/8 x 3/8 x 7/8 Shadow Molding (Option 2) 10 x 7/8 x 3/4 x 9/32 x 1-1/4 Shadow Molding Packaging/Ctn. LF Pcs. 480 40 480 40 480 40 400 40 240 20 480 40 480 40 400 40 250 25 250 25 240 48 250 25 200 20 250 25 300 25 Wt. (lbs.) 63 63 26 26 31 58 55 23 63 39 59 80 76 55 46 300 25 37 300 25 48 300 300 300 25 25 25 67 62 43 200 20 54 Notes (1) M7 and M9 available in color. For colors other than Flat White and Flat Black, packaging is 240 LF per carton. (2) Not all M20 modlings are available in all areas. Please contact your USG Sales Representative. (3) MS154 and MS174 available with exposed horizontal leg painted a color. 4 Accessory Product Guide Moldings US Channel Wall Molding Use with C-8 clip to hold down perimeter ceiling panels. US Channel Wall Molding w/Gasket US28CE Use with C-8 clip in cleanroom application with DONN CE suspension system. F-Molding Use to create ceiling breaks, soffits and changes in elevation. B A C Length x A x B x C US Channel Wall Molding F-Molding Catalog Number US12 US20 US28 US31 UA25 U-2-3/32 US28CE MF8 MF10 Description 10 x 3/4 x 1/2 x 1 U-Molding 10 x 1-1/4 x 1/2 x 1 U-Molding 10 x 1-11/16 x 1/2 x 1 U-Molding 10 1-15/16 x 1/2 x 1 U-Molding 10 x 1-9/16 x 1/2 x 1 Aluminum U-Molding 12 x 2-3/32 x 7/8 x 1-1/8 Aluminum U-Molding, Flat White 10 x 1-11/16 x 1/2 x 1 U-Molding w/ gaskets, Flat White 10 x 1/2 F-Molding (for 1/2 panels) 10 x 5/8 F-Molding (for 5/8 panels) 5 Accessory Product Guide Packaging/Ctn. LF Pcs. 500 50 300 30 300 30 300 30 300 30 360 30 300 30 100 10 100 10 Wt. (lbs.) 44 57 63 70 33 90 63 28 29 Donn Suspension Systems Molding Accessories Square Molding Corner Clip JS Use with angle molding. Outside Corner JS174 Use with MS174 shadow molding. Radius Molding Corner Clip JH, JB For radius or “bullnose” corners. Field-Modified Corner JM16 Cut out clip to fit field condition. Inside Corner Angle Mold A2 Use with angle molding. Prefabricated Inside Corner A174 Use with MS174 shadow molding. Catalog Number JS9 JS14 JS16 JS174 JS274 JH9 JH12 JH14 JH15 JH16 JB14 JB16 JM16 A2 A174 A274 Outside Corners Inside Corners 6 Description Square 90° Outside Corner Cap for 9/16 molding Square 90° Outside Corner Cap for 7/8 molding Square 90° Outside Corner Cap for 1 molding Square 90° Outside Corner Cap for MS174 Shadow Molding Square 90° Outside Corner Cap for MS274 Shadow Molding 1 Radius 90° Outside Corner Cap for 9/16 molding 1 Radius 90° Outside Corner Cap for 3/4 molding 1 Radius 90° Outside Corner Cap for 7/8 molding 1 Radius 90° Outside Corner Cap for 15/16 molding 1 Radius 90° Outside Corner Cap for 1 molding 3/4 Radius 90° Outside Corner Cap for 7/8 molding 3/4 Radius 90° Outside Corner Cap for 1 molding Field-Modified Corner for 1 molding Inside Corner Cap for 7/8 molding Inside Corner Cap for MS174 Shadow Molding Inside Corner Cap for MS274 Shadow Molding Accessory Product Guide Packaging/Ctn. Pcs. Wt. (lbs.) 100 3 100 3 100 3 50 1.5 50 1.5 100 3 100 3 100 3 100 3 100 3 100 3 100 3 100 3 200 4 50 1.5 50 1.5 Grid Installation Accessories Galvanized Hanger Wire A To suspend acoustical ceilings. Also use for flat and curved USG Drywall Suspension System. Drywall Grid Hanger Clip B To suspend secondary ceiling. Grid Load Transfer Bracket C To suspend secondary ceiling. Furring Clip for Grid to Channel D Seismic Attachment Clip for Perimeter Conditions E Attach tee ends at the perimeter in seismic design categories C, D, E and F. Molding Attachment Clip F Connect grid to 1-1/2 channel. Galvanized Hanger Wire1 Consult Customer Service for available lengths in your area. Grid to Primary Support Grid to Molding2 Catalog Number 215109 217128 217268 DGHC 256860 256861 256862 V-14 ACM7 MAC2 Attach tees to angle molding and shadow molding. 12-Gauge Wrapped 12 ft.; 50 lb. bundle 12-Gauge Wrapped 12 ft.; 36 lb. bundle 12-Gauge Wrapped 16 ft. Packaging/Ctn. Pcs. Wt. (lbs.) 140 50 100 36 100 48 A A A Drywall Grid Hanger Clip Grid Load Transfer Bracket, 15/16 grid Grid Load Transfer Bracket, 9/16 grid Grid Load Transfer Bracket, 1-1/2 grid Furring Clip for Grid to Channel Seismic Perimeter Attachment Clip Molding Attachment Clip 100 250 250 250 500 100 100 B C C C D E F Description 1.5 13 13 13 45 7 3 Note (1) For special lengths, contact your USG Sales Representative. Hanger wire complies with Federal Specification QA-W-461H. (2) Please refer to www.seismicceilings.com for more information about seismic applications with the ACM7 seismic clip. 7 Accessory Product Guide Detail Key Donn Suspension Systems Grid Installation Accessories MT/CT Converter G Changes main-tee direction 90° from adjacent main tee. 2-Way Seismic Separation Joint Clip H1 For seismic separation joints in IBC Seismic Design Categories D,E, and F. 3-Way Off-Module Connector H2 Use with cross tees and main tees that are he same height. 4-Way Seismic Separation Joint Clip I For seismic separation joints in IBC Seismic Design Categories D,E, and F. Paired Main Tee Clip J Use for linear air diffusers; use only with DX®/DXL™, DXLA™, ZXLA™, FINELINE® (DXF) and FINELINE® 1/8 (DXFF) Light-Fixture Clip K For CENTRICITEE™ suspension system; use black clips with parabolic fixtures. Cross tee must be connected to main tee. Catalog Number DXMT/CT DH2 DH3 DH4 V-32 LFC Tee to Tee Light Fixture Clip Description 9 x 1-1/2 MT/CT Converter, changes MT direction 2-Way Seismic Separation Joint Clip 3-Way Off Module Connector 4-Way Seismic Separation Joint Clip Paired Main Tee Clip (2 separation center to center) Light-fixture hold-down clip—for 9/16 grid Packaging/Ctn. LF Pcs. 75 100 100 100 100 100 Notes (1) Please refer to Submittal Sheet AC3301 for more information about the DH2 2-way seismic separation joint clip. (2) Please refer to Submittal Sheet AC3271 for more information about the DH4 4-way seismic separation joint clip. 8 Accessory Product Guide Detail Wt. (lbs.) 13 2 3 4 3 2 Key G H1 H2 I J K Grid Installation Accessories Seismic Compression Post 1 L For lateral bracing in IBC Seismic Design Categories D, E, F and exterior ceiling applications for wind uplift. Tee Face Sleeve M1 To cut in tees to existing system and for separation joints. Tee Face Sleeve 2 M2 To cut in tees to existing system and for separation joints. DX DXT 3 Accessory Hanger Hook O Remove top clip for use with standard 1/4 FINELINE suspension system. DXF DX Seismic Compression Posts Tee Accessories Partition Attachment Catalog Number VSA18/30 VSA30/48 VSA48/84 VSA84/102 VSA102/120 VSA120/144 TFS-1 TFS-2 TFS-3 TFS-4 TFS-5 TFS-5 DXI FC AH1 PAC15-SQ PAC15-SL PAC 9-FL 4 Partition Attachment Clip P1 and P2 Reveal edge Squarel edge Adjustable 18 to 30 Adjustable 30 to 48 Adjustable 48 to 84 Adjustable 84 to 102 Adjustable 102 to 120 Adjustable 120 to 144 Packaging/Ctn. Pcs. Wt. (lbs.) 1 2.0 1 2.5 1 4.5 1 7.5 1 9 1 11 L L L L L L Tee Face Sleeve (3 long) for 15/16 DX/DXL Systems Tee Face Sleeve (3 long) for 9/16 DXT Systems Tee Face Sleeve (3 long) for DXF Systems with 1/4 Reveal Tee Face Sleeve (3 long) for DXFF Systems with 1/8 Reveal Tee Face Sleeve (3 long) for DXI Systems with 1/8 Reveal Tee Face Intersection sleeve (3 long) for DXI Systems with 1/8 Reveal Accessory Hanger Hook (white, injection molded) Partition Clip for 15/16 or 9/16 SQ panels (245339) Partition Clip for 15/16 SL panels (254340) Partition Clip for 9/16 FL panels (254341) 100 100 100 100 100 100 50 100 100 100 M M M M M2 M2 O P1 P2 P2 Description 10 3 4 4 4 4 1 8 8 8 Detail Key Notes (1) Please refer to Compression Posts (SC2497) for more information about USG compression posts. (2) The DXI Tee-Face Intersection Sleeve (TFS-5 DXI FC) is used for off-module intersections to maintain the clean, uninterrupted aesthetic of the grid profile. (3) Whenever possible the accessory hanger hook should be installed on a main tee. If an accessory hanger hook is installed on a main tee the load should not exceed 10 lbs. without installing a supplementary hanger wire support to the structure at the location of the hanger hook. If an accessory hanger hook is installed on a cross tee the load should not exceed 4 lbs. without installing a supplementary hanger wire support to the structure at the location of the hanger hook. The accessory hanger hook is not designed to support loads exceeding 30 lbs. (4) The partition attachment clip shown above is manufactured by Revoe Manufacturing of Canada (www.revoe.com) and can be purchased through USG. 9 Accessory Product Guide Donn Suspension Systems Grid Installation Accessories Panel Retention Clip¹ Hold-Down Clips Panel Retention Clip 20428 P3 Attaches to 1-1/2 main tees and cross tees behind lay-in ceilings. The retention clips help prevent panel displacement from incidental contact. Recommended with ROCK FACE® ceiling panels for impaction resistant systems. Hold-Down Clip—Fire-Rated Grid Q1 Used when required in some fire-rated assemblies. Hold-Down Clip Q2 To maintain a cleanroom seal. Variable Locking Hold-Down Clip Q3 Use as a locking hold-down clip for various acoustical and metal panels. Accessible Hold-Down Clip R Use as a hold-down clip for 5/8 panels. Provides ready accessibility. Variable Hold-Down Clip S For 5/8 to 3/4 panels. Catalog Number 20428 L15 L15CE PZ L45 V15 Description Attaches to 1-1/2 main tees and cross tees behind lay-in ceilings. The retention clips help prevent panel displacement from incidental contact. Recommended with ROCK FACE® ceiling panels for impaction resistant systems. Hold-Down Clip—for 5/8 fire-rated panels Hold-Down Clip—for panels in CLEAN ROOM™ applications (same clip as L15; smaller quantity) Variable Locking Hold-Down Clip Accessible Hold-Down Clip for 5/8 panels Variable Hold-Down Clip Packaging/Ctn. Pcs. Wt. (lbs.) 200 17 Detail Key P3 1000 500 7 3.5 Q1 Q2 100 1000 1000 1 15 8 Q3 R S Note (1) For more information about the Keep Clip™ from American Retention Components, Inc., please visit www.retentionclip.com. 10 Accessory Product Guide Grid Installation Accessories Hold-Down Clips continued FINELINE Accessories Wall Spring Clip T To hold down perimeter ceiling panels. Useful for maintaining cleanroom seal with US28CE molding. Miter Closure Clip for FINELINE system U For closing off unused miters. CELEBRATION™ Hold-Down Channel Clip V Partition Attachment Clip W To screw-attach ceiling-height partitions. T-Bolt X To bolt-attach partitions, signage or pendantmounted indirect lighting. FINELINE Cut-Off Die Y Use to field-cut FINELINE tees. Catalog Number C-8 C-8CE MCC3 MCC2 T15 U-2-3/32 PAC1 TB1 FC1 Description Wall Spring Clip Wall Spring Clip (same clip as C-8; smaller quantity) 2 Miter Closure Clip for 1/8 FINELINE suspension system 2 Miter Closure Clip for standard FINELINE suspension system 10 x 11/32 x 1-9/16 x 3/4 Panel Hold-Down Clip 10 x 11/32 x 2-3/32 x 3/4 Panel Hold-Down Clip 3 Partition Attachment Clip 1 x 1/4 – 20 T-Bolt FINELINE Suspension System Cut-Off Die (scaffold mount) Packaging/Ctn. Pcs. Wt. (lbs.) 2000 29 500 8 50 1 50 1 500 30 500 30 50 1 100 1 1 10 Detail Key T T U U V V W X Y Note (1) Please refer to USG Exterior Ceiling Applications (SC2561) for more information about exterior ceiling applications with the U-2-3/32 hold-down clip. Use T-15 hold-down clip with UA25 molding and use U-2-3/32 hold-down clip with U-2-3/32 molding. 11 Accessory Product Guide Donn Suspension Systems Stabilizer Bars Standard Stabilizer Bar A Catalog Number Description Stabilizer Bars Standard Stabilizer Bars CC15-20 CC15-30 Locking Stabilizer Bars Accessible Stabilizer Bars Locking Stabilizer Bar B Accessible Stabilizer Bar C Packaging/Ctn. Detail LF Pcs. Wt. (lbs.) Standard 20 Stabilizer Bar 83.3 50 11 A Standard 30 Stabilizer Bar 125 50 17 A CC15-4-2 Standard 4' Stabilizer Bar notched 2' on center 200 50 27 A SB12 Locking 12 Stabilizer Bar 200 200 27 B SB24 Locking 24 Stabilizer Bar 400 200 52 B SB24-A Locking 24 Stabilizer Bar Elongated for Ashlar Connection 400 200 52 B SB36 Locking 36 Stabilizer Bar 300 100 40 B SB48 Locking 48 Stabilizer Bar 400 100 50 B SB48-24 Locking 24 Stabilizer Bar 24" Center to Center Notch 400 100 50 B SB60 Locking 60 Stabilizer Bar 500 100 64 B ASB24 Accessible 24 Stabilizer 50 25 17 C ASB30 Accessible 30 Stabilizer Bar 62.5 25 25 C ASB48 Accessible 48 Stabilizer 100 25 33 C ASB600MM Accessible 600mm Stabilizer Bar 15(m) 25 17 C ASB900MM Accessible 900mm 22.5(m) 25 25 C ASB1200MM Accessible 1200mm 30(m) 25 33 C Notes (1) Please refer to Perimeter Treatment (SC2540) for more information about USG stabilizer bars in a seismic application. (2) Please refer to Ashlar Condition (SC2550) for more information about the SB24-A stabilizer bar elongated for ashlar modules. (3) Please refer to Application Guide (IC592) for more information about USG stabilizer bars in plank and large panel applications. 12 Accessory Product Guide Key Miscellaneous Accessories Universal Field Cross Tee Hole Tool Hand-Held Field Cross Tee Hold Tool Air Diffuser For all DONN suspension systems. For all DONN suspension systems. Field-cut foil-backed ceiling panel to fit diffuser face. Use with FINELINE and CENTRICITEE suspension systems. SB2 Sloped Ceiling Bracket Cross Tee Hole Punches Touch-Up Paint Air Diffusers Recommended for use with 9/16 systems Adjustable Wall Molding Bracket Catalog Number 215738 200308 204755 276759 214418 276760 B14 B13 PC15 GAL PC16 QT PC19 GAL PC20 QT AD16 AD18 AD26 AD28 AD38 AD310 AD410 AD412 SB2 Description Universal Field Cross Tee Hole Tool Hand-Held Cross Tee Hole Tool Replacement Die Block for Universal Cross Tee Tool Replacement Die Block for Hand-Held Cross Tee Tool Replacement Punch for Universal Cross Tee Tool Replacement Punch for Hand-Held Cross Tee Tool Flat Black Spray Paint (205)1 Flat White Spray Paint (050)1 Standard Gallon2 Standard Quart2 Custom Gallon Custom Quart 2 x 2 1 Slot with 6 Collar 2 x 2 1 Slot with 8 Collar 2 x 2 2 Slot with 6 Collar 2 x 2 2 Slot with 8 Collar 2 x 2 3 Slot with 8 Collar 2 x 2 3 Slot with 10 Collar 2 x 2 4 Slot with 10 Collar 2 x 2 4 Slot with 12 Collar SB2 adjustable wall molding bracket used to secure standard wall molding at an angle to accommodate a sloped acoustical ceiling Packaging/Ctn. Pcs. Wt. (lbs.) 1 30 1 5 1 1 1 1 1 1 1 1 6 7 6 7 1 12 1 3 1 12 1 3 1 7 1 7 1 8 1 8 1 8 1 9 1 10 1 10 100 11 Notes (1) One carton contains six 12 oz. cans. Paints cannot be shipped air freight. (2) Specify color number from price list. (3) Punch tools are not covered under the USG Standard Product Warranty. There is a basic and limited warranty for 3 months of normal use. Any damage beyond 3 months must be evaluated and a repair fee may be assessed. Please refer to AC3264 for more information. 13 Accessory Product Guide Donn Suspension Systems Separation Joints When a separation joint is required, USG offers several options that are practical, easy to install, and designed for minimal visibility. DONN separation joints represent the greatest range of options to satisfy the stringent requirements for separation joints. For more information on seismic separation joints, please refer to Seismic Technical Guide SC2496. Tee Faced (Main Tee or Cross Tee) Sleeve Available for DX/DXL, DXI, DXT and DXF/DXFF. Tee Face (Cross Tee) Sleeve Expansion Joint – M12 Molding 12-ga. hanger wire 12-ga. hanger wire (existing) at 4'-0" o.c. hanger wire existing main tee cross tee field cut 1" cross tee tee-face sleeve 1" min. typ. hanger wire near tee end main tee or cross tee (3) M12 wall moldings cross tee tee-face sleeve one side of splice cap crimped to allow movement only on opposite end Expansion Joint – M20 Molding main tee or cross tee Expansion Joint – US28 Molding 12-ga. hanger wire min. within 8" of tee end 12-ga. hanger wire at 4'-0" o.c. stabilizer bar along tee ends to prevent spreading main tee M20 1" x 2" wall molding hanger wire field-fasten molding to main tee and through ct clips 1" min. typ. flatten CT clip cross tee Expansion Joint – M7 Molding hanger wire main tee or cross tee punch and hang M7 or M12 wall moldings in field fasten near horizontal face to assure tight joint 1/2" one side of splice cap crimped to allow movement only on opposite end tee cross tee US28 channel molding Expansion Joint DH2 lay-in ceiling panel back to back M7 or M12 wall moldings typ. 14 Accessory Product Guide lay-in ceiling panel pop rivet (typical) 1" typ. Expansion Joint – Accordion Style field-fasten channels securely back to back and field-punch hanger wire holes hanger wire main tee cross tee expansion joint by others lay-in ceiling panel Slip Joint 4-way seismic separation joint clip fasteners DXW main tee Technical Service 800 USG.4YOU Web Site www.usg.com Samples/Literature 888 874.2450 Samples/Literature E-mail samplit@usg.com Note All products described here may not be available in all geographic markets. Consult your local sales office or representative for information. Trademarks The following are trademarks of USG Interiors LLC: CELEBRATION, CENTRICITEE, CLEANROOM, DONN, DX, DXL, DXLA, FINELINE. USG in stylized letters. USG is a trademark of USG Corp. Notice We shall not be liable for incidental and consequential damages, directly or indirectly sustained, nor for any loss caused by application of these goods not in accordance with current printed instructions or Samples/Literature/Fax 888 874.2348 Customer Service 800 950.3839 Manufactured by USG Interiors, LLC. 550 West Adams Chicago, IL 60661 AC2396/rev. 10-13 © 2013, USG Interiors, LLC Printed in U.S.A. for other than the intended use. Our liability is expressly limited to replacement of defective goods. Any claim shall be deemed waived unless made in writing to us within thirty (30) days from date it was or reasonably should have been discovered. Safety First! Follow good safety and industrial hygiene practices during handling and installation of all products and systems. Take necessary precautions and wear the appropriate personal protective equipment as needed. Read material safety data sheets and related literature on products before specification and/or installation.