PID Controller Design with Constraints on Sensitivity Functions

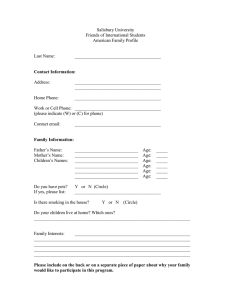

advertisement

Proceedings of the 2006 American Control Conference

Minneapolis, Minnesota, USA, June 14-16, 2006

WeA08.3

PID Controller Design with Constraints on Sensitivity Functions Using

Loop Slope Adjustment

Daniel Garcia*, Alireza Karimi*, Roland Longchamp* and Sebastián Dormido**

Abstract— This paper presents a PID controller design

method for stable minimum-phase systems. The approach is

similar to the one proposed in the so-called modified ZieglerNichols method, where only one point on the frequency response

of the plant is measured and then moved to the desired position

on the unit circle. This technique provides the specified phase

margin and crossover frequency to the closed-loop system.

However, the ratio between integral and derivative time is

not fixed prior to the design in the proposed approach. This

ratio is chosen is order to obtain the desired loop slope

at the crossover frequency. Constraints on the infinity-norm

of sensitivity functions are used to shape the loop transfer

function and to determine the corresponding loop slope value.

The proposed method, which is based on Bode’s integral

relationships for the slope adjustment, does not require any

parametric model of the plant and can be applied with only

modest effort.

I. INTRODUCTION

The conventional PID controllers are undeniably the most

commonly used control algorithm for industrial processes. In

spite of their very simple structure, they can often provide

satisfying closed-loop stability and performances as long as

their parameters are properly chosen.

Nowadays many different methods exist for the design

of such controllers. The simplicity of the PID structure,

which consists of only three parameters, constraints however

the design method to be not very complex. Among the

techniques currently available, the modified Ziegler-Nichols

[1] method has this advantage of simplicity and is known

to work well in many situations in process control. The

approach is very intuitive and can be applied with only

modest effort. It only requires the knowledge of the point

on the frequency response of the plant that corresponds to

the desired crossover frequency. This point can be moved

by the controller to a desired position on the unit circle in

order to satisfy a phase margin specification. Two equations

for phase and amplitude assignment are obtained and can be

solved to find the parameters of the controller. An additional

equation, which specifies the ratio between integral and

derivative time, should however be introduced in order to

obtain a unique solution. In the modified Ziegler-Nichols

* D. Garcia, A. Karimi and R. Longchamp are with the Laboratoire

d’Automatique, Ecole Polytechnique Fédérale de Lausanne (EPFL), 1015

Lausanne, Switzerland. {daniel.garcia, alireza.karimi,

roland.longchamp}@epfl.ch.

The work of these authors is financially supported by the Swiss National

Science Foundation under grant No. 2100-064931.01.

** S. Dormido is with the Dpto de Informática y Automática, UNED, c\

Juan del Rosal 16, 28040 Madrid, Spain. sdormido@dia.uned.es.

The work of this author is financially supported by the Spanish CICYT

under grant DPI 2004-01804.

1-4244-0210-7/06/$20.00 ©2006 IEEE

method, this ratio is chosen to be constant, i.e, Ti = αTd . The

closed-loop stability and performances are heavily influenced

by the choice of α [2]. In [1] it has been shown that the

ratio α = 4 is appropriate for many industrial processes.

For some systems, however, it has been pointed out in [3]

that better results are obtained with an α parameter in the

vicinity of 2.5. One problem associated with the modified

Ziegler-Nichols is that the ratio α is specified prior to the

controller design, without any a priori information of the

process dynamics. Only one point on the Nyquist curve of

the loop can then be positioned by the method, and the curve

cannot be shaped more precisely. In [2], a design procedure is

proposed in order to overcome this problem and to shape the

Nyquist curve between the crossover and critical frequencies.

The design procedure however requires a parametric model

of the plant and thus looses the advantage of simplicity.

Recently, in [4], [5] it has been shown how the slope of

the Nyquist curve at the crossover frequency can be adjusted,

without any model of the plant. The design is based on

Bode’s integrals and only requires the knowledge of the

frequency response of the plant at the crossover frequency

as well as its static gain. This approach is used in this paper.

The main contribution of this work is to shape the frequency

response of the loop, based on constraints on the infinitynorm of the sensitivity and complementary sensitivity functions. A closed-loop experiment is provided to measure the

point on the Nyquist curve of the plant corresponding to the

desired crossover frequency. The modified Ziegler-Nichols

method is then used to obtain the required phase margin.

The ratio between integral and derivative time is designed

to impose, in the Nyquist diagram, the slope of the loop

frequency response, which is chosen according to constraints

on the infinity-norm of sensitivity functions.

This paper is organized as follows: Section II recalls the

modified Ziegler-Nichols method as well as the procedure

for adjusting the loop slope at the crossover frequency.

The choice of the slope to shape the loop transfer function

according to sensitivity constraints is explained in Section

III. In Section IV the measurement procedure for identifying

the plant at the chosen crossover frequency is presented. A

simulation example is then provided in Section V to illustrate

the approach. Finally, some concluding remarks are offered

in Section VI.

II. PRELIMINARIES

This Section recalls briefly the so-called modified ZieglerNichols method. It also underlines that PID controllers

have more parameters than required for the design problem.

268

0.5

Finally it explains how this supplementary degree of freedom

can be used to shape the Nyquist plot of the compensated

system, without any model of the plant.

B. Loop Slope Adjustment

The slope ψ of the Nyquist curve of the loop transfer

function L(jω) at the frequency ωc is equal to the phase of

the derivative of L(jω) with respect to the frequency at ωc .

The derivative of the loop transfer function with respect to

the frequency is computed as follows:

dL(jω)

dK(jω)

dG(jω)

= G(jω)

+ K(jω)

(3)

dω

dω

dω

0

Imaginary Axis

A. Phase Margin Adjustment

Suppose that, for a given unknown system, specifications

on crossover frequency ωc and phase margin Φ are known.

Reasonable values for such design parameters are usually

easy to find: A phase margin specification does not depend

on the system structure and parameters, and is habitually

chosen between 40◦ and 60◦ . For the crossover frequency, a

specified value is not a priori known and depends especially

on the plant dynamics. Since the crossover frequency is

closely related to the rise time and thus to the bandwidth

of the closed-loop system, guiding rules on its choice based

on a specification on these performance indicators can be

formulated [6].

The amplitude and phase of the plant at the crossover

frequency ωc can then be measured with the procedure proposed in Section IV. The modified Ziegler-Nichols method

can now be used to adjust the phase margin. One obtains the

following equations for the controller parameters [1]:

cos(Φ − ϕc − π)

(1)

Kp =

|G(jωc )|

1

T d ωc −

= tan(Φ − ϕc )

(2)

T i ωc

where ϕc is the phase of G(jωc ). Eq. (2) has usually

an infinity of solutions for the parameters Ti and Td . In

order to have a unique solution, an additional equation has

been introduced in the modified Ziegler-Nichols method:

Ti = αTd . The choice of α influences heavily the closedloop performances and stability. This fact may be illustrated

with an example. Consider a plant with given closed-loop

specifications on phase margin and crossover frequency.

Suppose that three controllers are obtained, by solving Eq.

(1) and (2) with three different values for the parameter

α. Resulting Nyquist plots will show similar behaviors as

those depicted in Fig. 1. It can be seen, that the three curves

pass effectively through a common point and ensure a given

phase margin and crossover frequency. Nevertheless, stability

and performances of the three designed closed-loop systems

differ passably since the loops are shaped very differently.

The parameter α should thus be chosen in order to shape

appropriately the Nyquist curve of the compensated system.

Recently, it has been proposed in [5], [4], to design the

ratio between integral and derivative time in order to obtain

the desired loop slope at the crossover frequency. This design

is briefly recalled hereafter.

−0.5

−1

−1.5

−1

−0.5

0

0.5

Real Axis

Fig. 1.

Influence of the parameter α on the loop frequency response.

which gives after some calculations:

1

dL(jω)

= Kp G(jω) j(Td + 2 )

dω

ω Ti

1

)

+ 1 + j(Td ω −

ωTi

d ln |G(jω)|

d∠G(jω)

×

+j

dω

dω

(4)

Hence, the slope of the Nyquist curve at ωc is given by:

ψ= ∠

dL(jω) = ϕc + arctan

dω ωc

(Td Ti ωc2 + 1) + (Td Ti ωc2 − 1)sa (ωc ) + sp (ωc )Ti ωc

sa (ωc )Ti ωc − (Td Ti ωc2 − 1)sp (ωc )

(5)

where ϕc = ∠G(jωc ) and sa (ωc ) and sp (ωc ) are defined as

follows:

d ln |G(jω)| sa (ωc ) = ωc

(6)

dω

ωc

d∠G(jω) sp (ωc ) = ωc

(7)

dω

ωc

Straightforward calculation brings the following result for the

relation between integral and derivative time for the specified

loop slope ψ at the crossover frequency:

269

Td = [sa (ωc ) − 1 + sp (ωc ) tan(ψ − ϕc )

− Ti ωc (sp (ωc ) − sa (ωc ) tan(ψ − ϕ0 ))]

× [ωc2 Ti (1 + sa (ωc ) + sp (ωc ) tan(ψ − ϕ0 ))]−1

(8)

Eq. (8) and (2) give for the derivatives time Td :

1

[(sa (ωc ) − sp (ωc ) tan(Φ − ϕc ))

2ωc

× tan(ψ − ϕc ) + (1 − sa (ωc )) tan(Φ − ϕc )

− sp (ωc )] (9)

sa (ωc ) ≈

2

∠G(jωc )

π

sp (ωc ) ≈ ∠G(jωc ) +

m

It is thus possible, if the slope of amplitude and phase

sa and sp of the plant are known at ωc , to design the

Nyquist plot of the loop transfer function with the desired

slope at the crossover frequency. In [5], [4] it is shown

for stable minimum phase systems, how these slopes can

be approximated with an adequate precision for controller

design without any model of plant. The approximations

which are based on the Bode’s integrals, only require the

knowledge of the plant at the crossover frequency as well

as its static gain. The following expressions are obtained for

the slopes:

0.75

M , φ [rad]

Td =

1

0.5

0.25

0

0

0.25

0.5

Mc

0.75

1

Fig. 2. Lower bound of Mm (dashed line) and Φ in radian (solid line) in

function of the Mc value.

1.5

(10)

2

[ln |Kg | − ln |G(jωc )|]

π

1

Imaginary axis

where Kg stands for the plant static gain.

In the following Section, it will be shown how the slope

ψ can be chosen in order to appropriately shape the loop.

This design is based on constraints on the infinity-norms of

the sensitivity functions.

0.5

1

(− 1−M

2 , 0)

c

0

Φ

ψ

Mc

1−Mc2

-0.5

-1

III. SENSITIVITY CONSTRAINTS

-1.5

Consider the complementary sensitivity function T (s) and

the sensitivity function S(s) which express respectively the

closed-loop transfer function from set-point to process output

and the closed-loop disturbances amplification:

T (s) =

L(s)

,

1 + L(s)

S(s) =

1

1 + L(s)

(11)

It is well-known that the loci for constant values of |T | and

|S| are represented in the complex plane by circles [6].

In the following, the notations introduced in [6] will be

used for the complementary modulus margin Mc and the

modulus margin Mm . They represent respectively the inverse

of the infinity-norm of the complementary sensitivity and

sensitivity functions:

Mc = ||T ||−1

∞,

Mm = ||S||−1

∞

(12)

Consider now only one specification on Mc . This corresponds in the complex plane to a prohibited disk for the

frequency response of the loop. The radius rc and center cc

of the disk are given as follows [6]:

rc =

Mc

,

1 − Mc2

cc = (−

1

, 0)

1 − Mc2

(13)

It can be shown that a specification on Mc also ensures

a lower bound for Mm , which guarantees the closed-loop

-3

-2

-1

0

1

Real axis

Fig. 3.

Tangency condition at the loop crossover frequency.

stability, as well as for the phase margin Φ:

Mm ≥

Mc

1 + Mc

Φ ≥ − arccos

(14)

Mc2 − 2

2

+π

(15)

These lower bounds of Mm and Φ in function of Mc are

depicted in Fig. 2.

A necessary condition for a given specification on Mc to

be achieved is the tangency condition. In other words, the

Nyquist curve of the loop must be tangent to the prohibited

disk defined by the specification. The key idea of this design

procedure is to choose the loop frequency response to be

tangent to the prohibited disk at the crossover frequency ωc .

The loop slope ψ at ωc will then be determined according

to the tangency condition (see Fig. 3).

The specification on Mc is however not given by the user.

Only the phase margin Φ and the crossover frequency are

explicitly specified. However, since for each phase margin,

only one Mc circle exists, which crosses the unit circle at

the corresponding point, the Mc value is unique. It can be

270

0

1.5

d

_

-d

e−T s

G(s)

Imaginary axis

1

0.5

0

Φ

-0.5

ψ

Fig. 5.

Fig. 4 depicts this circle for a given value of Mm and Mc .

Now with the given specification on Φ, it is possible to do

exactly the same procedure as for the Mc circle. It consists

in determining the circle satisfying Eq. (20) and (21), which

intersects the unit circle at the point corresponding to the

phase margin. This circle includes the specified Mm circle

and the largest possible Mc circle. It can be determined by

solving the following equation:

-1

-1.5

-3

-2

-1

0

1

Real axis

Fig. 4.

Circle including both the Mm and Mc circles.

determined by solving the corresponding equation of the

circle:

Mc2

1

2

2

)

+

y

=

(16)

(x +

1 − Mc2

(1 − Mc2 )2

with:

x = cos(Φ − π),

y = sin(Φ − π)

Relay plus additional time delay feedback system.

(17)

In the complex plane, x + iy is the point on the unit circle

corresponding to the phase margin Φ. From Eq. (16), and

(17) one obtains:

Mc4 +Mc2 (−3 − 2 cos(Φ − π))+2+2 cos(Φ−π) = 0 (18)

which is a second order equation for Mc2 with only one

positive solution for Mc .

Now that the Mc circle crossing the unit circle at the point

corresponding to the phase margin is known, it remains to

compute its slope at this intersection. This slope in radian is

given by the following equation:

cos Φ + cc ψ = arctan −

(19)

sin Φ

where cc stands for the center of the Mc circle according to

Eq. (13). Now the PID controller can be design using Eq.

(1), (2), (9), (18) and (19), .

Remark: Instead of defining specifications on Φ

and ωc , specifications can be given on Mc and

ωc . Then the phase margin will be imposed by the

intersection of the Mc circle with the unit circle.

The problem can easily be generalized to other circles.

Suppose that, for a specific problem, a modulus margin larger

than the lower bound given by Eq. (14) is specified. For each

value of Mc , it is then possible to compute the smallest circle

in the complex plan that include both the Mm and Mc circle.

Radius and center of this circle are given as follows:

1

rcm = 0.5 −1 + Mm −

(20)

Mc − 1

1

,0

(21)

ccm = 0.5 −1 + Mm +

Mc − 1

2

(x − ccm )2 + y 2 = rcm

(22)

where x and y are defined according to Eq. (17). Equation

(22) can be solved analytically and has only one positive

solution for Mc . Then the slope of the circle at this intersection is computed and the frequency response of the loop

is then designed to be tangent to the circle at the crossover

frequency.

IV. MEASUREMENT PROCEDURE

For the proposed controller design procedure, the static

gain of the plant as well as the amplitude and phase of the

plant at the chosen crossover frequency ωc have to be known.

The static gain is very simple to measure (for example by

performing only one step response) and is thus assumed to

be known. To measure the frequency response of the plant

at the crossover frequency different experiments exist, either

in open loop or in closed-loop. In this paper, a closed-loop

relay experiment is used for the measurement. Relay methods

have usually been well accepted by the industrial world

because, compared to open-loop solutions, the sensitiveness

to disturbances is reduced, and the implementation of such

structures are simpler.

The standard relay method [7] provides the knowledge

of the critical point and frequency of a system. In order to

identify points on the Nyquist plot of the plant corresponding

to other frequencies an additional time delay is inserted in

the loop [8]. Figure 5 depicts the resulting closed-loop relay

experiment, where G(s) represents the unknown plant, T

the additional time delay (T > 0) and d is the amplitude of

the relay output. The influence of the time delay T on the

frequency response of the plant G(s) consists on moving

each point of the Nyquist plot of the plant, by adding a

phase lag, which is proportional to the frequency and to the

value of the time delay. As a result, the critical point and

frequency of the equivalent plant can be changed by varying

the time delay T . By choosing appropriately the time delay

T , the purpose of the method is to make the system oscillate

at the chosen frequency ωc , in order to identify G(jωc ). The

271

_

k

Imaginary axis

.

1

s

_

0

_

a)

0.5

δ

e−T s

G(s)

0

0

-0.5

-0.5

-1

-1.5

Nonlinear scheme for improving the measurement precision.

-2.5

-2.5

-1

-0.5

0

Tk−1 − Tk−2

ωk−1 − ωk−2

0.5

1

1.5

-3

-1.5

-1

-0.5

0

0.5

1

1.5

Real axis

Fig. 7. Nyquist plots (Dashed line: modified Ziegler Nichols, solid line:

proposed design).

problem is solved iteratively as explained hereafter, using the

secant algorithm:

1) Choose two different initial values for the time delay

T (T0 and T1 ). The value T0 is usually chosen to

be 0 and T1 > 0. Then two relay experiments can

be performed with the two time delay values. Each

experiment results in a limit cycle with the frequency

ω0 or ω1 which corresponds respectively to the time

delay T0 and T1 .

2) The time delay parameter is updated iteratively using

the secant algorithm:

Tk = Tk−1 + (ωc − ωk−1 )

-1.5

-2

Real axis

Fig. 6.

-1

-2

3

-1.5

b)

0.5

Imaginary axis

ε

(23)

where k represent the iteration number. A new relay

experiment can then be performed with the obtained

time delay, and the frequency ωk of the obtained limit

cycle can be determined.

3) Repeat the previous step until the obtained frequency

is closed enough to the desired one: |ωk − ωc | < η,

where η is a small positive number that represents the

absolute tolerance.

Remark: The secant algorithm is derived from

the Newton-Raphson algorithm. The derivative is

simply replaced in the secant algorithm by a quotient of differences. However, convergence conditions remain the same as for the classical NewtonRaphson method. In particular, the secant method

has a quadratic convergence rate near the solution.

There is however, one problem associated with the closedloop relay experiment (see Fig. 5). It is the generation by

the nonlinear relay element of higher order harmonics that

cannot be completely attenuated by the low-pass behavior

of the plant. By considering then only the first harmonic of

the signals with the describing function analysis, it leads

to identification errors. In order to improve considerably

the measurement precision, another nonlinear closed-loop

structure can be used (see Fig. 6). In this scheme, the relay

element is replaced by a saturation nonlinearity and a time

varying gain k [9]. The main idea of this scheme is to

automatically tune the gain k with an empirical adaptation

law in order to obtain the critical gain kkr of the resulting

system G(s)e−T s . Convergence analysis as well as guiding

rules on the choice of the parameters δ and ε are provided in

[9]. Different simulation examples and real-time experiments

[9], [10] show that this scheme leads to accurate results in

only few oscillations.

The iterative procedure based on the secant algorithm

associated with the structure of Fig. 6 allows to identify

with high accuracy the point on the frequency diagram of

a given plant G(s) corresponding to the given frequency

ωc . Furthermore, the time needed for the experiment is

reasonable since the secant algorithm converges usually in

less than 5 iterations to a frequency sufficiently near to the

desired one.

V. SIMULATION EXAMPLES

A simulation example is now provided to illustrate the

design method.

Consider the first-order process plus dead time proposed

1

e−0.2s . The specifications are set at

in [2]: Gp (s) = s+1

3 rad/s for the crossover frequency and 60◦ for the phase

margin. The measurement procedure presented in Section IV

is used to measure the point on the frequency response of

the plant corresponding to the desired crossover frequency.

A first controller is then designed using the modified ZieglerNichols method. This controller moves the point G(3j) of

the Nyquist curve of the plant to the point of K(jω)G(jω)

on the unit circle with the phase of 60◦ − 180◦ .

Now it is desired to adjust the controller parameters with

the proposed method. First the Mc circle which intersects the

unit circle at the point corresponding to the phase margin of

60◦ is considered. Solving Eq. (18) one obtains Mc = 1.

This value corresponds to a degenerated circle (radius rc =

∞) which is the line parallel to the imaginary with the real

coordinate of −0.5. Its slope at the crossover frequency is

thus ψ = 90◦ . The controller is then designed by using this

slope for the loop at the crossover frequency. The resulting

Nyquist curve is depicted in Fig. 7 a) and compared with the

result provided by the modified Ziegler-Nichols method.

A complementary modulus margin of 1 ensures a lower

bound equals to 0.5 for the modulus margin. Suppose now

that we want to give a larger specification for this one: Mm =

272

even if the slope is perfectly adjusted, the tangency condition

is not a sufficient condition for the curve to stay outside a

circle. The curve can enter the circle at other frequencies.

This can be the case for complex high-order systems, where

specifications may be satisfied just locally at the crossover

frequency and the behavior changes drastically elsewhere

leading to poor results. However, since the method needs the

same informations as the modified Ziegler-Nichols method

plus the plant static gain, it can constitute a good alternative

to this method when it does not provide appropriate results.

Furthermore the specifications can be chosen in a very simple

way (phase margin and crossover frequency) like in the

modified Ziegler-Nichols method, and the problem solution

is very easy, since it only requires to solve some algebraic

equations.

1

0.8

0.6

0.4

0.2

0

0

1

2

3

Time [s]

4

5

6

Fig. 8. Closed-loop step responses (dashed-dotted line: modified ZieglerNichols, solid line: proposed design with specification on Mc , dashed line:

proposed design with specification on Mc and Mm ).

TABLE I

S IMULATION RESULTS .

Method

Mod. Z-N

Specification Mc

Specification Mc , Mm

Kp

3.07

3.07

3.07

Ti

0.5203

1.016

0.6658

Td

0.13007

0.0258

0.0834

Mc

0.85

0.99

0.91

Mm

0.57

0.61

0.65

0.6. Specifications on phase margin and crossover frequency

are however preserved. Now we can find with Eq. (22), (20)

and (21) the circle which includes both the given Mm and

the largest possible Mc circle and which intersects the unit

circle at Φ. The corresponding Mc is found to be 0.875. The

slope ψ of the circle at the intersection is then chosen for

the loop slope at the crossover frequency. Again the achieved

loop frequency response is shown in Fig. 7 b) and compared

with the results of the modified Ziegler-Nichols method. The

different circles are also depicted in the figure. It should be

remarked here that, by introducing a circle which includes

the two sensitivity circles, conservatism is introduced.

Step responses obtained in closed-loop with the modified

Ziegler-Nichols and the proposed controllers are compared

in Fig 8. These curves show that both proposed controllers

improve the time-domain performances of the closed-loop

system in terms of overshoot and settling time. Furthermore,

the Nyquist plots (see Fig. 7) show that the frequency

responses with both proposed controllers are appropriately

shaped in the frequency range, which is crucial for closedloop stability and performances. Details of the design as

well as obtained values for the modulus and complementary

modulus margin are shown in Table I. It should be noted that

the obtained results are very close to the desired requirements

for the infinity-norm of the sensitivity functions. For different

reasons however, the proposed method cannot ensure these

desired values. On the one hand, the Bode’s integrals are

used to adjust the loop slope without any model of the plant.

These relations are not exact and consequently the obtained

slope can differ from the desired one. On the other hand,

VI. CONCLUSIONS

An similar approach to the one given by the well-known

modified Ziegler-Nichols method is presented in this paper.

However, instead of considering a fixed ratio between the

integral and derivative time, the ratio is adjusted to obtain the

desired loop slope at the crossover frequency. As a result, the

loop transfer function can be shaped, in this frequency range,

according to constraints on the infinity-norm of sensitivity

function. Compared to the modified Ziegler-Nichols method,

this procedure requires only one more information about the

plant, which is its static gain. It can thus be applied without

the need of any parametric model of the system to stable

minimum phase plants. This procedure can be considered

as an attractive alternative approach to the modified ZieglerNichols method to improve considerably the achieved stability and performances for systems where satisfactory results

cannot be obtained with the traditional method.

R EFERENCES

[1] K. J. Aström and T. Hägglund, Advanced PID Control. Instrument

Society of America, 2006.

[2] K. K. Tan, T. H. Lee, and Q. G. Wang, “Enhanced automatic tuning

procedure for process control of PI/PID controllers,” AIChE journal,

vol. 9, no. 42, pp. 2555–2562, September 1996.

[3] B. Kristiansson and B. Lennartson, “Optimal PID controllers including

roll off and Schmidt predictor structure,” in 14th Triennial World

Congress, Beijing, P.R. China, 1999, pp. 297–301.

[4] A. Karimi, D. Garcia, and R. Longchamp, “PID controller tuning using

Bode’s integrals,” IEEE Transactions on Control Systems Technology,

vol. 11, no. 6, pp. 812–821, 2003.

[5] ——, “PID controller design using Bode’s integrals,” in ACC, FP13-6,

May 2002, pp. 5007–5012.

[6] D. Garcia, A. Karimi, and R. Longchamp, “PID controller design with

specifications on the infinity-norm of sensitivity functions,” in 16th

IFAC World Congress, July, 2005.

[7] K. J. Aström and T. Hägglund, “Automatic tuning of simple regulators

with specifications on phase and amplitude margins,” Automatica,

vol. 20, no. 5, pp. 645–651, 1984.

[8] A. B. con Voda and H. Roux-Buisson, “Another version of the relay

feedback experiment,” J. Proc. Cont., vol. 7, no. 4, pp. 303– 308,

1997.

[9] M. Saeki, “A new adaptive identification method of critical loop gain

for multi-input multi-output plants,” 37th IEEE CDC, vol. 4, pp. 3984–

3989, 1998.

[10] A. Karimi, D. Garcia, and R. Longchamp, “Iterative controller tuning

using Bode’s integrals,” in CDC, FrM07-6, December 2002, pp. 4227–

4232.

273