Recommendations for the Production of Prepackaged Chilled Food

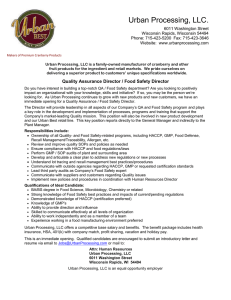

advertisement