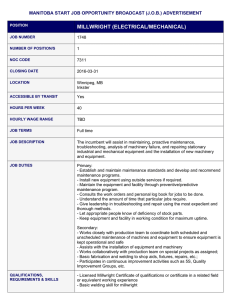

inside - Southern Millwright Regional Council

advertisement